1-Ethoxyethyl-3-Methylimidazolium Tetrafluoroborate: A Close Look at an Evolving Chemical Player

Historical Development

The road leading up to the synthesis of 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate weaves through advances in the world of ionic liquids. Interest in imidazolium salts picked up pace around the late 1980s, when researchers started looking for alternatives to volatile organic solvents. The first observations on their stability, non-flammability, and tunable properties came out of labs trying to push boundaries in green chemistry. Over the past two decades, this particular compound has gathered respect for offering a clever mix of organic and inorganic qualities, setting it apart from many older solvent systems. Through years of incremental innovation, different substituents like the ethoxyethyl group found their way onto the imidazolium ring, fine-tuning their solubility, polarity, and interaction profiles. Today, this compound stands as a product of persistent research, learning from both the successes and mistakes of earlier ionic liquid designs.

Product Overview

1-Ethoxyethyl-3-methylimidazolium tetrafluoroborate is a colorless or slightly yellowish liquid with a structure built around an imidazole core, carrying an ethoxyethyl group and a methyl group, partnered with the tetrafluoroborate anion. The molecular arrangement allows for high thermal stability, decent ionic conductivity, and a sweet spot between hydrophobic and hydrophilic behavior. This is no simple solvent – its ionic nature pulls it toward applications where classic organic molecules stumble, such as clean energy, advanced separation processes, and catalysis. Shelf life, ease of handling, and chemical robustness mark it as a favorite in many research labs.

Physical & Chemical Properties

In my hands, this ionic liquid reveals some of its quirks right away. Its boiling point stretches far beyond what's typical for organic solvents, and water solubility ranges from fair to good, depending on the exact conditions and counter-ions. Density usually floats near 1.2 g/cm³ at room temperature. It flows smoothly, but with a viscosity notably higher than plain water or ethanol. The compound remains stable across a generous temperature span, rarely decomposing under 250°C, which opens up process windows not easily reached by most solvents. The ionic character flips the usual rules: polarity stays high, but volatility stays at bay, which matters hugely in limiting environmental release and controlling workplace exposure.

Technical Specifications & Labeling

Official labels require information not just about purity, but also trace water content and halide contamination. Typical lots sold for laboratory research often claim over 98% purity, with specifications noting moisture levels under 0.5%. A Material Safety Data Sheet spells out the main hazards, emphasizing the need for nitrile gloves, goggles, and well-ventilated storage. Bottles tend to arrive tightly sealed and stored away from light, acids, and open flames. Country regulations demand GHS-compliant pictograms for toxicity and environmental risk. Each container carries the chemical’s IUPAC name, synonyms, batch number, gross and net weights, and the producer’s contact information.

Preparation Method

Ionic liquids take patience to make, especially ones with tailored alkyl and ether groups. Synthesis often kicks off by alkylating 1-methylimidazole with 1-ethoxyethyl chloride or bromide under controlled conditions, using a polar aprotic solvent to stick the fragile ether group onto the imidazole ring. The next step swaps the halide anion for tetrafluoroborate through a metathesis reaction, commonly using sodium tetrafluoroborate in aqueous solution. Careful extraction and drying – often in a vacuum oven over phosphorus pentoxide – helps drive down moisture and remove leftover salts or unreacted starting materials. Each stage faces its own headaches, like dealkylation or byproduct formation, so success depends on timing, stoichiometry, and a keen eye for detail.

Chemical Reactions & Modifications

This imidazolium salt doesn’t just sit in a flask; its structure lets it participate in a variety of chemical reactions. It supports nucleophilic substitution, ether cleavage, and serves as a phase-transfer agent, shuttling ions or molecules that otherwise won’t play together. Chemical modifications usually target either the side chains or the anion, which can be swapped for other non-coordinating or functional counter-ions to suit specific catalytic systems. In transition-metal catalysis, it often acts as a co-solvent, stabilizing reactive intermediates while reducing side-product formation. Derivatives built on similar skeletons fill shelves in electrochemistry, separation science, and as designer solvents in pharmaceutical synthesis.

