1-Dodecyl-3-Methylimidazolium Chloride: A Practical Perspective

Historical Development

The world saw ionic liquids move from laboratory curiosities to real tools in the toolbox over just a few decades. The late 20th century brought a surge of research, sparked by chemists chasing new solvents that could sidestep the hazards of traditional organics. 1-Dodecyl-3-Methylimidazolium Chloride came from this push, combining the imidazolium ring—already a favorite for tunable properties—with a dodecyl group that gives it the staying power for real-world use. Researchers at major universities wanted solvents that handled heat, salt, and moisture without buckling. This ionic liquid stepped forward, boosting tasks like biomolecule separations and greener catalysis. Over time, industrial partners and academic labs scoped out its strengths, pushing it from chemistry journals to pilot plants and process designs.

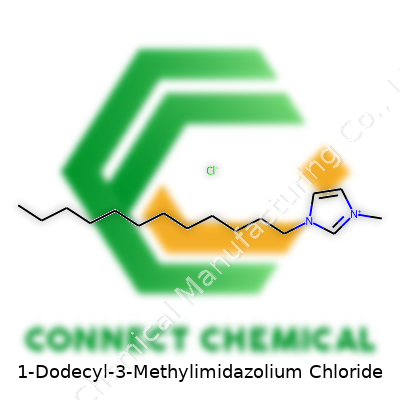

Product Overview

1-Dodecyl-3-Methylimidazolium Chloride stands out for its structure—a long hydrophobic tail attached to an imidazolium core paired with a chloride anion. This setup transforms it into more than just another ionic liquid. It does double duty as a surfactant, dissolving oils, dyes, and functional polymers. It resists hydrolysis and latches onto both organic and inorganic targets, opening doors for use in extractions and reaction media. Because it holds up under heat and salt, I have seen labs use it to process plant extracts without harsh conditions or equipment breakdowns. This is part of the appeal for researchers looking for better alternatives in engineering and biology.

Physical & Chemical Properties

Combining the imidazolium ring with a dodecyl chain delivers a compound liquid at room temperature but easy to crystallize below 15°C. Colorless to pale yellow and slightly viscous, it dissolves in water and organic solvents. Lab work shows it carries a significant ionic character, pushing conductivities into the tens of mS/cm range. The hydrophobic chain makes micelle formation straightforward, helping wash away greases or keep proteins stable. Boiling points stay well above those of normal solvents, and its negligible vapor pressure undercuts emissions in open use—a genuine advantage during scale-up or regular handling in the workplace.

Technical Specifications & Labeling

Reliable suppliers list 1-Dodecyl-3-Methylimidazolium Chloride as C16H33ClN2, molecular weight 305.92 g/mol, with purity standards touching 98% or better. Product sheets mark the chloride content, trace metals, water content (usually below 0.5%), and the melting point around 12–15°C. Proper labeling includes UN hazard codes, strong risk warnings due to skin and eye irritation, and disposal advice to match local regulations. An understanding of small print on labels can prevent nasty accidents: this compound travels as a mild irritant but never as a flammable material, sparing industries the tighter controls that come with fire risks.

Preparation Method

Most production routes rely on quaternization. Starting from 1-methylimidazole and 1-chlorododecane, the reaction goes forward in controlled low moisture environments to sidestep by-products. Careful temperature control (between 80–120°C for several hours) gets the job done. Afterward, purification uses repeated washing, filtration, and sometimes column chromatography to remove traces of unreacted raw materials. Choosing glass equipment stops metal ions from leeching into the product. In my own experience, using too much heat creates color changes and product darkening, so careful monitoring helps avoid waste.

Chemical Reactions & Modifications

This molecule acts both as a solvent and reactant. The long alkyl chain means it helps dissolve both fats and ionic compounds, so it pops up in phase separations and cation exchange studies. Chemists often swap the chloride anion for others—nitrate, tetrafluoroborate, hexafluorophosphate—to tweak solubility or lower toxicity. Sulfonation or even simple alkylation at the imidazolium ring has spawned dozens of analogues, each changing surface activity, anti-microbial effects, or even performance in battery electrolytes. Over time, interest grew in tuning these chemicals to target greener synthesis or to anchor catalytic metal centers.

Synonyms & Product Names

The chemical registry keeps a list: you might find it under 1-dodecyl-3-methylimidazolium chloride, [C12mim]Cl, or dodecyl methylimidazolium chloride. Some suppliers use names like N-dodecyl-N′-methylimidazolium chloride, or the short form DOMIM-Cl. Keeping track of synonyms matters; mistakes in ordering or referencing can cost a team both money and time, especially since small changes in the side chain can transform the chemical’s behavior.

