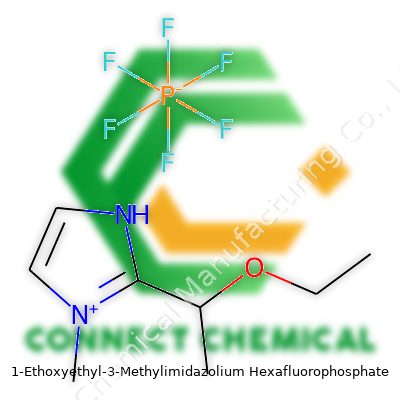

1-Ethoxyethyl-3-Methylimidazolium Hexafluorophosphate: An In-Depth Look

Historical Development

Chemists looking for safer, less volatile alternatives to old-school solvents turned their attention to ionic liquids in the late twentieth century. Laboratories worldwide started seeing 1-ethoxyethyl-3-methylimidazolium hexafluorophosphate around the early 2000s, mostly after researchers realized that imidazolium salts mixed with different anions could unlock unique solvent properties. The movement away from traditional, toxic, and flammable organic solvents didn’t happen overnight. Trial and error, new synthesis strategies, and a push from green chemistry advocates drove attention to these ionic liquids. Researchers and industries searching for less hazardous chemicals and better selectivity in reactions found a place for this compound, and it kept evolving from a bench-top curiosity into a staple for custom chemical environments.

Product Overview

People who work with 1-ethoxyethyl-3-methylimidazolium hexafluorophosphate know they’re handling a specialized ionic liquid distinguished by an imidazolium backbone and a hexafluorophosphate counterion. Its liquid state under ambient conditions brings a flexibility that traditional molecular solvents just don’t offer. This ionic liquid is used in laboratories and pilot plants, with product containers often labeled for research or specialized synthetic work in mind. Its purity and performance standards meet the scrutiny demanded by chemists, especially where trace contaminants sabotage delicate catalysis or separations.

Physical & Chemical Properties

On a practical level, this compound exists as a colorless to lightly yellow, viscous liquid. It doesn’t evaporate easily, thanks to basically nonexistent vapor pressure under normal temperatures. Odor barely registers, so there’s no sharp warning you get with many solvents. Its thermal stability stretches higher than basic organic solvents; direct heating still needs careful monitoring to avoid decomposition into hazardous fragments. Solubility skews toward polar organic compounds, and its miscibility with water varies depending on the ionic liquid’s fine structure, but most formulations show moderate hydrophilicity. Electrochemical windows surpass those of water or common solvents, unlocking a playing field for applied electrochemistry.

Technical Specifications & Labeling

Industry suppliers focus on clear batch information and safety data. Labels outline the molecular formula, C9H17F6N2O2P, with CAS registration and purity by weight. Material safety data sheets lists handling protocols and shelf life. Density, viscosity, and melting point stand prominent on technical documents, since engineers need to know flow and pump rates in real-world processes. Packaging sways between glass and high-grade plastics, since metal ions can cause unwanted reactivity. Customers in research and small-scale manufacturing know to look for warnings about moisture content; exposure to air increases risk of hydrolysis, especially in humid settings.

Preparation Methods

The synthesis process starts with an N-alkylation reaction on methylimidazole. 1-bromoethoxyethane often functions as the alkylating agent, reacting to form 1-ethoxyethyl-3-methylimidazolium bromide. This salt then gets exchanged with potassium hexafluorophosphate in an appropriate polar solvent, shaking out the final product. Removal of water and careful washing are crucial, since residual bromide or unreacted hexafluorophosphate ruin downstream reactions. Filtration and vacuum drying round off the process, giving chemists a high-purity ionic liquid fit for demanding work. Controlling moisture levels at every stage proves important, not just for purity, but for safety.

Chemical Reactions & Modifications

Electrochemical applications benefit from this ionic liquid’s wide voltage window and inertness under mild reducing or oxidizing conditions. Chemists sometimes tailor the imidazolium backbone by adjusting alkyl or alkoxy substituents, tuning solubility or viscosity without sacrificing core stability. In some cases, swapping the PF6 anion for something like bis(trifluoromethanesulfonyl)imide, changes conductivity or compatibility with certain metals. Crossover into organometallic chemistry comes from the ability to dissolve both organic and inorganic substrates, while still maintaining a degree of non-coordination with reactive centers, a boon for sensitive catalysts and reaction intermediates.

