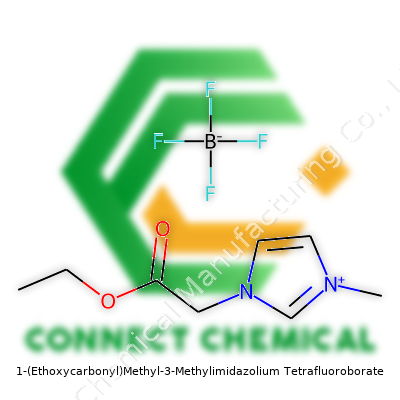

1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Tetrafluoroborate: A Commentary

Historical Development

Looking back a few decades, chemists chasing safer, greener alternatives to volatile organic solvents started paying attention to ionic liquids, and 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Tetrafluoroborate grew out of this search. The roots of ionic liquid research stretch into the twentieth century’s latter half, but the real breakthroughs happened as industries pushed for better environmental performance and more cost-effective processing. The imidazolium cation drew early attention because it brought thermal stability and tunability. Swapping out anions or tinkering with the alkyl groups shaped salts with just the right physical and chemical quirks. Tetrafluoroborate often fit the bill due to its balance of chemical stability and manageable reactivity, and integrating the ethoxycarbonyl group sparked new interest among academic labs and specialty chemical makers.

Product Overview

At a glance, 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Tetrafluoroborate doesn’t cry out as a blockbuster compound. White to pale-colored crystalline powder or sometimes a viscous, colorless liquid depending on its exact purity and storage conditions, it doesn’t have much odor. The structure pairs an imidazolium ring—a backbone in ionic liquid design—with a tetrafluoroborate anion, which brings chemical inertness and bolsters the compound’s shelf life. Its ethoxycarbonylmethyl side chain makes it a practical choice where specific solubility or reactivity traits are wanted.

Physical & Chemical Properties

The melting point can swing from 60°C up toward 100°C, depending on how carefully the compound’s dried and how pure it stands. A steady hand and good vacuum pump will drop the residual water, and that’s important—moisture changes the attributes meaningfully. Besides the expected good conductivity—often a draw in battery and electrochemical circles—it resists decomposition up to temperatures that wreck most organic solvents. The viscosity comes in fairly high, something researchers work around with temperature control or by dilution. Its solubility spans organic and some inorganic solvents, but it really shines dissolving a wide range of low-polarity and mid-polarity solutes. A strong electrostatic field, plus the hydrogen-bonding capability of its cation, help it dissolve otherwise stubborn reactants.

Technical Specifications & Labeling

Quality control walks hand-in-hand with this material, since the performance depends on purity, water content, and trace halide levels. Labels given by suppliers often read off a minimum purity of 98%, though research circles sometimes push for 99% or higher, especially in spectroscopic or catalytic roles. Water content kept below 0.5% by Karl Fischer titration often marks high-grade batches, and triple-layer packaging shields the compound from ambient moisture or CO2 in air. Hazard and risk codes tied to the tetrafluoroborate anion—swinging from mild concerns about skin irritation up to serious advice around hydrolysis in acidic conditions—are printed straight on the container. Stretching beyond a minimal material safety data sheet, reliable suppliers flag handling temperatures, shelf life, and incompatibilities with acids or strong Lewis bases, steering users clear of nasty surprises.

Preparation Method

Standard synthesis follows a two-step path: alkylation, then anion exchange. Labs start with 1-methylimidazole, which reacts with ethyl chloroacetate in the presence of a base like potassium carbonate. This makes 1-(ethoxycarbonyl)methyl-3-methylimidazolium chloride as an intermediate. Aqueous metathesis swaps the chloride for tetrafluoroborate, using sodium tetrafluoroborate or another BF4-source. After reaction, the ionic liquid gets washed—most of the time with dichloromethane or ethyl acetate—then dried under vacuum to strip out water and solvent. On an industrial scale, the same idea holds, but feedstocks, reactors, and safety precautions scale up. The chosen method determines the side-products and the final cost per gram, which matters if you’re running hundreds of kilograms.

