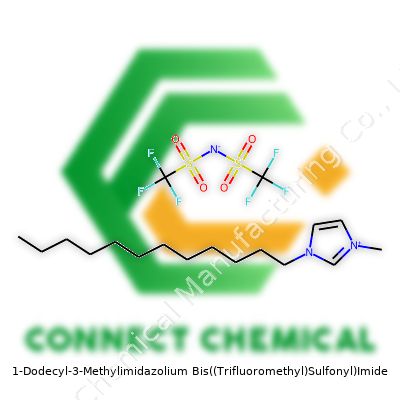

An Article on 1-Dodecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide

Historical Development

Back in the late 1900s, researchers started poking around with imidazolium-based ionic liquids, mostly because they needed alternatives to volatile organic solvents that choke up the atmosphere and make the lab stink. The big breakthrough came as folks realized these compounds didn't just dissolve stuff like a pro, they did it without catching on fire or evaporating too soon. The birth of 1-Dodecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, often shortened in the lab as C12mim NTf2, built on groundwork laid by earlier imidazolium systems; swapping out short alkyl chains for that lengthy dodecyl group turned the compound from a curiosity into something engineers and chemists could really use. This development grew out of decades of tinkering, starting with basic room-temperature ionic liquids and pushing for ever more stability, lower toxicity, and higher tunability.

Product Overview

C12mim NTf2 brings a lot to the table. It's an ionic liquid with an almost oil-like feel, clear, and it practically laughs off air and moisture, which makes it a favorite for demanding applications. That long dodecyl tail gives the compound surfactant qualities, letting it bridge the gap between watery and oily substances that normally refuse to mix. In the practical world, this means it works well in separation science, lubricants, and sometimes as a neat twist for drug delivery or as support in catalysis. Folks like me who have fussed with difficult extractions or faced stubborn separations know what a relief it is to have a tool that doesn’t degrade or evaporate mid-process.

Physical & Chemical Properties

On the bench, C12mim NTf2 stands out as a clear, viscous liquid at room temperature, which hints at strong ionic forces and a robust internal structure. Its density sits around 1.3 g/cm³. Expect a melting point too low to matter for most industrial uses (often below -10°C), and a boiling point high enough that you won’t see it vaporize easily. The trifluoromethanesulfonyl imide part gives the molecule both hydrophobic and lipophobic sides, pushing it towards applications other ionic liquids can't easily match. Thermal stability stretches over 300°C, which opens doors in high-temperature processes. Its conductivity isn’t off-the-charts, but for most electrochemical setups, it holds its own. Water solubility is minimal, and that’s a blessing for many reactions where stray water spells disaster.

Technical Specifications & Labeling

Those buying C12mim NTf2 spot a CAS number (they’ll remember 15801-02-8) and a chemical formula, C20H37F6N3O4S2, on the label, along with purity grades that range from above 95% for technical work up to 99% for sensitive jobs. Bottles tend to carry hazard symbols: a nod to mild skin irritation if handled sloppily. The labeling usually includes lot numbers for traceability and information about moisture content, as this tells you whether the supplier took drying seriously. My experience tells me, never trust a batch without checking the water content yourself; some vendors cut corners, and the performance takes a hit if it’s not bone-dry.

Preparation Method

Making C12mim NTf2 follows a kind of “swap and combine” approach common in ionic liquid chemistry. Start by quaternizing 1-methylimidazole with 1-chlorododecane to get your cation. Then bring in lithium bis((trifluoromethyl)sulfonyl)imide for anion exchange, usually in water. The reaction produces lithium chloride as a byproduct, which stays in the aqueous layer so you can separate the ionic liquid. It pays off to follow up with repeated washings and drying under vacuum since even a sliver of leftover water will mess with its physical properties. Having spent hours clearing impurities via column or liquid-liquid extraction, I know all too well that cutting corners at this stage means headaches down the line.

