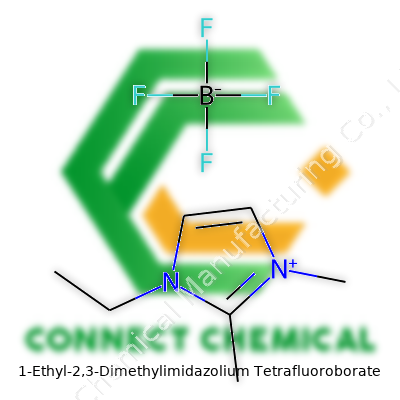

1-Ethyl-2,3-Dimethylimidazolium Tetrafluoroborate: In-Depth Commentary

Historical Development

Back in the late 1900s, researchers started poking around with ionic liquids because solvents needed an upgrade. Most organic chemists remember the push for greener alternatives once volatile organic compounds kept showing up as workplace hazards. Imidazolium-based salts weren’t the first, but they quickly started getting attention. As studies ramped up on cation-anion pairings, scientists stumbled onto a sweet spot with imidazolium rings. The addition of longer alkyl chains and side groups like ethyl or methyl led to all sorts of new combinations, but 1-Ethyl-2,3-Dimethylimidazolium Tetrafluoroborate caught extra interest. Labs in both Europe and Japan zeroed in on this particular salt for its unique mixture of chemical stability and physical properties. A steady stream of patents and academic papers drove refinements through the '90s and 2000s, and today it shows up across university textbooks and patent filings for modern green chemistry.

Product Overview

Digging into this compound, you find an ionic liquid that’s all about practical use—no fuss, just results. It sports two methyl groups and an ethyl chain on the imidazole ring, giving it a signature identity compared to bulkier counterparts. Tetrafluoroborate as the anion keeps the salt from getting sticky or overly reactive. Bottles of 1-Ethyl-2,3-Dimethylimidazolium Tetrafluoroborate usually arrive as clear, colorless or slightly yellow liquids without a sharp odor, making them easy to handle compared to pungent solvents like pyridine. Manufacturers label bottles in air-tight, moisture-resistant containers, since ionic liquids grab water straight out of midair if left open.

Physical & Chemical Properties

Most work in real laboratories leans on reliable physical behavior. This ionic liquid barely evaporates and stays stable across a wide temperature range, generally up to about 200°C or more before breaking down. For handling, it offers a notable density—higher than water—so it feels weighty in the flask. Its viscosity runs lower than many classic ionic liquids, speeding up mixing and mass transfer in reactions. Tetrafluoroborate delivers chemical inertness under neutral and mild acidic environments, side-stepping issues like uncontrolled side reactions or corrosion in glassware or reactors. The compound’s low volatility keeps it from filling the air with fumes, which matters a lot in shared workspaces. People working with this salt report smooth pouring and minimal stickiness.

Technical Specifications & Labeling

On the label, labs and suppliers print out the CAS number, purity grades (most batches top 98%), water content (often less than 0.5%), and any relevant storage warnings. Storage at room temperature usually works if humidity stays in check. Students and researchers checking certificates of analysis will find a list of trace impurities, since these can matter for sensitive catalytic or analytical work. Some manufacturers run extra tests for halide residue, trace metals, and color index to guard against unexpected surprises in reaction outcomes.

Preparation Method

The simplest preparation starts with 1-ethyl-2,3-dimethylimidazole, usually synthesized by sequential alkylation of imidazole. Cation generation takes place before adding tetrafluoroboric acid or sodium tetrafluoroborate. Mixing the two leads to metathesis, where sodium drops out as a precipitate, leaving the liquid salt behind. Filtering and careful distillation under reduced pressure remove any leftover volatiles. Further drying under vacuum at mild heat guarantees a ready-to-use ionic liquid with appropriately low water content, critical for air- and moisture-sensitive uses. Non-specialist labs without gloveboxes or automated lines can still run this synthesis under basic dry conditions.

Chemical Reactions & Modifications

In the hands of chemists, this ionic liquid acts beyond a simple solvent. Researchers use it to stabilize transition states in multicomponent reactions, boost yields in certain cyclizations, and promote unique selectivity in alkylation and acylation steps. Outside of standard organics, the imidazolium core can undergo functionalization through N-substitution or ring modification. Some graduate students test its response to Lewis acids or bases, exploiting shifts in hydrogen bonding and electron density to direct complex syntheses. This ionic liquid offers a playground for designing task-specific ionic liquids by swapping the anion or appending new groups to the ring scaffold, producing tailor-made solvents for special applications.

