1-Ethyl-2,3-Dimethylimidazolium Chloride: Insight and Perspective

Historical Development

Long before ionic liquids took off in research labs, most folks used traditional solvents like toluene, acetone, and ethanol to get their chemistry done. In the early 2000s, laboratories searching for alternatives that wouldn't spark fires or evaporate into the air landed on imidazolium-based salts as safer choices. Among these, 1-Ethyl-2,3-Dimethylimidazolium Chloride started grabbing attention. It popped up in published syntheses exploring green chemistry. Back then, researchers noticed its low volatility and high thermal stability, hoping to reduce some environmental hassle tied to classic solvents. Over time, demand spilled over from the bench into pilot scale as chemists spotted its advantages in electrochemistry and material preparation. Innovations in the 2010s led to more accessible and cost-effective manufacturing, turning this salt into a staple in research groups focused on sustainability.

Product Overview

1-Ethyl-2,3-Dimethylimidazolium Chloride does not act like your everyday table salt. It’s a pale, sometimes off-white solid that melts at a low temperature, around 67-70°C. Companies supply it in sealed glass bottles or polyethylene containers to prevent water uptake. Its molecular formula is C7H13ClN2, and plenty of people in chemistry circles recognize it under the short name [EMMIM]Cl. Some catalogues still sell it as “Imidazolium, 1-ethyl-2,3-dimethyl-, chloride”. The straightforward chemical makeup delivers versatility, so folks use it in solution or solid state, depending on their workflow. It dissolves quickly in water and polar organic solvents, which makes mixing straightforward.

Physical & Chemical Properties

The salt does not handle humid air well; it absorbs moisture with ease. Its melting point hovers just below normal laboratory hot plate settings, so you end up with a viscous liquid soon after heating. The ionic nature ensures its electrical conductivity lands above most neutral organic liquids, which suits it for electrochemical settings. Analysis shows it resists decomposition up to moderate temperatures, generally holding up to 200°C before breaking down. These imidazolium salts barely release vapors, so lab air stays cleaner compared to solvents like chloroform. Its density falls between traditional inorganic salts and conventional organics, making measurement and handling relatively intuitive.

Technical Specifications & Labeling

Suppliers provide purity data, frequently crossing 98%, which supports analytical and synthetic procedures. Alongside the lot number, bottles display a manufacture date, recommended storage (cool, dry place), and sometimes a hazard pictogram for skin and eye irritation. Each shipment arrives with a certificate of analysis, confirming compliance with regulatory requirements such as REACH in Europe or TSCA in the United States. For export, customs look for the HS code under “Organic chemicals; quaternary ammonium salts and hydroxides.” Labels use both systematic and short names to limit confusion during audits or safety checks. Trace metal content receives attention because excessive impurities disrupt high-sensitivity electronics assembly or catalysis experiments.

Preparation Method

Most laboratory syntheses start by methylating 1-ethylimidazole using methyl chloride, usually in anhydrous conditions, monitored for heat release. A vented hood helps, since methylation steps sometimes give off fumes. Once the reaction mixture cools, solvents get stripped away by rotary evaporation, then the crude salt goes through recrystallization using isopropanol or methanol to wash out any byproducts. Industrial setups scale this up with continuous flow lines and automated temperature monitoring. After filtration and drying in vacuums, the powder or crystals reach the final packaging phase. Some groups push for greener routes, swapping out hazardous reagents and integrating stepwise quaternization processes. Not all routes match in speed or yield, but steady attempts aim to cut costs and waste.

Chemical Reactions & Modifications

Chemists rarely use 1-Ethyl-2,3-Dimethylimidazolium Chloride in isolation. It often finds its way as a starting point for metathesis reactions, where the chloride swaps out for other anions, like tetrafluoroborate or hexafluorophosphate, yielding new ionic liquids tailored for specific tasks. In organometallic synthesis, this chloride version supports catalysis, thanks to its ability to dissolve metal precursors and stabilize reactive intermediates. Some materials science projects exploit its thermal stability to synthesize functional polymers or design new nanocomposites, using it as a template or reaction medium. Folks also modify the imidazolium ring, replacing groups at other positions to change the solubility profile or improve compatibility with different reagents.

