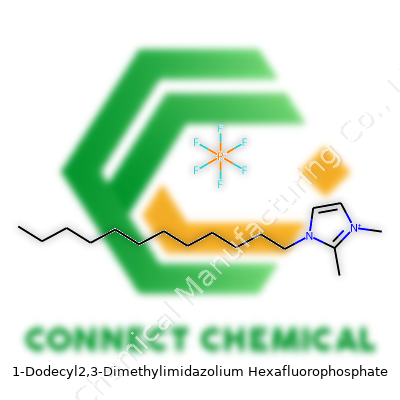

1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate: Unpacking a Modern Ionic Liquid

Historical Development

Chemists started chasing new types of salts that could stay liquid below the boiling point of water in the late twentieth century. Ionic liquids, especially imidazolium-based compounds, caught on fast, as their molecules opened doors that old salts couldn’t touch. Years back, most of us in the lab knew only common imidazolium salts. Putting a long dodecyl tail and dimethyl branches onto the imidazolium ring changed things. That move created 1-dodecyl-2,3-dimethylimidazolium hexafluorophosphate—a salt that didn’t just dissolve in water or organics, but changed how chemists thought about liquids and solid-phase reactions. When researchers first combined bulky alkyl chains with fluorous anions, they noticed these molecules didn’t give off that strong ionic scent in the workspace, signaling unique volatility and handling. The field hasn’t slowed down, with patents rolling out describing tweaks on both the cation and anion for all sorts of reactivity and thermal properties.

Product Overview

Suppliers label this compound with a reputation for purity and consistent melting. It comes as a pale, sometimes waxy solid at room temperature, but it melts fast—long before reaching boiling water’s heat. It hits shelves as a key ionic liquid for both academic labs and companies working on electrochemical engineering. Folks look for its ability to dissolve metals, catalyze reactions, and sometimes to stabilize nanoparticles. Long-chain imidazolium systems like this one serve where both hydrophobic and ionic character help manage mixtures that stymie conventional solvents. Common catalogues use names like 1-dodecyl-2,3-dimethylimidazolium hexafluorophosphate or its short tag C12C1C1ImPF6.

Physical & Chemical Properties

Every chemist handling it notes the signature slipperiness under gloves thanks to the long dodecyl chain. This ionic liquid melts modestly under 50°C, sometimes as low as 35°C, making it handy for room-temp setups. Its viscosity runs higher than water, and it has a faint aromatic scent. Imidazolium ionic liquids like this one balance a polar imidazolium head with a hydrophobic chain, explaining why they stand out when mixing with organics and resisting solvation in water. Hexafluorophosphate as the counterion gives very low volatility—hardly any vapor pressure shows up, sidestepping inhalation risks common with more volatile liquids. The salt is stable against oxidation up to a few hundred degrees Celsius, resists hydrolysis under mild conditions, but hydrolyzes slower in wet air than non-fluorinated analogues. Its limited solubility in water, but full solubility in polar organics, lets it partition conveniently between phases and simplifies isolation.

Technical Specifications & Labeling

High-end suppliers guarantee purity often above 98 percent, supported with NMR, FTIR, and mass spec data. Labels state the batch, melting range, and moisture content—some also check for residual chloride or other common imidazole byproducts. Safety information points to its corrosivity in the presence of water and calls for use of chemical-grade gloves and glasses. Containers come sealed, protected from light and moisture, as the hexafluorophosphate anion shows slow breakdown releasing HF when left long in damp air. Packaging labels call out the need for dry storage and quick cap replacement.

Preparation Method

The manufacturing starts with a methylated imidazole—react it with dodecyl chloride in a polar solvent, and then exchange the chloride anion with potassium hexafluorophosphate in an aqueous-organic biphasic system. The product forms in the organic layer, while potassium chloride drops out. Purification means repeated washing: removing trace water, and extracting leftover salts. Most researchers dry the liquid over molecular sieves or with vacuum. Few labs skip high-performance liquid chromatography for this class, as N,N-dimethyl branching sometimes causes extra isomers if the starting imidazole is less than 100% pure. That step—tracking purity and dialkylimidazolium content—keeps the field careful.