Synonyms & Product Names

In catalogs, 1-Ethyl-2,3-Dimethylimidazolium Tetrafluoroborate often hides behind nicknames like [EMMIM][BF4] or just EMMIM BF4. Some suppliers add their own suffixes or prefixes, but reputable chemical providers stick to IUPAC-based names. Street-level jargon in chemistry groups might shorten it to EMMIM tetrafluoroborate or even just “the ethyl-methyl imidazolium IL.” For documentation, everyone circles back to the CAS registry number to clear up doubts.

Safety & Operational Standards

Practical safety always gets attention. The substance itself isn’t as flammable as old-school ethers or alcohols, yet direct skin or eye contact causes irritation. Labs with proper PPE—nitrile gloves, goggles, lab coats—reduce risk. Cleaning up spills requires more attention because the liquid resists easy evaporation, so paper towels or absorbents get used for pickup, then all cleanup waste goes into specific solvent waste bins. Ecotoxicity studies remind everyone that these ionic liquids don’t break down as easily as some hoped, so sewer disposal stays strictly off-limits. Over the last decade, labs have set up better ventilation and written protocols on handling and storage. These adaptations keep safety records up to par and shield researchers from long-term exposure.

Application Area

Working chemists and engineers like to experiment with this salt because it solves real-world process bottlenecks. Its chemical stability, low volatility, and strong ionic character have opened doors for applications in electrochemistry, as electrolytes in batteries, and as medium for metal plating. Analytical chemists run it as a mobile phase in high-performance liquid chromatography, sometimes swapping it in for classic acetonitrile. In organic synthesis, researchers push the boundaries on C–C bond-forming reactions because of the salt’s ability to dissolve polar and nonpolar components side by side. Many energy storage projects tap this ionic liquid for use in double-layer capacitors and advanced lithium-ion cell technology. Green chemistry circles have pointed out its role in reducing hazardous solvent emissions and facilitating catalytic cycles with better atom economy. No shortage of technical papers highlight its use from the bench scale all the way through pilot plant runs.

Research & Development

PhD students and postdocs constantly test new modifications of this base structure in search of even better performance. In recent years, machine learning models have started to predict new cation and anion modifications, increasing the hit rate for useful new compounds. Major university labs and a handful of industrial process firms keep pushing studies focused on performance under extreme temperatures, compatibility with novel electrode materials, and use in green separations. Collaborative grants between academia and private industry have led to half a dozen new patents that draw from the versatility of this salt. Researchers publish pilot studies showing how slight structure tweaks change melting point, viscosity, or solubility, paving the way for even broader adoption.

Toxicity Research

Toxicology investigations don’t get overlooked because ionic liquids occupy a gray zone—less volatile than toluene, but not necessarily harmless. Chronic exposure in rodents points to mild organ effects at high doses. Cells in vitro sometimes show cytotoxic response at surprising low concentrations, so real-world process design focuses on keeping things contained and minimizing accidental release. Waste management regulations in the EU and US now reference detailed safety studies, including biodegradation rates and aquatic toxicity. Long-term environmental studies remain ongoing, but smarter containment techniques and improved user education help mitigate most acute risks.

Future Prospects

Based on everything seen so far, the story for 1-Ethyl-2,3-Dimethylimidazolium Tetrafluoroborate isn’t finished. Energy researchers want to make lithium and sodium batteries work better at higher voltages, and these salts look promising as the next generation of electrolytes. Efforts in separation technology and analytical chemistry hint at even more roles in bio-compatibility and protein crystallization, if toxicity challenges can be ironed out. Synthesis routes continue evolving to lower costs, scale up production, and shrink the environmental footprint. For every chemist or engineer frustrated by the limits of traditional solvents, there are a dozen new projects betting this class of ionic liquids will open up processes that once seemed out of reach. Green chemistry, high-tech manufacturing, and energy storage all stand as likely homes for even broader application in the years ahead.

Not Just Another Chemical: Why It Matters

Chemicals rarely get household name status, but in labs and industry, a few quietly shape the future. 1-Ethyl-2,3-dimethylimidazolium tetrafluoroborate hardly rolls off the tongue, yet it brings a punch where cleaner, smarter processes are in high demand. My years around chemical engineering have shown that the right solvent can mean less waste, less danger, and more reliable results. This ionic liquid delivers on a few of those promises—at a time when the world cares about green chemistry.

Greener Solvents for Better Chemistry

Traditional solvents often have short lifespans and long environmental bills. Most are volatile, flammable, or just plain tough to dispose of properly. Ionic liquids like this one flip the script. Thanks to their low vapor pressure, they don’t release clouds of fumes and sidestep much of the fire risk. This property lowers costs for ventilation and gets workers out of the splash zone, addressing worries I saw on the shop floor year after year.