Safety & Operational Standards

Working with 1-Dodecyl-3-Methylimidazolium Chloride means gloves and goggles for personal safety, plus a working fume hood. Reports show it can sting on contact, redden skin, or irritate mucous membranes. Inhalation of vapors seems rare because it barely evaporates, yet splashes during weighing or mixing do occur. Company guidelines urge full disposal in well-marked chemical waste streams—never in the sinks or ordinary trash. Scrupulous attention to labeling and staff training heads off most accidents and keeps labs OSHA-compliant.

Application Area

Industries pick this compound for extracting natural products, stabilizing proteins and enzymes, or mixing novel polymers. Environmental engineers choose it for treating wastewater or separating pollutants that traditional solvents miss. It acts as a support for catalysts and as a medium for electrochemical devices. Medicinal chemists value its stabilizing effect on peptides and its odd knack for carrying drugs across membranes. Academic groups lean on its ability to speed up paper chromatography or manage stubborn separations, making it a staple for both benchwork and industry-scale processing.

Research & Development

Behind the scenes, scientists test tweaks to the dodecyl group or the imidazolium ring, looking for new performance peaks. Much effort goes to swapping anions to match each task: lower viscosity for easier pumping, higher polarity to improve solubility. Ongoing research measures its effect on living cells, explores its potential for enzyme stabilization, and checks how it behaves in batteries or solar cell prototypes. There’s steady funding trickling into labs chasing new uses, as interest in sustainable chemistry and greener processes drives this compound’s continued study.

Toxicity Research

Toxicology studies reveal that like many ionic liquids, this chloride can prove harmful to aquatic life. Mammalian cell assays often report moderate cytotoxicity linked to the long dodecyl chain—it disrupts membranes easier than shorter analogues. Lab rats exposed to higher doses show signs of irritation but little systemic poisoning. Waste management remains a concern, since runoff into water supplies may hurt plankton and smaller fish. Ongoing research at universities and government agencies works on ways to break down these compounds after use, keeping them from leaving a mark on the environment.

Future Prospects

Looking forward, both industry and academia push toward developing less toxic analogues by switching out anions and shortening alkyl chains. Green chemistry keeps the pressure high on finding efficient recycling or degradation steps. Companies eye it for advanced batteries, drug delivery systems, and more selective catalytic supports. Improvements in process design and real-time monitoring cut down on waste and lower the cost of broader use. The market for ionic liquids, including 1-Dodecyl-3-Methylimidazolium Chloride, stands ready to grow as cleaner materials and safer operations draw greater interest. Smart investment in this sector promises a mix of environmental responsibility and industrial reliability.

More Than a Long Name: What This Chemical Does

Sometimes lab jargon makes something sound more mysterious than it really is. Take 1-Dodecyl-3-Methylimidazolium Chloride. The name doesn’t roll off the tongue, but it’s found its way into research circles for good reasons. This compound belongs to a class called ionic liquids. Unlike traditional solvents with strong smells and toxic fumes, ionic liquids like this one often work without many of those headaches. Years ago I worked in a lab that grew tired of constantly cracking open windows when using regular solvents. After switching to alternatives like this, work felt safer and the air cleaner. For people handling chemicals for hours every day, that comfort makes a difference.

Why Chemists and Tech Developers Reach for It

One main use of 1-Dodecyl-3-Methylimidazolium Chloride comes from its surfactant qualities. Picture a chemical that helps oil and water mix; that’s the kind of role it plays. This property lets it clean up reactions and dissolve ingredients that usually stick stubbornly to glassware or each other. Research teams studying nanoparticles, for example, discovered how this chemical helps stabilize tiny particles in water. Without stable dispersions, it’s nearly impossible to produce reliable results in areas like drug delivery or electronic inks. My own experience working with these mixtures showed that finding a “helper” compound can save weeks of trial and error.

Another area seeing growth is green chemistry. Companies under pressure to meet stricter safety and waste rules have started looking for options that reduce pollution. 1-Dodecyl-3-Methylimidazolium Chloride doesn’t evaporate easily, cutting down on airborne toxins. Its stability and effectiveness allow it to be recycled across several reactions, reducing both costs and waste. According to a 2023 review in Green Chemistry, several research groups now target ionic liquids as the backbone for cleaner production lines.

