Understanding 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate: Building Blocks, Breakthroughs, and Behind-the-Scenes Insights

Historical Development

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate didn’t just pop up overnight. Researchers aiming to develop efficient ionic liquids for use in chemical processes drove its creation. The rise of "green chemistry" in the late 20th century triggered wide exploration of alternatives to volatile organic solvents. Imidazolium-based ionic liquids became standout options due to their tunable properties and broad stability. Early experiments focused on basic methylimidazolium cations, but curiosity about improving solubility and expanding use cases pushed teams to experiment with various functional groups on the imidazolium ring. The discovery that replacing a methyl with an ethoxycarbonylmethyl group brings new physical and reactivity features sparked publications and patents around the early 2000s. Many recall academic debates at conferences in those days—engineers scratching their heads, wondering how to scale up production or predict downstream effects from awkward new anions and cations.

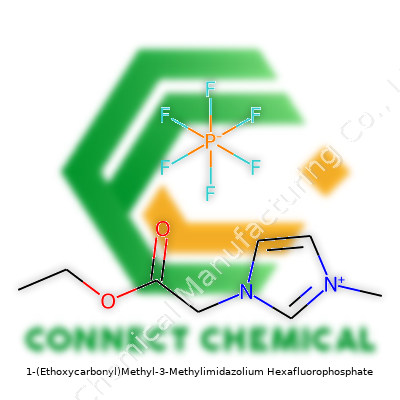

Product Overview

This compound shines in ionic liquid research circles. The basic architecture centers on an imidazolium ring, methyl substitution at the 3-position, and a bulky ethoxycarbonylmethyl substituent at the 1-position. The hexafluorophosphate anion balances out the positive charge and delivers impressive thermal and electrochemical stability. Most chemists who’ve handled this salt remark on its power to dissolve a range of polar and nonpolar compounds and its low vapor pressure, cutting concerns over inhalation or flammability during lab work.

Physical & Chemical Properties

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate typically appears as a white crystalline powder or sometimes a viscous liquid, depending on purity and storage conditions. Density hovers around 1.4 to 1.5 g/cm³, which means it sinks in most organic solvents. It melts in the range of 100–120°C and resists decomposition to roughly 300°C before the hexafluorophosphate anion starts breaking down and releasing toxic byproducts. The ionic structure means strong conductivity in solution, along with resistance to most bases and weak acids. Water solubility stays modest, thanks to the hydrophobic PF₆⁻ anion, but the ethoxycarbonylmethyl substitution enhances compatibility with certain polar organics—a big selling point for reactions requiring tough reaction partners.

Technical Specifications & Labeling

Commercial packages often list the compound as C9H15F6N2O2P with a CAS number for traceability. Labels spell out moisture sensitivity and the need for dry storage under inert gas. Product batches typically test for purity above 98%, with water content under 0.2%, confirmed by Karl Fischer titration. Labs require clear hazard labeling on all jars, indicating potential for hydrolysis if exposed to moisture, and potential for irritating or corrosive effects due to both the cation and anion acting synergistically. Not every supplier achieves consistent particle size, so those who need reproducible performance in catalysis or electrochemical applications rely on reputable chemical distributors with batch certification.

Preparation Method

Making 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate isn’t for the faint of heart or the careless bench chemist. Most routes begin with 1-methylimidazole, which reacts with ethyl chloroacetate under controlled temperatures. This alkylates the nitrogen at position 1, and the desired ethoxycarbonylmethyl group locks in. Workup involves phase separation, repeated washes, and then anion exchange with potassium hexafluorophosphate. The last step requires deionized water and deeply dried solvents, since any excess water trashes product purity and yields. The lot usually crystallizes out during slow solvent evaporation. Everyone who’s scaled up this method battles the same issues—getting rid of unreacted imidazole and excess hexafluorophosphate byproducts without contaminating the main batch, and protecting sensitive equipment from corrosion by PF₆⁻ and HCl fumes.

Chemical Reactions & Modifications

Tinkering with this ionic liquid in the lab opens up a toolbox of chemical possibilities. The imidazolium core resists most nucleophilic attack, but the ethoxycarbonylmethyl group can act as an ester-reactive site under the right conditions. Researchers have functionalized the cation for custom catalyst support or grafted it onto polymer backbones to tune membrane properties. The anion, PF₆⁻, can be swapped for other less toxic or more hydrophilic counterions through metathesis, making this structure a sort of modular hub for other ionic liquids. Some methods harness its stability to serve as a solvent or co-catalyst under extreme temperatures, where traditional solvents would degrade or boil off.