Chemical Reactions & Modifications

The chemistry around C12mim NTf2 sits on the “tunable” side. That dodecyl chain opens up surface modification, while the imidazolium core sometimes gets swapped out for related cations where labs crave different solubilities or electrochemical properties. Folks have tried adding functional groups to the alkyl chain to anchor it on solid supports or tweak its self-assembly in water and oil mixture. Another lab tweak involves switching anions or sticking fluorinated tails, to steer everything from wetting properties to biocompatibility. After years adjusting similar structures, I’ve seen that even a small change — just a few carbons — can steer the liquid's use from a straightforward solvent into a rare catalyst for multi-phase reactions.

Synonyms & Product Names

Over time, researchers have called this stuff a dozen things, but the main ones you’ll spot include Dodecylmethylimidazolium bis(trifluoromethylsulfonyl)imide, C12mimNTf2, and sometimes just 1-Dodecyl-3-methylimidazolium NTf2. Suppliers might go with their own brand names, sometimes prefixing “Ionic Liquid” to remind you what you’re buying, but experienced researchers know the real story comes in the fine print — you can't trust one supplier's C12mim NTf2 to be exactly the same as another’s without close scrutiny.

Safety & Operational Standards

Safety routines hinge on handling C12mim NTf2 with basic common sense and good lab hygiene. Splash goggles and gloves are a must, since skin contact brings irritation and inhaling vapors is best avoided. Spills don’t catch fire easily but make floors slick and tough to clean. Ventilation should be strong since no one wants to spend hours in a stuffy room filled with ionic liquid fumes. Disposal routes pass through a licensed chemical waste facility since environmental persistence keeps regulators wary. My own policy has always been to treat every new batch with a test vial before running large reactions — not every impurity is obvious, and lab disasters have taught me the cost of overconfidence in clean-up and disposal.

Application Area

Uses for C12mim NTf2 ripple out into materials science and green chemistry. In my years working with advanced coatings, I saw the liquid’s effectiveness in forming self-assembled monolayers, offering a dense surface coverage far slicker than old-school surfactants. Analytical chemists turn to it for separating stubborn compounds via liquid-liquid extraction, especially when standard organic solvents flop. Battery engineers value its high thermal and electrochemical stability — that’s often crucial for high-energy storage devices where something less stable would simply break down. The pharmaceutical field probes its use as a solvent, but concerns about toxicity linger, so its run as an inactive carrier demands more proof.

Research & Development

Much of today's research with C12mim NTf2 focuses on using its amphiphilic properties for next-gen solar cells, solid-state electrolytes, and green separation processes. I’ve followed studies that link this ionic liquid to metal ion extraction, where it boosts yields and selectivity without spewing volatile organic compounds into the air. Others look at its role in nanomaterial synthesis, often enabling breakthroughs by stabilizing nanoparticles that would otherwise clump or dissolve. Teams also probe its interaction with proteins and membranes, hopeful that it will play a role in biomedical engineering, but finding the sweet spot between effectiveness and non-toxicity keeps those results moving at a cautious pace.

Toxicity Research

Labs and regulatory agencies agree: safety data matter. Early work painted all ionic liquids as benign, yet the longer folks studied the effects, the clearer it became that the story wasn’t so simple. Tests show C12mim NTf2 isn’t likely to vaporize and choke up the atmosphere, but it breaks down slowly — sometimes not at all — in soil or water, raising flags for long-term environmental impact. Acute toxicity is low for humans at normal exposure, but marine tests have indicated that aquatic life feels the impacts at higher concentrations. My own take is that risk grows if folks get careless with disposal or let it accumulate in waste streams. Legislative requirements call for transparency in lifecycle analysis, more rigorous chronic exposure testing, and mandatory worker training for folks in regular contact.