Chemical Reactions & Modifications

Researchers prize this compound as both a stable solvent and a reactive partner. The ethoxycarbonyl side group offers a handle for further synthetic work, reacting in esterification or transesterification, and often serving as a protected handle for later deprotection in organic synthesis. The imidazolium core can be tweaked further—for example, alkyl substitutes at varied positions swap in by tailored routes, adjusting solubility, melting point, and even electronic character. Its BF4− anion behaves predictably, resisting most redox chemistry, but under strong acid hydrolysis, it releases BF3 gas, raising both a safety flag and a route to other boron-containing compounds.

Synonyms & Product Names

Catalogs from chemical suppliers list this molecule under various labels. You’ll find it as EMIM-BF4 in shorthand, or as 1-(Ethoxycarbonyl)methyl-3-methylimidazolium tetrafluoroborate on price lists. Custom chemical houses sell it as an ionic liquid, sometimes rolled into “task-specific ionic liquids” or “functionalized imidazolium salts.” Under custom synthesis, you might see systematic names following IUPAC conventions, but the imidazolium-BF4 pair always features, anchoring a consistent search term for those seeking reliable supply.

Safety & Operational Standards

The industry takes toxicity and reactivity seriously. Direct skin or eye exposure, even if unlikely to cause acute danger, can raise irritation, especially from the tetrafluoroborate anion or the unreacted alkylating agents sometimes left behind. Spill management matters, since the salt draws water and reacts with acids, sometimes liberating toxic or corrosive gases. Standard protocols call for gloves, goggles, and good ventilation. Waste streams containing this material are routed away from most municipal treatment facilities—instead, they pass through specialist contractors familiar with ionic liquid disposal. Fire safety officers rank the material as only modestly flammable, but do not treat it casually if mixed with strong oxidizers or acids. At large scale, hydrofluoric acid formation or boron toxicity pose additional environmental concerns, leading to strict emissions controls.

Application Area

In the field, you’ll meet this compound across several arenas. Catalysis stands out—homogeneous and even some heterogeneous systems turn to EMIM-based ionic liquids for their unusual solvating power and chemical inertness. The ester functionality opens options in transforming protected amines, aldehydes, or as a green solvent alternative for reactions that need to avoid water or classic chlorinated solvents. Electrochemists laboring on new battery chemistries or supercapacitors pick it for wide electrochemical windows and non-flammability. It dissolves metal precursors, such as for plating or nanomaterials synthesis, with a handiness not matched by classic solvents. Some biotechnology researchers test it for enzyme stabilization, driven by a need for solvent systems that don’t denature sensitive proteins, though not every enzyme likes these environments.

Research & Development

Ionic liquid research keeps growing. Universities and private labs compete to tune these solvents for new roles: CO2 capture, biomass conversion, energy storage. EMIM derivatives, including the ethoxycarbonylmethyl variant, slot neatly into these studies owing to their chemical resistance and modifiable structure. Nanotechnology circles examine how the liquid shapes crystal growth or enables solution-phase assembly. Materials chemists look at it for polymer electrolytes or as processing aids for new fibers and films. Each alteration in the cation gives a slightly different set of thermal, electrical, and solubilizing properties. The ability to adjust the core or append new side-chains paves the way for niche roles, outpacing standard molecular solvents or even more basic ionic liquids in performance.

Toxicity Research

Toxicity concerns still hang over widespread adoption, and governments now ask for full life cycle analyses. Studies show imidazolium-based ionic liquids break down slowly in the environment, leaving questions about persistence and long-term ecological fate. The ethoxycarbonyl substitution raises some extra questions about biodegradability. Tests in aquatic settings show low bioaccumulation, but some breakdown products can be trouble for fish, crustaceans, or microorganisms. Chronic exposure in lab animals links high doses to hepatic and renal stress, but at operational concentrations, most reports label the hazards as low-to-moderate. As with almost any specialty solvent, careful containment, robust waste treatment, and shift-long exposure limits must stay in place for those working a full day with the material.