Challenges and Next Steps

No tool comes without problems. The real-world catch with this compound rests in how it breaks down once it leaves the lab. Some ionic liquids may linger in the environment, raising new questions about long-term water pollution or unforeseen ecological effects. Early studies, such as those coordinated by the European Chemicals Agency, point to the need for more toxicity and breakdown tests. It’s not enough to shift pollution from the air to the water; evaluating trade-offs takes ongoing research and transparent reporting.

Newer forms of ionic liquids are already under investigation. Developers are tweaking the structure of molecules like 1-Dodecyl-3-Methylimidazolium Chloride to balance strength with faster, safer breakdown after use. Open access to research data and clear labeling can help industries pick compounds with fewer environmental tradeoffs. Cooperation between companies, regulators, and scientists moves the conversation forward.

Looking Ahead: Striking a Balance

Taking something as complex as 1-Dodecyl-3-Methylimidazolium Chloride from the lab to a plant floor requires care. In my experience, the forward-thinking teams always test new chemicals not just for performance but for the whole journey—how they get made, how people interact with them, and what happens after use. No one answer fits all, but asking tough questions from the start keeps progress responsible. As chemists, manufacturers, and watchdog groups pay more attention to the full story, compounds like this will contribute to innovation without ignoring their responsibility to the environment and the people using them.

Chemistry Demands Respect

Working with chemicals always calls for a humble attitude. Over the years, I’ve learned that even with glassware, gloves, and white coats, overconfidence leads to trouble. 1-Dodecyl-3-Methylimidazolium Chloride, a popular ionic liquid, is no stranger here. You’ll see it used in labs focusing on green chemistry and material science. People like to tout its lower vapor pressure compared to organic solvents, but that doesn’t mean you can go easy. I once watched a new lab tech splash some on their hand, brushing it off because “it’s just an ionic liquid.” The redness and irritation that followed served as a reminder: every substance deserves respect.

Personal Protection Always Comes First

Nobody walks into a lab without goggles and gloves. Some folks, especially those starting out, get complacent. Disposable nitrile gloves should be standard. If you’re handling the powder, a dust mask or even a proper respirator keeps those tiny particles out of your lungs. To those who scoff at lab coats: trust me, you won’t laugh when a chemical eats through a sweatshirt and burns your arm. Closed shoes, tied-back hair, and no food or drink anywhere near your workbench—it’s basic but critical. Chemical burns don’t care if you’re hungry.

Good Ventilation Isn’t Optional

I remember an incident in an older lab with a broke fume hood where someone decided to push ahead anyway. The air turned acrid in minutes. Even ionic liquids, which rarely evaporate quickly, can produce unpleasant dust or fumes under certain conditions. Work inside a functioning, certified fume hood at all times. Ventilation removes any airborne particles before they reach your face. If your facility doesn’t supply decent airflow, push for a fix or refuse to proceed. Your lungs depend on it.

Skin and Eye Contact—Not Just Minor Risks

Some believe dangers come only from swallowing or long-term exposure. That’s false. This chloride compound can irritate skin and eyes. A researcher I knew ignored a splash to the forearm—redness, itch, and then a rash followed. Immediate washing under running water helps, but medical help may be needed after significant exposure. Have an eye-wash station and emergency shower within easy reach. Every minute counts when chemicals make contact with the body.

Spill Control and Waste Disposal: No Corners to Cut

Stories float around of lab waste getting poured down the drain. That’s illegal and dangerous. 1-Dodecyl-3-Methylimidazolium Chloride must go into designated waste containers—typically labeled “halogenated organics” or as required by local regulations. For spills, absorbent materials, not paper towels, give the upper hand. Clean-up kits with gloves, goggles, and neutralizers belong within sight. Write incident reports if trouble occurs; hiding accidents always creates worse problems down the road.

Training and Labels Save Lives

Routine safety training saved me from serious harm more than once. Every new bottle needs a clear, up-to-date label. Safety Data Sheets (SDS) hang on the wall for a reason. Not just bureaucracy: glance at those sheets before using a substance for the first time. They list storage conditions, fire hazards, and what steps to take if things go wrong. Review procedures with every new student or employee, even if it feels repetitive. One well-led walkthrough beats a dozen boring handouts.

Respect Science, Protect People

These safety rules may slow progress but they keep people safe. Every chemist, from student to principal investigator, should practice care inside their lab. Trust earned by doing things the right way protects careers, health, and the next generation. Chemicals challenge us; respect and preparation keep us in the game.