Synonyms & Product Names

You run across a handful of names for this compound, reflecting different supplier lines and naming conventions. Its systematic name reads as 1-(1-ethoxyethyl)-3-methylimidazolium tetrafluoroborate. Some catalogs shorten that to [EeMIM][BF4], EeMIM-BF4, or just Ethoxyethyl-methylimidazolium tetrafluoroborate. Each label points back to the same molecular structure, though trade names or proprietary blends sometimes sneak in extra stabilizers or claim higher purity grades.

Safety & Operational Standards

Practical experience teaches caution with any ionic liquid, even those considered “green.” 1-Ethoxyethyl-3-methylimidazolium tetrafluoroborate poses low flammability compared to hydrocarbons, but the tetrafluoroborate anion brings its own risks, such as hydrolysis to hydrogen fluoride under acidic or humid conditions. Most organizations working with it require chemical fume hoods, skin protection, regular air monitoring, and spill kits rated for inorganic acids. Disposal streams go through regulated chemical waste protocols; pouring them down the drain isn’t just bad form – it’s illegal in most regions. Safety training and updated documentation back up every step from receipt to cleanup.

Application Area

This chemical finds itself everywhere from advanced battery labs to chemical manufacturing pilots. In electrochemistry, the combination of high ionic conductivity and broad electrochemical windows makes it useful for lithium battery electrolytes and supercapacitor research. Organic synthesis teams value its swapping of low volatility for strong solvent power during alkylation, cyclization, and coupling reactions. In separation science, it helps extract valuable metals or organic molecules where water and hydrocarbons fall short. Environmental engineers look into its ability to dissolve tricky pollutants. Its ionic structure even paves the way for immobilizing catalysts, letting them work through dozens of cycles before losing activity. These are not just hype stories – published papers and patents show real-world results from teams refining process conditions and scaling up from bench to pilot plant.

Research & Development

A steady flow of studies push at the edge of what 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate can do. Researchers in university and industry alike compare it against related imidazolium salts, examining new reaction mechanisms or pushing for breakthroughs in separation efficiency. Electrolyte research drives a lot of interest, especially as demand for safer, higher-capacity batteries ramps up. Each paper tests modifications, such as swapping the tetrafluoroborate for hexafluorophosphate or tweaking side chains to boost performance under stress. Teams swap notes at conferences, sharing both positive and negative data for the scientific community to build on.

Toxicity Research

Nobody wants to bring in a compound with hidden dangers. Early toxicity screens showed promise: imidazolium-based ionic liquids tend not to release toxic fumes during normal use, which means less risk for the folks preparing electrolyte solutions or running extractions. Still, long-term studies have flagged some persistence in aquatic environments, and breakdown products—especially if the tetrafluoroborate anion hydrolyzes—can generate fluoride ions, raising both environmental and personal safety concerns. Research teams measure cytotoxicity in model organisms, tallying LC50 and EC50 values, but real clarity will come only as long-term data builds up from field studies and industrial settings. Near-term best practice means closed handling, proper waste capture, and routine monitoring for signs of degradation or leakage.

Future Prospects

Looking at the future, 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate stands poised for a bigger share of specialty solvent and electrolyte markets. Rising interest in renewable energy and regulatory drives for lower-emission processes lift demand for non-volatile, thermally stable, and recyclable compounds. Synthetic chemistry can open new doors with further structural customization—changing cation or anion to suit specific reaction paths or material properties. Battery engineers stay on the lookout for next-generation electrolytes blending safety and performance, and this class of ionic liquids fits the wishlist. None of this progress comes free: sharper toxicity screens, life cycle analysis, and scalable green synthesis routes will all play big roles as research shifts into commercial production. The biggest gains will come from those willing to walk the hard road of careful, transparent science and open collaboration across industry, academia, and regulators.

