1-Ethyl-2,3-Dimethylimidazolium Hexafluorophosphate: The Story and the Science

Historical Development Shaping the Present

My own time in research labs introduced me to a world where classic solvents ran into serious environmental problems, especially in large-scale chemical processes. The arrival of ionic liquids sent a ripple through chemical circles, breaking the mold of volatile, flammable, and often toxic solvents. 1-Ethyl-2,3-Dimethylimidazolium hexafluorophosphate, sometimes called EMIM PF6, started gaining traction alongside this movement. Around the 1990s, groups across Europe and Asia began experimenting with imidazolium-based salts, attracted by their low melting points and unusual ability to dissolve both polar and non-polar compounds. This era established EMIM PF6 as more than a curious chemical — as a serious tool in labs trying to answer both practical and philosophical questions about “green chemistry.”

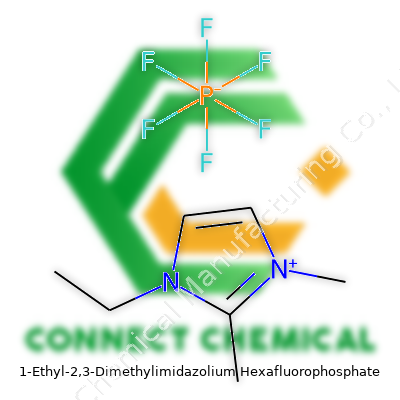

Product Overview

The commercial world greeted EMIM PF6 with open arms for its ability to replace traditional solvents in a broad range of specialties. Its unique structure — an imidazolium ring substituted with ethyl and methyl groups, paired with a hexafluorophosphate anion — delivers non-volatile, highly conductive liquid right at room temperature. Researchers and manufacturers pick it for its longevity in processes like catalysis, electrochemistry, and advanced separations. Not limited to bench-scale research, EMIM PF6 now appears in industrial lists and specialty chemical catalogs worldwide, favored for batch and continuous flow systems.

Physical & Chemical Properties

Anyone who’s worked with EMIM PF6 will mention its clear, almost oily appearance, and its near-odorless quality. Its melting point sits below room temperature, usually around 9 to 14 °C, making it a true ionic liquid at ambient conditions. Its density usually measures between 1.25–1.32 g/cm³, which makes it heavier than water, and its viscosity tends to be higher than many solvents we use, landing in the 35–40 cP range at 25 °C. Its ionic nature brings high electrical conductivity—valued for electrochemical uses—typically about 1 mS/cm at room temperature. Hydrophobicity and thermal stability grant EMIM PF6 excellent resistance to decomposition up to 350 °C in the absence of water. An important caution comes from its moisture sensitivity; it absorbs water from air, which can compromise both performance and lifespan in unsealed containers.

Technical Specifications & Labeling

Most suppliers mark EMIM PF6 under Chemical Abstracts Service (CAS) number 280406-82-8, with a purity specification above 99%. Laboratories track both the water content and levels of halide impurities, since moisture or chloride traces can alter its conductive or catalytic properties dramatically. On packaging, hazard codes like “Corrosive” and PF6-specific warnings about toxic hydrolysis products (namely, hydrofluoric acid) appear. In my experience, technical sheets reliably list shelf life, storage temperatures (usually 2–8 °C), and reminders about handling in dry atmospheres or glove boxes.

Preparation Method

Building EMIM PF6 in a laboratory usually follows a two-step synthetic route. First, 1-ethyl-2,3-dimethylimidazolium chloride forms from a quaternization reaction between 1-ethyl-2,3-dimethylimidazole and methyl chloride. This intermediate then undergoes anion exchange with potassium hexafluorophosphate in water or acetonitrile, causing EMIM PF6 to separate—usually as a dense lower liquid phase. After washing several times with water to remove residual chloride and drying under vacuum, the liquid’s ready for bottling. Careful attention to water content throughout each stage pays off at the end when purity and performance really count.

Chemical Reactions & Modifications

Much of the buzz around EMIM PF6 swirls around its non-innocent behavior in certain reactions. Its stability resists nucleophilic attack and basic hydrolysis—of course, up to a certain point. If water sneaks in, hydrolysis accelerates, sometimes producing toxic HF and ultimately degrading the salt. Its cation backbone allows substitution at the 2, 3, or 4 position, letting custom derivatives appear with different physical properties, all while maintaining the PF6 anion’s crucial benefits. Adding different alkyl groups, or even swapping the anion, lets chemists tune solubility, melting point, or electrochemical windows for specific tasks.