Synonyms & Product Names

Depending on the catalog or region, you might see this compound sold under names like 1-(1-ethoxyethyl)-3-methylimidazolium hexafluorophosphate, EOE-MIM PF6, or EMI(EtOEt) PF6. Each label aims for clarity in the alkyl chain on the imidazolium ring and the PF6 anion. Mislabeling doesn't just risk confusion at the bench, it could also violate shipping and compliance rules, so professional suppliers take this seriously. From personal experience, I’ve found cross-checking product names with structural diagrams saves a lot of headaches for both procurement and safety teams.

Safety & Operational Standards

Working with this chemical, I’ve always prioritized gloves, goggles, and fume hoods. Hexafluorophosphate salts can form aggressive byproducts when hydrolyzed; hydrofluoric acid being both a health and environmental hazard. Transport and storage in airtight containers away from acids and open flame keeps things routine. Many research environments rely on regular training and labeling audits. Waste disposal includes neutralization and treatment as halogenated material; regulatory standards stick close to hazardous waste protocols laid out for fluorinated chemicals. Spills can’t be handled with simple paper towels—teams need protocols for fluoride management and environmental capture, especially when scaling up production or use.

Application Area

Over the last decade, I’ve seen this ionic liquid pop up across a surprising spread of applications. Electrochemistry labs have gotten mileage from its stability, using it in supercapacitor electrolytes and custom lithium battery formulations. Separation science makes good use of its solvent properties for extractive distillation, where water content, non-volatility, and chemical resistance beat traditional mixtures. Some catalysis research relies on its controlled environment for C–C coupling, hydrogenation, and other sensitive reactions. Organic synthesis, chromatography, and even pharmaceutical extraction have all seen successful case studies. Compared to traditional solvents, users can fine-tune everything from viscosity to selectivity by mixing in small amounts or swapping out alkyl groups on the imidazolium core.

Research & Development

Academic and industrial labs chase improvements with every new batch. Pursuing greener manufacturing, teams aim to recycle or even biodegrade spent ionic liquids. Ongoing research into replacing toxic anions (like PF6) with less hazardous ones isn’t just regulatory red tape; safer ions mean those who make and use these chemicals face fewer health risks. I’ve worked with teams trying to reduce moisture pickup, engineering more stable and less hygroscopic batches. Data-driven modeling looking at solubility, thermal performance, and viscosity offers a route to smarter design of not just this liquid, but whole classes of next-generation solvents.

Toxicity Research

Long-term impacts matter. Hexafluorophosphate anions and imidazolium cations both have a history of toxicity concerns—especially for aquatic life. Incineration or improper disposal could generate toxic fluorine-containing gases, so processes center around containment and controlled breakdown. I’ve read case studies tracking enzyme inhibition and cell damage at low parts-per-million exposure, underscoring the need for both acute and chronic toxicity screens. In-house practice always includes personal protective equipment alongside regular training about chemical hygiene and event escalation paths for exposure or spills. Regulators push for full toxicology reports, going well past simple LD50 measures.

Future Prospects

Looking ahead, I expect user demand will drive manufacturers to develop ionic liquids with better biocompatibility and environmental safety. The push for sustainable chemistry doesn’t stop at cradle-to-gate; full life cycle analysis shapes which products become tomorrow’s standards. Applications in energy storage, precision separations, and even medical diagnostics will shape a market that increasingly demands safety and low environmental footprint. For manufacturers, meeting rising regulatory expectations and delivering clear documentation about toxicity and recyclability will likely separate successful players from those stuck with yesterday’s hazardous formulas. In these evolving circumstances, the ability of 1-ethoxyethyl-3-methylimidazolium hexafluorophosphate to adapt—through clever chemistry and responsible handling—promises to keep it in the mix, so long as innovation keeps pace with both market needs and ethical obligations.

A Look into Everyday Chemistry

Most people don't stop to wonder about the chemicals behind the scenes in today’s industries. Yet, in labs and factories, compounds like 1-Ethoxyethyl-3-Methylimidazolium Hexafluorophosphate play a vital role. Across fields as different as pharmaceuticals, batteries, and green chemistry, this ionic liquid has become more than just a mouthful of syllables. Its unique combination of properties shapes how modern chemistry tackles challenges.

Shaping How We Synthesize Medicines

Pharmaceutical manufacturing has become intensely focused on efficiency and sustainability. Old-school organic solvents can create enormous waste, pollute waterways, and require costly cleanup. Ionic liquids offer a way out, and this specific compound stands out for its stability and its power as a solvent. In my experience researching drug synthesis, using solvents that don’t evaporate easily helps keep sensitive reactions running smoothly. This means chemists can pull off reactions that would normally fizzle out under normal conditions, or that would gum up with byproducts. The result? Faster development of new treatments. That impacts how quickly new drugs can move from the lab to the pharmacy shelf, especially when time matters most.

