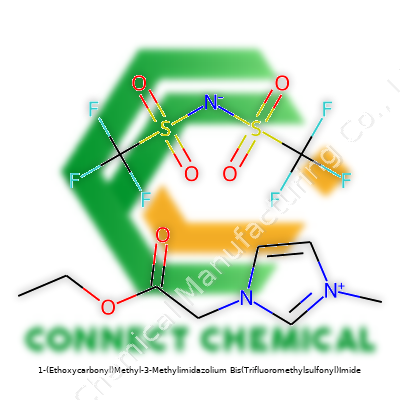

Exploring 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide: A Closer Look

Historical Development

A couple of decades ago, most folks working with solvents and electrolytes looked toward traditional, often volatile organic compounds. That started to change in the 1990s, as interest in ionic liquids surged, especially for research aiming to cut down on flammable and environmentally hazardous substances. Chemists went through mountains of journals and conferences, trading stories about new salt-like compounds with low melting points. Out of this search for green and efficient solutions, 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide—often referred to by its shorthand EMI-TFSI—became a fixture in technical literature. At first considered exotic, EMI-TFSI crept into academic labs focused on electrochemistry, catalysis, and sustainable manufacturing, slowly winning respect for its stability, conductivity, and flexibility compared to old-school solvents. Its rise tells the story of collaboration between industrial pragmatists and academic explorers who recognized that better chemistry could actually make a difference for real-world problems.

Product Overview

EMI-TFSI comes off as a long, complicated name, but what’s really important is its role in laboratories and manufacturing. This compound mixes traits that many researchers crave: it’s non-volatile, thermally stable, and highly conductive. These qualities push EMI-TFSI into the spotlight for demanding applications, from next-gen batteries to high-stakes organic synthesis. Academic research often discusses its potential as an alternative to dangerous or less-efficient solvents, especially where performance is crucial and safety concerns can’t be ignored.

Physical & Chemical Properties

This compound typically appears as a clear, pale yellow liquid under room temperature, a stark contrast to the toxic fumes and crystalline dust associated with many legacy chemicals. EMI-TFSI packs a high ionic conductivity—numbers hover above 10^-3 S/cm in many conditions. This isn’t just a technical detail; it matters for anybody trying to design batteries or supercapacitors with faster charge-discharge cycles. The thermal stability stretches past 350°C, based on thermogravimetric analysis, leaving behind the constant worry of decomposition that shadows other candidates. Its hydrophobic nature makes it play nicely with hydrophobic reactants, creating custom solvent environments for tricky chemical transformations. Most importantly, EMI-TFSI avoids giving off nasty smells or evaporating into lab air, which anyone who has spent hours handling solvents in poorly ventilated spaces can appreciate.

Technical Specifications & Labeling

Manufacturers often label EMI-TFSI by purity, most commonly above 99% (with moisture levels usually below 0.1%). The product’s CAS number is 944171-06-6. Common packaging options include amber glass bottles or PTFE-lined containers, designed to keep out light and stray moisture, both of which can degrade the compound over time. The technical specification sheets back up claims with data: refractive index (around 1.43–1.45), density near 1.45 g/cm³ at 25°C, and water solubility in the single-digit milligrams per liter range. Each batch has its own lot number and comes with a certificate of analysis showing trace metal content, which matters for anyone dealing with electrochemical processes.

Preparation Method

Making EMI-TFSI isn’t an exercise left only to the industrial giants. The process usually starts with 1-methylimidazole and ethyl chloroacetate in the presence of a base, forming the imidazolium cation. The subsequent ion-exchange reaction with lithium bis(trifluoromethylsulfonyl)imide allows for precipitation or extraction of the final ionic liquid. Experienced chemists go over every procedural step, using dry nitrogen and vacuum techniques to avoid moisture. Even small mistakes, like failing to control temperature or letting in too much water, can shift the purity and performance—painful lessons learned in countless academic syntheses. Yields often exceed 80%, and purification through repeated washings and filtration underscores the effort put into guaranteeing product quality.

Chemical Reactions & Modifications

Beyond its role as a solvent or electrolyte, EMI-TFSI celebrates a flexible molecular backbone, especially the imidazolium ring. This core structure invites alkylation, acylation, or even functionalization on the nitrogen atoms, impacting everything from solubility to ionic conductivity. In the presence of strong bases, the ethoxycarbonyl side chain may engage in transesterification or hydrolysis, so careful control proves necessary for specific applications. Some researchers experiment with modifying the anion—replacing the TFSI group—to tune properties like polarity or viscosity, pushing the limits of what these compounds achieve in different settings.