Synonyms & Product Names

Chemists who track down data or order this material from suppliers may see names like EMIM-PF6 or 1-ethyl(carbonyl)methyl-3-methylimidazolium hexafluorophosphate. The most common shorthand in academic circles is [C2COOMmim][PF6], and some catalogues abbreviate the structure slightly differently, leading to confusion until someone checks the exact molecular formula. The "EMIM" family often covers a bunch of similar compounds, but the unique ethoxycarbonylmethyl handle matters for fine-tuned synthesis and properties.

Safety & Operational Standards

Lab work with 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate leaves absolutely no excuses for skipping gloves and safety glasses. Both the cation and PF₆⁻ anion can irritate skin and eyes, and toxic HF can form if it decomposes in strong acid or under high heat. Labs must keep stocks away from hydrolyzing agents and stay alert for white residue on surfaces, which usually signals accidental release or contamination. Local environmental rules kick in for waste disposal, thanks to the persistent, bioaccumulative nature of hexafluorophosphates. Ventilation and fume hoods reduce risk of accidental inhalation, but emergency protocols should also account for accidental spills, which can turn sticky and hard to remove from benchtops.

Application Area

This ionic liquid turns up in battery research, especially as an electrolyte additive in lithium-ion and supercapacitor cells—its low volatility and high conductivity make it a promising candidate for next-gen energy storage. Reaction engineers experimenting with organometallic catalysis love its capacity to dissolve metal complexes while providing a chemically inert, high-boiling medium. High-value separation techniques in pharmaceuticals and separation science depend on it as a tunable solvent for extractions not feasible with conventional solvents. Electrochemistry groups push its use in experiments involving redox mediators, ionic conductivity benchmarking, and development of sensors for trace analytes. I’ve seen startup teams burn through grams of it in prototype development for CO₂ capture or green synthesis, often chasing metrics that promise game-changers in efficiency or waste reduction.

Research & Development

Universities and industrial labs keep tweaking this molecule and its close relatives, hunting for improved chloride-free syntheses or ways to swap out PF₆⁻ for less contentious anions. Some teams explore incorporating functionalized imidazolium cations into solid supports, opening new doors in membrane and ion-exchange technology. Computational chemists spend late nights modeling ion-pairing and solvation dynamics, hoping to predict new application domains and stability limits. Crowded poster sessions at conferences now show cross-disciplinary studies—chemical engineers, material scientists, and even biotech entrepreneurs testing out new reaction pathways in this surprisingly versatile solvent. Funding agencies pile on grants for projects reducing toxicity, assessing lifecycle impacts, or using this class of ionic liquids in renewable energy and emissions reduction.

Toxicity Research

Tales of green chemistry sometimes gloss over the environmental persistence and toxicity of both the imidazolium cation and PF₆⁻ anion. Recent studies raise flags about biotoxic effects in aquatic life and long-term environmental buildup. In vitro data shows membrane disruption and inhibition of cell division at surprisingly low exposures. Hexafluorophosphate breakdown products, notably HF and other fluorinated acids, pose real threats to lab and commercial users if not handled correctly. Environmental chemists increasingly call for more non-fluorinated analogs and tighter disposal guidelines—landfill ban proposals aren’t just theoretical as regulatory pressure grows. The takeaway for any lab group or company is clear: Stay vigilant on safety, and don’t oversell the “green” benefits until all the data is in.

Future Prospects

Interest in this ionic liquid will only grow if researchers solve the toxicity puzzle and address environmental disposal. Continuous investment flows into developing alternatives with shorter environmental half-lives and safer decomposition profiles. Some chemical startups bank on tweaking the imidazolium core or using biodegradable anions to carve out niches in pharmaceuticals, renewable energy, and sustainable chemical synthesis. Demand for reliable and tunable ionic liquids keeps rising, fueled by real-world needs for safer, more efficient solvents. If developers can maintain high conductivity and chemical resilience while dialing down environmental risks, 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate and its next-gen relatives could help drive a quieter, cleaner chemical industry.

Why Chemists Value This Compound

Many in the research and industrial chemistry world recognize the significance of ionic liquids. Among them, 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate often grabs attention. Its core appeal lies in a unique mix of stability, low volatility, and efficient ionic conductivity. These properties have drawn focus ever since labs and companies realized solvents need to be both safe and high performing.

It’s easy to overlook the power of using such ionic liquids until you start working on tricky syntheses. The first thing that stands out? The sheer flexibility. Traditional organic solvents like acetonitrile or dichloromethane come with challenges: toxicity, flammability, and strict regulations slowing down workflow. Here’s a compound that not only cuts those risks but also helps push reactions to higher yields than ordinary solvents.