Chemical Reactions & Modifications

Chemists often use this compound as a starting point for further functionalization by adding reactive handles onto the dodecyl tail, giving access to surface modifications or anchoring groups. The methyl groups at positions 2 and 3 on the imidazolium core hinder certain side reactions, giving a big boost in thermal and oxidative stability. Still, the hexafluorophosphate anion won’t take kindly to strong bases or strong reducing conditions—it may break down, so care sits front and center during deprotonation reactions or in electrochemical cells where cathodic potentials dip really low. Researchers combine this salt with palladium or ruthenium for ionic liquid phase catalysis and even try swapping out the anion for others such as BF4 or NTf2 for improved solubility or conductivity, highlighting its role as a platform, not just an endpoint.

Synonyms & Product Names

Distributors trade under variations of the full name, such as C12C1C1ImPF6, dodecyl-dimethylimidazolium hexafluorophosphate, or simply imidazolium PF6 ionic liquid. Academic literature sometimes just refers to it using the shorthand [C12m2mim][PF6]. CAS numbers and registry keys remain critical for clear identification as naming conventions shift with supplier and region.

Safety & Operational Standards

Common lab practice demands extra caution since the hexafluorophosphate breaks down to hazardous byproducts in wet or hot environments. Hydrofluoric acid can form if mismanaged. Respirators won’t see much use compared to acids or bases, but fume hoods and splash shields help. Gloves must resist organic solvents—nitrile or better. Anyone working with it soon figures out that although imidazolium salts look benign, their bioaccumulation risk and long-term exposure remain poorly studied compared to older solvents. Proper waste disposal routes run through incineration or specialized ionic liquid recycling, not down the drain. Environmental, Health and Safety (EHS) teams stress sealed containers and urgent cleanup of spills to prevent accidental hydrolysis.

Application Area

Electrochemical engineers rely on this ionic liquid for batteries, fuel cells, and capacitor research. Its stability under voltage lets designers avoid common breakdown routes seen with conventional solvents. Synthetic chemists take advantage of its polar phase and hydrophobic tail to run selective extractions or biphasic reactions, often with transition-metal catalysts locked in an ionic liquid environment. Material chemists use it to stabilize nanoparticles and control morphology during deposition. Laboratories exploring textiles and polymers find it a candidate for conductive fibers and films. Not every use gets green lighted—some worry about persistence if leaks or spills hit soil or water outside containment.

Research & Development

Studies keep probing its role in green chemistry, looking to replace volatile organic solvents in large-scale synthesis. Projects underway pair imidazolium salts with CO2 capture, enzymatic catalysis, and even as additives in lubricants. Universities push for systems that can both serve as a reaction medium and help separate out products without extra solvents. Industrial research has turned to studying how its long-chain structure can template supramolecular assemblies or act as co-ligands for transition-metal complexes, which matters in sustainable catalysis and materials science. Intellectual property filings pile up around new derivatives and coupling it with new anions for greener performance.

Toxicity Research

Toxicological work suggests low acute toxicity but urges caution for chronic exposure. Imidazolium cations can harm aquatic life, especially if released untreated. Dodecyl side chains and perfluorinated anions slow down degradation, letting the compound persist in water and soil. Many research articles call for more long-term data on bone marrow, neurotoxicity, and respiratory effects in mammals. HF release remains a top operational risk, especially at scale—hospitals see rare incidents, but industrial exposure deserves monitoring. Waste management and personal protective equipment still serve best—long pants, sleeves, fitted goggles, and nitrile gloves get the job done.

