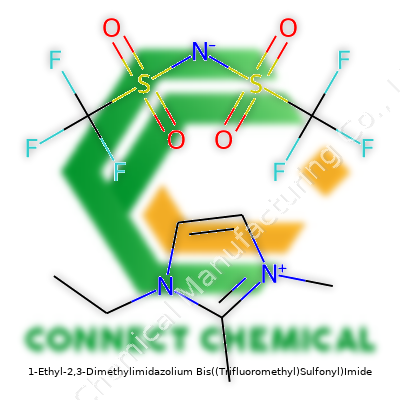

1-Ethyl-2,3-Dimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: A Deep Dive

Historical Development of Ionic Liquids

In the hunt for alternatives to traditional solvents, chemists reached for new answers in the late 20th century. Conventional organic solvents, typically flammable and volatile, raised safety and environmental problems. Then, ionic liquids emerged as possible fixes. Early imidazolium-based ionic liquids like 1-ethyl-3-methylimidazolium chloride sparked a genuine shift in research circles. Tinkering with the imidazolium ring and anion partners brought dramatic changes in properties. Chemists keen on safer handling and greener chemistry quickly gravitated to these novel fluids. 1-Ethyl-2,3-dimethylimidazolium bis((trifluoromethyl)sulfonyl)imide, with its bulky cation and highly delocalized, non-coordinating anion, marks a result of years designing chemicals from the molecular level up. The motivation doesn’t sit only with lab safety or process performance; there’s a serious push to lower ecological footprints in chemical production and use.

Product Overview

1-Ethyl-2,3-dimethylimidazolium bis((trifluoromethyl)sulfonyl)imide, commonly shortened to [EMMIM][NTf2], falls into a family of room temperature ionic liquids known for low vapor pressure and robust solvent abilities. This material appears as a clear to pale yellow liquid at ambient conditions. Its reputation has grown among industrial and academic users for its ability to dissolve a wide range of polar and nonpolar compounds. In some circles, folks refer to this liquid as a “designer solvent” because careful combination of the imidazolium core and bis(trifluoromethylsulfonyl)imide anion gives it extraordinary chemical flexibility. It has long outgrown experimental or niche status. These days, labs order it from commercial suppliers, who now offer it in various purities to suit work ranging from specialized research to pilot-scale manufacturing.

Physical & Chemical Properties

[EMMIM][NTf2] stands out for tolerating a broad range of temperatures before breaking down. Its melting point often falls below -10°C, staying liquid even in the cold. With a thermal decomposition point well above 350°C, workers rarely worry about material loss from evaporation or ignition under standard or even elevated lab conditions. Viscosity clocks in on the lower end compared to many ionic liquids, which makes sample handling and process transfer smoother than with more sluggish fluids. Many appreciate its strong resistance to hydrolysis—a property owed in large part to that bis(trifluoromethyl)sulfonyl)imide anion. As for solubility, this liquid dissolves many organic and inorganic species while offering weak coordination that allows for unusual chemistries in solution. The high electrochemical window of [EMMIM][NTf2], spanning roughly 5 volts, expands its use out to batteries and electrochemical devices, where everyday solvents simply break down.

Technical Specifications & Labeling

Commercial [EMMIM][NTf2] usually ships in air-tight, opaque bottles to reduce possible moisture or photochemical impacts. Material with 99% purity or higher supports most synthetic and analytical work. Certificates of analysis include spectroscopic confirmation—NMR and FTIR fingerprint both the cation and anion. Key physical data such as density (about 1.4 g/cm³ at 25°C), refractive index, and conductivity fill out the safety and technical sheets. Because of the fluorinated anion, clear labeling and Material Safety Data Sheets spell out chemical resistance, recommended compatible materials, and accidental release measures.

Preparation Method

People synthesize [EMMIM][NTf2] using a two-step approach. For the cation, alkylation of dimethylimidazole produces 1-ethyl-2,3-dimethylimidazolium halide. The anion exchange typically follows, often relying on lithium or sodium bis(trifluoromethylsulfonyl)imide. Metathesis proceeds in aqueous or organic media, and the product separates out due to water immiscibility. Washing, drying under vacuum, and rigorous filtration strip away residual halide and water. Modern protocols skip solvents like dichloromethane in favor of those friendlier to workers and the environment. Preparative steps include in-line monitoring—ion chromatography and Karl Fischer titration help nail down quality before the product ever leaves the bench.

