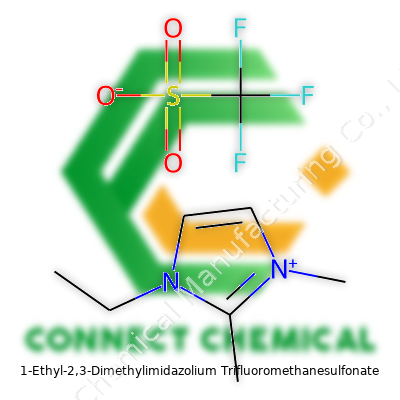

1-Ethyl-2,3-Dimethylimidazolium Trifluoromethanesulfonate: A Deep Dive

Historical Development

Looking back at the history of ionic liquids, 1-ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate stands as a testament to how chemistry keeps adapting to push the boundaries of what’s possible. In the late 20th century, researchers grew fascinated by salts that stayed liquid below 100°C. These early discoveries pointed to imidazolium-based compounds, which led to several labs racing to synthesize new derivatives throughout the 1980s and 1990s. New functional groups meant fresh properties, and this is where the ethyl and methyl groups attached to the imidazolium ring, alongside the robust, non-coordinating triflate anion, came into play. Projects combining European, North American, and Asian chemists underlined a trend: academic curiosity and industrial needs kept converging, especially as companies wanted greener and more flexible alternatives to volatile organic solvents.

Product Overview

This ionic liquid, with its catchy name shortened in lab notes to [EMMIM][OTf], has become a favorite across research and industry. Folks look for stable, nonvolatile fluids that don’t break down under a bit of heat or exposure to air. That’s where this compound delivers. The unique mix of the imidazolium core and the triflate anion gives it low vapor pressure, remarkable stability, and real versatility, putting it in high demand for processes that need less hazard and more efficiency. In my own experience, you run into this stuff when someone in the lab wants a new solvent for electrochemistry, catalysis, or separation processes. It tends to be sold as a clear or slightly pale liquid at room temperature and usually comes in bottles lined for chemical resistance.

Physical & Chemical Properties

You can count on this ionic liquid to be clear, viscous, and practically odorless. The melting point hovers below room temperature, which keeps it practical for liquid-phase work. As for density, it punches in above water at near 1.3 g/cm³. This higher density matches what you’d expect from molecules packed with heavy atoms like fluorine and sulfur. Its thermal window stretches beyond 300°C before you see significant breakdown. It barely evaporates, even if left on the bench overnight. Electric conductivity tends to fall in a decent range, especially compared to more traditional solvents, thanks to the ionic character. Polarity is another big selling point—polar aprotic behavior helps it dissolve a huge range of inorganic and organic compounds. The trifluoromethanesulfonate part supports chemical stability, even with strong acids or bases, though you always need to test compatibility when pushing into aggressive chemistries.

Technical Specifications & Labeling

Manufacturers ship this product with top marks for purity, typically better than 99%. Detailed technical sheets show water content (usually below 0.1%) and list key physical constants so researchers can match batch performance. Labels highlight the systematic name, common abbreviations like EMMIM OTf, and the CAS number. You expect to see hazard warnings aligned with GHS. Storage guidance favors cool, dry, airtight containers—open bottles guarantee a slow pickup of water from the atmosphere, which can affect experiments. On the supply side, technical documentation tracks origin, methods for quality control, and analytical data (NMR, IR spectra) to prove the substance meets specification. These details become a big deal in regulated industries or when scaling up synthesis.

Preparation Method

The journey from raw materials to bottled ionic liquid starts with the alkylation of imidazole. By adding ethyl and methyl groups in an alkylation sequence, chemists craft 1-ethyl-2,3-dimethylimidazole as a core intermediate. Next, reaction with an alkyl halide or methyl sulfate produces the imidazolium salt. Finally, a metathesis reaction swaps out the halide with sodium or potassium triflate. Careful washing and vacuum drying rid the final product of trace ions and water. Some labs work under nitrogen to ward off moisture. Each pure batch depends on patient solvent extractions, precise pH adjustment, and thorough drying before bottling.