Synonyms & Product Names

Those outside the field might get tripped up by the many names this compound goes by. EMI-TFSI pops up in literature as 1-(Ethoxycarbonyl)methyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide, CMI-TFSI, or simply ethylcarboxymethyl-methylimidazolium TFSI. Distributors list it with abbreviated forms and proprietary branding, so researchers need to check CAS numbers and molecular weights to avoid confusion—mistakes that quietly kill productivity and research budgets.

Safety & Operational Standards

Spending time in the lab has taught a hard lesson: never assume any new material is inherently safe, no matter how “green” the label. EMI-TFSI benefits from low volatility, so inhalation risk is reduced, but contact with skin or eyes leads to irritation, and accidental ingestion is a serious concern. Safety data sheets highlight the need for nitrile gloves, eye protection, and fume hoods. Waste management follows strict protocols, since improper disposal carries risks of groundwater contamination, thanks largely to the fluorinated imide anion. Emergency procedures for spills require absorbent material and containment, not a casual wipe-up with paper towels.

Application Area

Battery developers chase compounds like EMI-TFSI for their unique properties. Lithium-ion battery electrolytes made with EMI-TFSI handle wider temperature swings, resist thermal runaway, and sometimes support the use of alternative electrode materials. Supercapacitor engineers look to this compound for improved charge density and service life. In organic synthesis, EMI-TFSI’s solvating power outperforms traditional solvents in select coupling reactions and catalysis schemes, giving cleaner products and fewer side reactions. Corrosion inhibition, biotransformation, and gas separation processes push the envelope in industry, while academic projects in next-generation solar cells slowly nudge this ionic liquid from the margins toward center stage.

Research & Development

Labs worldwide devote resources to exploring EMI-TFSI’s impact in real-world settings. Groups in Europe and Asia publish results on its performance as a battery electrolyte, often reporting greater thermal stability or cycling performance under rigorous testing. Customization of the imidazolium ring for pharmaceutical or advanced materials synthesis requires detailed kinetic studies, turning up data on reaction rates and selectivity. Research into recycling and recovery of spent EMI-TFSI from industrial streams continues, fueled by necessity as costs rise and sustainable chemistry takes greater importance. The real progress depends on persistent problem-solving, not just theoretical promise or batch-to-batch consistency.

Toxicity Research

Toxicologists haven’t overlooked EMI-TFSI, knowing that every new compound needs a clear understanding of its impact on health and environment. Studies in aquatic organisms flag moderate toxicity at concentrations above 100 mg/L, particularly due to the fluorinated anion. Long-term bioaccumulation risks remain under examination, but EMI-TFSI scores better than some legacy solvents on air quality and flammability metrics. Lab-scale exposure often brings mild irritation without severe long-term effects, yet strict adherence to handling guidelines prevents rare but serious incidents. Regulatory bodies update permissible exposure levels based on ongoing data from chronic exposure models, serving as a checkpoint against hasty commercialization.

Future Prospects

Ionic liquids like EMI-TFSI promise to disrupt established norms in energy storage, clean manufacturing, and material science. As battery innovations require safer and smarter electrolytes, this compound could edge out less-stable alternatives. Ongoing development of recycling and recovery protocols will address economic and environmental costs, making adoption more realistic beyond boutique applications. If upcoming studies confirm lower toxicity and lifecycle impacts than other emerging ionic liquids, EMI-TFSI might anchor the next wave of green chemistry—bridging the gap between lab curiosity and real-world resilience, helping industries run cleaner and smoother for years to come.

Digging Into the World of Ionic Liquids

Many folks in chemistry circles know this mouthful of a molecule as a member of the ionic liquid family. Scientists didn’t just come up with these compounds to look clever. The real drive came from the need for solvents that don’t evaporate easily, don’t catch fire like traditional ones, and can break down tough-to-dissolve substances. This specific ionic liquid—let’s just call it EMC-MIM TFSI for short—spends most of its time in research labs and tech companies, quietly doing the heavy lifting in advanced chemical engineering.

Why Chemists Keep Reaching for EMC-MIM TFSI

My background in materials research brought me face-to-face with ionic liquids during some long days battling battery problems. EMC-MIM TFSI shines because it’s highly stable both thermally and chemically. This means it won’t break down when things get hot or interact badly with other chemicals, a big plus in any busy reactor. Unlike regular solvents, it's non-volatile—no clouds of fumes choking out the lab.

