1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride: Beyond the Surface

Historical Development

Chemists have long hunted for cleaner, more efficient alternatives to traditional chemical solvents. By the early 2000s, a push for ionic liquids took root in research circles, spurred by growing environmental regulations and a desire to cut waste. Within this landscape, 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride started gaining traction as academic papers and industry reports surfaced. Researchers saw it as less hazardous than chlorinated solvents and noted its resistance to evaporation, which seemed promising for scaling up greener processes. My introduction to this compound came during an industry R&D collaboration, where we dug through countless synthesis routes to match both purity and sustainability standards. As demand for customized ionic liquids increased, this compound’s flexible cation framework let researchers tailor its features for project-specific goals, including catalysis and extraction.

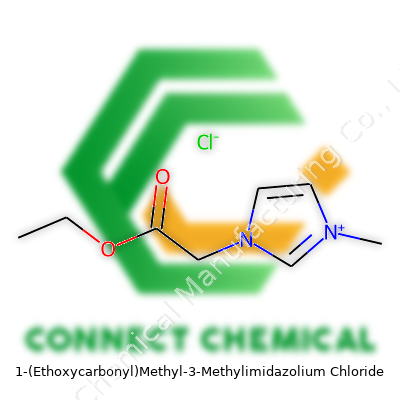

Product Overview

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride stands out in the ionic liquid family because its structure balances hydrophilicity with moderate organic solubility. Its molecular design threads an ethoxycarbonyl group onto a methylimidazolium core, giving it a unique balance of stability and reactivity. This product often appears as a pale white or off-white crystalline powder, compact and almost waxy to the touch, dissolving quickly in water and most polar solvents. Unlike conventional imidazolium salts, this variant boasts enhanced compatibility with a broad suite of organic substrates. Multiple vendors stock the product at high purity, typically above 98%, shipping it in sealed, moisture-resistant containers with detailed technical dossiers on batch origins.

Physical & Chemical Properties

This compound weighs in at 220.67 g/mol, with its melting point hovering between 135 and 145°C depending on crystal hydration. It resists decomposition up to around 220°C. Dense compared to simple salts, it pours almost like finely ground sugar, but unlike sugar absorbs atmospheric water, turning sticky if exposed too long. The chloride counterion grants solubility in water and alcohols, yet the ethoxycarbonyl group tweaks its solubility profile just enough to allow selective extraction in biphasic mixtures. The chemical holds steady through basic and mildly acidic conditions, though trace hydrolysis can occur in persistent humidity, something I encountered early on while storing open bottles near a sink—lesson learned.

Technical Specifications & Labeling

Manufacturers supply certificates of analysis listing purity, water content, residual solvent levels, and batch numbers. Labels highlight acute toxicity precautions and storage recommendations, stressing ventilation and desiccation. Safety Data Sheets (SDS) note its incompatibility with strong bases and oxidizers, as well as proper disposal pathways according to European REACH and American OSHA standards. Barcode systems track inventory and shipment, and regulatory compliance symbols go front-and-center: CE, RoHS, GHS. Researchers should always check for the IUPAC designation (1-(ethoxycarbonyl)methyl-3-methyl-1H-imidazol-3-ium chloride) to avoid mix-ups, since synonyms abound.

Preparation Method

Production takes several steps. Most routes kick off with methylimidazole and a haloacetate ester, usually ethyl chloroacetate. The methylimidazole is mixed with the ester under inert atmosphere—nitrogen or argon, depending on the scale—to form an N-alkylated imidazolium intermediate. Next, a chloride source is introduced, or the reaction relies on displacement during cyclization. Once the salt crystallizes, purification follows: repeated recrystallization in dry ethanol washes away unreacted precursor, while vacuum drying drives off any trace volatiles. I’ve spent hours hunched over stirring plates, watching the powder form and drift down through flasks, each batch slated for different downstream applications.

Chemical Reactions & Modifications

The imidazolium core lends itself to broad modification schemes. Chemists often swap counterions to tailor the salt for tasks like phase-transfer catalysis or enzyme stabilization. The ethoxycarbonyl arm can undergo hydrolysis or saponification, producing carboxylate derivatives for synthetic organic applications. Researchers regularly graft functional groups onto the imidazolium’s methyl tails to shape selectivity or ion mobility. One team in our lab once explored fluorinated analogs, pushing the envelope for battery chemistry—changing just one group transformed inert powders into potent electrolyte additives. These chemical tweaks crack open opportunities in supramolecular assembly, bioconjugation, and more.