Synonyms & Product Names

The chemical goes by a handful of names, confusing anyone outside specialty circles. Some catalogs call it EMIMPF6, others use its full IUPAC name, “1-ethyl-2,3-dimethylimidazolium hexafluorophosphate.” You’ll also see N-ethyl-2,3-dimethylimidazolium hexafluorophosphate, or shorter codes like EMIMPF or [C2dmim][PF6]. These aliases all point at the same structure, though labeling always trails the whims of suppliers and patent offices.

Safety & Operational Standards

A quick look at safety data sheets, and anyone handling EMIM PF6 gets serious reminders. The main worry comes from hydrolysis: water breaks the PF6 anion, releasing hydrofluoric acid — well known for its dangerous effects on skin and bones. Workers use gloves and splash protection. Fume hoods or gloveboxes limit accidental exposure, and spill cleanup requires calcium gluconate solution on standby. Once in the waste stream, ionic liquids like EMIM PF6 require special disposal procedures to prevent harm to aquatic environments. My experience says that proper staff training and regular stock-keeping audits prevent most lab mishaps.

Application Area

It’s easy to spot the reach of EMIM PF6 once you start looking. Electrochemists use it as an electrolyte for batteries and supercapacitors since it offers wide electrochemical windows and low volatility. In biochemistry, it dissolves tough biopolymers like cellulose, opening new paths for sustainable paper and fiber technologies. Synthetic chemists leverage its properties as a solvent for catalytic transformations and extractions, eliminating volatile organic solvents that pollute the air and risk worker health. Even materials science draws on EMIM PF6 for producing specialty polymers, nanomaterials, and composites with unique conductivity or mechanical properties.

Research & Development

Academic journals and patent filings show scientists chasing new applications for EMIM PF6. Chemists explore its impact on catalyst recycling and reaction rates, while engineers check how it shapes the efficiency and safety of flow batteries. Recent trends push deep eutectic mixtures and more sustainable alternatives, but EMIM PF6 often gets used as a benchmark for next-generation ionic liquids. As someone who’s run headlong into equipment fouling and solvent emissions, I see how these studies translate from the literature into real, on-the-ground improvements. Regulatory bodies, industry consortia, and university collaborations now treat EMIM PF6 as a crucial piece in the bigger “green chemistry” puzzle.

Toxicity Research

A sober look at toxicity research pulls EMIM PF6 back from the green pedestal. Studies clock moderate toxicity to aquatic life, especially freshwater organisms, and results show bioaccumulation potential in sensitive environments. Long-term worker safety studies remain limited, but animal models link skin and eye irritation to prolonged exposure. The worst dangers stem from the PF6 anion’s breakdown, releasing hydrofluoric acid — one of the nastiest industrial chemicals out there. Strong containment strategies and environmental monitoring serve as the best defenses while the science catches up.

Future Prospects

The reputation of EMIM PF6 grows with every application, but the world keeps asking for better, safer, and more sustainable chemicals. I think there’s a real chance to improve the story by fine-tuning both its synthesis (using cleaner routes and sustainable feedstock) and end-of-life treatment. Emerging research into recyclable ionic liquid systems, biodegradability, and lower-toxicity analogues promises to shape the next decade. If regulatory agencies, industrial partners, and research groups keep pushing, “ionic liquid technology” could transform whole sectors by swapping in a safer, smarter generation of solvents — while EMIM PF6 holds its ground as both trailblazer and perennial standard.

The Chemistry Behind the Name

The name 1-ethyl-2,3-dimethylimidazolium hexafluorophosphate rolls off the tongue like a challenge from a spelling bee. Stripped down, this chemical formula comes together as C7H13N2PF6. The core is an imidazolium ring with ethyl and methyl groups attached, pairing up with a hexafluorophosphate anion. These elements make up a salt that stands out, mostly because scientists prizes it as an ionic liquid.

The Importance in Real-World Applications

This salt matters well beyond the blackboards and glassware of university labs. Researchers and engineers look at ionic liquids, like this one, for tackling tricky chemical reactions and industrial processes. Many solvents out there give off toxic fumes, waste energy, and leave a hefty environmental tab. Ionic liquids tend to stay stable, work under lower temperatures, and don’t evaporate into the air. Statistically, studies in journals such as Chemical Reviews show a steady rise in research into greener alternatives, pointing to a future with less chemical pollution and lower production costs.