Synonyms & Product Names

Markets and journals use a handful of names, ranging from 1-ethyl-2,3-dimethylimidazolium chloride, EMMIM chloride, EMIMMeCl, and even more technical labels like CAS 70899-08-4. Catalogues may highlight it as a subset of ionic liquids or as an imidazolium salt. Product specifications from chemical vendors often post the name alongside a structural formula or SMILES code, which matters for inventory control. Informal work groups call it EMMIMCl, especially in collaborative research documents. Recognizing all variants helps avoid confusion, since even minor catalog discrepancies can lead to mistaken orders or flawed labeling during audits.

Safety & Operational Standards

Working with 1-Ethyl-2,3-Dimethylimidazolium Chloride does not involve explosive hazards, still, direct skin or eye contact frustrates lab workers, since it generates irritation. Gloves, safety goggles, and standard lab coats block most routine exposures. Any spills on benches or floors must get mopped up fast, with water or alcohol for most cleaning purposes. Disposal should follow local hazardous waste protocols, keeping it away from drains to prevent environmental discharge, since chloride ions disturb aquatic systems. MSDS documents advise working in well-ventilated areas even if vapors are minimal. In my time in wet labs, keeping a wash bottle and eye rinse station nearby always helped, especially for trainees unfamiliar with the substance. Safety officers check that bottles remain tightly sealed after each use, because moisture degrades quality and complicates weighing out samples.

Application Area

Ionic liquids like 1-Ethyl-2,3-Dimethylimidazolium Chloride turn up most often in places regular solvents struggle. Electrochemists working on supercapacitors or lithium-ion batteries look for high ionic conductivity without fire risk. In synthetic chemistry, this salt’s low flammability and high thermal tolerance keep hazardous events in check and make cleanup easier, since the residue does not evaporate away. In catalysis, its ability to dissolve a wide range of metals broadens reaction options, pushing forward new CO2 capture and conversion methods. Biotechnologists use it to break open plant materials or solubilize polymers that plain water cannot touch. Companies working in advanced materials add it to composites, coating technologies, or as an agent to fine-tune surface properties.

Research & Development

In the last decade, investment poured into developing new uses for ionic liquids like this imidazolium chloride. National laboratories and private companies alike direct focus at cleaner processing of biomass, recycling rare earth metals without caustic waste streams, and expanding renewable energy storage. In my academic experience, group projects frequently tested EMMIMCl for dissolving cellulose in biofuel research or as a solvent phase in cross-coupling chemistry. Some startup ventures scan patent databases for tweaks to the imidazolium ring or mix-and-match different anions to create “designer solvents” for upscale electronics. The research buzz keeps going due to the broad gap in public knowledge about managing solvent waste and shrinking industry carbon footprints.

Toxicity Research

While considered safer than many industrial solvents, 1-Ethyl-2,3-Dimethylimidazolium Chloride has its drawbacks. Early cell culture studies warned about toxicity at higher concentrations, particularly on aquatic organisms. Chronic exposure data in mammals stays limited, but short-term rodent tests show mild to moderate irritation if ingested or splashed. Regulatory agencies in Europe review new data steadily, so some labs err on the safe side and avoid large-scale solvent disposal. Most risk management revolves around limiting inhalation and preventing accidental release into water systems. Some environmental scientists push for more transparency in reporting workplace incidents and accidental spills, since subtle bioaccumulation effects often slip past surface-level analysis.