Chemical Reactions & Modifications

Chemistry doesn’t stop with the bottled product. Researchers tweak the imidazolium ring or the trifluoromethanesulfonate anion for custom features. Functionalization on the imidazolium ring opens up ionic liquids for new catalytic or separation tasks. Sometimes, changing the alkyl groups adjusts physical behavior, like viscosity or melting point. There’s also interest in attaching pendant groups to interact with specific metal ions or organic molecules. Chemists have explored chemical oxidation, reduction, and even complexation with transition metals. I’ve seen labs test its resilience by pushing acid/base equilibria or by launching nucleophilic substitutions. It generally stands up well, but some extremes—like strong nucleophiles at high temperatures—can cause ring opening or dealkylation.

Synonyms & Product Names

This compound doesn’t lack for alternate names. In the literature, you’ll see “1-ethyl-2,3-dimethylimidazolium triflate”, “EMMIM triflate”, or the handy abbreviation [EMMIM][OTf]. Some vendors refer to it simply as “imidazolium triflate ionic liquid (ethyl, 2,3-dimethyl)”, depending on their in-house coding. The triflate counterion also gets called “trifluoromethanesulfonate”, “triflyl”, or “CF3SO3”. Product catalogs use systematic nomenclature to avoid confusion, especially given overlapping acronyms in the crowded ionic liquid space.

Safety & Operational Standards

Safety gets a lot of attention, and rightly so. Despite being less volatile than many classic solvents, this ionic liquid poses risks if handled carelessly. Skin contact can lead to irritation, especially after repeated exposure. Inhalation of aerosol or vapor brings respiratory discomfort, though actual vapor concentrations stay low at room temperature. Gloves and splash goggles form part of every protocol in my experience. Waste handling needs a thoughtful approach since breakdown products—especially from combustion—release hydrogen fluoride and other toxic gases. Disposal guidelines discourage pouring down the drain, pointing to incineration at approved facilities. Emergency protocols spell out procedures for accidental contact or spills, noting that cleanup teams need adequate ventilation and protective equipment.

Application Area

The uses for this ionic liquid touch everything from synthesis to energy storage. Chemistry labs turn to it as a reliable solvent and supporting electrolyte in electrochemistry, owing to its broad electrochemical window and thermal resilience. Synthetic chemists exploit its polarity to boost rates and selectivity in cross-coupling, cycloadditions, or organic extractions. Industrial outfits see potential in batteries, specifically non-aqueous electrolyte systems that push stability and conductivity. You’ll find studies on catalysis, separation science, gas absorption, and even biomass processing tapping into its unique ion structure. I’ve seen research teams borrow ionic liquids for lubrication and surface modification, riding on their thermal and chemical durability. Some emerging work in pharmaceutical manufacturing leverages their low volatility for greener route design.

Research & Development

Current research stretches across synthesis, process optimization, and device integration. Academics explore how different cation/anion combinations affect solvent features, measuring everything from solubility trends to reactivity profiles. R&D groups inside major chemical companies invest in process engineering, aiming to scale up manufacturing with less waste and lower costs. Teams develop polymer composites by dissolving or dispersing tough substrates in the ionic liquid. There’s plenty of not-yet-published work on tuning interfacial properties for batteries and supercapacitors. In the world of pharmaceuticals and fine chemicals, teams screen ionic liquids to replace halogenated or aromatic solvents. Funding keeps flowing to collaborations focused on tailoring properties for tech applications, evidenced by recent patent filings linking ionic liquids to next-generation solar cells and CO2 capture media.