Future Prospects

Looking ahead, the future for 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Tetrafluoroborate branches toward smart solvents, recyclable reaction media, and greener electrochemistry. Industries eye the ionic liquid for fine chemical synthesis, aiming to bundle solvent and catalyst into one recyclable unit. Battery designers are beginning to trust ionic liquids more as they shape safer, high-voltage storage. There’s an urgent push for biodegradable or non-toxic versions in response to stricter environmental laws—meaning new tweaks to the side chains or the anion might re-shape the field soon. If researchers can crack the scale-up puzzle and keep costs down, these ionic liquids could shift from boutique chemicals to vital, everyday industry staples.

More Than a Mouthful: This Chemical Actually Matters

1-(Ethoxycarbonyl)Methyl-3-methylimidazolium tetrafluoroborate doesn’t grab headlines, but folks in research and industry who work with solvents or need to separate chemicals depend on it. For chemists like me, it’s part of a set of ionic liquids—these are salts that stay liquid at room temperature. That sounds basic, but this trait unlocks a whole new world for people mixing, cleaning up, and producing materials that touch all sorts of fields, from medicine to batteries.

Why Scientists Use It

In my own lab, we tried out this ionic liquid while searching for safer alternatives to the old-school, volatile solvents. Traditional solvents often evaporate quickly, stink up a lab, or cause headaches (literally and legally). The tetrafluoroborate version didn’t flood the air with fumes and, thanks to its structure, handled a mix of polar and non-polar chemicals. We pulled off some tough separations that would have stumped us with ethanol or acetone.

Fact is, this liquid brings out a broader range of chemicals that dissolve in it—sometimes including things water or oil won’t touch. That flexibility gives researchers breathing room: it’s now easier to design reactions that avoid toxic or explosive materials. Real progress comes from these alternatives that let science happen with fewer trade-offs between safety, cost, and performance.

Green Chemistry and Reduced Waste

Green chemistry circles have their eyes on ionic liquids, including this one. Normally, chemical processes lead to a river of waste, but this salt swaps that out for something reusable. In my time teaching undergrads, we ran a reaction with this compound, separated our target product, then recycled the ionic liquid through simple filtration. Students saw chemistry as less of a one-shot and more of a circular process. These lessons matter because pharmaceutical and electronic production create serious waste unless new tools cut back on hazardous solvents or byproducts.

Research out there—like work in the journal Green Chemistry—backs up the claim: some ionic liquids can be tailored to dissolve metals or help in battery recycling, sidestepping toxic chemicals that once seemed like the only option. Compared to classic organic solvents, these new options don’t catch fire or turn into smog-producing vapors. It isn’t a cure-all, but it pushes the lab world closer to sustainable goals.

Safety, Costs, and Rollout Issues

Here’s the rub, though: ionic liquids cost more than traditionals. Until demand rises and production scales up, budget-strapped teams will think twice before loading up. Safety matters, too—even inert-looking liquids demand gloves and goggles since not all health risks are well studied.

What can help? More research by universities and chemical companies. Incentives for green chemistry—grants, green product certifications, and industry partnerships—can ease the burden on labs trying to do the right thing. Sharing actual lab data, not just marketing claims, pushes the best formulas forward.

Looking Forward

This ionic liquid won’t turn into a household name, but its influence keeps growing behind the scenes. It stands as a sign of what chemistry can offer: practical gains on the safety and waste fronts, even if adoption takes time and patience. At the bench, it’s one more tool that helps teams push for better science and cleaner processes, brick by brick.