Future Prospects

Demand for safe, robust ionic liquids grows as technology pushes into energy storage, nanofabrication, and green processing. Companies and universities moving toward circular economies invest in developing new mixtures and derivatives based on 1-Ethyl-2,3-Dimethylimidazolium Chloride. With continuous improvement in synthesis and purification, costs keep trending downward, which supports broader adoption beyond academic labs. Rapid advances in automation let researchers tailor properties to match niche tasks, spurring cross-industry collaboration. As toxicity data improves and new disposal strategies develop, regulatory barriers will likely give way to wider usage. My work in lab and industrial settings has shown that even incremental shifts in safer solvent use ripple outward, reducing risks for both people and the planet. Pioneering projects signal a bright outlook for ionic liquids, with EMMIMCl holding steady as a player in the transition toward cleaner and more efficient chemistry.

What Makes This Compound Stand Out?

1-Ethyl-2,3-dimethylimidazolium chloride doesn’t show up in daily conversation, but folks working in labs and advanced manufacturing know it well. This compound belongs to a class called ionic liquids, which is another way of saying a liquid salt that stays fluid even at room temperature. The real magic happens because these liquids carry almost no vapor pressure—they barely evaporate—which makes them less of a problem for air quality compared to older industrial solvents.

Why Research Labs Reach for It

Back during my university days, one task in the lab involved breaking down plant material for biofuel research. The typical solvents were toxic and fussy. Our team got a chance to try an ionic liquid—something like 1-ethyl-2,3-dimethylimidazolium chloride. Suddenly, dissolving stubborn cellulose fibers became possible without harsh acids. That’s the draw for research: these liquids break up plant biomass, plastics, and even some metals. Researchers value them since they're efficient and reusable.

Friendly to the Environment?

Many ionic liquids, including this one, come with a reputation for being “green solvents.” That label matters in a world where cities buzz about chemical spills and the air people breathe. I’ve read studies showing they don’t evaporate into the air like classic solvents—think acetone or hexane. Since there’s less evaporation, folks handling them in the lab or factory breathe in less pollution. Still, “green” isn’t automatic. If the used liquid gets dumped down a drain, local water and soil might not agree with that choice. Best practice calls for capturing and recycling these chemicals.

Industry Leans on Novel Solutions

This compound steps beyond just helping break things down. Industries making pharmaceuticals, batteries, and even solar panels find ionic liquids useful. I once visited a battery plant where these compounds got used for extracting metals out of old electronics, replacing rougher acids. The smooth extraction means less hazardous waste to handle after the fact. Chemists can tune these liquids—by swapping ions around—to fit the job, whether it’s creating a cleaner reaction or separating valuable minerals.

What Could Go Smoother?

Prices for some of these salts still run high, and large-scale users worry about cost as much as safety. Another kink is that not all ionic liquids have well-understood health effects, especially after years of use. Regulators and chemical engineers would rather get ahead of surprises, so there’s a need for ongoing toxicity testing and detailed disposal plans.

A Strong Push for Smarter Chemistry

Growth in cleaner manufacturing keeps these liquids in the spotlight. With better recycling and careful handling, they can offer real advances that support both industry and the planet. The research community already looks hard for ways to turn leftover plant matter into fuel, medicines, and materials, and these liquids hold promise for more breakthroughs ahead. Every step away from older, dirtier solvents brings safer workplaces and a healthier environment.

The Basics: What We’re Dealing With

1-Ethyl-2,3-Dimethylimidazolium chloride sounds complicated, but at its core, it’s part of a bigger group of chemicals called ionic liquids. Labs and industries use it because of its unique ability to break down or dissolve certain materials, often in places where old-fashioned solvents wouldn’t cut it. This chemical gets used in things like making batteries run longer, pulling heavy metals out of water, and even helping certain drugs dissolve. With all that promise, the question: is it actually safe to handle?

So, Is It Dangerous?

I’ve seen too many cases where folks assume odd-sounding chemicals instantly mean toxic. Sometimes, they do. Sometimes, they don’t cause immediate harm, but can quietly make trouble over time. The truth sits in the gray area—a lot depends on how you handle it. With 1-ethyl-2,3-dimethylimidazolium chloride, lab safety data sheets spell out that it can irritate eyes, skin, and the lungs if you breathe in dust or vapors. A splash in your eye or on your skin won’t send you to the hospital, but you won’t forget it, either. Inhaling it over the long term isn’t much of a study topic yet; no one can swear it’s harmless.