Future Prospects

The track ahead for C12mim NTf2 looks busy, but not without speed bumps. Growth continues as industries hunt for solvents that outperform conventional ones and put them through scenarios where no single property fits the bill. The compound’s future depends on how researchers address toxicity and persistence concerns, balancing them against the undeniable value it brings to advanced materials and separation science. Regulatory scrutiny will tighten, and funding will flow to projects replacing or modifying the dodecyl group for better biodegradability or lesser ecotoxicity. After years watching the arc of ionic liquid research, I can say that nothing stands still; people combine molecules in ways never imagined a decade ago, often blurring the lines between synthetic chemistry, materials science, and environmental safety. C12mim NTf2 will stick around in the toolbox, but expect companies to sharpen its profile for applications where its unique mix of properties isn’t just a convenience, but a necessity.

Making Electrolytes Work for Better Batteries

Battery advances catch everyone’s eye these days, and 1-dodecyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide, often called a mouthful even by chemists, plays a role behind the scenes here. I’ve watched battery labs test this ionic liquid for its knack at carrying charge without letting batteries overheat or break down. Standard lithium-ion batteries sometimes suffer from fires and short circuits. This ionic liquid’s high thermal stability and nearly zero vapor pressure keep things safer. Researchers use it to build electrolytes that squeeze out more cycle life, helping electric vehicles last longer on a charge.

Smoothing Catalysis for Cleaner Chemistry

Catalysts need a steady partner to distribute material evenly and speed things up. This compound’s combination of a hydrophobic long alkyl chain with a flexible imidazolium core lets it dissolve tricky, greasy molecules that water rejects. Chemical manufacturers use this property in phase-transfer catalysis, where dancers from oil and water sides finally get to meet and mingle. Cleaner and less wasteful processes become possible. The demand for environmentally kind solvents grows each year, and the strong chemical resistance of this ionic liquid often outshines typical organic solvents—especially for biomass conversions and pharmaceutical reactions. Scientists I’ve chatted with say it lets them skip harsh acids and helps avoid toxic leftovers.

Separating Gases in Industry

Every refinery and power plant needs to separate gases, and traditional solvents cost energy and create pollution. Here, ionic liquids like this one give engineers a new tool to sift out sulfur dioxide or carbon dioxide. Their low volatility means less loss to the air. I’ve seen pilot projects where these ionic liquids snatch up CO2 more efficiently than amine scrubbing. Environmental regulators look for ways to shrink the carbon footprint, so using this compound in gas separation lines offers a link in that chain. It also avoids the dangerous fumes some older systems put out.

Stabilizing Nanoparticles for High-Tech Products

In nanoscience labs, creating metal nanoparticles seems simple until tiny particles clump together and spoil the mixture. This ionic liquid wraps around nanoparticles, stabilizing them and letting researchers tune their properties for catalysts, sensors, or even drug delivery. Colleagues experimenting with gold or silver particles mention how this liquid prevents oxidation and aggregation—two big headaches in nanotechnology.

Challenges and What We Can Do Next

No chemical solution comes without a few bumps. Large-scale use of 1-dodecyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide costs more than traditional solvents. Workers must keep an eye on safe handling. The fluorinated sulfonyl group in this ionic liquid can pose challenges for recycling and environmental fate. Companies aiming for green chemistry might push for easier recycling, or design safer degradation pathways. More public cross-talk between chemical firms, regulators, and environmental groups helps iron out these wrinkles.

Each time someone asks about sustainable manufacturing or cleaner energy storage, I point to these overlooked molecules making all the difference in the background. The challenge remains: combining true innovation with responsible use. That’s where experience on the lab bench and open discussion with industry partners still matter most.

Why Solubility Shapes Our Choices

Anyone who has stood over a lab bench or tried to mix instant coffee understands solubility. It shapes decisions far beyond the laboratory—think about cough syrup dissolving in a glass of water, or oil separating from vinegar in salad dressing. Solubility answers the simple riddle: Will this dissolve or not? Scientists and manufacturers have to know if a product blends smoothly into water, or slides right into oily organic solvents.