Future Prospects

The future for 1-dodecyl-2,3-dimethylimidazolium hexafluorophosphate looks tied to how we handle sustainability in chemical manufacturing. Work continues to tune both its biodegradability and function, targeting lower toxicity analogs and safer anion-swapping procedures. Funding bodies favor projects that replace old, volatile solvents and tackle electronic waste recycling. As tech firms look for better electrolytes and catalysis platforms, more demand falls on improving recovery and reuse. Chemistry departments press ahead, using green chemistry checklists to ensure new variants measure up in both lab scale and pilot plants. For those developing new ionic liquids, the lesson from this compound is clear: balancing performance, safety, and disposal options guides every upgrade.

Chemical Innovation in the Lab

Few chemicals spark curiosity among researchers like 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate. Throughout my experience in chemical laboratories, I’ve seen lab teams explore this compound’s remarkable stability and ionic nature. It shows up often as an ionic liquid, which brings a whole new set of possibilities. The world of ionic liquids grabs attention because traditional solvents usually come with hazards—flammability, toxicity, and volatility. This compound barely evaporates, making it great for safer lab environments. The scientific community recognizes ionic liquids for their green chemistry contributions, since they allow for many reactions with fewer emissions. Scientists reach for this salt to dissolve tough-to-handle chemicals or to coax tricky reactions, especially those blocked by less versatile solvents.

Energy Storage Applications

The drive to improve batteries and capacitors never stops. In the search for materials that don’t leak, break down, or cause fires, researchers turn to novel ionic liquids. 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate helps as an electrolyte in lithium-ion batteries and supercapacitors. Its chemical structure supports high ionic conductivity, letting energy devices work more reliably at a wider range of temperatures. This can extend the service life of rechargeable batteries or make portable tech run longer per charge. There’s a lot of published data showing safety advantages over many conventional battery fluids, cutting risks of fire and breakdown under stress.

Industrial Catalysis and Synthesis

Many industries constantly need chemicals that make reactions faster or select one product over another. In catalyst research, specialists see this salt as a medium that boosts reaction speed or picks specific “routes” in organic synthesis. I remember working with teams testing new alkylating agents—using this ionic liquid often delivered more product and cut the steps needed to separate out chemicals at the end. Factories looking to cut waste can benefit. Recent reports show it can replace traditional solvents in some pharmaceutical and fine chemical processes, trimming toxic byproducts and saving energy since many operations use lower temperatures.

Green Extraction and Separation

Classic solvent-based extraction often creates huge waste streams and costs a lot to clean up. In contrast, chemists have developed extraction methods using 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate. This chemical offers selective extraction for metals or organic compounds. The mining and recycling sectors, for instance, use ionic liquids like this to pull rare metals from ore or old electronics without harsh acids or aggressive solvents. Some labs recover valuable platinum-group metals with this salt while reducing the overall environmental hit. Other teams use it to purify natural products from plants, getting high yields without a huge solvent footprint.

Potential for Safer and Greener Chemistry

Regulators and scientists talk a lot about the need for sustainability across industries. Materials such as 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate often show real progress. They reduce the volume of hazardous waste, support recycling, and lower the risk of accidental release. Challenges remain—cost, production scale, and fully understanding long-term environmental fate. Teams keeping worker safety and environmental impact front-of-mind keep pushing forward, testing this and related compounds for greener industrial chemistry. By supporting innovation and safe handling guidelines, the scientific community can bring about broader adoption and contribute to responsible chemistry.

Looking Danger in the Eye: Chemical Handling is Serious Business

Every day in labs, factories, and even home garages, folks come across chemicals that range from harmless to downright risky. Some substances, even in tiny amounts, can put health and safety on the line. Just take hydrofluoric acid—even a small skin splash can eat through tissue and bones, causing terrible burns. Over the years, people in my field have seen sharp reminders that underestimating a chemical’s hazards can lead to life-changing injuries.