Backing Claims With What We Know

European Chemicals Agency (ECHA) lists this substance as having eye and skin irritation hazards. The US National Institutes of Health marks it as not mutagenic or carcinogenic from the standard battery of animal tests. Still, these results don’t get at small, long-term risks. Repeated mishandling of similar ionic liquids caused rashes and breathing problems among some researchers. Too often, people working with chemicals don’t notice mild symptoms at first and keep exposing themselves, not realizing the damage adds up.

Personal Experience and Lessons Learned

During work in research labs, I’ve watched new grad students treat all colorless liquids as “safe enough,” skipping gloves or fume hoods. Later, a trip to the campus doctor could have been avoided with the right precautions. The problem isn’t just the chemical—it’s overconfidence and poor training. I learned the hard way that if official guidance says wear goggles, just wear them. The time spent running for the eye-wash station after a spill ruins your day.

Improvement Through Better Practice

No solution beats education and access to safety data. People need to know there’s no shame in asking questions about odd-looking labels or unfamiliar smells. Easy-to-read safety posters and routine training go a long way. Places handling this chemical should keep good ventilation, require gloves and goggles, and lock up containers. As part of a global science community, anyone using chemicals owes it to themselves and others to keep risk low. If you’re ever unsure, err on the side of overprotection—no experiment is worth a health problem.

Moving Forward with Informed Caution

While research into all long-term effects keeps moving, practical steps make the real difference. Don’t trust assumptions about synthetic chemicals. Respect even the minor hazards, share know-how, and keep clear records of what’s been handled. People deserve to work in places where safety takes priority above speed or convenience. 1-Ethyl-2,3-dimethylimidazolium chloride won’t cause headlines, but the risks of careless handling can show up in small ways that matter.

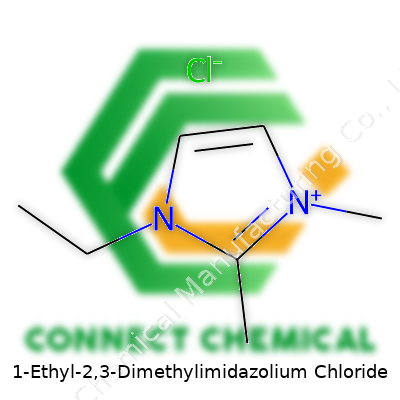

Chemistry Up Close

1-Ethyl-2,3-dimethylimidazolium chloride offers a specialized twist on classic imidazolium salts. Its formula pops up as C7H13N2Cl. The structure starts with an imidazole ring, which is a five-membered setup: three carbons, two nitrogens sitting next to each other. One side holds an ethyl group at position one. Both the second and third positions get a methyl group. That adds up to a more crowded ring than plain old imidazolium.

Structural Formula and Details

Chemically, imidazolium rings bring a positive charge, which usually means these forms work together with a counterion. Chloride steps in as the counterion here. Picture a central ring with two short carbon branches next to the nitrogens, then a longer two-carbon branch on the opposite nitrogen. This variation locks in the compound’s unique electronic properties and physical traits.

Why This Arrangement Matters

The actual arrangement of atoms and groups isn’t just an academic question. The positions and shapes of the groups on the ring modify how this ionic liquid behaves. For work in research labs, these tweaks shift things like melting point, viscosity, and even chemical stability. That gets noticed in real-world tasks. Right now, imidazolium salts stand out in battery work, chemical separation, and some environmental cleanup designs.

Plenty of my lab time has shown that subtle swaps—like putting methyl groups at both the second and third positions—boost resistance to breaking down at higher temperatures. I remember swapping between dimethyl and basic imidazolium salts and watching small shifts create huge differences for solubility and stability in ionic liquid work. Lower melting points open doors for green solvents. Single-digit Celsius melting points mean labs can run at room temperature without glassy, sticky messes.