The Basics: Structure Drives the Show

Most people learn early—water dissolves salt, oil dissolves grease. It’s more than a kitchen curiosity. Molecular structure isn’t just a textbook image, it’s the rulebook for how substances interact. Water, a polar molecule, loves things with charges or partial charges. Sodium chloride, table salt, vanishes easily in a glass of water because both carry those polar features. Toss some butter into water and watch it float—fat molecules don’t have the same charge breaks. Pour acetone over that butter, and it breaks apart—the similar chemical behavior makes that trick possible.

Industry relies on this: drug makers must know if a medicine dissolves in the bloodstream (mostly water) or needs a different carrier. Cleaning product engineers tweak ingredients so grease lifts off plates. Sometimes, the difference between a simple solution and sludge stuck at the bottom is worth millions.

Fact-Checking Solubility: More Than Guesswork

A molecular formula on its own doesn’t tell the full story. Solubility tables exist for a reason, and so do experiments. Chemists shake vials, watch for clarity or cloudiness. Technologies such as mass spectrometry or spectroscopy give more certainty. A product might look chalky and useless in water, but melt away in ethanol or hexane. Those results decide if a paint dries clean or a medication works in liquid form.

Sometimes formulas get tweaked with special groups called functional groups—just adding an -OH (hydroxyl) can flip something from greasy to water-friendly. It’s not theory for theory’s sake. Painkillers might only absorb efficiently if modified for better water solubility. The stakes can be high: in high-tech batteries, the right solvent can make or break a device’s lifespan and safety.

Bridging the Gap and Finding Answers

Knowing solubility isn’t just for scientists in lab coats. A farmer wants fertilizer that dissolves quickly in rainwater. A chef chooses the right oil for roasting. Homeowners need de-icers that disappear in slushy driveways. This knowledge helps avoid wasted effort, spoiled products, and environmental messes.

Some solutions come from smart testing. Basic experiments—stirring, heating, or mixing—reveal a lot. For companies, databases and certificates covering product properties guarantee a standard. Still, new materials keep things interesting. No database covers every mixture, especially as industries push into advanced polymers, nano-coatings, and green solvents.

Better Choices for a World in Motion

Reliable information on solubility saves time, money, and resources. For every bottle of cleaner that works as promised, or paint that sticks clean, months of solubility testing line up behind the scenes. The right dissolve-or-don’t-dissolve decision means less waste and fewer headaches—whether you’re working in a lab, on the production line, or just hoping yesterday’s soup mixes nicely with water for one more meal.

Getting Storage Right: The Everyday Impact

Proper storage of chemical compounds often goes beyond just following the label. Small lapses can cost research labs money, compromise results, and sometimes even put people’s health at risk. My years in chemistry labs have shown that small details shape safety and progress. A little extra diligence now often saves a lot of upset later. Even the simplest rules, like keeping a cap tightly closed or using the right type of container, become habits worth reinforcing.

Temperature: Not Just a Number

Temperature control stands out for a reason. Many sensitive reagents, pharmaceuticals, and laboratory standards change character fast if left at the wrong temperature. Some turn to mush in the heat; others degrade quietly in cool storage that isn’t cold enough. For example, storing active enzymes at room temperature, even for a few hours, can mean starting over from scratch. Most compounds—especially those with a shelf life—last longer between 2°C and 8°C, a typical range for refrigeration. For truly sensitive items, −20°C freezers protect potency and quality. Freshness matters for food, medicine, and research-grade compounds alike, so a good thermometer and regular checks keep things on track.

Humidity: An Overlooked Threat

Humidity sneaks up in places you wouldn’t expect. Powders that clump together, liquids picking up water—these small changes can ruin results or lead to barely noticeable yet harmful byproducts. One summer, leaving a desiccant jar open in a humid storeroom led to a surprise: the product wouldn’t dissolve in water the way it usually did. Keeping compounds in tightly sealed containers, often paired with silica gel or other desiccants, keeps moisture out and materials reliable. For those not working in climate-controlled rooms, regular checks on seals and switching out spent desiccants go a long way.