Toxicity Research

Environmental and health scientists continue to run studies on the fate and effects of 1-ethyl-2,3-dimethylimidazolium triflate. Preliminary animal and cell-based tests suggest low acute toxicity, but researchers have flagged potential issues with chronic exposure and persistence in aquatic environments. Ionic liquids like this one often degrade slowly, raising concerns about bioaccumulation. Fish and invertebrate studies demonstrate variable toxicity, with results shaped by both the imidazolium cation and the triflate anion. Regulatory bodies want lifecycle studies plus work on decomposition pathways before scaling up to massive industrial use. With tighter REACH and TSCA oversight, manufacturing and laboratory use go hand-in-hand with regular toxicity reporting and environmental risk assessments. Work continues on developing “greener” alternatives, tweaking molecular structures to cut toxicity without losing performance.

Future Prospects

Looking ahead, this compound sits firmly on the “to-watch” lists for green chemistry advocates and industry leaders. Its blend of resilience and versatility keeps it at the center of debates over safer solvent systems. As energy storage, renewable fuel synthesis, and sustainable manufacturing keep ramping up, demand looks poised to rise. Researchers continue to experiment with custom imidazolium designs, chasing better selectivity, lower cost, and less environmental impact. Advances in computational chemistry help predict property changes before new analogs are even made, speeding up innovation. At the same time, regulatory and safety concerns drive parallel work on waste handling and end-of-life recycling. The next few years might see this ionic liquid, or next-generation variants with similar core chemistry, open doors to processes and products not yet on the market, provided labs and manufacturers stay vigilant about health and environmental challenges.

Unlocking Cleaner Chemistry

Anyone who’s worked in a chemistry lab knows the anxiety of flammable solvents and the mess they leave behind. 1-Ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate, often called an ionic liquid, brings a safer and cleaner touch. In synthesis labs, researchers gravitate to this stuff because it barely evaporates and refuses to catch fire. Swapping out volatile organic compounds (VOCs) with this ionic liquid cuts down on toxic fumes, which means fume hoods work less overtime and folks breathe easier. Environmental agencies like the EPA have pointed out that green solvents reduce lab-related hazards, and this compound fits that bill.

Battery Tech and the Push for Better Storage

Battery gurus keep chasing safer electrolytes for lithium-ion and other modern batteries. This ionic liquid shows up because it can carry ions smoothly while keeping batteries less likely to overheat. Ionic liquids don’t burst into flames under normal stress, and that becomes a selling point for electric vehicles and grid storage. Anyone paying attention to EV recalls and battery fires will know how valuable thermal stability can be. Startups and global companies try out mixtures with 1-ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate, aiming for power and peace of mind in the same cell.

Making Stronger, Lighter Parts

Materials engineers want durable, lightweight polymers for everything from airplanes to medical devices. This ionic liquid acts as a plasticizer, which means it makes polymers easier to work with and improves flexibility. Unlike old-school plasticizers, which leach out or break down under heat, this compound gives stability through a wide temperature range. It ends up in specialty polymers for electronics and lightweight parts, playing a behind-the-scenes role in innovation. The European Chemicals Agency has flagged many legacy plasticizers over safety issues; newer ionic liquids cut down risk compared to those older options.

Fieldwork in Catalysis

Ever tried running a reaction at room temperature and wished for a faster yield or cleaner separation? This ionic liquid lends itself to catalytic chemistry, helping speed up transformations without extra heat or pressure. Researchers like working with it because, after a reaction, they can often pull out products more easily, saving solvent and energy. Some catalysis teams report reusing this medium several times, trimming waste in labs and pilot plants. These cost- and waste-saving features influence the direction of new process design, especially as green chemistry standards shift worldwide.

Pathways to Cleaner Recovery

Water treatment sometimes calls for odd solutions to nasty problems. This ionic liquid offers an innovative way to extract metals from waste streams or recycle rare earths in electronics. A study out of Japan’s National Institute for Materials Science mentioned how ionic liquids outperformed older extraction methods, reducing contamination and capturing more of the metals sought after by tech makers. With e-waste ramping up every year, tackling the recovery issue without massive toxic inputs deserves attention. This compound, by design, resists water, doesn’t mix with hydrocarbons, and helps pull out stubborn pollutants.