Why the Formula Stands Out

C7H13N2PF6 signals more than a sum of atoms. The imidazolium cation brings an adaptable short-chain alkyl structure; that means it can dissolve both polar and non-polar substances. The hexafluorophosphate brings stability while keeping reactivity in check. This balance gets chemists excited, especially when searching for solvents that can handle complex organic reactions, extract metals with minimal residue, or even power batteries and supercapacitors. A 2023 industry survey by Grand View Research pegged global growth in ionic liquid demand at nearly 8% annually, driven largely by sectors looking to replace hazardous solvents.

The Safety and Sustainability Challenge

Not everything about C7H13N2PF6 falls under the green umbrella. Some ionic liquids, including those with hexafluorophosphate, can cause headaches when handled carelessly. Hexafluorophosphate has a risky side: it can generate toxic gases under the wrong conditions, such as overheating or contact with acids. The European Chemicals Agency now demands stricter labeling and disposal protocols for compounds like these. My own time in the lab has taught me to respect the glovebox, double-check waste containers, and confirm ventilation before uncapping any bottle holding this compound.

Moving Chemical Science Forward

With experience comes a desire to solve problems. Cleaner chemistry means more than switching one solvent for another. Teams in industry and academia need funding for real-life toxicity studies, better recycling systems for ionic liquids, and clear rules about waste handling. By focusing research on alternatives—perhaps swapping the troublesome hexafluorophosphate for less hazardous anions—there’s a shot at building a safer foundation for green chemistry. Stronger collaboration between companies, regulators, and universities can make ionic liquids like C7H13N2PF6 both high-performing and widely accepted.

Staying Informed

Information about ionic liquids, including 1-ethyl-2,3-dimethylimidazolium hexafluorophosphate, evolves constantly. Chemists must stay plugged in through journals, professional networks, and safety bulletins. Anyone handling these chemicals shoulders a responsibility to keep safety in focus while helping move toward smarter, cleaner industrial chemistry.

How This Compound Shows Up in the Lab and Industry

Pulling a bottle labeled “1-ethyl-2,3-dimethylimidazolium hexafluorophosphate” from the shelf doesn’t exactly spark excitement. Still, for chemists and engineers, it delivers something special. It shows up most often as an ionic liquid – a mouthful for a salt that stays melted at lower temperatures. This unique trick lets it act as a solvent far different than water or oil. Its structure lets people run reactions that stall out in other liquids, sidestepping evaporation and fire risk that haunt other industrial setups. I’ve seen labs choose this compound when they need things stable, clean, and able to handle tough conditions.

Working Behind the Scenes in Energy Tech

Ionic liquids like this one help in batteries, especially for high-performance setups. Standard lithium-ion designs count on flammable solvents. Here, you get a safer option. By swapping in 1-ethyl-2,3-dimethylimidazolium hexafluorophosphate, engineers squeeze out better thermal stability and slow down battery wear. It won’t turn your phone battery into a super-battery overnight, but in big-grid storage or electric cars, improvements in reliability go a long way. Tech developers chase longer battery lifespan and fewer safety recalls. Every percent of reduced risk matters. We aren’t talking about some far-off hope; patent filings and published test data already spotlight this trend.

Cleaner Chemistry for Synthesis

Lab work used to rely on toxic, temperamental organic solvents. Modern push toward green chemistry means more ionic liquids on the bench. 1-ethyl-2,3-dimethylimidazolium hexafluorophosphate stands out for handling sensitive reactions. It lets chemists swap in ingredients that don’t like water, and it also dissolves salts other organic liquids won’t touch. It doesn’t fly off as vapor, reducing headaches and chemical exposure. The greener angle matters in a world where chemical plants face tighter regulation and bigger scrutiny from watchdog groups. I’ve talked to graduate students who appreciate not choking on solvent fumes in the name of science.

Helping Separate Metals for a Modern World

Devices keep shrinking, and rare metals like gold, platinum, and palladium turn up in more places than just jewelry. Recyclers use ionic liquids in extraction to keep landfills from filling up with discarded electronics. This compound handles metal ions that old-school processes can’t grab efficiently, making it popular in pilot recycling projects. Costs add up, but the gain comes from less environmental damage and smaller reliance on mining. These solutions rely on properties specific to compounds in this class—like fine-tuning which metal ions get captured and which are ignored based on a tweak to the molecule.