Light and Air: Subtle Dangers

Transparent glass looks pretty but sometimes lets in more trouble than it blocks. Some compounds react with light, changing color or losing strength in just a few hours. I’ve seen students accidentally ruin sensitive dyes by storing them on a sunny windowsill, thinking it didn’t matter. Amber bottles, wrapped foil, or a simple dark cabinet block harmful rays. Oxidizing compounds need to be kept away from air to avoid reactions, and for those, using nitrogen or argon headspace can extend shelf life dramatically.

Safe Storage: Labeling and Segregation

Chemicals with wildly different behaviors sometimes end up side by side. In a small storage room, a stray splash or a broken vial can mix compounds that react in dangerous ways. Acids and bases, oxidizers and flammables—they belong to separate shelves, with spacing or barriers. Labels help even experienced hands avoid mix-ups, especially when dozens of similar bottles crowd together. Some institutions now require QR codes or inventory checklists; these steps catch problems before accidents happen.

Looking for Solutions: Practical Steps

Standard procedures only work if people follow them, and that means training matters. Introducing small reminders—posters, checklists, or even a weekly check-in—nudges everyone toward safer habits. Regular cleaning routines, audits, or spot checks reveal cracks in the system before they fail. After seeing the impact of small mistakes, I always advocate for written records of storage conditions and expiration dates. It sounds tedious, but it offers peace of mind and helps prove due diligence for audits or safety inspections.

Relying on Facts, Not Just Habits

No two compounds require exactly the same care, and not every risk stands out at first glance. Sustainable progress comes from staying informed and making small improvements over time. Sharing stories and data about near-misses or successful storage upgrades helps everyone in the lab or workplace make safer, smarter choices. At the end of the day, investing in storage protects budgets, research, health, and sometimes lives.

Why Ionic Liquids Stand Out, and What That Means for Care

Ionic liquids look pretty modern—these chemicals skip the usual volatility of solvents and open doors in energy storage, synthesis, and cleaning. They don’t make clouds of fumes in the air like acetone or ether. They sometimes get an unwarranted label as “benign.” Years working in chemistry shows that “non-volatile” is not the same thing as “harmless.” Their low vapor pressure hides risks, not erases them. You let your guard down, you increase the chance of expensive errors and personal injury.

Skin Isn’t a Shield, Protective Gear Absolutely Matters

Some ionic liquids soak right through gloves and skin, often before you catch a scent or feel discomfort. Toxicity takes on new meaning when you see rapid absorption. I’ve seen colleagues stick to old nitrile gloves only to find their hands tingling after a few minutes. Every lab has a Material Safety Data Sheet (MSDS) for these liquids for a reason. Many labs carry specific lists for glove compatibility—it pays to read them. Common practice means double-gloving or using laminate gloves, which hold up longer against aggressive chemicals.

Breathing Easy Adds a Layer—But Don’t Assume No Smell Means No Risk

Certain ionic liquids release only a trace of fumes at room temperature. This trait tricks even seasoned chemists. Eyes, nose, throat can take a hit even if you can’t see anything in the air. Lab work with ionic liquids belongs in the fume hood, every time. No shortcut wins over safety. For larger tasks or splashy procedures, I’ve seen labs require respiratory protection—especially for liquids mixed with acids or strong bases, since those cocktails can release harmful gases.

Why Disposal Never Deserves a Guess

Waste handling defines the real environmental story behind ionic liquids. Some can’t break down easily, so careless dumping can put extra stress on water systems. Solubility in water gives the illusion that they’re fit for a drain—rarely true. I’ve seen waste containers overflow because someone poured their beaker down the sink. Regulations set by local waste agencies and the EPA highlight that many ionic liquids count as hazardous due to toxicity or persistence. Segregate waste streams and mark every bottle. Proper disposal costs a lab less headache than an environmental citation or cleanup process.