Opportunities and Solutions

Finding better chemicals for real-world challenges always throws up new questions. Price, purity, and scale need to line up if ionic liquids are to leave the research stage and hit industry. One path forward comes from improving how these compounds get recycled after use, keeping things circular rather than single-use. Another smart move for decision-makers involves shifting funding into scalable production methods and public-private partnerships. Every new chemical technology brings promise and responsibility—1-ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate shows how the right choice can nudge chemistry toward greener, safer, and more creative solutions.

Understanding the Compound

1-Ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate isn’t exactly a household name. It falls into the class of ionic liquids—salts in a liquid state at room temperature. Lab techs and researchers use these materials for various applications: from green solvents in synthesis to electrolytes in batteries. This compound stays liquid at typical room temperatures, which provides some flexibility, but also brings specific safety questions to the table.

Health and Safety Challenges

Lab safety signs almost always include imidazolium-based liquids like this one. Most ionic liquids avoid volatility, so you don’t have to worry about inhaling clouds of vapor, but that doesn’t give anyone a free pass. If you spill it—especially on skin or into the eyes—you face irritation, redness, and in some cases, burns. The trifluoromethanesulfonate part can introduce additional risks because it breaks down into harmful substances under enough heat, especially strong acids and fluorinated byproducts. Anyone who knows their way around a glovebox or chemistry hood probably remembers the harsh smell of broken-down sulfonates.

Handling Precautions

Working with 1-ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate calls for full personal protective equipment. Gloves (nitrile or neoprene), a solid lab coat, and splash-proof goggles form the baseline. Accidents lurk in chemical labs; the buddy system and good training reduce mistakes but can’t eliminate them. Inexperienced users sometimes get reckless, and that’s how most chemical burns happen. Safe transfer techniques using pipettes or sealed syringes help minimize drops or spills. Always clean spills with materials that can neutralize acidic residues, and keep a chemical fume hood handy for weighing or pouring, even if you don’t sense vapors.

Environmental Considerations

People call ionic liquids “green” solvents because they don’t evaporate or light up easily. That reputation skips over the waste disposal issue. Many of these compounds persist in water and soil, accumulating over time without breaking down. Studies suggest some ionic liquids—especially those with fluorinated groups—can stunt plant growth and interfere with microorganisms in aquatic environments. That means waste goes in chemical disposal, never the sink. Safety routines must include segregating ionic liquid waste and labeling every container so nothing gets mixed by mistake.

Better Safety Culture Starts With Training

As experienced chemists learn, caution grows with every odd symptom after a late-night run: headaches, itchy skin, burning eyes. It’s easy to forget how a seemingly stable compound can hurt you. Label bottles, keep protocols close, and never dilute safety standards to save a few minutes. Regular refreshers on safety data sheets keep risks real in the minds of both students and pros. Reviewing a spill drill or chemical burn response at the start of every semester may feel repetitive, but few complain after an accident is avoided. Good lab culture grows out of constant reminders—not from hope or assumptions.

Room For Safer Alternatives?

Ionic liquids continue to push chemistry forward. Still, the hunt for safer chemicals should never lose momentum. Green chemistry shouldn’t stop at low vapor pressure. New designs can strip out toxic ions where possible or swap hazardous groups for ones with proven low bioaccumulation risk. Until then, solid lab habits and respect for the unknown protect everyone—from the seasoned bench chemist to the curious intern.

Getting Real About Purity

Purity tells you a lot about what you’re actually getting. Sometimes a label says 98%, and you might wonder where the other 2% wandered off to. Manufacturers measure purity with plenty of care, because every percent can change how the product acts. In my years talking shop with folks in chemical supply, purity levels can swing decisions by entire industries. Think pharmaceuticals: even minor contamination might trigger side effects or mess with a medicine’s performance. Pure material means less headache and more trust down the line.