Industries treating batteries, pharmaceuticals, and dyes use ionic liquids to replace nasty solvents such as dichloromethane or toluene. In the lab, using this chemical speeds up organic reactions and gives more precise control over the results, especially for reactions that stall out with ordinary solvents. I’ve watched colleagues switch their syntheses to ionic liquids and cut down on time, energy, and hazardous cleanups.

Batteries Get a Health Boost

A friend working in energy storage swears by the stability that this ionic liquid brings to lithium batteries. Since leaks and breakdowns keep battery designers up at night, a heat-resistant, non-flammable electrolyte makes a difference. Putting 1-ethyl-2,3-dimethylimidazolium tetrafluoroborate inside the separator keeps batteries running stronger for longer, easing the pressure on critical minerals and slowing down battery waste.

More electric vehicles on the road means more demand for batteries that handle charge cycles and high temperatures. By resisting degradation, this liquid cuts maintenance and boosts device safety. Fewer fires and fewer replacements build trust—not just for big manufacturers but for families charging scooters in their garages.

Cracking Complexity in Extraction & Separation

Industries need tools to tease out valuable materials from massive waste. Whether it’s recycling rare earth metals or cleaning up after oil spills, selectivity matters. This chemical gives operators flexibility by tuning its properties for either extraction or dissolution. I’ve seen it recover palladium and platinum from spent electronics, curbing the need for new mining and shrinking the mountain of e-waste.

It’s more than just industry—universities have jumped on the bandwagon, exploring this ionic liquid in CO₂ capture and water purification. Given that carbon emissions and clean water top today’s challenges, any edge helps. The chemical’s compatibility with membranes and absorbents keeps innovation moving. I know labs where young researchers are cutting their teeth on this, learning how a liquid can nudge sustainability along.

Steps Toward a Safer, Smarter Workflow

Of course, no chemical arrives without some scrutiny. Cost, purity, and scale still need ironing out to put this liquid into every plant or lab. Based on studies from peer-reviewed journals, efforts to recycle and reclaim the solvent after use point toward more circular workflows. It’s encouraging to see both industry and academia publishing blueprints, shifting from one-off use toward repeated cycles.

From lab benches to battery packs, the journey for 1-ethyl-2,3-dimethylimidazolium tetrafluoroborate reflects a wider push for tools built with the future in mind. As long as folks keep pushing forward, chemicals like this will keep showing up in the stories behind everyday progress.

The Significance of Chemical Stability

Chemical stability touches every moment a compound lives on a lab shelf, pharmacy drawer, or production line. Instability burns through resources in research, manufacturing, and even home storage. Lapses in stability can send years of work or entire product lines down the drain. Speaking as someone who has watched lab results change overnight due to a forgotten storage note, I know the pain of lost time and wasted material.

Several personal experiences in research labs taught me that chemical stability is more than a number on a data sheet. The slow yellowing of a supposedly “stable” compound after a single week outside the fridge proved that published shelf life is not always reality. Light, moisture, and even everyday air can nick away at molecules, quietly shifting test results and product performance.

Key Threats to Chemistry on the Shelf

Air exposure invites trouble, especially with compounds prone to hydrolysis or oxidation. One week in a humid climate can ruin a batch thought to be rock-solid. Temperature swings silently push reactions forward; a warm warehouse in summer never treats a compound gently. I’ve seen crystalline powders turn sticky after forgetting them near a sunny window.

Light does more damage than most folks imagine. Sensitive compounds, especially those built on aromatic rings or double bonds, fade or break apart with only mild sunlight. COAs might boast two-year shelf life, but a sunbeam across a bench can undo that in days. Measuring real-world shelf life takes more grit than staring at lab reports — it takes opening bottles, running tests, and taking good notes over time.

Industry Standards and Real-World Practice

Pharmaceuticals, food ingredients, and specialty chemicals each carry stability testing standards. Regulatory guidelines usually demand rigorous shelf-life data under a range of storage conditions. The International Council for Harmonisation (ICH) pushes companies to evaluate compounds at multiple temperatures and humidities. ICH Q1A(R2) is the document most labs use for pharmaceuticals, but even then, results depend on real-world factors like transportation, repackaging, or patient storage at home.

Based on my experience working with small biotech startups, less-resourced operations often overestimate product shelf life. Funding gaps push companies to stretch their lots beyond expiration, risking unreliable results. On the other hand, established firms invest in stability chambers and long-term testing, providing more accurate guidance. Consistent monitoring often marks the difference between stale and fresh product.