Greener Chemistry: Cutting Down on Waste

Every year, chemical plants pump out mountains of waste. I remember touring a facility plagued by noxious solvent fumes. It was clear that new solutions needed to be safer for workers and less damaging to the air. Ionic liquids like this one have almost zero vapor pressure, slashing the risk of harmful vapors spreading. They also don’t ignite like some volatile organic solvents. This improves worksite safety and helps companies stick to tighter environmental rules. It’s becoming more common for major chemical companies to swap out old solvents for this kind of alternative, reducing risk not just for workers but for communities around manufacturing sites.

Energy Storage and Battery Research

Modern electronics—from phones to electric cars—depend on better batteries, and the race to pack more energy into smaller, safer cells is heating up. Electrolytes matter. The unique ionic conductivity of this particular compound means it can keep lithium ions moving smoothly inside batteries, even when pushed to extremes. Standard electrolytes in lithium-ion batteries can degrade or catch fire, which has led to a string of product recalls and safety concerns over the years. By swapping in a stable ionic liquid, researchers can squeeze more energy out of a battery and run it at higher or lower temperatures. That keeps devices running longer and safer. From my time working on battery failure analysis, I can say that safe chemistry in a battery makes all the difference in the real world.

Moving Forward: What Could Be Better?

One drawback with ionic liquids sits in the price and current availability. Large-scale refining and purification remain costly. There needs to be sustained investment to scale up green manufacturing of both the starting materials and the finished product. Policies that reward companies for sustainable practices could tip the balance and drive down cost. Collaborations between public research labs and private industry can also spur innovation, making safer and more efficient chemicals like this one a standard part of the chemical toolkit, not a luxury item. Clear choices backed by sound research can help industries shift toward greener, safer, and more responsible practices, all fueled by advances in chemistry.

Understanding Chemical Stability

Every chemist I’ve worked with knows you can’t cut corners on storage conditions for lab chemicals. The moment a compound loses its stability, you risk faulty results, wasted resources, and sometimes real danger. Back in grad school, my group once overlooked the light sensitivity of a photosensitive dye. After a week, we found brown sludge instead of the expected vibrant pigment. That ruined a set of experiments and drove home the lesson: you ignore stability guidelines at your own peril.

Stability refers to how well a chemical compound keeps its structure and properties over time. Water in the air, heat, light, or even a trace of metal in the bottle can set off changes no one wants. A stable compound gives you reliable reactions and makes scale-up possible. If the storage conditions slip, even a pure chemical can pick up impurities or turn into something else. Literature on chemical hazards proves that many lab accidents link back to storage errors—including mixing up labeling, or keeping something near a heat source.

Proper Storage: Giving Chemicals a Safe Home

Good storage means thinking about more than a locked cabinet. You always want to know: does this need low humidity, refrigeration, or protection from light? Materials like sodium react with water, so you keep them under oil. Some organics need fire-proof cabinets—always away from acids and oxidizers. Familiarity with these basics stems from hard-learned lessons in the lab.

Regulations make sense here. For example, OSHA and the ACS both lay out standards around flammables, corrosives, and toxic materials. These aren’t just red tape. Poor storage once led to a container leaking chloroform, which quietly formed toxic phosgene gas under regular room lights. Cases like this show strict storage saves lives.

Preventing Degradation: Practical Steps

Most compounds keep best at low temperatures. Fridges and freezers slow down breakdown reactions. For those that don’t handle moisture well—think lithium aluminum hydride—desiccators and dry boxes take top spot on the equipment list. Light-sensitive chemicals go in amber bottles, and all freshly made compounds need tight seals, so no air sneaks in.

Labeling shows its value again and again. You jot down the open date, contents, and hazard class. In shared labs, I’ve hunted through shelves crammed with mystery bottles. No one likes risking cross-contamination or not knowing what reactive leftovers might sit inside.

An overlooked point: storage tracking. Listing chemical inventory, with storage rack location and expiry date, cuts down on hazardous waste bills and keeps the whole lab safer. In my own experience, setting up clear protocols avoided expired solvents getting tossed into a standard trash bin, dodging fire code violations by a hair.