Prime Uses in Research and Industry

Electrochemistry benefits most from ionic liquids like this one. Electrolyte research strolls ahead thanks to their wide electrochemical windows and strong ionic mobility. For anyone who’s ever tried to push an energy storage project to new heights—think of advanced batteries and supercapacitors—switching to a liquid like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate can lead to longer cycle lives, better charge/discharge rates, and higher safety margins.

Catalysis offers another lane where this compound makes a difference. Working with metal catalysts often means battling with unwanted by-products or tricky purification steps. Using this ionic liquid lets chemists produce cleaner compounds, cut down waste, and dodge extra purification steps. Greater efficiency means lower costs and fewer headaches.

This compound’s promise extends into greener chemistry, too. Many find its lack of measurable vapor pressure attractive, leading to safer lab conditions and less environmental escape. Add the fact that it supports biotransformations, enzyme catalysis, and even certain pharmaceutical routes, and you have a solvent with real range. Labs no longer have to sacrifice green goals to get peak results.

Addressing Some Real-World Challenges

Real life isn’t all perfect, though. Hexafluorophosphate as an anion means PF6 can release hydrofluoric acid if it gets wet—a major safety concern. Frequent glove changes, careful storage, and solid ventilation turn from optional extras into necessities. The high cost of ionic liquids compared to classic solvents can also be a sticking point. Companies trimming budgets might hesitate, even if the long-term gains show promise. Repurposing waste or recycling spent liquids remains tricky, leaving disposal and lifecycle impact as issues to tackle.

Looking Ahead

Based on past experience in both academic and industrial settings, the best progress comes from thoughtful risk management and innovation. Labs that track solvent recovery and look for safer anion alternatives tend to stay ahead. Startups exploring new energy storage rely more on green ionic liquids, embedding better safety systems into every step from R&D to scale-up. Researchers pooling knowledge about chemical compatibility and improved recycling methods lead the way, showing that improvements don’t just come from flashy discoveries—they grow from steady, experience-driven change.

Understanding Chemical Stability in Everyday Work

I’ve spent years handling all kinds of substances—from ones that break down in a hint of sunlight, to those that could sit on a shelf through the apocalypse and barely change. Stability isn’t just a label on a lab sheet; it defines how trustworthy a chemical will be over weeks, months, or even years. If a compound reacts to air, light, or heat, it’s not just inconvenient; it can lead to wasted money, failed experiments, or even health hazards. I once opened a bottle that nobody had checked in months and got hit with a smell so sharp, I knew right away something had decomposed. That’s a reminder that not every chemical can be left alone without thought.

Building Good Habits Around Storage

Every lab worth its salt posts safety sheets near their shelves, but it really comes down to daily habits. If a substance is sensitive to moisture, you’ll want it in a tightly sealed container with a desiccant packet inside. I always tuck silica gel packets into jars if there’s any doubt. For light-sensitive materials, amber glass jars go a long way—regular glass just doesn’t cut it. I’ve learned from experience that some compounds degrade just sitting by a sunny window. Even a short exposure can make them lose strength or become dangerous. Putting those containers back in their dark, cool spots feels like a small chore, but it’s the kind of habit that stops major problems before they start.

Temperature and Storage Choices

Cooling matters for more than just leftovers in the fridge. I’ve noticed temperature swings in an unregulated storage room will ruin plenty of chemicals. Many compounds hold up best around 2–8°C, so refrigerators labeled for chemicals (not lunch!) are a staple. Some tricky reagents want to go even colder—straight into the freezer. But frost and condensation can do their own damage, especially after repeated freeze-thaw cycles. No one enjoys tossing out pricey materials that could have lasted with just a bit of extra planning. Manufacturers usually stamp storage temperatures on packaging, and it pays off to read those labels closely. If it says “flammable,” storage near electrical outlets or heat sources isn’t just lazy—it puts everyone at risk.

Monitoring Humidity and Handling

Where I work, we track temperature and humidity with cheap sensors stuck on the shelves. It’s surprising how quickly humidity sneaks up if ventilation drops or someone leaves a window open during summer. Some powders turn lumpy; others go from fine white to ugly brown, all thanks to a bit of extra dampness. When handling volatile or reactive powders, quick transfers and tight lids avoid costly spoilage. I’ve made mistakes scooping out too much and letting air in, only to see stability drop off by the next check. Keeping chemicals in their original packaging—or resealing carefully—makes a clear difference.

Routine Checks and Labeling

No one likes paperwork, but skipping label updates after opening bottles leads straight to confusion. Marking the date of receipt and open date helps track how old things get, and gives everyone on the team a fighting chance to spot problems early. I’ve avoided ruined batches just by noticing a faded or curling label, then checking the condition before mixing or measuring. Some labs invest in digital inventory systems for large collections, and even simple spreadsheets help flag anything nearing the end of its recommended life.