Practical Steps for Improved Stability

Controlling environment matters most. Reliable desiccators, temperature monitoring, and proper packaging help keep compounds in shape. Nitrogen or argon atmosphere storage, especially for materials that oxidize fast, stretches shelf life longer. I remember one project saved when our team switched to amber glass and silica gel, proving packaging choices can mean everything for sensitive stock.

Label clarity counts. Mislabeled dates or ambiguous lot numbers destroy trust in shelf life claims. Sticking to a strict log, confirming expiration before use, and using first-in-first-out rotation dramatically reduce surprises down the line. Small changes in warehouse policy, like regular spot-checks, make a bigger difference than most realize.

Moving Forward

Chemical stability serves as both a science and an ongoing practice. Staying curious about evolving risks, testing under actual usage conditions, and investing in good packaging keeps shelves safe and data reliable. Every bottle’s journey from factory to bench deserves that respect.

Why Storage Matters

Anyone who’s ever spent time around chemical research knows that proper storage often makes the difference between a smooth lab day and a big headache. Working with 1-ethyl-2,3-dimethylimidazolium tetrafluoroborate (EMIM BF4), things become a bit more personal. This ionic liquid serves in battery development, green chemistry, and material science labs. Its quirky mix of stability, conductivity, and environmental friendliness has marked it as a favorite among researchers working on the next generation of electrochemical devices.

Humidity and Moisture: Uninvited Guests

Open the lid on a bottle of EMIM BF4 and let it sit out, and you’ll probably spot a problem pretty quickly. The stuff loves water almost as much as it loves conducting ions. Left in regular room air, it soaks up moisture—turning what should be a clean, tightly specified compound into a bit of a gamble. Water in the mix can throw experiments off, spoil reactions, and even promote slow degradation of the ionic liquid. If you care about reproducibility, leaving EMIM BF4 exposed wastes time and resources.

Tough Containers for a Tough Job

Glass bottles with airtight caps do a reliable job. Avoiding plastics is not just a tradition; it’s a practical step, since some can leach or degrade. Parafilm is a solid backup for short-term use, but it won’t match the seal you get from a good screw lid. For long-term stashes, amber glass keeps out stray light, which can add heat or even nudge certain reactions along. No one enjoys explaining why a whole bottle degraded from sunlight—keeping it in a cupboard or away from bright lights works better than any apology.

Cool and Dry: Practical Steps

Room temperature sounds simple, but labs run hot. If central air sputters in the summer, a cool cabinet or low-traffic shelf away from heaters helps the most. Some labs go further, storing EMIM BF4 under an inert atmosphere using a glove box, usually argon or nitrogen. That extra step keeps moisture and oxygen out if purity sets the bar high. For the average teaching or quality-control lab, a dry, well-labeled, tightly sealed container stands up well.Try not to store it next to acids, strong bases, or reactive metals. That can prevent surprise cross-reactions. I’ve seen students regret lazy sorting, so storing like with like isn’t just for neatness.

Simple Solutions, Big Payoff

The good news is these steps don’t cost much time or money. Labeling dates keeps track of shelf life and rotation. Double-checking seals after each use becomes a habit that pays off in reliable results. If you spot cloudiness or changes in viscosity, set that bottle aside. Better to troubleshoot than risk a ruined experiment.

Looking Ahead: Smarter Storage Means Better Science

After years working with specialty chemicals, I’ve learned a little patience and attention up front solves most problems before they begin. Taking care of reagents like EMIM BF4 isn’t just about following guidelines. It’s about building trust in your own results. Future researchers and projects always benefit from these small bits of discipline. Keep it dry, keep it dark, and make every experiment count.

Recognizing What’s Risky in Plain Sight

Growing up, I never thought much about what went under the kitchen sink. Bleach, oven cleaner, drain openers—they all looked like magic helpers. I figured if stores sold them, they weren't that dangerous. As it turned out, I was wrong. One day, my younger brother got into the cabinet, and I realized these products could do real harm. Many households contain hidden hazards. The risks often go unnoticed until it’s too late.

Looking Past Labels

Plenty of products come with tiny print and odd pictograms. Sometimes it feels easy to tune them out. The skull-and-crossbones or the flame pictures mean more than branding. They highlight a real risk, whether that’s poisoning, burns, or starting a fire. According to the U.S. Poison Control Centers, over two million poisoning incidents occur every year. A lot of those cases come from cleaning products, automotive fluids, or gardening chemicals used incorrectly at home.