Synonyms & Product Names

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride also goes by names like EMMImCl and Ethylcarboxymethyl-3-methylimidazolium chloride. Suppliers might list it as [EMMIM][Cl] or use Roman numerals depending on catalog convention. Even small differences in name can hide significant changes in performance, so buyers and bench chemists always cross-check product codes before starting a synthesis run.

Safety & Operational Standards

Direct handling requires gloves and splash-proof goggles. Vapors don’t pose the risks seen with volatile organic solvents, yet carelessness with powders around wet surfaces can create slip hazards or low-level corrosive conditions. Labs maintain spill kits and run local exhaust ventilation near benches working with the salt. The ethoxycarbonyl group makes it less caustic than some imidazolium analogs, but prolonged skin or eye contact causes irritation and should be avoided. Lab and manufacturing protocols call for sealed containers and secured storage below 25°C, away from bright light or high humidity. Waste goes straight to halogenated solvent collections—landfill isn’t an option here.

Application Area

Companies and universities alike leverage this compound for catalytic systems, solvent extraction, and separation science. It finds niches in CO2 capture research, acting as a shuttle for metal ions or reactive intermediates. In materials chemistry, the salt stabilizes nanoparticles and lubricates electrode assembly in advanced battery setups. Its ionic structure lets it replace conventional toxic solvents in select organic syntheses, easing environmental impact. Colleagues have reported promising results in enzyme-catalyzed reactions and biopolymer dissolution, citing efficiency gains and simplified downstream cleanup. Emerging applications include electrolytes in solid-state batteries and lubricants in microfabrication, where standard solvents can corrode sensitive surfaces.

Research & Development

Labs across North America, Europe, and Asia keep experimenting with new chemical routes to manufacture this ionic liquid at lower cost and higher environmental efficiency. Funding agencies back projects trying to tap biodegradable or recyclable variants. Some teams try to tune the balance between hydrophilic and hydrophobic behaviors for use in oil spill cleanups and protein extraction. Performance metrics stretch beyond simple yield; sustainability audits trace energy and water used over each batch. My own work has involved stress-testing new derivatives in fuel cell prototypes, where even minor tweaks in ionic conductivity or electrochemical window can boost output. Industry partners chase scale-up without sacrificing purity, mindful that even trace contamination derails innovations in pharmaceuticals or electronics.

Toxicity Research

Most published data pegs this compound as low-moderate in acute toxicity compared to traditional solvents, but uncertainties linger over chronic exposure. Cell culture experiments show few harmful effects at low concentration, yet higher doses can disrupt membrane integrity and hinder enzyme activity. Degradation products also raise concerns, especially with open-air storage. Tests on aquatic organisms suggest environmental risks in case of spills, leading to demands for closed-cycle or recoverable process flows. Regulators continue to press for deeper research into long-term accumulation, biotransformation, and safe incineration routes. Clinical research remains at the pre-approval stage, but preliminary results suggest gloves-on, mask-on handling should remain standard until more is known.

Future Prospects

Ionic liquids like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride consistently draw attention for their mix of tunable properties and reduced environmental risks relative to many organic solvents—if waste is managed responsibly. Down the road, research aims to shift manufacturing to renewable feedstocks, minimize byproducts, and engineer more targeted molecular modifications. Industry demand for green chemistry keeps fueling projects in pharmaceutical extraction, sustainable battery assembly, biomaterials, and recyclable electronics. Safe, cost-effective recovery and re-use options must mature before widespread adoption lands outside niche markets. The trajectory suggests more collaboration between chemists, engineers, supply chain managers, and regulators—each bringing knowledge, tools, and cautionary tales to the table.

Understanding the Formula: More Than Just Letters and Numbers

Whenever I step into a lab, chemical names like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride will greet me above the shelf. These names look intimidating, but each one opens a window into the substance itself. Stripping it right down, the chemical formula for 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride is C9H15ClN2O2.

Let’s break this apart. The “imidazolium” core means this molecule builds on imidazole, which brings two nitrogens and three carbons in a five-membered ring. The “3-methyl” part tacks a methyl group (a simple -CH3) onto one of those carbons in the ring, not so different from adding a keychain to your regular house key.