Breaking Down the Name

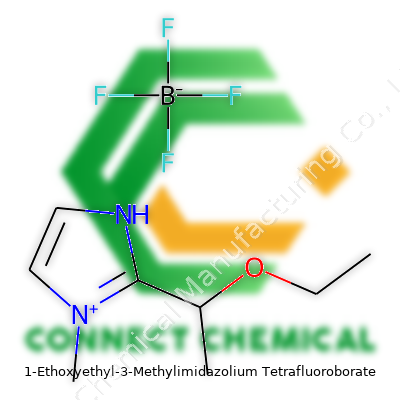

Long names in chemistry often carry a map to a molecule’s architecture. Take 1-Ethoxyethyl-3-methylimidazolium tetrafluoroborate. Start with the imidazolium core—that five-membered ring in so many ionic liquids. This isn’t just theory for me; I still remember cracking an old textbook open, seeing imidazole-based structures, and realizing their power to dissolve just about anything. Toss a methyl group at position three and stick an ethoxyethyl side chain at position one—suddenly, the chemical picks up unique handling characteristics. The tetrafluoroborate part, that’s the anion, a cluster of boron and four fluorine atoms. It keeps the molecule’s overall charge balanced and ramps up thermal stability.

Structure in Plain Terms

Here’s what you look at on paper. The imidazole ring sits at the center—a nitrogen atom at positions one and three, carbon at two, four, and five. Position three sports a methyl group. At position one, instead of hydrogen, you see an ethoxyethyl group (basically, an ethyl group attached to an oxygen, which is connected to another ethyl)—the sort of twist that gets a chemist’s attention. This side group makes the molecule less symmetrical, which in my experience helps with solubility in certain solvents.

The molecule forms a salt with tetrafluoroborate. Each cation pairs up with a BF4– anion. Why pick tetrafluoroborate? Because it brings both chemical stability and low reactivity, allowing safer handling and fewer surprises during experiments or industrial processes.

Ionic Liquids in Lab and Industry

I remember my first hands-on session with an ionic liquid based on this structure. No smell, barely any evaporation, handled heat like a champ. That’s the point with ionic liquids—they carry low volatility for green chemistry. The cation part, with the ethoxyethyl group, offers extra flexibility in fine-tuning melting points and viscosity. That comes in handy for tasks like extractions, battery electrolytes, and even as reusable solvents in catalysis.

Researchers use 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate because its balance of size, symmetry, and charge gives it favorable physical and chemical properties. Tuning the side chains tailors solubility, viscosity, and thermal range. In practice, this means less waste, cleaner reactions, and safer workspaces.

Potential and Responsibility

There’s no denying that as these materials grow in use, more eyes turn to their environmental impact. Ionic liquids avoid problems common to traditional organic solvents—such as flammability and air pollution. They still need thoughtful disposal and careful management around water and soil, given incomplete toxicology data. Researchers in the field, myself included, keep a close watch on new reports about breakdown products or long-term environmental behavior.

One practical solution comes from closed-loop systems, where ionic liquids recycle on-site or through specialized facilities. Some companies work on novel cations and anions that break down quickly after use. Others target clear guidelines on handling and end-of-use to prevent buildup in the environment.

Direct Impact on Everyday Science

A molecule like 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate matters for more than its neat structural quirks. It brings real value to chemists designing safer, greener syntheses. Its unique arrangement of nitrogen, carbon, oxygen, and methyl and ethoxyethyl groups ushers in a modern approach—one where smart design and environmental responsibility go hand in hand.

What Makes This Ionic Liquid Stand Out

1-Ethoxyethyl-3-Methylimidazolium Tetrafluoroborate is much more than an academic curiosity. After spending years following developments in green chemistry and alternative solvents, I see this compound rising in research circles, industry labs, and even in conversations about sustainable practices. Seeing its place in the world through real work and the latest literature reminds me that chemicals like this hold real promise if used with care and creativity.