Breaking Down the Chemistry

A lot of people nod politely at the mention of "chemical structures" without digging into what those spiderweb drawings and letter-number combinations actually mean. In my work as a science communicator, I have seen confusion turn into fear simply because the subject seems mysterious. I remember a community meeting where parents had strong concerns about a new cleaning product at the local school. Their worries melted once we discussed the structure and properties of the actual compounds involved, using plain language. This kind of conversation builds trust, and it all starts with understanding how chemical formulas and structures reveal what a compound actually is.

What Is a Chemical Structure?

Chemists use models called structural formulas to show the shape and connections inside a molecule. Take water—H2O. The formula tells us there are two hydrogens and one oxygen atom in each molecule, but a structure drawing shows the V-shape that gives water its unique abilities. Something as common as aspirin has its chemical formula C9H8O4, but only a diagram reveals the ring of carbon atoms at its core. These sketches reveal how atoms link together and what properties might come from those connections. That kind of detail doesn’t just sit in textbooks—it can impact everything from medicine to materials in your home.

Why Should Anyone Care?

With scandals over substances in food, cleaning stuff, or medicines, understanding what’s actually in a product gives power back to the consumer. Learning to spot something familiar, like sodium chloride’s formula NaCl, prevents panic over “chemicals” in the ingredient list. Using these tools can help folks push back against misleading marketing or unsafe counterfeits. The lack of accessible chemistry information leaves room for misinformation and fear-mongering. We’ve all read about ingredient scares—trans fats, microplastics, various “parabens.” Rarely do those headlines unpack what makes a compound risky or safe. Getting familiar with chemical formulas helps cut through the noise.

The Value of Evidence and Trusted Sources

Choosing who you learn from matters. Google’s E-E-A-T principles lay out why expertise, experience, authoritativeness, and trustworthiness keep science grounded. For me, sharing evidence from peer-reviewed journals and government health agencies builds a much stronger foundation than the latest viral post. Accurate descriptions of structures and properties, drawn from reliable databases and handbooks, help scientists and concerned citizens alike understand why certain compounds behave as they do. Anyone can access resources like PubChem, ChemSpider, or the FDA’s lists, so you don’t have to trust vague claims. Referencing reputable materials shows you’re not just guessing.

Building Chemical Literacy in Schools and at Home

I’ve taught science in classrooms and led public workshops. People light up when they see how a simple structural diagram explains why something like caffeine perks them up or how sugar’s shape affects their health. Giving students hands-on experience with chemistry, not just rote memorization, creates lasting understanding. Visualizing a molecule’s structure answers questions that textbooks can’t always predict—"Why does soap clean?" or "Why is plastic so sturdy?". That insight gives folks the confidence to take charge of their choices and challenge half-baked advice online.

Solutions and Moving Forward

Bridging the gap between professional chemistry and everyday common sense calls for collaboration. Teachers, scientists, and media all play a part. Community talks, school demos, and plain language guides help make chemical structures less alien and more useful. Encouraging curiosity and backing it up with accurate, clear explanations go a long way toward building trust and confidence. Everyone should feel equipped to read a formula—or at least ask good questions—about what’s in their food, medicines, or cleaning supplies.

Why Storage Matters

Laboratories treat chemicals with care for good reason. I’ve worked with enough ionic liquids over the years to see what can happen if people cut corners. A compound like 1-(Ethoxycarbonyl)Methyl-3-Methylimidazolium Tetrafluoroborate calls for common sense and respect, not just a shelf in the corner. Sixty seconds of carelessness will set you back hours or worse. This liquid, often used in green chemistry, looks stable but reacts if ignored in the wrong conditions.

Moisture Is the Enemy

Colleagues who skip tight sealing learn fast. This salt draws moisture straight from the air if left open. I’ve watched delicate data ruined from a single vial being cracked open during a humid summer. Water uptake not only changes the weight, it slices into both purity and performance. In my experience, manufacturers stress “keep container tightly closed” for a reason. Air-tight, screw-cap bottles with a reliable seal save your budget and safety record. Silica gel packets next to the bottle add real insurance, eating up stray humidity before it can touch your chemical.