Why Storage Makes a Difference

Anyone who’s handled chemicals outside textbooks knows a tidy shelf can save a project. 1-Dodecyl-3-Methylimidazolium Chloride, a mouthful of a name for a useful ionic liquid in labs and green chemistry, asks for more than just a clear space in the chemical storeroom. Long alkyl chains and imidazolium salt structure often translate into some special needs on the storage front, impacting safety, purity, and overall research success. I’ve seen the results: a sample left in the wrong spot can go from a reliable reagent to a mess of unknowns.

Keeping the Bottle Sound: Moisture and Air

This salt pulls in moisture from the air, a classic case of hygroscopic behavior. If you leave the lid loose, you won't just be risking a clumped mess. Water uptake can change the physical properties and even the outcomes of experiments. Researchers usually prefer working with dry, pure chemicals, especially in applications like catalysis or electrochemistry, where a little contamination shifts results. So, stay ahead — reach for airtight containers, not the old beaker you found at the back of the drawer. After opening a new bottle, I’ve always tossed in a fresh desiccant packet to keep things on the dry side.

Temperature: A Simple, Overlooked Factor

Room temperature is often all this compound needs, but in a hot lab, temperatures climb much more than expected. Excessive warmth can accelerate degradation, especially over long storage, and with any impurities creeping in. A key lesson I picked up in a humid, poorly ventilated workspace: even a chemical marked ‘stable at room temp’ prefers a cooler, constant spot. For longer storage, I always recommend a standard chemical refrigerator, set away from food and regular-use items. Keep it out of the freezer—below its melting point, crystals form, creating dosing headaches later.

Sunlight and Labeling: A Simple Investment

Direct sunlight speeds up discoloration or even breakdown in many chemicals, this one included. Some labs use clear glass, which offers zero UV shielding. My own routine avoids this mistake — I reach for dark or opaque bottles, or at least tuck them away in a shaded cabinet. Reliable labeling closes the loop: batch number, purity, arrival date, and each person's name who breaks the seal. Trust me, it beats untangling confusion halfway through a reaction series.

The People Factor

People often underestimate the simple actions that lead to safe, effective lab work. One slip, like leaving a bottle open overnight, forces everyone downstream to second-guess results from contaminated or decomposed reagents. Good training and clear storage protocols—walk-throughs, routine checks, and basic signage—do more to protect work and health than fancy monitoring systems. Fresh eyes, whether from a colleague or a student, often spot early warning signs: condensation on a bottle, off-odors, or a sticky residue.

Safer Labs, Reliable Science

Safe storage of 1-Dodecyl-3-Methylimidazolium Chloride impacts research quality and everyone’s well-being in the lab. Simple steps—airtight storage, cool and dark placement, clear labels, and steady vigilance—offer rewards in consistent results and a safer workplace. Skipping these basics doesn't just waste money and time, it chips away at trust in the science itself. This isn’t theory; it’s how I’ve kept work honest, day in and day out, with chemicals that demand respect.

Ask a chemist about 1-dodecyl-3-methylimidazolium chloride and you’ll probably get a nod of recognition. This isn’t some rare or mystical ingredient found only in high-tech labs—it’s pretty standard among ionic liquids. The main question: does it dissolve well in water?

What Happens in Water?

Pour good old table salt in water and it vanishes almost immediately. The scene shifts with bigger molecules, especially those with long hydrocarbon tails. 1-dodecyl-3-methylimidazolium chloride packs a 12-carbon tail, much more than something like sodium chloride ever has.

The charged imidazolium part enjoys water’s company. It wants those hydrogen bonds, pulls in the water, and enjoys some stability. Now, that dodecyl tail—the long, waxy hydrocarbon chain—doesn’t play along. Tails like this tuck away from water, almost in a huddle, since hydrocarbon chains are mostly about oiliness, not friendliness toward polar molecules.

Why Does Solubility Matter?

Solubility of specialty ionic liquids can shape what you can actually do in the lab—or even at a factory scale. High solubility means the chemical disperses cleanly, which benefits processes like catalysis, separations, and making new materials. If the compound just floats or sinks without mixing, you’re not going to get much use.

Researchers have tried adding longer or shorter tails to imidazolium salts for years, looking for a balance: make it dissolve just enough, not too much, keep qualities like low volatility and thermal stability. With a tail as long as dodecyl, you run into a wall. Scientific reports and chemical supply catalogs mark 1-dodecyl-3-methylimidazolium chloride as not particularly friendly with water. Compared with the shorter analogs, its solubility drops off. Water can’t really surround the bulky tails, so the salt prefers to clump or form aggregates—sometimes even micelles, acting more like a detergent.