Building a Culture of Awareness

Chemical stability and storage seem basic, but they build the foundation for every safe and effective lab. Understanding what destabilizes a compound—humidity, light, temperature shifts, or reactive neighbors—lets everyone act before small mistakes snowball. Regular training, peer checks, and accessible data sheets help keep the focus sharp. My time in labs, both in school and industry, taught that prevention is more valuable than finding out what went wrong after the fact.

Looking Past the Name, What’s Inside?

1-Ethoxyethyl-3-Methylimidazolium Hexafluorophosphate sounds intimidating, and for good reason. It belongs to a family known as ionic liquids, which pop up in research labs for their unique properties. Chemists use these substances in everything from advanced batteries to organic reactions. But long names and cool uses rarely tell the whole safety story.

The Real Worries: Toxicity and Hazards

On paper, ionic liquids seem harmless compared to old-school industrial solvents. They don’t easily evaporate, so there’s less risk of breathing in dangerous fumes. But 1-Ethoxyethyl-3-methylimidazolium hexafluorophosphate is built around an imidazolium core, paired with a hexafluorophosphate anion—a mix that throws up real red flags in toxicology circles.

I've seen warnings about this type of compound because of what happens when things break down. For example, hexafluorophosphate can give off hydrogen fluoride (HF), which hits skin, mucous membranes, and even bones hard. Everyone remembers stories of industrial accidents with HF—permanent wounds, long hospital stays. Not a substance you want splashing around carelessly.

Handling the cation part of this molecule—ethyl, methyl, and imidazolium groups—has less baggage, but nobody really knows the long-term health effects. Most ionic liquids haven’t gone through exhaustive safety studies outside the lab, so what seems safe in a controlled experiment might prove otherwise if spilled or released. There’s often no escape from the fact that chemists still know more about how these liquids help reactions than about how they creep into lungs and soil.

Environmental Risks Get Too Little Attention

Stories from green chemistry conferences keep circling back to environmental persistence. These liquids resist breaking down in water or soil, sometimes ending up in wastewater if people fail to clean up all traces. Hexafluorophosphate groups can linger in the environment, building up in ways scientists don’t fully understand. I’ve chatted with folks in wastewater labs who’ve seen persistent organofluorine compounds pop up unexpectedly years after a factory stopped using them.

This brings up a problem that doesn’t go away quickly—bioaccumulation. Fish and plants can pick up toxic ions, then pass those up the food chain. Some tests show that imidazolium-based compounds affect aquatic life and soil bacteria far more than we once thought. Add to that the fact that HF byproducts never break down fast, and there’s a need for vigilance.

Pushing Lab Safety Further

In my own lab days, splash goggles and gloves always felt like overkill, until a close call with a leaky bottle reminded me why those rules matter. Ionic liquids like this one call for more than just the usual safety posters—emergency showers, proper neutralizers, and real training for anyone using them.

I’ve seen good habits pay off. Segregating waste, choosing the least hazardous alternative, and talking through every handling step beat shortcuts every time. If a spill happens, quick action with the right neutralizer on hand makes the difference between a headache and a call to emergency services. Chemical companies can't cut corners with staff education, and researchers should demand full disclosure of toxicology records before these materials leave the controlled world of the lab.

Choosing safer options whenever possible always stays top of mind. In settings where these chemicals support genuine breakthroughs, they should stay behind locked cabinet doors, never mixed with casual practices or short-sighted cost-cutting.

Why Physical Properties Matter in Daily Work

Every time I handle a new chemical, I check three main things: how it looks, how it mixes with other stuff, and what temperature turns it from a solid to a liquid. These details can point you toward smart decisions in the lab or on a job site. Over the years, skipping even one detail has led to wasted money, or worse, safety headaches.

Appearance Tells a Story

You can tell a lot just by looking. Some chemicals come as white crystalline powders, others as sticky viscous liquids, and a few as shiny flakes. Take sodium chloride: always white, granular, and familiar to anyone who’s ever salted their food. Then compare it to copper(II) sulfate, which stands out with its bright blue crystals. The look tells you about possible contamination, storage needs, and even purity. I’ve spotted off-color batches before that saved us from using spoiled material. For folks who work with pharmaceuticals or food, visual inspection can catch problems before they hit consumers.

Melting Point: More than a Number

The melting point stands as proof of a product’s identity. If your chemical’s documentation says it should melt at 128°C, and your batch turns gooey at 115°C, something’s off. In college, I learned the hard way that even small impurities can pull the melting point down and turn a crisp transition into a wide, sloppy melt. The tighter the range, the purer the product. Factories check it to verify quality every shift, and researchers use it to guess at what’s gone wrong during synthesis.