Solvent Uses and Cleaner Processes

Green solvents have gained attention, and this ionic liquid offers some new possibilities. Labs often face tough questions about waste and toxic solvents; swapping out volatile organic solvents for these ionic liquids offers a practical path. 1-Ethoxyethyl-3-Methylimidazolium Tetrafluoroborate dissolves a wide range of organic and inorganic materials, so researchers can run reactions and separations with less pollution, fewer emissions, and even chances to recycle their solvents. This not only helps facilities keep up with regulations but also saves real money on waste disposal and supplies.

Electrochemistry Gets a Boost

Electrolytes set the stage in batteries, capacitors, and other electronic devices. Traditional options like lithium salts dissolved in carbonates can be dangerous and degrade quickly. By swapping in this ionic liquid, developers create more stable and non-flammable setups. Lower volatility means less risk of fire. Plus, these ionic liquids stick around longer and let devices run at cooler or hotter temperatures without breaking down. I’ve heard engineers talk about test cycles where devices using these ionic liquids outlasted common commercial batteries by months on end. An extra benefit: The high ionic conductivity supports faster charge and discharge cycles, a direct win for electric vehicles and portable electronics.

Catalysis and Synthesis: A Chemist’s Perspective

Every synthetic chemist has run a reaction that seemed impossible until the right solvent came along. Using this ionic liquid as a reaction medium opens doors that stubbornly stay closed with traditional choices. It’s not only about dissolving odd combinations of reactants; it’s about providing a solution that lets catalysts perform at their best and allows for easier product recovery. Take transition metal-catalyzed reactions—yields bump up, solvents last longer, and side reactions drop. A good friend in the pharmaceutical sector once pointed out that a single switch to an ionic liquid system saved weeks in process development for a new active ingredient.

Environmental Gains and What Stands in the Way

Switching to ionic liquids like this one cuts down on volatile organic compound emissions, which makes a genuine environmental difference. Over time, industries using these solvents have reported easier compliance with air quality rules and worker safety standards. Still, widespread adoption hinges on lower costs and greater availability. At the moment, academic and pilot-scale applications outnumber full-scale adoption. As manufacturing processes improve and prices drop, I expect to see this compound move beyond specialty uses. Developing routes from renewable feedstocks could push adoption forward, lowering dependance on fossil resources.

Smart Choices for a Changing Market

From solvent replacement and improved safety in electronics to better yields in fine chemicals, 1-Ethoxyethyl-3-Methylimidazolium Tetrafluoroborate isn’t just a lab curiosity. The pace of change in regulatory environments, growing awareness of chemical sustainability, and improving cost structures all point toward its greater use. My hope comes from watching chemists, engineers, and policy folks get together to discuss practical steps: making synthesis routes cleaner, designing recycling strategies, and finding safer chemical replacements. The compound shines most where there’s a willingness to rethink old routines and invest in longer-term benefits, both for profit and for the environment.

Understanding How This Ionic Liquid Mixes and Matches

The world of ionic liquids keeps growing, fueled by research projects that look for new, unconventional solvents. 1-Ethoxyethyl-3-methylimidazolium tetrafluoroborate lands high on this list thanks to its unique blend of a polar, room-temperature-stable cation and a flexible anion. People working in green chemistry and materials science want to know where this substance feels most at home—water or organic solvents. The answer says a lot about where this ionic liquid can step up and replace traditional solvents known for volatility or toxicity.

Looking at Water Compatibility

Anyone who's poured salt or sugar into water recognizes how solubility rules daily life. This ionic liquid shows strong affinity for water—not surprising due to hydrogen bonding and dipole interactions linking its imidazolium core and the anion's fluorine-rich structure. Direct reports suggest it dissolves easily, forming clear solutions in water at room temperature. Numbers from research usually put its water solubility above 20 g per 100 mL, sometimes pushing to full miscibility, depending on production purity or trace impurities.