Chemical Reactions & Modifications

[EMMIM][NTf2] doesn’t sit on the sidelines for chemical reactions. In fact, chemists use it as a medium for a range of organic transformations, from alkylation to oxidation and transition metal catalysis. Its low nucleophilicity and ability to stabilize charged intermediates has unlocked new routes to products that fail in classic solvents. While the parent compound’s structure stays stable under many conditions, some swapping at the imidazolium or anion position further customizes its profile. Researchers functionalize the cation with longer alkyl chains or add functional groups for ionic liquid-supported catalysis or separations. Changes on the anion side, usually substituting perfluorinated or sulfonyl groups, adjust hydrophobicity and ion-pairing strength.

Synonyms & Product Names

A few synonyms float around, especially in catalogs and regulatory filings. “1-ethyl-2,3-dimethylimidazolium bis(trifluoromethylsulfonyl)imide” pops up most frequently. Some also use “EMMIM NTf2,” “EMMIM-TFSI,” or “EMMIM bis(triflylimide).” CAS registration numbers clear up sourcing confusion between similar-sounding chemicals. Standardized product names help avoid mix-ups during ordering or reporting in research, and labels almost always print the full chemical name alongside any shorthands.

Safety & Operational Standards

Lab workers know that the safety profile of [EMMIM][NTf2] outshines volatile organics, thanks to its negligible vapor pressure and non-flammability. That doesn’t let workers skirt safe handling, though. The chemical’s strong solvency can pull toxins from gloves, so double-gloving or specialized resistant materials typically enter the SOP. Adequate ventilation and spill containment limit inhalation or skin contact risks. Disposal routes steer clear of sewer or incinerator options due to potential fluorinated degradation products. Regulatory agencies expect documentation—chain of custody, exposure records, and periodic environmental monitoring—especially in facilities handling ionic liquids at scale.

Application Area

One of the biggest strengths of [EMMIM][NTf2] comes from its ability to step into roles far outside classic solvents. Battery engineers lean on it in electrolyte blends to boost safety, lifespan, and energy density in lithium-ion designs. Separation scientists load it into extraction columns and membrane systems, taking advantage of its compatibility with both organic and metal ions. In organic synthesis, the liquid supports catalytic cycles that fail in water or polar aprotic solvents like DMSO, often yielding cleaner products and less waste. Researchers working in enzyme stabilization and biocatalysis have reported high retention of protein activity versus traditional solvents, pushing forward greener routes to pharmaceuticals. Academic and pilot-scale teams in CO₂ capture have picked it up due to strong physical sorption of gases and thermal stability under recycling. Each sector expands the boundaries of what this liquid can do, feeding back into demand for more targeted formulations.

Research & Development

Chemists and engineers around the globe continue to dig deeper into the behavior of imidazolium-based ionic liquids like [EMMIM][NTf2]. Structure–property correlations guide synthesis of even more effective fluids. Modeling work has closed the gap between laboratory bench and full-scale implementation by predicting material costs, lifetime, and regeneration cycles. R&D teams now routinely test ionic liquid mixtures for improved selectivity, lower viscosity, or higher ionic conductivity, using automation and high-throughput screening. Academic partnerships study biodegradability, aiming for ionic liquids with high performance and genuine cradle-to-grave sustainability. In my own experience, the leap from academic publication to commercial product requires thick data sets, regulatory sign-off, and third-party validation of all safety and toxicity claims. Labs that join with process engineers and regulatory scientists hit fewer snags than those who treat these stages as afterthoughts.