On the other side, the mouthful “1-(ethoxycarbonyl)methyl” describes a side chain. Ethoxycarbonyl stands for an ester group – think of the scent of the nail polish remover aisle, which owes a lot to esters. Here, though, this group latches to a methyl (-CH2-) and then hooks onto the nitrogen in the ring. Toss in chloride, and you’re looking at a salt: the imidazolium part carries a positive charge, chloride grounds it with a negative one.

Why This Formula Matters Outside the Textbook

Some people see chemical formulas as dusty old skeletons of science. In my experience, formulas like C9H15ClN2O2 get meaningful in real-world settings. For one, chemists use ionic liquids like this in synthetic labs and manufacturing, not just for fun but to solve problems that classic solvents can’t touch. Safety and environmental impact take center stage here: swapping out volatile organic solvents with ionic liquids often cuts down on workplace hazards.

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride gives researchers more options. It dissolves a broader range of compounds compared to water or alcohols. Several studies highlight the role of imidazolium salts in extracting valuable metals, recycling electronic waste, or speeding up chemical reactions. This isn’t just a handful of letters; it points toward greener chemistry. By understanding the structure, chemists tailor the properties to sweat less over volatility or toxicity.

Sorting Problem from Potential: Addressing Drawbacks

It wouldn’t be honest to say every ionic liquid solves every problem under the sun. Some release decomposition products if you turn the heat up too high. Disposal questions crop up, too. While these compounds don’t vaporize like gasoline, they can still slip into water supplies if waste isn’t managed well.

I’ve seen the difference made by strong protocols in the lab: Closed waste systems, quick response to spills, regular training. The best way forward means pairing scientific curiosity with responsible handling. Researchers lean on published data, like toxicity studies or environmental fate assessments. That’s critical. Regulations slowly catch up with research, so scientists have to read the fine print and act with integrity.

Looking Further: Building Expertise and Trust

Personal experience has taught me that the details behind a formula shape smart choices. Industry moves forward fastest when science, safety, and transparency travel together. People deciding how to use 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride need to dig deeper than its formula – they owe it to themselves and everyone down the line. With the right knowledge, this chemical and its siblings help turn ambitious ideas into safer, cleaner realities.

A Useful Tool in Chemical Synthesis

Some chemicals only make sense on paper, tucked into research papers or patent filings, but 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride has earned its place in many labs. As an ionic liquid, this compound brings a unique mix of stability, low volatility, and an ability to dissolve a wide range of materials. Chemists value these qualities. Over the years, I've seen more academic groups rely on this reagent to replace traditional organic solvents, especially in transformations involving nucleophilic substitutions or alkylations. Ionic liquids like this cut down on toxic fumes and can sometimes push reactions to finish faster or with a better yield.

Cleaner, Greener Chemistry

As someone interested in sustainability, I pay attention when the chemical industry starts shifting toward less harmful methods. Many old-school solvents leave behind a legacy of environmental headaches due to their toxicity and evaporation into the atmosphere. The push for greener processes has nudged chemicals like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride into the spotlight. It's not just about the solvent sitting in a flask; it's about what gets left in the waste drum. This ionic liquid offers low volatility, which means less of it ends up in the air, making it easier to work with in large-scale or sensitive environments.

Biocatalysis: A Natural Fit

I’ve noticed more biotech labs reaching for this compound in enzyme-driven reactions. Many enzymes won’t survive conventional solvents, but they keep working in ionic liquids thanks to the less harsh environment. This broadens the tools available for making fine chemicals, pharmaceuticals, and even flavors and fragrances. Industrial biocatalysis now leans on specialized ionic liquids to fine-tune reactions for higher yields, purer results, and enzymes that last longer.

A Helping Hand in Materials Science

Polymers and nanomaterials keep showing up in everything from medical devices to batteries. This ionic liquid serves as both a reaction medium and a dopant for conductive polymers. In my experience with electronics projects, ionic liquids make the difference between a brittle sensor and one that bends but doesn’t break. When chemists want to spin new fibers or create thin films packed with precision nanostructures, stable ionic liquids like this one offer the right balance of conductivity and processability.

Practical and Economic Challenges

While the promise of ionic liquids sounds great, there are still speed bumps. Cost can dampen the excitement, especially outside of academia or high-value industries. Disposal and recycling add another layer of challenge. Even "greener" solvents need responsible handling at the end of their life, since imidazolium salts can complicate wastewater treatment. From what I’ve seen, industrial players who want to scale up need to plan up front for solvent recovery systems and staff training.

What Moves the Needle?