A solid melting at room temperature isn’t much use in hot climates, either; it forms puddles in the warehouse. Wax used for packaging needs a careful melting point or you end up with boxes falling apart during summer shipping.

Solubility: Deciding Where It Belongs

Ask anyone in a kitchen or a lab: if it doesn’t dissolve, it’s a pain. Water solubility decides if you mop up with water or need something stronger. Salts generally dissolve easily, so cleaning glassware after an experiment with table salt is simple. Oils refuse to mix with water, forcing chemists to swap to organic solvents. Years ago, I tried stirring sugar into cold tea and watched it sit stubbornly at the bottom—a miniature reminder that temperature dramatically changes solubility. Chemists use solvent choice to purify products, and engineers designing fire suppressants want materials that dissolve instantly for quick action.

Relevance to Real Problems

People ask why these physical properties get so much attention. I remember a factory manager whose supplier sent in something labeled “the usual plastic resin,” but poor solubility crashed the manufacturing line and ruined a week’s orders. Digging into appearance and melting point exposed the mix-up. Reliable facts about these properties guard against that kind of mess.

Pay attention—always. Don’t just trust the label. Chemicals have a way of telling you exactly what you’re dealing with, and listening to that makes the work—and everyone’s safety—a whole lot better.

Why Care About Safe Handling?

Anyone who has spent time in a chemistry lab knows the mix of curiosity and caution that comes with bottles labeled with tongue-twisting names. 1-Ethoxyethyl-3-Methylimidazolium Hexafluorophosphate falls into that category. With its blend of imidazolium ions and fluorinated phosphate, this compound pops up in research for its use in ionic liquids, catalysis, and as a solvent in challenging reactions. The things that let it do such unique chemistry—the reactive ions and persistent fluorinated groups—make it a compound you treat with respect, not just interest.

Day-to-Day Handling: Personal Gear Matters

I once worked in a lab that prided itself on speedy setups, but speed never replaced protection. Nitrile gloves, splash goggles, and a chemical-resistant lab coat became second nature. 1-Ethoxyethyl-3-Methylimidazolium Hexafluorophosphate doesn’t mix well with skin, eyes, or open air. Keep it in well-sealed containers. Transfer and weigh out enough for the day inside a fume hood. Even experienced hands make mistakes—a spill on an unprotected wrist or the wrong container left open can end a productive day with a trip to occupational health.

Storage Practices: No Room for Guesswork

This compound handles moisture like a foe, pulling in water from the air and slowly degrading. In the real world, that means glass bottles with tightly fitting lids. Store away from sunlight and sources of heat—no shelf near the hot plate or steam bath. Even a dark-corner cabinet can get too warm or humid, so silica packs or desiccators come in handy. It’s tempting to stock up for a semester’s worth of experiments, but smaller bottles make it easier to avoid accidental exposure.

The Disposal Challenge: Thinking Ahead

Too many hazards show up when cleaning up after others. Leftover 1-Ethoxyethyl-3-Methylimidazolium Hexafluorophosphate isn’t something you pour down the drain or toss in a municipal waste bin. Its hexafluorophosphate anion breaks down into persistent fluorinated residues. The EPA puts fluoride pollution high on the list of things to avoid, and improperly handled chemicals have a way of showing up in places no one expects—groundwater, local treatment facilities, backyards a few blocks from campus.

Most universities and research labs now follow strict waste protocols—red bins, chemical inventory systems, hazard labels with CAS numbers, and coordinated pickups by qualified professionals. I’ve seen labs fined or even shut down due to casual dumping of fluorinated waste. It’s just not worth the risk to health or the environment. Take notes on the exact contents, fill out the hazardous waste log, and hand containers off only to licensed handlers who know how to incinerate or neutralize the compound safely.

Better Solutions and Long-Term Thinking

It’s not unreasonable to ask—couldn’t researchers switch to something safer? For many applications, green chemistry offers safer ionic liquids or solvents. Switching takes effort and sometimes compromises results. Still, every research group should seriously weigh alternatives before sticking with hexafluorophosphate salts, especially as new regulations come out almost every year. Training newcomers never gets old either—knowledge about safe handling, storage, and waste doesn’t just trickle down. Vehement reminders and hands-on demonstrations get everyone on the same page.

Responsible labs stay organized. They post clear instructions, run inventory audits, and empower everyone to speak up about concerns or accidents. I’ve seen the difference this makes: less confusion, fewer accidents, and a legacy of safety that carries forward year after year. Investing a little more time up front—safer storage, thorough cleanup, careful disposal—always pays off in the end.