A Glance at Real Applications

Working in a teaching lab and later in a research group, I found that these types of ionic liquids get used carefully because of these quirks. Shorter-tailed imidazolium compounds like [bmim]Cl (with butyl) mix easily—students can handle them for basic solution experiments and even extraction practices. The dodecyl version works differently. It acts a bit like a surfactant, pulling together in water and creating layered structures, especially at higher concentrations.

This property actually carries value in some contexts—experts developing green solvents or new ways to carry drugs or clean up pollutants turn to less soluble ionic liquids as a tool. Still, relying on it for everyday water-based reactions can get messy, literally.

Finding a Better Approach

It’s tempting to just drop any fancy “designer” salt in water and hope it dissolves, but that’s ignoring key facts. Adjusting chain length and the types of substituents on these salts controls everything from toxicity to recyclability. I’ve learned through trial and error (and a lot of pipetting) that hitting the right solubility means thinking about structure—long chains often signal low water-solubility, no matter how well-known the starting materials.

Chemists seeking to use such ionic liquids should start with small-scale tests and check available solubility data in reputable sources—databases, peer-reviewed papers, and technical sheets from reliable suppliers. Stir, check if the solution stays clear, and don’t trust appearances alone. In short, 1-dodecyl-3-methylimidazolium chloride barely dissolves in water, and that fact means you need the right setup before counting on it for a water-based project.

The Role of Purity in Chemical Work

Every synthetic chemist or formulation scientist who’s had to troubleshoot a project knows the headache impurities bring. With 1-Dodecyl-3-Methylimidazolium Chloride, small changes in purity swing reaction outcomes, affect reproducibility, and leave lab teams scratching their heads. Over the years, I’ve watched even small tweaks in purity ranges—say moving from 97% to 99%—make all the difference between a clean column and a frustrating mess with side products that seem to appear out of nowhere.

What It Means for Research and Industry

Research runs best on clean inputs. In academic settings, a bottle of 97% pure ionic liquid might suffice for basic phase separation demos or electrochemical bench work. As the focus sharpens towards device fabrication, advanced catalysis, or pharmaceuticals, purity starts climbing to >99%. For the drug pipeline, trace contaminants matter, whether they're leftover synthesis intermediates or process residues. I’ve seen grant projects hinge on purity documentation, especially for collaborative programs and scale-up, where repeatability cannot become a gamble.

Why Grades Vary

The purity grade offered by suppliers largely depends on market demand and technical capability. 1-Dodecyl-3-Methylimidazolium Chloride for general laboratory use often lands at 97–98%. Certain suppliers push the envelope, offering batches up to 99%, sometimes even annotated with LC-MS or NMR trace levels for target applications. Niche high-tech sectors look for lots analyzed for metals, halides, or even water by KF titration. I've had to scrutinize certificates of analysis more closely than some journal reviewers—sometimes transparency and detail matter just as much as the number on the label.

Supporting Claims with Evidence

The American Chemical Society and similar organizations have documented how impurity profiles alter ionic liquids’ performance. Trace metals or unreacted alkylating agents from manufacturing cloud data and even invalidate a pivotal result. In published battery materials research, unexplained performance drops sometimes trace back to batches of 1-Dodecyl-3-Methylimidazolium Chloride sourced without strict batch indices or quality assurance. For pharmaceutical or medical device R&D, regulatory demands require a documented chain of analysis, going beyond spot-check purity and demanding detailed impurity breakdowns.

Potential Solutions and Workarounds

Buyers often face a trade-off between availability, price, and grade. Requesting proof—such as COAs showing residual solvent, water content, or heavy metals—supplies trust. Trusted manufacturers typically offer data beyond the front-label percentage: think 1H NMR printouts, elemental analysis, or even additional vendor batch references. To avoid surprises, some labs run their own checks for water or halide content using Karl Fischer titration or ion chromatography. In my experience, even a quick TLC or melting point check has saved more experiments than I care to admit.

On a larger scale, institutions working with critical applications pool purchasing power to secure high-purity, well-characterized sources. It’s less about chasing the highest spec and more about consistent, verified quality with transparent batch records. When purity matches the application—whether for standard lab work or high-sensitivity projects—the experiments run smoother, budgets stretch farther, and teams focus on discovery, not cleanup.

Key Takeaways for Buyers

Few things derail a promising research project like unexpected contaminants. Demand the right grade for your application, check supporting documentation, and consider running your own spot-checks when scale or risk rises. For anyone navigating the chemical supply chain, clear questions about purity and traceability start more productive conversations—and, from what I’ve learned, fewer headaches down the line.