Why Some Products Require Extra Care

Chemical companies follow strict rules. Agencies like OSHA and EPA demand clear communication about things like toxicity levels, corrosiveness, flammability, and reactivity. For instance, mixing ammonia and bleach forms poisonous gas. Simple mistakes in storage or use create emergencies. Even so, it’s easy to ignore instructions. Sometimes, manufacturers try to hide harsh realities behind pleasant branding, making it look like dish soap and oven cleaner share the same level of risk. They don’t. A splash in the eye from one might sting; the other can cause lasting damage.

Precautions That Matter

Everyone can improve safety at home with small changes. I started wearing gloves and goggles after getting a bleach splash. It stung for hours, and since then, I haven’t taken chances. Ventilating the area, separating chemicals, and locking up anything with a toxic warning became second nature. Using products with ingredients you understand helps too. Labels like “biodegradable” or “plant-based” often suggest safer options, but not always—checking the full ingredient list matters.

Workplaces sometimes have it tougher than homes. Factories, labs, and even construction sites handle acids, solvents, and fuels on a daily basis. About 94% of industrial accidents come down to human error—usually shortcuts, rushed jobs, and ignored regulations. The right training and clear labeling cut risks dramatically. Equipment like eye wash stations, chemical showers, and smoke hoods make a huge difference in a pinch.

What Solutions Actually Work?

Stricter enforcement helps. States that hold businesses accountable for poor labeling or bad training see fewer accidents. Technology like QR codes on packaging gives people direct access to safety data sheets, not just legal jargon. Community education works best, starting with schools teaching students about household chemicals. Retailers and manufacturers sharing plain-language safety advice online and in stores goes a long way.

Some companies reformulate products to reduce hazards, swapping out ammonia, strong acids, or volatile solvents for safer ingredients. This shift cuts down on risks at the source and offers better choices for families and employers.

Staying Informed and Careful

Paying attention to warning signs—both in literal labels and in your own gut—offers real protection. If a product carries words like Danger, Poison, or Corrosive, take them seriously. Storing things away from kids and pets saves lives. Having the Poison Control number nearby never hurt anyone. Learn from others’ mistakes. After years of working around chemicals and raising a family, I’ve seen how routine habits prevent disasters. With a few thoughtful steps, most risks are easy to control before they turn into headlines.

What Purity Really Means for Buyers

Purity in a product makes a real-world difference. For someone buying chemicals, food ingredients, or pharmaceuticals, seeing a product marked “99% pure” offers peace of mind and reduces risk. Impurities can mean wasted batches, unexpected reactions, or product recalls. So when companies advertise a certain level of purity, they're setting a level of trust.

In my own work, I have seen how a small drop in purity can cause headaches. When you expect a 99.5% pure ingredient and get 98.7%, adjustment becomes tricky. Quality slips become process headaches. So asking about purity before the first order is a basic but essential step.

Why Specifications Deserve a Closer Look

Beyond one number, a product’s specification sheet lays it out: physical appearance, moisture content, trace elements, and how often tests are run. Some details seem picky but often spell success or trouble. In chemical labs, for example, details like “low iron content” stop unwanted reactions. In food, knowing sodium or allergen traces keeps products safe for allergy-sensitive customers.

Clear specifications protect the buyer. They also send a message that the supplier understands the value of consistency. An ambiguous document or vague answers should draw out more questions. No one wants a batch of raw material to throw off months of careful planning.

Testing Matters: Certificates and Labwork

Suppliers who respect their customers back up claims with regular testing and share certificates of analysis. These are proof, not guesswork. In years of dealing with both big manufacturers and small shops, I have learned to ask for the paperwork. It reveals not only actual purity but shows if the supplier uses reliable labs.

Some buyers take an extra step and send a sample to their own lab before a big purchase. This approach costs extra, but it saves money when a shipment fails to match the supplier’s numbers.

How to Avoid Nasty Surprises

Details in the final paperwork should match details in earlier negotiations. Relative density, solubility, particle size—all these can matter for different uses. A buyer who ignores one of these details often regrets it later. Surprises might not show up for weeks, but they still lead to downtime or lost revenue.

Good communication with suppliers solves many issues up front. Listing the exact specification required—not just purity but all the small print—means a supplier knows exactly what to deliver. Phone calls and direct emails clear up the rest.

Solutions for Getting What You Expect

Reputable suppliers publish recent test results, make certifications easy to access, and answer technical questions without delay. If a supplier hesitates to share complete specs or is slow to send paperwork, consider it a warning sign. Trade associations sometimes keep lists of suppliers with a good track record. Talking to peers in the industry can also flag issues before an order ships.

By treating product purity and specification as more than a checkbox, both buyers and suppliers benefit. Products work as they should, processes run without hiccups, and trust builds between both sides of the deal.