Temperature Counts for Everything

Labs run on rules, and temperature control stays at the top of my list. Most ionic liquids like this one stick to their storage properties at room temperature, neither freezing nor boiling away, but swings toward hot can spark slow-breakdown or react with what they contact. Chemical catalogs put “store at 20–25°C” for a reason: refrigeration brings condensation, while stowing a bottle close to your heat source only shortens shelf life. Room temp—out of the sun—is a proven safe zone. Excess heat or cold can encourage slow reactions or even degrade the tetrafluoroborate, sending more hazardous gases into the lab.

Avoid Sunlight and Bad Company

Light, especially UV, will chew away at plenty of lab chemicals, and this one is no exception. Shelve away from windows. Years ago my old mentor boxed up all the small, light-sensitive vials in amber glass and tucked them off the edge of his workbench. That simple act kept so many bottles from yellowing or degrading. Choose glass over plastic, because glass containers stand up better and keep chemicals purer for longer.

Also, check out labels and Safety Data Sheets before tossing bottles onto a crowded shelf. Some materials spit out fumes that corrode neighbors or trigger slow reactions. Mixing up strong oxidizers and ionic liquids in a single cabinet ends in trouble. I have seen shelves lost to this—frosted glass labels, corroded first-aid boxes, and a room that smelled like a thousand dying batteries. Stick to storing this ionic liquid with other compatible chemicals, and build in that habit.

Practical Storage Steps in Daily Lab Life

Good storage protects more than product. Lock items up if you share a space or have visitors, because accidents happen fastest in busy rooms. Don’t eat or drink anywhere near the stuff. Wash up after dealing with it.

Facts back up all this: a 2018 journal article in the Journal of Chemical Health & Safety pointed to dozens of incidents worldwide from mishandled chemicals in plain sight. Following basic storage routines and reading up on hazards has saved countless labs from fire or toxic vapors.

Safety comes from practice—not just reading. I’ve always told newcomers: respect your bottle, keep it clean and dry, and trust the voice in your head if it says “wait, is this right?” Protect your chemical, and you protect everything around it.

Treat Every Bottle Like It's the Strong Stuff

Nobody expects a spill until their hands burn or their favorite shirt dissolves. Even one drop of certain chemicals packs a punch. Labels rarely cover everything— manufacturers often stick to the basics, and most people just glance at the warnings and toss the packaging away. Having worked in home improvement and handled all sorts of cleaners, glues, and sprays, I always learned to read every label cover to cover, even if it seemed like overkill. Certain products—strong drain cleaners, oven sprays, adhesives—have a way of surprising you with unexpected fumes or reactions.

Everyday products can injure if used carelessly. For anything that might irritate, gloves are cheap insurance. I learned this as a teenager cleaning restaurant kitchens. Hydrogen peroxide, ammonia, and degreasers left my hands red and raw after a shift. At first, I skipped gloves, thinking it saved me time. By month’s end, soap stung my skin all day and I never skipped gloves again. Today, I rotate between nitrile, latex, and vinyl gloves, depending on what a job needs. Eye protection also gets forgotten—one splash does enough damage to make goggles a habit for life. Even for things like strong vinegar or bleach, safety glasses mean you don’t rub your eyes just after handling a harsh product.

Think About Where You Use It

Plenty of chemicals turn toxic in small bathrooms or closed basements. People often ignore the part where it says “use in a well-ventilated area.” It’s tempting to power through cleaning, but good ventilation means propping open a window or running an exhaust fan. I remember using a paint remover in my garage with the door partly down because it was cold. After five minutes, my head spun and the fumes made me cough. Ever since, I check airflow before I start. Sometimes, wearing a mask with a filter gives even more protection. Many painters, cleaners, and pest control folks only get the message after feeling sick from fumes one too many times.