Battery engineers value EMC-MIM TFSI for its use as an electrolyte or electrolyte additive, especially in lithium batteries. When you’re trying to keep high-powered lithium ions zipped between anode and cathode safely, you don’t want a solvent that evaporates or breaks down, risking leaks or fires. EMC-MIM TFSI helps create a stable environment, reducing risks and extending a battery’s working life. With electric vehicles at the front of technology headlines, demand for better, safer batteries keeps pushing this compound into fresh experiments.

Greener Approaches in Chemistry

A lot of new chemistry pushes toward sustainability. EMC-MIM TFSI rarely replaces water or super-safe chemicals in everyday products, but, compared to petrochemical solvents, it’s much less likely to end up polluting waterways or contributing to smog. Researchers have used ionic liquids to process plant materials, recycle metals, and break down complex chemical waste. The low vapor pressure of EMC-MIM TFSI means fewer emissions, helping cut down on lab and factory pollution.

Where Issues Creep Up

Nothing is perfect, and EMC-MIM TFSI has its headaches. Intense scrutiny comes with ionic liquids because some can be costly to make and tough to recycle. Laboratories, including a few I’ve worked in, often collect spent ionic liquids for specialized waste treatment instead of pouring them down the drain. Toxicity sometimes pops up as a concern, depending on the specific makeup and how used. Even green chemistry isn’t a free pass—some ionic liquids linger in water if spilled.

Most promising solutions come from refining manufacturing to lower cost, developing better recovery systems, and running thorough toxicity tests. Many commercial outfits are now piloting closed-loop systems to reuse their ionic liquids again and again. Academics focus on creating new versions of these compounds, swapping out parts that stick around in nature for ones that break down easily. Upgrading these processes could keep EMC-MIM TFSI and its relatives on the right side of both innovation and environmental safety.

No Hype, Real Impact

EMC-MIM TFSI doesn’t make headlines like big breakthroughs in medicine or computing, but its steady, quiet presence shapes some of the most important advances in high-tech manufacturing. It helps batteries last longer, supports cleaner reactions, and pushes research away from polluting, flammable solvents. For those working inside the world of lab chemistry and industrial processing, this compound isn’t just another chemical—it’s a tool to build safer, more sustainable technologies.

Getting to Know the Molecule

Walking into any busy academic or industrial chemistry lab lately, you don’t have to look far to find talk about ionic liquids. Among these, 1-(Ethoxycarbonyl)methyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide, often abbreviated as [EMMIm][NTf2], stands out. The structure speaks volumes once you break it down: an imidazolium core forms the backbone, linked to an ethoxycarbonylmethyl group and a methyl group, each attached at different nitrogen sites on the five-membered ring. On the other side, a bis(trifluoromethylsulfonyl)imide anion brings balance, bulk, and incredible chemical stability.

Delving Into the Imidazolium Core

The imidazolium ring, recognizable for its aromatic stability, pulls together a rich electron cloud. Attaching a methyl group to the third carbon and an ethoxycarbonylmethyl chain to the first nitrogen tweaks its reactivity and melting point dramatically. The ethoxycarbonyl chunk introduces flexibility and expands the compound’s ability to dissolve various substances, especially those tough-to-handle inorganic salts. Seeing chemists use this ring system reminds me how much power gets packed into small modifications on an already sturdy scaffold.

The Power of the Anion

If you look at industrial trends, the selection of the bis(trifluoromethylsulfonyl)imide anion almost always impresses with its versatility. The two sulfonyl groups, chained to a central nitrogen, each attached to a trifluoromethyl wing, make this anion both highly hydrophobic and resistant to chemical breakdown. This structure doesn’t just sound exotic—it allows the resulting ionic liquid to shrug off water, avoid hydrolysis, and keep performing even under punishing temperatures. You see people in my field quickly gravitate towards this pairing because it unlocks electrochemical stability and non-flammability you don’t easily find elsewhere.

Why the Structure Matters to Science and Industry

In practice, this cation-anion match sets up an ionic liquid with a wide window of thermal stability and low volatility. As someone familiar with frustrating spills and stubborn solvents, I appreciate the safety aspect here. The molecule’s design keeps it liquid over a broad range, without sneaking vapors into the air, meaning safer labs and cleaner processes. Tasks like battery electrolyte design, advanced separation techniques, and catalytic reactions all benefit from this stable and versatile environment.

Publications demonstrate how these structural features support ambitious green chemistry initiatives. Swapping out traditional volatile organic solvents for these ionic liquids curbs environmental impact. The molecule remains hardy in challenging chemical environments, making it a common pick for sustainable process design. For instance, companies have reported fewer emissions, smoother recycling of materials, and fewer hazardous byproducts when moving to ionic liquids of this class.