Toxicity Research

Every solvent carries risks, and the reputation of “green” only sticks if toxicity stays low for both humans and ecosystems. Research on [EMMIM][NTf2] suggests low acute toxicity for mammals compared to volatile organic solvents. Standard tests—the OECD battery for aquatic and terrestrial toxicity—point toward moderate persistence and lower bioaccumulation than some older ionic liquids. Chronic exposure data still build slowly, and most labs avoid routine discharge or open-environment use. Degradation in sewage or soil proceeds more sluggishly than for hydrocarbons or alcohols, raising flags for long-term exposure. Current thinking in regulatory circles leans toward closed-loop use and rigorous post-use reclamation, a model that will likely define future facility design. Systemic reviews flag the fluorinated content as requiring special scrutiny, given established concerns around perfluorinated byproduct persistence.

Future Prospects

The future for [EMMIM][NTf2] and similar ionic liquids points in the direction of even deeper integration into advanced manufacturing, green synthesis, and clean energy storage. The search for safer, more sustainable electrochemical storage options makes this liquid an essential focus in next-generation battery projects. Its role in advanced separations will probably grow as industries require better methods to recover rare or valuable elements without toxic waste streams. If material scientists and policymakers collaborate to standardize testing for environmental fate and long-term biological effects, the door opens wider to mainstream industrial adoption. Investment in lifecycle analysis and scalable recycling infrastructure stands out as the clearest path to addressing sustainability concerns raised by critics. Regulatory harmonization—agreement on purity requirements, workplace exposure limits, and acceptable disposal methods—will bring confidence both for end-users and the public. Technological breakthroughs may further refine the structure—tuning both the cation and anion—so the best properties of [EMMIM][NTf2] mesh with emerging demands from renewables, pharmaceuticals, and circular-economy models.

An Inside Look at a Modern Ionic Liquid

Scientists and engineers searching for alternatives to traditional solvents often turn to ionic liquids. Among them, 1-Ethyl-2,3-Dimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide takes a front-row seat. I first ran into this compound in the early days of exploring battery research, and its performance stood out for all the right reasons. This ionic liquid comes packed with stability, a wide temperature range, and a knack for dissolving things that never budge in regular solvents.

Electrochemistry and Energy Storage

Batteries and supercapacitors keep popping up as the demands for longer-lasting phones, cars, and backup power keep rising. Here, traditional electrolytes limit how much energy—or how quickly—you can stash and recover power. The ionic liquid in question beats out many organic solvents by holding up under high voltage and refusing to break down. During my time working with prototype lithium-ion cells, the story repeated itself: less risk of catching on fire, more cycles before things start to fall apart. Scientists at national labs point out the same thing—cycles keep counting upward, even under serious stress.

Green Chemistry and Synthesis

Regular solvents can choke the environment or cause headaches for workers. Chemists looking to clean up synthesis routes keep revisiting this ionic liquid. Since it barely evaporates, air stays cleaner. That alone eases worries around compliance and worker safety. I’ve seen researchers use this in making pharmaceuticals, specialty polymers, and advanced catalysts. Reaction yields often creep a bit higher than old-school methods, and clean-up doesn’t chew up as many resources or water.

Separations, Extractions, and Industrial Uses

Refining metals, recycling batteries, and making fine chemicals demand sharp separation of mixtures. The compound stands out for grabbing onto certain ions or organic molecules in ways standard mixtures can’t match. I watched a pilot plant crew pull rare earth elements out of a mess of ores and scrap, and the difference wasn’t subtle. Yields jumped, and the process could run at a lower temperature. Petrochemical sites lean on it to separate aromatics from aliphatics. An academic team in Germany used it to pull out environmental contaminants, tracking down pollutants at parts-per-billion levels.

What Comes Next?

Cost remains a sticking point. Raw materials and synthesis drive up the price tag, so large-scale adoption won’t happen without some clever chemistry on the supply side. Disposal and long-term effects need more clear-eyed study, since even “green” chemicals should stay out of rivers and drinking water. There’s plenty of reason to invest in better recycling or recovery methods—some university labs recycle up to 80% of used liquid. Industry leaders and policy groups expect new regulations to start catching up with the fast pace of research, setting real standards for safety and disposal. These challenges push companies and governments to keep looking for cheaper ways to make and reuse ionic liquids, ensuring the benefits start to trickle downstream to products and people.