I’ve tried mixing similar imidazolium-based ionic liquids in a lab setting. The moment you tip them into water, there's no struggle—they slip in with barely a swirl. No oily layers, no cloudiness, and certainly no clumps. In real research, that means less waiting around for things to dissolve, fewer worries about stirring speeds, and simpler reaction setups. The environmental upside stands out too, since these compounds don't evaporate or ignite like ether or acetone.

Organic Solvent Action

Moving into organic solvents brings a different story. The long side chain in the cation, the ethoxyethyl group, gives this salt a foot in both camps—polar and nonpolar. In alcohols such as methanol or ethanol, it keeps up its solubility act, going in as smoothly as in water. As the solvent shifts more nonpolar, the solubility drops. In solvents like dichloromethane or chloroform, the salt may still dissolve, but not completely—cloudiness gives away incomplete mixing. Hexane or heptane leaves it behind, with crystals stubbornly sitting at the bottom or stubbornly clinging to the sides of the beaker.

Lab-wise, solubility in polar organic solvents means reactions that need both organic and ionic environments get a big boost. This helps when trying to extract organic products out of water, speed up electrochemical reactions, or run catalysis where phase separation drags down yields or complicates purification.

Tailoring the Mix: Fine Tuning Solubility for Greener Chemistry

Researchers and industries look to ionic liquids like this one to replace more dangerous or less efficient solvents. But high solubility isn't always a universal plus. In water-heavy processes, easy mixing reduces waste and keeps equipment cleaner. In organic extractions, limited solubility sometimes becomes a benefit, letting the substance act as a controlled transfer medium instead of causing cross-contamination or difficult separations.

Solutions appear in adjusting the length of the ethoxyethyl group, swapping out the anion, or using co-solvents. There’s also active work on recovery: ionic liquids like 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate can get recycled across several cycles by taking advantage of their selective solubility. This closes loops, cuts down on costs, and supports effort toward green chemistry rules.

What Future Work Brings

Better data sharing, clear labeling from manufacturers, and open reporting on impurities all smooth the road for using this ionic liquid at scale. Scientists should keep pushing for more real-world trials, where actual product quality and operator safety improve daily practice. Mixing and matching solvents won’t go away, but knowing exactly how this ionic liquid acts in water and organic solvents hands out big advantages that the next wave of industry needs.

The Challenge of Storing Products Safely

Most of us don’t think much about storage until a problem shows up. Maybe it’s a bag of rice going moldy before you finish it, or a bottle of medicine losing its punch too soon. My own kitchen holds a jumble of food, cleaning items, and aspirin, and learning from some costly mistakes taught me that storage isn’t just about putting things away. It’s about keeping products fresh, usable, and safe.

Sensible Steps to Protect Quality

Every product comes with guidelines for a reason—ignoring them means throwing money away and risking health. If you’ve ever stored cooking oil above the stove, you probably noticed it turning rancid pretty fast. Heat, moisture, and sunlight chip away at a product’s quality, each in their own nasty way.

Storing items in cool, dry places helps you keep quality steady. For example, a pharmacy controls temperature for medicines, not just for the sake of formality but because chemical stability depends on it. The United States Pharmacopeia recommends dry storage between 15–25°C (59–77°F). That kind of detail guards the potency of what you’re buying. It’s not just about rules—good storage saves you from wasting resources and keeps your family safer.

Common Pitfalls and Why They Hurt

Everyday mistakes cost people more than they realize. Keeping bread in the fridge hardens it. Refrigerating tomatoes dulls their flavor. On the practical side, keeping strong-smelling products near pantry staples leads to contamination. More than once, I’ve opened a cupboard to find flour tasting faintly of laundry detergent—a mistake you make only once.

For supplements or medications, small details make a big difference. The bathroom medicine cabinet gets steamy, and humidity speeds up breakdown. In fact, the U.S. Food and Drug Administration warns that heat and moisture can destroy certain drugs. It’s not just a medical scare—these products really do lose effectiveness. So, switching to a closet shelf away from the stove or shower brings better peace of mind.