Room to Grow: What Comes Next

People want new materials that cut waste and boost safety. Questions hang over long-term environmental impact, production cost, and scalability. Research teams test for toxicity and possible byproducts that might pollute water. Increased demand drives down price. More open research, along with clear labeling and safe disposal guidance, keeps the risks in check. Collaboration between academics, industry, and regulators forms the core for smarter and safer use. I see a path forward where this chemistry helps industries clean up while powering new technologies behind the scenes.

The Real Risks Worth Knowing

Working with any chemical, whether in a school lab or a research facility, carries real risks. Years ago in a college lab, I saw firsthand what happens when someone brushes off labels or skips gloves. No one expects irritation, burns, or worse, but cuts and rashes show up quickly if you get too comfortable. Some substances seem harmless until they react with skin or a bit of water. Even a bit of powder settling on a bench can linger for weeks, quietly waiting to cause problems.

Personal Protection Isn't Optional

Skin doesn’t forgive carelessness quickly. Most folks know to reach for gloves, goggles, and coats, but skipping one piece of gear leaves a door open. Splash-proof goggles keep eyes safe even from tiny drops. Nitrile or neoprene gloves fit most settings, but sometimes only thick, chemical-resistant gloves stand a chance. Regular eyewash checks and keeping fresh gloves nearby make a big difference for anyone handling these compounds. The smell of a fume hood running is like music when dealing with fumes or dust.

Air, Dust, and Fumes: Keep Them in Check

Inhaling even a hint of certain vapors can turn a good day into a hospital visit. Closed windows and poor ventilation trap danger fast. A sturdy fume hood or direct exhaust keeps the air clear, something that's easy to overlook in a pinch. I’ve seen labels ignored, only to find the air humming with solvent fumes half an hour later. Reading safety data sheets might sound like red tape, but those warnings about inhalation and exposure exist for a reason—they keep people out of the emergency room.

Spills Happen Fast—and Need Fast Action

No matter how careful you are, spills happen in real labs. Absorbent pads and neutralizing agents save a lot of panic, but there’s no time to dig through drawers during a spill. Easy access to spill kits and emergency showers keeps everyone safer. A clean bench, a mop within reach, and clear exits stay on my mind all the time after watching a friend panic with a bottle tipped over.

Label Everything, Every Time

It only takes one unlabeled bottle to set up a disaster later on. Too many accidents come from mixing up containers or forgetting what’s inside. Fresh, clear labels—including date and details—take seconds to write but prevent nasty surprises later. As soon as anything goes in a secondary container, slap a label on it instead of waiting.

Storing Chemicals with Respect

Not all bottles play well together. Something as simple as stacking acids next to bases will create risks. Even similar-looking substances can erupt if mixed. Cabinets with clear separation, locked doors, and steady temperature control prevent most storage nightmares. It’s worth double-checking storage rules every few weeks.

Get Training, Never Stop Learning

No one should walk into a lab or factory without clear training. Complacency builds up fast and leads down a rough road. Regular drills and real conversations about close calls keep everyone vigilant. Talk openly about slips, scares, or near-misses; learning from each other means no one feels alone in facing chemical risks.

Build a Culture of Respect, Not Fear

Working safely with chemicals comes down to habit and respect, not paranoia. Mistakes cost more than just time—they can risk lives. Clear talk, shared responsibility, and honest reminders create safer spaces, at work or at home. Every glove, label, and plan can turn a tough moment into just another story instead of a tragedy.

Looking Closer at Purity

In research circles, there’s little room for guesswork on chemical purity. The story stays the same for 1-ethyl-2,3-dimethylimidazolium hexafluorophosphate, often written as [EMIM][PF6]. People use it in electrochemistry setups, catalysis, and sometimes even to help store energy. In my own lab days, I learned fast: anything below 98% purity spells trouble if your goal involves sensitive reactions or electrical measurements. Trace water, leftover solvents, or other organic molecules—these all mess with results in silent ways. Sometimes, you spot differences only after hours of head-scratching and failed runs.

Certificates of Analysis, often from suppliers with a reputation to keep, quote purity levels above 98%, some pushing 99%+. Eye-check never tells the full tale. Vendors use NMR spectroscopy, mass spectrometry, and Karl Fischer titrations to comb out non-obvious contaminants, especially water and leftover reactants. But numbers on paper don't always match reality. I’ve ordered from two suppliers and watched one bottle last weeks before clouding up, picking up water from the air despite careful handling. This kind of hidden degradation means even bottles marked “anhydrous” or “high purity” need smart storage—always sealed tight, out of light, and with a desiccant pack hugging the neck of the vial.