Fact-Based Approach to Safety and Longevity

Ignoring best practices with chemical storage risks more than just inconvenience. The CDC documents dozens of lab incidents every year, many from ignored storage rules. Fumes, fire, and waste pile up fast when chemicals lose stability, and these accidents rarely end well. Proper container choice, humidity control, and regular checks all add up to a safer lab and better results. I’ve seen teams transform their whole workflow just by adopting a maintenance mindset—with sharp eyes and good habits, shelf life gets stretched, costs drop, and routine work stays predictable.

Why Safety Isn’t Optional

I’ve seen labs where people rush through experiments in a hurry to chase results, but working with chemicals like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate demands respect. This compound, belonging to a class of ionic liquids, can unlock interesting possibilities in synthesis and electrochemistry, yet ignoring proper care can lead to unnecessary health risks. Breathing in the dust or getting it on your skin can trigger allergic reactions or more serious issues over the long term. Even research from the past decade, published in journals like Chemosphere, shows that some imidazolium-based ionic liquids aren’t nearly as harmless as they once seemed.

Hands-On Protection Matters

Gloves are non-negotiable. Not those thin food service ones—I’m talking about nitrile or neoprene gloves. Safety goggles, not just glasses, because a splash in the eyes can ruin more than a day. I wipe down benchtops both before and after handling this compound because residues can linger and you never want to let them build up. Breathing protection like a well-fitted mask or respirator also makes sense, especially if you’re weighing or working with powders. Anyone who’s gotten a whiff of fluorinated compounds knows their irritation risk isn’t a myth.

Building Safer Work Habits

I’ve always double-checked I’m in a fume hood before opening any bottle labeled “hexafluorophosphate.” Some labs skip this step to save minutes, but the moment you notice a sweet smell or a tingle in your nose, you realize why the airflow matters. Hexafluorophosphate can break down over time to form toxic hydrogen fluoride. If a spill happens, having calcium gluconate gel on hand is smart, because it can help treat accidental skin contact with fluoride compounds.

Proper Storage: Out of Sight, Out of Harm’s Way

Storage should be dry, cool, and shielded from direct sunlight. Moisture in the air can cause side products you don’t want to mess with, and light exposure tends to break down a lot of these delicate ionic liquids. Solid secondary containment like a tight, chemical-resistant bottle with clear labeling makes sure nobody grabs the wrong thing, and avoids accidents. I never leave these types of containers outside of storage overnight; too many stories float around about what happens in a humid room.

The Human Element in Risk Reduction

Training saves more than regulations ever will. I’ve watched younger researchers benefit from quick debriefs about emergency showers and eyewash stations. No procedure is perfect, but keeping the “worst case” in mind leads to thinking ahead. Peer-reviewed reports and even government chemical safety bulletins agree—incidents drop when people know how to handle a spill or exposure calmly and quickly. Relying on experience from others who handled similar fluorinated salts helps prevent painful mistakes.

Aim for Continuous Vigilance

Personal experience taught me that real safety never comes down to a single checklist. It’s built into daily habits, communication, and a willingness to pause and ask questions. Keeping up to date with fresh safety data—especially SDS updates or new toxicity findings—makes a difference in the world of research and synthesis. No shortcut beats preparation and a healthy respect for chemicals with names this long.

Understanding Purity: Beyond the Numbers

A lot of people overlook purity grade, thinking that small differences in quality don’t really impact the big picture. After spending years digging into how products are made and used, I’ve seen time and again how the purity of a chemical turns an “okay” result into a home run—or a disaster. Pharmaceutical companies, for example, don’t gamble with anything less than the highest standard, because an impurity—even a tiny one—sometimes triggers side effects or ruins batches worth millions.

Let’s talk real numbers. Take laboratory reagents: Companies mark them as technical, laboratory, analytical reagent, or HPLC grade. Technical grade works for many industrial applications, but if you’re running instruments to measure trace substances, you’d better grab HPLC or analytical reagent grade. While it’s tempting to save a few bucks using a lower grade, the fine print can bite back. Impurities in lower grades turn up as unwanted peaks in chromatography, skew data, or damage sensitive equipment. Even within high-grade categories, certificates list content, trace metals, and even moisture—details that make all the difference in research or manufacturing.