The Basics: Gloves, Goggles, and Good Sense

Gloves aren’t just an afterthought. One simple slip-up, and your skin can soak up toxins or dangerous solvents. Nitrile gloves work for most chemicals, but not all. Strong acids, some solvents, and other heavy-duty substances need special glove materials. Tossing on a basic pair just won’t cut it—always check the certificate for chemical resistance before grabbing anything from the shelf.

Eyes are another weak spot. A splash can mean permanent vision loss. Not long ago, someone in a school lab lost vision in one eye after a tiny squirt of sodium hydroxide reached behind regular glasses. Lab goggles that seal against the face save eyes in ways regular spectacles never will.

Don’t Gamble With Fumes—Use That Fume Hood

Even familiar substances can cause trouble when vaporized or aerosolized. Chlorine bleach, ammonia, concentrated acids—these can burn airways and do slow, hidden damage to the lungs if fumes build up. Fume hoods pull contaminated air away from your face and out of the room. Coughing is a warning sign, not a harmless nuisance. Once your sense of smell goes numb, you are already overexposed.

Read the Label and Respect the SDS

Every chemical comes with a safety data sheet (SDS) that spells out hazards, handling steps, and emergency plans. Ignoring the SDS is like ignoring a weather warning—danger rarely cares about ignorance. Countless times, “it looked harmless,” or “I’ve handled it a hundred times,” came right before an ambulance ride. Understanding whether a material catches fire, decomposes with heat, or reacts with water makes a difference you feel long after you clock out.

Keeping It Clean—Storage and Spill Response

Tight lids, dry containers, labeling everything clearly—these steps keep chemicals where they belong. Accidents start with mixtures and leaks, especially when two reactive substances find each other in the trash or on a bench. Vinegar and bleach seem innocent apart, but mixed together by mistake, they can fill a room with toxic chlorine gas in minutes.

Spills will happen. Absorbent pads, neutralizers, and a plan to handle emergencies keep an accident from turning tragic. More than once, I’ve watched small leaks get ignored until they sent a coworker to the hospital. If you don’t know the clean-up steps, don’t try to improvise. Leave it to people who’ve trained for it, and flag the area before someone else gets exposed.

Training: The Real Lifeline

Habits keep people safe as much as equipment. Everyone, from veterans to new hires, deserves up-to-date training. No one learns everything on day one, and staying sharp cuts down on winging it “because that’s how we’ve always done it.” Open conversations about close calls can do more to prevent repeat disasters than any posted checklist. Safety grows from a blend of hard-won experience and honest, ongoing education.

Direct Experience with Chemicals Shapes Respect for Storage

Anyone who’s spent time in a lab knows the hard truth: proper storage of specialty chemicals lays the groundwork for safety. With chemicals like 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate, the stakes land higher than with simple salts. Over the years, I’ve seen what happens when corners get cut or when a label gets lost under a dust layer. Forgetting about the unique demands of some ionic liquids turns simple missteps into headaches. This particular imidazolium salt, with its long dodecyl tail and paired with a hexafluorophosphate anion, draws attention not only for its niche uses but for the way improper handling complicates things for everyone—from the benchtop scientist to the facilities team.

Factoring in Chemical Characteristics

Storage rules don’t come out of thin air. The structure of 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate usually means it resists water, but that doesn’t give a free pass to expose it to humidity. PF6-based salts create traces of corrosive and toxic hydrofluoric acid when they get damp. Anyone with a scar from handling HF, even for a second, remembers it forever. It’s a silent, invisible risk. So, a totally dry environment matters—think desiccators with fresh silica gel or well-sealed containers that don’t let ambient moisture drift in.

Temperature and Light: Two More Troublemakers

Too much heat opens doors to decomposition. It’s easy to forget how fast temperatures swing near sunny windows or under powerful overhead LEDs. I’ve pulled bottles off storage shelves and noticed sticky residues and warped labels. It happens fast in the wrong spot. A temperature around room temperature, but not above, keeps most ionic liquids in check. Sudden spikes—say, near old radiators or hot-plate storage racks—create long-term instability risks. Light can sometimes promote slow breakdown processes, especially for compounds with elaborate organic groups. Our answer doesn’t rest in complicated light-proof vaults, just using amber bottles and keeping the material inside a closed cabinet, away from stray lab light. Simple steps save money and health in the long run.