Applications and Real-World Impacts

Chloride-based ionic liquids, like this one, help dissolve compounds that usually clump up. Some industrial syntheses benefit when metal catalysts stay active more efficiently. Electrochemical cells, especially experimental batteries, pick up longer life and smoother performance with these tweaks. Environmental engineers eye these compounds when extracting metals from water or cleaning up hazardous spills.

One sticking point comes from the chloride ion itself. Chloride sometimes makes corrosion more likely, especially in metal-contact setups. Production and disposal concerns also follow closely; laboratories focus on safer handling protocols, strict labeling, and collection of waste for proper treatment. That’s a growing challenge as these compounds become more common.

Science Built on Experience

Scientists who handle these liquids daily know the devil lies in the details. Changing a methyl to an ethyl can mean the difference between a clear, pourable liquid and a hard-to-use solid. Modern safety practices include regular glove use, well-labeled containers, and training for every person who puts their hand on a sample jar. There’s also a wide push to use these salts in greener, less-polluting processes, in part because of their design flexibility.

Potential Pathways Forward

The chemical world keeps pursuing modifications to these cations and their paired anions. Shifting the alkyl groups or swapping out chloride for a less reactive anion could address corrosion—one of the main real-life issues with these salts. Researchers have eyes on bio-based imidazolium systems for more sustainable chemistry. Every fresh experiment helps clarify which tweaks matter most for safer, more useful solvents.

C7H13N2Cl offers one more chapter in this ever-expanding story, linking targeted molecular structure to new functions across chemistry and industry.

Why Storage Matters for This Compound

Anyone who has spent time handling chemicals knows there are a few universal truths: keep things clean, keep things dry, and always remember which bottle holds something dangerous. 1-Ethyl-2,3-dimethylimidazolium chloride isn’t exactly a household name, but this compound pops up in labs for research and sometimes in industrial applications. People often overlook the basics until a spill or a crusty bottle reminds them chemistry doesn’t forgive carelessness. That’s where smart storage comes in.

Moisture: The Main Threat

Imidazolium salts like this one tend to grab onto moisture from the air. Leave the lid a little loose, and you could end up with a sticky mess inside the jar. Water doesn’t just make the powder clump; it helps impurities creep in, and in some cases, moisture can nudge the compound to break down or behave unpredictably in future experiments.

Like many chemists fresh out of grad school, I once wrote off the need for a desiccator until I watched perfectly good material ruined by humidity in a muggy storeroom. The frustration lingers longer than the damp patch on your bench. Silica gel, molecular sieves, or an actual desiccator cabinet can keep that risk low. Storing the bottle away from sinks, autoclaves, and humidifiers helps, too.

Light: An Often-Ignored Factor

Direct sunlight can raise the temperature in any workspace and push chemical bottles to sweat. Certain ionic liquids and salts respond to extra light as if someone showed them a sunlamp: they might yellow or thicken, or their purity can slide just a little. The safest bet always involves a cool, dark shelf—preferably in a cabinet away from open windows. The label might not say “light sensitive,” but prevention beats surprise deterioration.

Temperature: Room Temp Is Not Just a Phrase

People sometimes believe “room temperature” just means anywhere not on fire or freezing. That thinking runs into problems when outside heat waves push inside conditions to over 30°C. Temperature swings can impact the stability and shelf life of a lot of salts, including this one. If your lab or storeroom can hit extremes, especially in summer, set aside an insulated cupboard or use temperature monitors. Dry, steady, and cool makes all the difference.

Refrigerators can keep some chemicals happy. For this compound, though, low temperatures below 0°C might encourage unwanted precipitation or viscosity changes. Aim for steady temps between 15 and 25°C. If your storage area has wild swings, invest in some environmental controls.