Why Safety Talks Matter

Most of us don’t bother reading safety instructions unless something goes wrong. Maybe it feels a bit much to scan the tiny print or hunt for the “real” warning. But I’ve seen what happens when you cut corners. A simple product—cleaner, paint, battery—could send someone to urgent care. That’s not hype. Years ago, a roommate skipped gloves while using a drain cleaner and ended up with burns. We had to run to the ER, and he was lucky not to lose function in his hands. Overlooking basic info can ruin your whole week, month, or worse.

Check for Risks Before You Start

I always tell people to start by checking a product’s label. Companies have to follow rules to list out hazards clearly. Look for hazard symbols (like flame, exclamation mark, skull and crossbones). If you see words like “corrosive,” “flammable,” or “irritant,” you’re dealing with something that deserves respect. Even products sold for household use, like disinfectants or garden sprays, may eat through gloves or give a nasty cough if you breathe them in. Nothing takes the place of skimming the label, even if you think you know what you’re doing.

Common Sense Goes a Long Way

Years of experience have taught me to never assume a new brand works the same as the last one. Different formulas lead to different risks. If the label says “avoid skin contact,” wear gloves—not just any gloves, but ones designed for chemicals if you’re handling solvents or acids. If “ventilate area” is printed on the container, open windows and run a fan. No one wants a headache or worse from fumes. I find it easy to forget this step in winter, but it’s a mistake you only make once.

Don’t Mix and Match

Mixing products is a gamble. For example, combining bleach and ammonia—the cloud can put you in the hospital. I once watched someone try this to clean up a stubborn stain. He ended up dizzy and coughing just minutes later. Always stick to using one cleaner at a time. If you’re unsure, the label and Safety Data Sheet (SDS) provide guidance you can trust more than any online hack.

Protect Eyes, Skin, and Lungs

A product that’s safe for one job might become a real danger in another setting. Powders and sprays go airborne fast. Whenever I use powders or anything that sprays, I reach for goggles or a dust mask. Contact lenses don’t block anything. If the label suggests eye protection or says “seek fresh air if inhaled,” there’s a good reason for it. It doesn’t matter if you’re just using it for a minute—accidents strike fast.

Smart Storage Keeps Everyone Safer

Products meant to clean, kill weeds, or fix leaky pipes often belong out of reach of curious kids or pets. After my niece tried tasting a dishwasher pod, my whole family installed cabinet locks. I’ve made it a habit to store anything with a risk label on a high shelf, with lids tight. Original packaging matters because it tells paramedics and poison control what they’re dealing with if a disaster happens.

Seek Help if Something Feels Off

If you get splashed or spill something, don’t guess about first aid. Rinse with water right away, remove exposed clothing, and update a doctor about the specific product used. Bring the label with you if possible. Poison centers answer calls 24/7 in the U.S., and so do similar hotlines elsewhere. That call could save eyesight or lungs.

Stick to Reliable Guidance

You won’t find every answer on the label. Manufacturers’ websites, poison control, and physicians all offer trustworthy resources beyond guesswork found on forums. They’ve seen the worst cases and know what truly works. Taking ten minutes to check could save you pain and expensive treatment down the line.

Purity Isn’t Just a Number

Ask anyone who spends their days working in a lab, and they’ll tell you the number printed next to “purity” isn’t just for the paperwork. Growing up watching my uncle in his small-scale lab, I learned that even a fraction of impurity in a chemical can throw off research, ruin experiments, or, in some industries, endanger health. For example, food-grade and pharmaceutical-grade chemicals go through intense scrutiny because impurities can cause harmful side effects or allergic reactions. Purity matters in industrial settings, too — lower grades might be fine for treating wastewater, but fall short for medical or electronic uses.

People working in materials science or chemistry usually rely on grades like ACS, Reagent, or Technical. ACS purity (set by the American Chemical Society) means the chemical passed a strict test for contaminants, often to parts-per-million levels. Labs tracking every decimal for consistency and reproducibility need these levels. In my college days, I remember a project stalling because a small bottle labeled “95% pure” introduced irregularities that just wouldn’t go away. It proved how those silent 5% traces can undo hours of work.