Labeling, Segregation, and Personal Vigilance

One memory comes to mind: a colleague stored an imidazolium salt near oxidizers, thinking the bottles looked the same. It didn’t turn out well. The need to segregate by hazard class gets drilled in for a reason. 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate stays happiest away from oxidizing agents and acids. Some labs use color-coded tape; others rely on storage maps by chemical family. Both approaches keep things clear in busy spaces with dozens rushing around. As for the container, tightly sealed, intact glass or HDPE works best. Replacing cracked lids pays dividends, since air sneaks in fast—especially for reactive salts.

Solutions: Building Good Lab Habits

Expecting written rules to save the day misses the point. Safety works as a practice, not just a checklist. Rotating stock—using older chemicals first—reduces the risk of forgotten, degraded material. Regular audits, with a few trusted people cross-checking each other, help catch early signs of trouble. Keeping desiccant fresh becomes a shared routine, not a one-person task. Training new lab members with real-life examples, not just textbook answers, helps everyone understand why these steps matter. The bottom line: respecting each chemical for what it is, not just what the paperwork says, protects time, budgets, and lives.

References and Best Practice Sources

The American Chemical Society, chemical safety boards, and the National Institute for Occupational Safety and Health point to similar best practices for specialty ionic liquids. A deep dive into peer-reviewed papers and the manufacturer’s safety data sheets gives specifics—water exclusion, temperature limits, and emergency steps. Following these guidelines means nobody faces unexpected surprises, even with rarely used reagents like 1-Dodecyl-2,3-Dimethylimidazolium Hexafluorophosphate. Learning from shared experience brings lab safety out of the abstract and into daily routine.

Understanding Solubility in Everyday Life

Whether mixing sugar into coffee or cleaning up an oil stain, people deal with the idea of solubility every day, often without thinking twice. Putting substances into water and expecting them to dissolve feels natural. With something more complicated than sugar, like a cleaning product or a new medicine, things can get confusing. Water, often called the “universal solvent,” isn’t always up to the task. Some compounds just shrug off water and need an organic solvent—think alcohol, acetone, or oil—to blend in.

Why Do We Care About Solubility?

If a new pain reliever dissolves only in oil, a tablet won’t break down properly in the stomach. Food preservatives that won’t mix with water may settle to the bottom of a beverage. Jobs in agriculture, manufacturing, or even painting all share this demand: figuring out which substance plays well with which solvent. A chemist may want a compound to dissolve in a specific medium for a reaction to take off. At home, dealing with stains, people reach for water or something stronger based on what they spilled. Every time this happens, there’s a decision about solubility.

Facts That Drive the Choice

Water dissolves polar compounds. Table salt vanishes in water because of its charged ions. Sugar’s polar groups grab onto water molecules, so it sweetens cold lemonade without a gritty mess. On the other side, organic solvents step in for things like fats, waxes, or tar. Cooking oil will never blend with water, but swipe it with some rubbing alcohol, and soon it disappears from the counter.

The science isn’t always straightforward. Some substances only partially dissolve, going cloudy or leaving residue. Even how hot the water is can change the outcome—think of steeping tea in hot versus cold water. Organic chemists often juggle between ethanol, acetone, hexane, or chloroform to get a stubborn material to finally go clear. Somewhere along the way, rules like “like dissolves like” pop up. That phrase points toward similar chemical structures and polarity driving what dissolves, but real life tosses in exceptions to keep people on their toes.