Real change doesn’t just spring from new molecules but from how labs and factories adapt. Academic groups now focus on finding cheaper ways to produce and recycle ionic liquids. Industry groups partner with universities to push these advances beyond the bench and into production lines. Tools like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride can only make a true impact if companies and regulators back up their use with smarter safety practices and waste management.

Final Thoughts

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride isn’t magic, but its blend of stability, low volatility, and ability to dissolve diverse reactants makes it valuable in chemical synthesis, biocatalysis, and materials science. While not a household name, it sits at the crossroads of chemistry’s push toward cleaner, more flexible processes, so its story promises to get bigger as labs embrace sustainable practices.

Why Storage Conditions Matter

Anyone who’s spent time in a chemistry lab knows that the success of work often boils down to care and respect for the materials involved. Some chemicals, especially ionic liquids like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride, show impressive stability for a range of applications—from organic synthesis and catalysis to electrochemistry and material science. Still, treating them well keeps tests consistent and builds safety into every process.

This compound, with its blend of an imidazolium cation and a chloride anion, plays by similar rules as other ionic liquids: humidity, heat, light, and contamination each put quality and usability at risk. Scientists who take shortcuts—leaving bottles open in humid labs, or stacking containers near a window—often run into skewed data, wasted batches, or even safety scares.

Where to Put the Bottle

I learned quickly as a junior chemist that dry, tightly closed containers are not “overkill”—they're basic lab practice. This ionic liquid draws water from the air. Even a little moisture introduces uncertainty, changes reactivity, or triggers clumping. I always kept these bottles in cool and dry environments. For me, “room temperature” meant a real 20-25°C, away from radiators or direct sunlight, not just wherever the nearest shelf happened to be.

The safety datasheet backs up that experience. Direct sunlight can break down sensitive organic salts. Warm parts of the lab speed up slow decomposition processes. Unsealed containers give chlorides—well-known for being hygroscopic—plenty of chances to soak up water, and possibly pick up stray molecules floating around from other solvents. Some chemists wrap bottles in aluminum foil just to keep stray light from doing damage over long storage periods.

Cross-Contamination Must Be Avoided

Shared labs can get messy fast. Pipetting from one bottle to another feels trivial, but small mistakes lead to contamination. I've seen white, chalky clumps form inside a bottle after someone accidentally mixed in another ionic liquid. That ruined our batch and cost the group a week of work. Using disposable tools, clean spatulas, and labeling containers the moment they're opened should not be considered optional. Common sense and steady habits save money and keep data honest.

Humidity and Cleanliness Lead to Reliability

For the best results, storage in desiccators filled with silica gel or other drying agents works. Samples stay dry, avoid hydrolysis, and maintain chemical stability. If the compound won’t be used for months, refrigeration at 2-8°C helps too, though freezing brings its own complications like condensation problems on thawing. Any exposure to humid air, even for a minute, can stick around as a risk—especially if that compound will go into precise measurements or catalytic runs where impurities amplify errors.

Accountability Builds Trust

Colleagues trust each other more in labs where chemicals are labeled with date and initials. In my teams, tracking who ordered a bottle and who last opened it made fading labels or missing caps much less common. If a batch spoiled, we could retrace every step and prevent the same mistake. This isn’t just about saving money; it shapes a culture of care and transparency in science that pays off over the long run.

If you treat 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride as delicate and valuable every step of the way, that care ripples forward. Good storage practice helps science move forward, avoiding the headaches that come from laziness or poor planning.

Perspective on Chemical Safety in the Lab

After years working in labs, I know how new chemicals can raise questions about safety. 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride landed on my radar not long ago. It's not a name you find in everyday conversation, but in research environments, scientists often use imidazolium-based salts like this as solvents, catalysts, or in battery research. Even people who handle chemicals for a living can feel uneasy, especially when information looks thin.

Understanding What Science Says

The first thing I do whenever an unfamiliar chemical shows up is read its safety data sheet (SDS). Some standards are universal: check for acute toxicity, skin or respiratory irritation, risks to the organs, environmental harm, or chronic health effects. With 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride, toxicity studies look sparse. Most published data on the class of imidazolium salts suggest moderate concern. Some, particularly those with longer alkyl chains, show more toxicity: they harm fish, invertebrates, or cell cultures at higher doses. Shorter chain variants, like the one in this article, usually show lower risk, but the word "safe" never appears in toxicology. Until toxicologists say more, the label on this compound sits in a gray area.