Physical State: Not Just About Looks

It’s easy to overlook physical state, but it shapes how a chemical will behave or be used. Take sodium chloride — everyday folks call it salt, but it comes as granular crystals, fine powders, solutions, or even compressed blocks. Each state tells you something about its dryness, reactivity, and ease of handling. Grabbing a solution off the shelf skips the tedious (and sometimes risky) process of dissolving solids in solvents, and errors go down.

From my own experience teaching high school chemistry, students get their hands dirty with liquids and solids, and they learn quickly how different forms dissolve at different rates or react differently. That’s not trivial information if you’re running a production line or mixing chemical feeds in agriculture or water treatment. The solid form may offer shelf life or ease of storage, but the liquid might speed up processing or ensure even distribution.

Where the Two Intersect

Purity and physical state often intertwine. High-purity chemicals are rarely stored as solutions unless stabilized or used quickly — solutions can pick up contaminants from air or degrade as time passes. Take hydrogen peroxide: in pure liquid form, it’s a strong oxidizer and must be kept away from light and heat. Pure forms break down faster, so stabilizers are often added for shelf products, which slightly lowers the purity. That tiny trade-off can mean the difference between a chemical safe for home cleaning or one meant for rocket fuel.

The semiconductor world offers a striking example of these principles colliding. Super-pure silicon, shaped into flawless wafers, forms the foundation of our electronics. Contamination at any stage — from dust, from water, from the air — can ruin entire batches of chips. Billions of dollars hinge on addressing these issues, and strict control over purity and physical state safeguards these investments.

Practical Steps for Safety and Success

Trustworthy suppliers must deliver clear certification — a certificate of analysis goes beyond a sales pitch. Anyone buying or using chemicals should demand batch-specific data and know how to interpret it. Storage needs detailed attention. Don’t just look at expiration dates; pay careful attention to storage conditions (humidity, light, container integrity). Mixing up physical states, especially by mistake (think: confusing a concentrated acid solution for a dilute one), causes accidents that nobody wants.

Science rewards the details. Overlooking either purity or physical state can lead to lost time, failed projects, or worse. Years working in both education and the lab have shown me respect for the label, the analysis, and the simple truths behind them: purity and physical state are as vital as the molecules themselves.

Why Storage Matters for This Ionic Liquid

Working with chemicals in a lab has taught me one key truth: a small slip in storage can make life harder than it needs to be. 1-Ethyl-2,3-dimethylimidazolium bis((trifluoromethyl)sulfonyl)imide—let’s just call it EMIM TFSI—often serves in demanding roles, from battery research to organic synthesis. Keeping this type of ionic liquid safe starts with understanding its quirks and real hazards, not just glancing at a datasheet.

How the Wrong Storage Cost Us Time

Once, an unlabeled bottle in a shared fridge taught me a fast lesson about the importance of proper chemical management. EMIM TFSI can pull moisture out of the air, even when humidity doesn’t feel high. Water sneaking in during storage means researchers see wild swings in conductivity, not to mention degraded electrochemical performance. Sometimes those swings don’t even show up until you’re deep into an experiment.

Simple Rules: Dry, Cool, and Tight

Getting serious about its care, I learned that EMIM TFSI’s structure lets it soak up water in ways you often don’t see until things go wrong. Manufacturers supply it with warnings, but following them feels intuitive after scrambling to repeat work due to hidden contamination. It all comes down to common sense:

- Avoid moisture: Water breaks down its reliability for applications like lithium batteries. Keep containers sealed tight—polypropylene, glass, or Teflon work best. Never trust an open bottle or cap left askew overnight.

- Control temperature: Room-temperature storage often works, but wild temperature swings or direct sunlight can trigger decomposition or slow reactions with airborne contaminants. I’ve seen labs use desiccators with silica gel for ionic liquids to stop water from creeping in. These simple steps become habits that help projects stay on track.