Challenges and Looking Ahead

No compound comes without hurdles. Creating these tailored ionic liquids not only demands meticulous purification but also faces questions about biodegradability and end-of-life disposal. Even with their promise, chemists must find ways to recycle and reclaim these molecules from process streams. The field pushes forward with more research into lifecycle impact, finding catalysts that help speed up breakdown or separate these chemicals for reuse.

Collaborative effort bridges the gap between safe molecule design, industry practicality, and responsibility toward the environment. Innovative chemistry, grounded in solid structural understanding, offers better routes toward sustainable solutions. This makes 1-(Ethoxycarbonyl)methyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide more than a mouthful—it’s a promise for smarter, cleaner chemistry in action.

Why Storage Isn't Just a Checkbox

Anyone who's ever worked with chemicals or pharmaceuticals knows one thing—proper storage can make or break a compound. I remember my early lab days, thinking a fridge and a label would handle everything. Learned the hard way that moisture, light, and temperature swings ruin samples in no time. A poorly sealed bottle in a warm room once turned a crystalline powder into a sticky mess. Turns out, good results start with honest storage.

Temperature Tells Its Own Story

Compounds like a predictable environment. Temperature swings cause them to break down, react with air, or even catch fire in the wrong scenario. Many need refrigeration, sometimes below freezing, to slow down chemical reactions. For sensitive pharmaceuticals and biological samples, a -20°C or -80°C freezer isn't overkill—it’s mandatory. Food for thought: the World Health Organization points out that vaccines spoil if kept above 8°C for too long, and chemical reagents often lose potency fast. Even slight warmth can start reactions that you’ll never see coming.

Light Doesn't Mix Well With Everything

Sunlight and fluorescent lights bring UV rays that transform certain compounds into something useless or even toxic. Amber bottles and dark drawers aren’t a lab décor choice—they’re protection. Take nitroglycerin or certain vitamins: with just a little sunlight, they lose punch or change color. I once saw a warehouse full of bulk chemicals ruined by a skylight nobody thought to cover. Easy to avoid with some basic foresight.

Humidity and Air Are Slow Trouble

Moisture signals trouble for powders especially. Hygroscopic chemicals suck water straight from the air and clump, sometimes even react. That sticky white powder in a lazy cork-sealed jar? That’s moisture at work. Silica gel packets, dry boxes, and proper seals make all the difference for things like anhydrous salts or dusty pharmaceuticals. Even household medicines tell you to tighten lids for a reason.

Labeling Isn't Just Bureaucracy

Accurate, honest labels cut the biggest risks. Expiry dates, storage temperatures, and handling notes help future you—and everyone else—avoid screw-ups. Once a researcher swapped two nearly identical white powders. The result was project delays for months—and a lesson learned about readable, detailed labels. No one beats the odds when guessing how a chemical was stored.

Practical Steps That Help

Simple habits work best: double-check your bottles for tight closure, keep a log of expiry and opening dates, segregate incompatible chemicals, and store all potential hazards away from plain sight or reach. Industrial setups go further with safety systems, alarms for temperature spikes, and strict access control. Even at home, smart storage for medicines keeps kids and sun beams away.

Keeping Eyes Open for Problems

Regular checks spot trouble early. Discoloration, moisture buildup, strange smells, or pressure under sealed caps all signal it’s time to pitch the batch. Trust your eyes and your nose more than any paperwork.

Why This All Matters

Safe, planned storage isn’t about red tape; it’s core to safety, research integrity, and health. No research paper or quality certification saves a reagent gone bad. Stored with care, compounds pull their real weight, and the rest of the lab—or job—moves forward without nasty surprises.

Chemicals Like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide in the Lab

Every lab worker has a mental list of bottles in the cabinet that need extra respect. This ionic liquid, with its chemical tongue-twister of a name, often shows up in specialty synthesis and advanced battery research. Many who handle these substances become careful by instinct—gloves on, goggles secured, hood fans humming. The worry isn’t just about what a chemist can see or smell. Invisible risks linger on a molecular level, and proper habits protect not only workers but also the greater community.

What Makes This Compound Concerning?

Ionic liquids sometimes get praise for their low vapor pressure and usefulness in high-tech applications. Companies like to push “green solvent” marketing when no fumes escape. The story doesn’t end there. Just because a liquid doesn’t stink up a room doesn’t mean it belongs down a drain or smeared on the skin. Many ionic liquids, especially those based on imidazolium and bis(trifluoromethylsulfonyl)imide (often called TFSI) anions, have raised eyebrows due to their persistence and possible health impact.