Hazards and Exposure

No chemical gets a free pass. Even water can be dangerous in excess. Researchers have linked some imidazolium salts to skin and respiratory irritation. If enough lands on skin or gets inhaled, rashes or coughing could follow. Eyes need careful protection, since even a splash can cause irritation. During one project, my colleague forgot her goggles for a split second; even a non-corrosive compound left her with discomfort and a doctor’s visit. Lessons like that stick.

Chemical spills draw concern, too. Ionic liquids can be sticky and hard to clean. Waste handling becomes just as important as the work itself. Some ionic liquids resist breaking down in the environment, and that means they persist for years. Some studies point to lingering effects on aquatic life, especially in freshwater settings. Small-scale use reduces risk, but cumulative spills or improper disposal cause problems that ripple outward.

Solutions: Smarter Handling and Transparency

Nobody wants an accident or a story about contamination. Safety always starts with knowledge. While clear, specific toxicity data for this compound looks scarce, that doesn't mean users should ignore risks. Gloves, goggles, lab coats, and fume hoods: these choices shape workplace health for the better. Training must spell out the worst possible mishaps, so people don’t skim protocols.

Company transparency matters just as much. Manufacturers sometimes hold back safety data for newer chemicals. This compounds the uncertainty for students, technicians, and researchers. Regulatory agencies and journals should demand better disclosure. Accelerating independent research into toxicology or environmental impact helps close the information gap.

Companies introducing new ionic liquids like this should support independent safety studies. Regulators should require true hazard assessments before scaling up. Even if toxicity turns out moderate, vigilance pays dividends. In research, small oversights stack up. A culture of asking, “Is this safe—do we have evidence?” guards health, the environment, and those who work with chemicals every day.

Why High Purity Specification Really Matters

Working with 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Chloride asks for more than just a bottle and a label. In the lab, purity sets the base for every result. I’ve seen unpredictable reactions derail whole projects because the chemical grade didn’t match what the catalog promised. Most suppliers list purity for this ionic liquid at 98% or higher. Anything under that number signals possible contamination or leftover synthesis byproducts.

A trace of moisture, an overlooked halide, or extra methylimidazole brings down reaction yields. Sometimes it hides until the final analysis, sending you back to square one. One supplier’s fine print once cost my group weeks, as a small percentage of an impurity showed up as a side reaction product. Even high-throughput teams run into the same wall—one faulty batch, and suddenly downstream processes or data lose reliability.

Supplier Claims and What Labs Really Get

Most chemical suppliers put “≥98%” on their certificate of analysis. This seems like enough on paper, but experience teaches skepticism. There’s a real difference between purity measured on a dry basis and what gets shipped in a container that’s been open too long or transported carelessly. Some vendors check only for total organic impurities; others go deeper, testing for water content, chloride accuracy, and residual solvents.

One standout supplier I dealt with routinely delivered batches running at 99%+ purity, and each lot came with detailed reports including HPLC, NMR, and Karl Fischer titration for water, not just the general “meets specification.” This attention to detail gave me more peace of mind than any standard-number guarantee. R&D labs benefit from these deeper checks. There’s less troubleshooting, sharper peaks in spectra, and far fewer returns or wasted runs.

What’s Behind the Numbers

Reality in the synthesis world doesn’t always match neat catalog listings. Ionic liquids like this compound often cling to solvents from their production route, or pick up moisture from the air. But for Catalysis or organic synthesis, even a little bit of water breaks reaction cycles and clogs up purified product streams.

Academic groups chasing new catalysts or electrochemical cells usually care about “99% anhydrous” as the gold standard. In the pharmaceutical sector, regulations push for certificates listing every trace impurity and solvent. Lower grades might work for industrial cleaning, but nobody wants false positives or failed batches in pharma or fine chemical R&D.

Improving Confidence in Purity

I’ve learned to demand independent testing in-house, not just rely on a supplier’s paperwork. Running checks like NMR and GC-MS catches what can slip through batch records. Some research teams partner with local universities for analytical help, especially if budgets don’t stretch to big equipment. Many suppliers will provide extra purity data on request—third-party verification goes a long way toward keeping projects on track.

Regulators and journals now expect transparency: full certificates, traceable lot numbers, and clear notes about how purity was calculated. As more labs share experiences—good and bad—buyers can start to spot patterns and steer clear of vendors who cut corners. Users who spend a few minutes double-checking before signing the requisition slip save themselves days or weeks of lost time down the line.