Seeing Is Believing: The Look and Feel

Walk into a lab and pour out a bit of [EMIM][PF6] onto glass: at room temperature, you get a colorless or pale yellow liquid. Sometimes, the yellow gets a bit more pronounced. In my experience, a deep yellow or brown cast raises alarms about degradation, likely small organic impurities or breakdown products. This liquid doesn’t smell sweet or sharp. Instead, it sits heavy on the spatula, slow-moving, much denser than water. Viscosity stands out—the fluid runs thick. Handling it outside a glovebox, especially in humid air, quickly shows you its appetite for moisture.

If the temperature drops below 40°C, [EMIM][PF6] can start to turn into a foggy or crystalline solid. Most cold labs see this transition during storage in winter, and it catches folks off guard if nobody checks for crystallization before use. I’ve had to warm up bottles gently—never too hot—because overheating can change the chemistry or push off volatile bits. Transparency means purity, mostly, but it isn’t a guarantee. You’ve got to check with proper instrumentation if color or viscosity starts drifting from what’s expected.

Getting Consistent Results

Inconsistent quality or contaminated bottles slow down even the best-run labs. Keeping up with regular checks—like NMR or conductivity—saves projects from avoidable errors. Reliable suppliers list detailed impurity profiles and water content, but once opened, keeping the chemical sealed away from air matters more than most realize. If a lab skips these steps, odd results creep into the work, wasting both money and hard-earned time. Batching protocols, logging every new lot, and running quick purity tests before big experiments become routine in seasoned groups. Simple changes like these turn bench frustration into steady results.

Knowing the Risks, Not Just the Name

Everyone in a lab knows those long chemical names tend to blend together. Yet, 1-Ethyl-2,3-Dimethylimidazolium Hexafluorophosphate packs real hazards behind its tongue-twisting label. This ionic liquid pops up in batteries, electrochemistry, and advanced material research, so mishandling can cause trouble in all sorts of ways—health, legal, or plain old equipment damage. You read enough about accidents in the news; nobody wants to be part of the next headline.

Understanding What We’re Dealing With

Imidazolium-based salts aren’t just tricky on the tongue. They can react with water and air, sometimes releasing toxic compounds. Organofluorine compounds especially can be bad news after a spill: they might burn the skin, irritate the lungs, or put a dent in expensive hardware. From stories I’ve heard and mistakes I’ve seen, skipping safety gear or sloppy storage has a way of turning a lazy afternoon into a trip to the ER.

Building the Right Storage Habits

Glass bottles with tight screw caps—those always beat plastic since chemical compatibility matters. Choose containers that don’t react with the chemical, and never grab a bottle that looks cloudy or cracked. Use the chemical straight from the dedicated flask; don’t tempt fate by double-dipping tools between chemicals.

Put the bottle in a cool, dry place. Moisture is the enemy, and this salt tends to grab water if it can. I always rely on a desiccator or an atmosphere that carries dry nitrogen if the storage room feels muggy. Air never improves shelf life. Many labs lean on inert gas atmospheres to avoid nasty surprises.

Protect People—And Science

Personal protective gear never goes out of style: gloves rated for chemical use, goggles, and lab coats act as your insurance plan. The first face shield I ever strapped on felt weird, but getting a friend to the emergency eye wash made me wish it was standard.

Every bottle should have a date and a legible label—no excuse for scribbles. Remember to enter the chemical in the inventory, so everyone knows what’s in the cabinet. More than once, I’ve seen chemicals outlast the people who ordered them, and someone down the line is left guessing.

Tackling Waste and Cleaning Up

What goes in must come out. Used imidazolium compounds need a sealed waste container that resists acid and doesn’t crack under pressure—nobody dumps these down the drain. Local regulations rule: chemical waste gets handled by certified crews. In smaller groups, pooling waste until the regular pickup probably saves everyone a headache.

Spills call for absorbent materials that can cope with both organic liquids and salts. I keep a kit handy—no reaching for a paper towel. Wipe up, seal the mess, and mark it for disposal with the rest of the waste. Even if you think only a drop spilled, treat it like evidence at a crime scene.

Room for Improvement in Every Lab

People cut corners when they’re rushed or just get used to taking risks. I've seen old habits die hard, but strong protocols and regular checklists fight that urge. Quick reminders posted where people actually look—next to the storage cabinet, not buried in a manual—work wonders. New researchers benefit from a walk-through, not just a lecture.