Testing Solubility: Getting Hands-On

Sometimes labels spell things out, but a lot of products just land on your desk, and the answer isn’t obvious. A small test—mixing a bit of the material in water and another bit in an organic liquid—tells a lot. Watching for cloudiness, separation, or a clear solution often answers the question faster than any label. For specialty chemicals, it helps to check product documentation or safety data sheets, which often list solubility in water and common solvents. Safety should never get skipped. Some materials react with water or solvents, giving off heat or dangerous gases.

DIY folk, hobbyists, and researchers all tinker with these tests. In my time fixing up furniture, there’s often a mystery stain or finish. Testing small spots with water and then with mineral spirits tells me what product comes next. In the lab, knowing whether a powder dissolves in water or something like ethanol guides experiments and waste disposal protocols.

Solutions and Moving Forward

Learning about solubility pays off, whether tackling a tough mess, improving a recipe, or pushing boundaries in science. Sharing clear information—through labels, instructions, or guides—removes a lot of guesswork and frustration. Schools could bring hands-on kits for kids so they can see what happens first-hand, making science real rather than abstract. For industry, investing in better documentation and digital resources shortens the learning curve, speeds up troubleshooting, and improves safety.

The Value of Knowing What You're Getting

Standing in a lab or on a factory floor, it never takes long to realize that purity isn't just a technical label on a bottle. For chemists, manufacturers, and even hobbyists, purity shapes how confident you can feel about your results. More than a few projects have gone sideways after someone assumed a reagent’s grade could slip by unnoticed. In my own first year working with synthesis, I learned fast that not all white powders are equal. That realization probably saved me from wasting months and money.

Packing Choices: Size Does Matter

The more you use, the more you notice that supply chains have quirks. Not every shop stocks the same sizes, and sometimes, suppliers don’t offer the grade you actually need. Consider a common lab compound like potassium carbonate. It’s available at different purity levels: technical, laboratory, and analytical, running up to 99.5% or higher. These differences often decide whether you get reliable results or end up chasing contamination in your data. And each level comes packaged to suit different needs: small bottles for research; 25-kilogram sacks for production lines.

I’ve always felt that packaging size tells you about the intended end user. Run a pilot plant? You’ll want drums or bags—something you can pour into a process feeder. Set up a high school experiment? The one-liter bottle makes more sense. This isn’t just convenience. Handling smaller, sealed bottles saves time and reduces waste when purity could degrade with repeated use, especially for hygroscopic solids or volatile liquids.

Beneath the Label: Source and Specs

Purity grades do more than satisfy regulatory panels. They protect reputations and financial investment. No one wants a recall triggered by a contaminant that sneaked through due to lax sourcing. Take pharmaceuticals: USP- or EP-grade materials back up every claim with a standard. Food-grade compounds track contaminants below strict limits. Quality goes beyond just a number; documentation, traceability, and batch consistency matter every bit as much.

As a senior tech once said to me, “Ask three vendors about purity, get five answers.” Some suppliers cut corners on paperwork; others test every batch with care. Without a certificate of analysis, you’re gambling with your outcomes, whether that means a failed pilot run or an academic paper you can’t trust.

Solutions That Raise the Bar

Tighter regulation has pushed many suppliers to sharpen their documentation and handling. Chain-of-custody records, on-demand analysis, and clear expiry dates are steps in the right direction. Customers should push for specifics: don’t rely on vague promises. If you’re buying in bulk, do your own verification. Spot-checking one or two drums per shipment adds a layer of confidence.

Education helps too. There’s too much at stake to let cost trump quality for critical projects. Training team members to spot misleading specs and ask for the right paperwork seems small until you tally the risks of cutting corners. For many shops, the payoff comes in saved time, more consistent results, and less drama when auditors come knocking.

Looking Forward

Markets drive change. As buyers get more informed, suppliers who can’t back up their purity claims or offer the right packaging slip down the pecking order. By demanding details—down to the last decimal point and batch record—we push for a culture where “good enough” stops being an excuse. That pursuit keeps progress ticking in every chemistry-driven industry.