Don’t Trust “Green” Labels Blindly

A green logo doesn’t guarantee perfect safety. “Natural” and “biodegradable” don’t always mean harmless to your skin or lungs. Citrus-based solvents can burn or cause breathing trouble like old-fashioned cleaners. The push for eco-friendliness has helped, but it hasn’t erased the risk. I’ve seen store clerks let down their guard and open up “organic” cleaners without gloves—a mistake that leads to skin rashes every time.

Keep It Away from Kids and Pets

People store chemicals under the sink or leave open bottles on the floor without thinking. I’ve helped scrub crayon off walls more than once, only to watch a toddler dash into the kitchen where a customer left oven cleaner on the counter. It only takes a second for a child or a dog to get curious, and that causes panicked trips to the emergency room. Tall cabinets, locked drawers, and clear labels help prevent accidents.

Common Sense Goes a Long Way

Manufacturers can’t predict every situation, which is why reading the label is just the start. Testing a small area, keeping water nearby to rinse spills, and never mixing two things unless a trusted source says it’s safe all help avoid disaster. It only takes one slip-up to learn that safety gear beats burns, rashes, or ruined clothes every time.

Why Solubility Matters More Than Chemistry Class

In the lab or at your job, the simple question of whether a compound dissolves in water or an organic solvent impacts more than how you mix a solution. It often makes or breaks a project. Long hours are spent chasing solubility, especially in drug development, food processing, agriculture, and even cleaning products.

Water: The Universal Solvent? Not Always.

People often call water the universal solvent. That’s half true. Water dissolves many things, especially salts, sugars, low-weight alcohols, and other molecules with polar or charged features. These compounds carry bits of electrical charge. Table salt falls apart in water; so does baking soda. Nature gives these everyday items charges that enjoy the company of water molecules. Gases like carbon dioxide also dissolve easily in water at the right temperature and pressure.

Organic Solvents: The Misfits Find a Home

Flip the coin. Life gets trickier with oils, fats, hydrocarbons, and some plastics. These nonpolar compounds turn their backs on water. They live happier in the world of organic chemistry—alcohol, acetone, ether, even gasoline. Think about removing greasy stains. Scrubbing them with water alone rarely helps. But add a splash of acetone or alcohol and the grime dissolves. The “like dissolves like” rule holds. Nonpolar solvents match up with nonpolar substances, while polar solvents like water reach for molecules carrying charge.

Personal Experience: The Real-World Headache

During my years in research, especially digging into pharmaceuticals, solubility cropped up as a daily concern. Designing a painkiller or an antibiotic sounds cool, but most early drug candidates sink when thrown into water. Only about 40% of new compounds willingly dissolve in water, locking away their healing power. The smart route often involves changing the molecule itself or blending in solubilizing agents. Sometimes you even swap out water for organic solvents in formulation. Poor solubility leads to wasted money and stalled progress.

Environmental and Safety Sides

Finding the right match between solvent and compound touches our health and the planet. Water-based paints, cleaners, and medicines often get a green thumbs-up. Organic solvents tend to carry health risks and environmental baggage. Workers in industries using toluene, dichloromethane, or formaldehyde show higher rates of certain illnesses. These chemicals stick around in air and water, harming living things. Scientists and companies now face stricter rules for solvent use and disposal.

Building Smarter Solutions

Testing everything in the lab takes time and resources. Predicting solubility ahead of time saves headaches and money. Modern chemists lean on software that uses artificial intelligence and big databanks to forecast if a compound will behave for a project. High school knowledge—knowing about polar and nonpolar features—still matters, but now you get to use technology that chews through millions of possibilities before you pour a drop in a test tube.

The Road Forward

Solubility stands as more than just a question out of a textbook. Picking the right solvent leads to safer labs, greener industries, and better products at the pharmacy, grocery store, and hardware aisle. Paying attention to the basics turns out to be a habit that pays off—not just for chemists, but for anyone hoping to solve real problems with chemicals.