Real Experiences Point to Long-Term Risks

Looking up records on common ionic liquids—BMIM PF6 or EMIM BF4—throws up eye and skin irritation, possible reproductive harm, and aquatic toxicity. If you plan to work with new or less-documented liquids, less data does not equal less risk. I remember reading about an accidental splash with a so-called “low hazard” liquid that led to a hospital visit due to a skin burn lasting weeks. The worker returned to the lab with thicker gloves and new respect for the protocols.

What Makes a Good Precaution Routine?

Basic steps still rule: eye protection, gloves, lab coats, and a fume hood. Keep incompatible chemicals apart—some ionic liquids mix badly with strong acids or oxidizers. Neutralizers or spill kits save trouble, but you need them within reach before trouble strikes—not after. Training and frequent reminders matter more than posters on the wall. Those who work around ionic liquids benefit from honest communication of incident stories, not just dry lists of “do nots.”

Ionic liquids don’t shout their dangers like some other reagents, but behind that quietness lies the need for sharp attention, careful handling, and a willingness to seek out and use reliable data. Respect for the unknown matters as much as trust in the data you do have.

Pushing Beyond Industry Minimums

Anyone who works with chemicals for a living recognizes how much rides on purity. Not just for regulatory paperwork, but for the actual performance of the products that shape our lives. The typical purity specification for a chemical product isn’t some arbitrary number printed for show. It’s an anchor for trust, safety, and effectiveness.

What Real-World Purity Looks Like

Think about pharmaceutical ingredients or food additives—most producers shoot for a minimum purity of 98% or higher. That’s not a random target. Tiny impurities, sometimes less than half a percent, can tip the scales toward an allergic reaction, an unstable mixture, or even a legal recall. For substances used in electronics or medicine, suppliers usually provide purity certificates showing values up to 99.9% or more. Lab techs and QC managers pore over each certificate, hunting for signs of contamination or batch-to-batch deviation.

Meeting Specifications Isn’t Enough—Surpassing Them Matters

Some companies chase the lowest price and settle for that 98%. But in the lab, I’ve seen small drifts in purity wreck months of work. In personal projects, I’ve had batches of chemicals arrive under spec, and testing exposed issues that downstream users would have blamed on their own equipment. Real improvement starts with demanding greater transparency from suppliers. Getting a full impurity profile can spare customers nasty surprises down the line.

Regulations Set the Floor, Reputation Sets the Bar

Purity specs often come from organizations like the American Chemical Society (ACS), United States Pharmacopeia (USP), or European Pharmacopoeia (Ph. Eur.). These groups issue exhaustive minimum requirements and testing protocols: sometimes a maximum of 0.5% water content, sometimes limiting heavy metals to parts per million. Companies that routinely clear these obstacles pick up a reputation for reliability. Reputation fuels repeat business, so the smart firms go the extra inch.

Checking the Label Isn’t Enough—Demand Proof

A glossy spec sheet can’t be the only reassurance. Certificates of analysis, batch test reports, and third-party audits help spotlight who’s doing things right. The best producers invite outside inspection. In food prep and pharma work, blind sampling and regular QA tests keep everyone on their toes. The worst breaches in product history have come when buyers took claims at face value—without digging deeper.

Solutions for a Better Future

Modern chemical supply chains add another layer of risk: suppliers in distant countries or channels selling re-labeled products. To address this, many firms have put digital tracking in place: scan the QR code, see the factory, supplier, and quality control records. Creating feedback loops between customers, suppliers, and standards bodies helps keep people honest.

Ultimately, high purity should be seen as a way to guarantee outcomes for everyone down the line. Customers deserve to get what’s promised—and a little more. In my experience, a few extra decimal points of purity have meant the difference between routine and disaster. It’s time for more people in industry, research, and regulation to demand better, not just accept the minimum.