Why Labeling Makes All the Difference

Confusion creeps in fast where many similar clear liquids fill shelves. Label every bottle—date received, date opened, who used it last. This basic tracking gives everyone in a lab a sense of responsibility. It also means less risk of cross-contamination or accidentally using degraded material. My first year in the lab, I watched senior researchers insist on strict logs for every substance. It seemed tedious at first, but it paid off whenever we could trace an error back to a storage slip-up instead of wasting days blaming method or equipment.

Thinking About Broader Responsibility

Safe storage isn’t just about protecting data or samples. This kind of ionic liquid poses risks if left open or spilled. Trifluoromethylsulfonyl imide can break down under sunlight, and spilled material causes headaches for both users and waste handlers. I’ve seen respected chemists build a strong safety culture just by staying alert to these risks. Proper signage, secondary containment, and checked inventory keep mistakes rare. Every desk or hood with a clear safety protocol makes the workplace better for new students and veterans alike.

Building Smarter Solutions

Demand for EMIM TFSI grows in fields like green energy and advanced manufacturing. As its use spreads beyond top research labs, spreading practical knowledge about storage protects both innovation and people. Manufacturers now often include QR codes on bottles linking to safety data or storage reminders, a simple advance that keeps knowledge accessible. Training new users to respect drying agents, audit their stock, and treat unusual ionic liquids with care only opens more doors for discovery.

Understanding Chemical Identity

Science in the real world rarely looks like the neat diagrams from high school textbooks. Every bottle, packet, or drum of chemicals in a lab or factory comes with some numbers that might look cryptic at first glance. The Chemical Abstracts Service (CAS) number stands out as one of those. Some may see it as just another string of digits, but it holds everything together when organizing compounds, tracking research, and ensuring safety.

The CAS number tells you about a compound’s unique identity. Similar sounding chemicals can turn out to be very different compounds, with wildly different risks. If you’ve ever worked in a busy laboratory or even tried to cross-check ingredients in a pharmaceutical, you'll know how quickly mistakes can crop up without a clear reference. Using the CAS number, search platforms like PubChem and ChemSpider retrieve verified facts instead of just close guesses. This effectively reduces real dangers or costly errors.

The Value of Accurate Molecular Weight

Every chemist has reached for the balance to weigh out a chemical sample, and every calculation in that moment depends on the right molecular weight. For complex molecules, guessing or using an outdated value can spoil months of research or kill the yield in scale-up manufacturing. Take the fight against counterfeit drugs: manufacturers depend on correct molecular weight for every batch. It's not just theory — mistakes make way for underdosed or overdosed medicines hitting the shelves.

The food industry uses this value every day. Nutrition labeling sticks to legal guidelines because food chemists accurately report every ingredient’s weight. In water treatment, the folks dosing chlorine or fluoride check that molecular weight to keep things safe for everyone at the tap. Precise numbers promote public trust and prevent disaster on both large and small scales.

Trust in Regulated Numbers: Why This Process Works

Scientists and regulatory officials need clarity to make decisions that directly affect public health and the environment. Pesticide approval, for instance, hinges on accurate CAS numbers in government paperwork, helping legislators track substances from farm to grocery aisle. In one personal project, I needed to order boric acid for pest control at home. Web searches turned up wildly different "boric acid" variants — but the correct CAS number zeroed in on exactly what matched safety guidelines. Mistakes here could mean the difference between a safe solution and a dangerous substitute.

Laboratory professionals trust reference standards built around these identifiers. Traceable sourcing means less risk of contamination, wasted batches, or confusing audits. With decades of attention on product recalls and safety advisories, suppliers and end-users both depend on CAS registration to cleanly communicate and authenticate their materials every step of the way.

Pushing Toward Open Data and Digital Tools

Decades ago, CAS numbers lived mostly in big printed books. Fast forward to now: reach for open databases and digital platforms that cross-reference everything from supply chain shipments to environmental impact reports. Students and researchers benefit equally, because these systems cut through marketing names and regional lingo. Working with digital records reduces language mistakes and makes chemical tracking faster for everyone.

For those jumping into science or product formulation, start using CAS numbers and correct molecular weights early. Teaching this habit leads to fewer mix-ups and a lot more confidence in your results. Chemical literacy is an everyday tool, important far beyond the dusty corners of laboratories.