Industry Experience and Home Lessons

From experience working in food kitchens, keeping dry goods sealed tight and away from light prevents bug infestations. Rolling the tops of ingredient bags, using glass containers, and labeling with purchase dates make it easier to rotate stock and avoid spoilage. Cold and dark do more than slow time—they prevent bacteria and fungi from making themselves at home.

Simple Changes Make a Big Impact

Nobody wants to turn their house into a laboratory, but a few basic changes pay off. Use airtight containers for bulk items. Pick low shelves away from the oven or heating vents. For open products, label them with the date you bought or opened the item. Small steps keep value in your pocket and make daily life less stressful.

Checking storage guidance on packaging may seem tedious at first, but it beats finding out the hard way that something spoiled too soon. By following manufacturer recommendations and using common sense, we avoid food waste and keep our families and ourselves healthier. That’s the simple value of proper storage: it protects your investment and your well-being in one shot.

Real-World Chemistry Brings Real Risks

Dealing with chemicals like 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate shifts the routine of any lab or workplace. People sometimes see “ionic liquid” on a label and imagine gentle, harmless stuff. The truth feels a lot more practical and demands respect. Tetrafluoroborate salts, for instance, don’t carry the same fear factor as strong acids or volatile solvents, but casual treatment never pays off. My years working with similar compounds taught me: protective gloves and proper ventilation keep accidents rare and consequences minor.

Protective Gear Earns Its Place

A casual spill or splash with this chemical might irritate the skin or eyes. Even if the safety data sheet lists modest risks, skin breaks down over time after repeated contact. I learned quickly that nitrile gloves stay useful every time handling starts. Safety glasses aren’t negotiable. One stray drop or an unexpected reaction can turn a normal day into an emergency. Face shields belong on the bench where any energetic mixing or transfer can happen.

Ventilation Beats Regret

Working close to liquids that release vapors brings its own set of problems. 1-ethoxyethyl-3-methylimidazolium tetrafluoroborate stands out for being far less volatile than many organic solvents, yet tiny residues still collect at workstations and might turn into problem dusts. Fume hoods take most of the edge off, sending unwanted vapors out of people’s breathing space. I’ve watched too many people trust an open window in place of a proper hood—air systems beat improvisation.

Storage Stays Simple—If You Plan Ahead

Not every chemical wants the same home. This one likes cool, dry storage away from moisture and strong acids or bases. Humidity can trigger slow breakdown, creating hydrofluoric acid in trace amounts. Nobody wakes up looking to handle HF burns or glass etching. Segregate tetrafluoroborate salts from incompatible chemicals; it’s a small task for a big reward. Never leave the container open longer than needed. Resealing after each use saves more than just material.

Spills: Addressing Them Without Delay

Spills don’t wait for convenience. A paper towel won’t cut it. For small spills, absorbent pads keep the mess contained and leave less dust. Bigger incidents need trained hands, proper eyewash access, and documented cleanup steps. Always wet-clean floors—sweeping dries out compounds, letting dust move around and raising inhalation risks. If disposal feels uncertain, ask supervisors or check guidelines. Anything containing fluorine brings extra disposal steps for environmental reasons.

Training Leaves No Room for Guesswork

Newcomers often hesitate to ask about handling precautions, but those discussions separate safe labs from reckless ones. Nobody ever gained from hiding uncertainty. Regular refreshers on hazard communication, spill drills, and waste handling matter more than any fancy equipment. I’ve seen complacency scuttle promising research. Scheduled training and honest conversations help teams manage risks without drama.

Shared Responsibility Means Fewer Accidents

A safe workplace grows from repeated actions, not checklists stuffed into binders. Using these practical habits, people reduce exposure and build trust. Chemical safety means more than rules—it’s the difference between smooth workflows and hard lessons. Lean on firsthand experience, follow data sheets, and encourage everyone to speak up; success follows those who prepare, not those who just hope it all works out.