Labeling and Access

It sounds simple, but clearly marking every container with the compound name, concentration (if applicable), and date received or opened can prevent a lot of confusion. I’ve seen more than one experienced chemist curse a faded or missing label. Keeping chemicals organized on the shelf—by hazard class and by chemical type—puts safety and clarity ahead of speed.

Waste and Repackaging

If moisture or discoloration shows up, retire the batch. Impurities or unknown products make recycling or reusing risky. Always use compatible containers—glass with tight seals beats plastic jars that warp or let air in. Follow local chemical waste rules to keep both people and the environment protected.

Solid habits—dry storage, cool temps, proper labeling, and swift disposal—keep 1-ethyl-2,3-dimethylimidazolium chloride safe and easy to handle. Every careful step saves time, money, and stress down the road.

What Is 1-Ethyl-2,3-Dimethylimidazolium Chloride?

This compound, an ionic liquid, shows up in advanced chemistry labs, green chemistry projects, and sometimes in research about new batteries or specialty solvents. Its structure packs a unique punch. That makes it a hot commodity for researchers working on clean tech or those testing novel solvent systems.

How People Find and Purchase This Chemical

I’ve been in a lab where each reagent on the shelf told a story—1-Ethyl-2,3-Dimethylimidazolium Chloride rarely comes from the local store. Most folks serious about research use specialty suppliers like Sigma-Aldrich, TCI, or Alfa Aesar. Searching “buy 1-Ethyl-2,3-Dimethylimidazolium Chloride” lands you on pages with grades, purity levels, and sometimes safety notes.

Before you make a purchase, companies look for business credentials. They might ask for proof you belong to a legitimate institution (think university or registered laboratory). It’s not about gatekeeping—this keeps dangerous chemicals out of the wrong hands and follows strict chemical safety laws.

Obstacles for Students and Hobbyists

If you’re just getting started or running DIY chemistry at home, prepare for a hard time. Most reputable sellers won't ship to a residential address or to an individual unless you can show a valid scientific purpose. Site accounts involving professional affiliations often unlock the catalog and pricing. These steps aim to limit misuse, so companies don't sell substances without a solid context.

Faculty and established researchers have an easier path. Universities often pool their chemical orders and handle shipping through a professional receiving area. In those cases, a researcher clicks through a catalogue, submits paperwork, and waits for the chemical room to call or email when the bottle arrives.

Sourcing a Sample the Legitimate Way

For people looking to get just a sample instead of a bulk amount, suppliers like Sigma-Aldrich sometimes list sample or catalog sizes, usually less than five grams. If you’re in academia, reach out to the company’s scientific sales rep—sometimes they give small samples for interesting research projects, especially if a publication or collaboration might follow. Writing a clear request with the planned purpose often helps.

If you’re working in an industrial R&D setting, chemical distributors might provide samples to vet their product quality before a bigger order. The catch is almost always paperwork—sometimes MSDS review, other times an end-user agreement.

Why Proper Channels Matter

Laboratory chemical accidents stick in my memory—the time my colleague misunderstood a safety form led to a shipment refusing entry at customs. Countries impose strict controls, because chemicals like this, while not commonly dangerous, require careful handling. The safety data sheets spell it out: proper labeling, professional oversight, and storage far from children or pets.

Cutting corners puts people at risk and leaves you exposed to legal trouble. Using reputable suppliers means you get a certificate of analysis, which guarantees the contents. Quality matters, especially for sensitive applications like battery development or pharmaceutical research.

Real Solutions for Responsible Access

Researchers often join forces with university departments to source what they need, which simplifies legal hurdles and paperwork. If you’re motivated, connecting with science outreach groups or local colleges might open doors. They may share a gram for educational projects, under supervision, keeping learning safe and legal.

Nothing replaces a legitimate relationship with a certified supplier. Learning the ropes—registering with verified credentials, explaining your use case, being open about safety—keeps promising chemistry moving forward and everyone out of trouble.