How Product Supply Shapes Workflows

The way a company supplies a product reflects how customers actually use it. Over-the-counter goods don’t look anything like industrial drums or high-purity bottles. Think about bakeries: Bulk flour comes in massive sacks, but for someone baking a cake at home, those bags don’t fit the kitchen. In the lab, high-purity chemicals arrive in glass bottles – protected from contamination and easy to store. Industrial users get the same chemicals packed in drums or even tankers, tailored for seamless feeding into machines.

I’ve watched lab staff pour one-liter bottles for delicate reactions, and I’ve seen truckloads make their way into plant tanks for dye production. Each supply form matters. Aluminum foil packaging locks out water and oxygen for sensitive chemicals. Amber glass blocks light that could break down a compound. It might sound trivial, but the right packaging preserves quality and makes everyone’s life easier. Transport and storage pose real risks. One friend who ran a clean-room facility told me how one leaky shipment threw weeks of work out the window.

Getting Past the Hurdles

Problems crop up all the time: inconsistent labeling or leaky containers, for example. Staff end up working overtime to track down unexpected test results or trace the root cause of machine breakdowns. It makes sense to demand a certificate of analysis with every batch. Suppliers that back up labels with documented test records build trust. In regulated industries, those papers count as much as the chemicals.

Moving forward, the fix comes from both sides. Buyers push for suppliers who put real muscle behind quality checks and transparent reporting. Suppliers invest in tamper-proof seals, clear labeling, and storage guidance. Digital tracking helps too—scannable codes let people check purity or shipment status in seconds.

Why Purity Grade and Supply Options Matter to Everyone

After working in labs and factories, I can’t stress enough how much stress and money a quality grade saves down the line. Picking the correct grade and right supply format keeps things running smoothly, limits waste, and protects everyone’s reputation. In the end, success starts with knowing exactly what’s inside that bottle or drum on your shelf—and making sure it arrives there in perfect condition.

Everyday Work and Chemical Safety

Cooling a reaction, measuring out raw materials, or cleaning up spills—routine steps in a lab or on a production line—introduce you to the realities of chemical incompatibility. If you’ve ever seen a reaction take an unexpected turn, maybe with a sudden release of fumes or heat, you remember how quickly things can get risky. It’s more than a checklist item in safety training; real hazards hide in overlooked pairings and stored containers.

The Hazards Lurking in Decomposition

Mixing incompatible substances can bring out the worst in both. Some combinations spark fires, while others give off toxic gases even at room temperature. For instance, bleach and ammonia, both common in cleaning supplies, together can make chloramine vapors—sure to send you out of the room coughing and teary-eyed. On a larger scale, labs and factories deal with even nastier byproducts, such as hydrogen cyanide or phosgene, released by accidental mixing or overheating.

Industry Lesson: No Shortcuts

Ignoring incompatibility wastes money and risks lives. The Bhopal disaster in 1984 serves as a harsh reminder—water and methyl isocyanate shouldn’t meet. Leaking valves and bad communication killed thousands. Shortcuts, half-read labels, and unclear documentation repeat these patterns on smaller scales every day.

How to Prevent the Worst

Knowledge and attention stand between order and disaster. Every chemical comes with a safety data sheet, making hazards and incompatibilities clear for anyone who bothers to look and understand. Safety signs and locked storage likely ring familiar, but more often, accidents slip through when knowledge gaps exist or complacency sets in. Companies often keep incompatible materials apart through color-coded shelving or dedicated cabinets with labels easy to read at a glance.

Monitoring temperature also matters. Many chemicals break down in the heat, giving off flammable or toxic gases. Peracetic acid, for example, can explode under the wrong storage or when mixed with reducers (like many metal salts). Even stable powders can turn dangerous if moisture or friction triggers a breakdown.

Taking Accountability Seriously

Real safety comes from a culture that values hands-on awareness. I’ve watched seasoned technicians pause to check both label and lot number before opening a container—not walking through the steps half-awake. In one case, I witnessed a junior staffer catch a mismatch after cross-checking an unfamiliar drum’s barcode with the SDS. These moments prevent small mistakes from growing big teeth.

Regulatory rules exist for a reason, and routine audits back them up. Even then, the strongest tool remains a questions-are-welcome environment, where a new hire can pause work to clarify whether two bottles should share a shelf. In complex environments, experienced workers often keep detailed notebooks of near-misses and share lessons during shift changes, building a living record of what works and what could fail.

Building a Smarter Chemistry Culture

Incompatibility won’t disappear, but smart practices, speaking up, and reading the details shift the odds in our favor. The stakes go beyond spilled liquids or ruined batches; the health and safety of everyone nearby depend on it. Combining common sense with clear, up-to-date information turns a risky workplace into a safer one. Those who spend the time to look for incompatibilities and think about decomposition pathways earn more than compliance—they earn the trust of their coworkers and community.