Here's what stands out: imidazolium-type ionic liquids can disrupt proteins or cell walls, and animal model work sometimes points to toxicity with long-term exposure. The TFSI part brings in fluorochemicals that have stubborn staying power in soil and water. Over the past decade, research teams in Europe and Asia have tested several similar structures. Some, after regular contact, hampered aquatic life or stunted plant growth. Regulators and industrial buyers look closely at these findings. I’ve worked around similar materials; nobody touches these compounds without a plan for spills, waste, and personal safety.

Company Safety Sheets and Real-World Handling

Most chemical suppliers publish safety data for customers. For this particular substance, the literature tends to use phrases like “causes skin or eye irritation,” “harmful if swallowed,” or “may cause respiratory irritation.” Stuff like this rarely carries the drama of hydrofluoric acid or cyanide, but the labels are serious. Microgram exposures might not mean much in a controlled space, but routine splashes or bad habits build risk over time. I’ve seen junior staff dismiss the lack of immediate discomfort, only to get red, itchy skin hours later. A research group in Japan ran tests and tracked mild but lasting inflammation in animal skin, even after a short exposure.

Waste issues stack up. The TFSI anion doesn’t break down quickly. No city water treatment plant can reliably catch or destroy chemicals like this. What heads to the drain, flush, or trash will probably show up in the ecosystem years later. Colleagues in analytical chemistry pull upstream drinking water and still find traces of persistent ionic compounds. Most responsible users try to collect and burn (incinerate) this waste at high temperature to destroy it completely, not send it to a landfill.

Moving Forward with Caution and Smarts

Research keeps moving, and new compounds always need better safety checks. For now, the answer is not to avoid these materials entirely, but to handle them with more care and transparency than generic lab chemicals. Labs should keep clear safety training, avoid dumping any amount down the drain, and call for full personal protective gear. Chemical manufacturers need to share honest data on worker exposure and long-term risk. Green chemistry, if it’s going to mean anything, ought to look at full life cycles—not just what happens in the beaker.

Trust Begins with Understanding Purity

Walking down any supermarket aisle or skimming through supplier catalogs online, a curious mind starts to wonder about those tiny details printed on packaging or data sheets: the purity or specification of that product. Many might shrug it off, thinking it only matters for scientists mixing chemicals in labs. Years spent both inside research settings and dealing with everyday consumer goods have taught me just how much hinges on these numbers.

A Number That Shapes Quality and Safety

Take something as ordinary as table salt. Seems straightforward, right? But the difference between food-grade and industrial-grade salt boils down to impurities. Lower-grade salt might pack extra minerals or even trace contaminants that affect taste or worse, cause problems for folks with sensitive health conditions. A manufacturer labeling salt at 99.5% purity means only half a percent is made up of unintended stuff—something as basic as this plays a direct role in safety.

Packing More Than Just a Label

Plenty of buyers and users skip the specs, assuming someone else checked them. This trust can backfire, especially in areas like pharmaceuticals or food processing. Take vitamin supplements as an example. Without clear purity data, fillers or unknown substances can slip into the capsules. Sometimes, they trigger allergic reactions or interfere with medical treatments. One recent report from an FDA inspection found that even minor contamination in a dietary supplement triggered a recall and widespread distrust among consumers.

Specification Clarity—Not Just for Experts

I remember a friend working in bakery supply who almost lost a big customer when a batch of flour arrived containing more ash content than specified. Breads came out denser, off-color, and the chain’s brand took a hit. Once they tightened their quality checks, including asking every supplier for up-to-date specifications and lab test results, complaints dropped and customers noticed fresher products. Turns out, those details matter all the way to the breakfast table.

Solutions for Reliable Purity

Relying on simple claims isn’t enough. Companies owe their customers transparency, through regular third-party lab testing and easy-to-read certificates of analysis. QR codes printed on packages linking to raw test data have become more common—a smart move that builds real-world trust. For bulk buyers, quick on-site purity tests add an extra layer of confidence before processing begins.

For everyday folks, asking questions and reading labels bring power back into their hands. For businesses, clear documentation and transparent communication catch issues before they become problems. In my experience, suppliers who regularly publish clear, honest test results (and stick to them) stay ahead of their competitors. Purity isn’t just a lab number—it’s a promise, a measure of reliability, and a quiet force behind lasting reputations.