No less important, food production leans on purity to protect consumers and keep flavor and color from shifting batch to batch. Nobody forgets the rare headlines about tainted batches that slip past quality checks. The number stamped on a certificate comes from repeated lab tests—everything from high-performance liquid chromatography to loss on drying. Skipping a corner on purity drags down the value and safety for everyone in the chain, including the final user.

Physical State: It’s Not Just About Looks

Here’s the deal: physical state affects how you handle and use a product every step of the way. Growers, lab workers, or manufacturers ask for powders, liquids, and crystals with a reason. In agriculture, powder blends dissolve quicker in spray tanks, which saves time and money fixing clogged lines. On the other hand, a sticky or clumpy version might slow things down or break the process outright.

The physical state links back to purity too. For example, moisture or air might sneak in during storage, pushing powders to cake together. Even tiny changes in manufacturing or handling make their mark. That’s why some labs stick silica gel in every shipment, or seal bags tighter than a drum. Product consistency—whether that’s fine powder, chunky granules, or clear liquid—directly decides dosing, ease of measuring, and shelf life. Early in my career, I found out the hard way: switching physical states mid-process can upend workflow, lead to miscalculations, and stack up costs.

Why Both Factors Shift Industry Standards

Regulators keep a close eye on minimum purity and physical state for a reason. Think of fertilizer and crop protection: too low in purity and plants don’t get the nutrients. Granular or dusty form? That changes how safely workers can handle and spread it. Food and beverage makers bank on strict standards to dodge recalls and plug gaps in batch flavor. Purity level and reliable state translate to smoother audits and fewer customer complaints. This isn’t just red tape—real risks push companies to set their own in-house specs above the legal floor.

Some places use third parties to double-check supplier promises, asking for regular batch samples and random tests. The best suppliers take it further, publishing detailed certificates of analysis with each shipment. Technology helps too. Automated packaging and climate controls now play a big part in keeping purity high and product stable during shipping. Talking with quality managers, I saw firsthand how they plan for every variable—heat, humidity, even vibration—in every mile a shipment travels.

Moving Forward: Solutions and Steps

Staying on top of purity and physical state always takes clear standards and frequent checks. Staff training, good lab instruments, and transparent records put companies ahead. Questions from customers push producers to go beyond the bare minimum. Modern traceability—from barcodes to digital records—makes it easier to track what’s working, and fix what’s not, before small issues snowball. My biggest takeaway? Open lines of communication between manufacturer, supplier, and end user help everyone solve problems before they end up in the news.

Why Shoddy Storage Ruins More Than Budgets

Lab life teaches some lessons fast. Go slapdash with storing chemicals, and sooner or later you come face-to-face with waste, bad data, or even flat-out danger. One compound that drives this home: 1-ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate. This ionic liquid brings efficiency to catalysis and electrochemistry, but plays by its own set of storage rules.

Moisture and Air: Not Welcome Guests

Get distracted, leave the container open for a few minutes, and you risk moisture getting in. Most ionic liquids draw in water vapor fast thanks to their hygroscopic nature. With this one, a careless cap can mean trouble—changes to composition, performance, worse shelf life. I saw two samples—one fresh, one tap-sealed and forgotten—give completely different results during a simple conductivity test. A dry atmosphere matters for more than neatness.

What Actually Works in the Real World

A tightly sealed glass bottle delivers the best results here. Polyethylene sometimes reacts or lets tiny amounts of water through, so glass beats plastic. Store away from sunlight—UV light nudges many organic molecules toward breakdown, and 1-ethyl-2,3-dimethylimidazolium trifluoromethanesulfonate falls into that camp. My old supervisor used brown glass vials, tucked in the driest cabinet in the lab, for ionic liquids—those samples lasted years, with zero odd smells or cloudy batches.

Temperature and Chemical Neighbors

Temperature swings cause headaches too. This compound handles room temperature but hates heat. Too much warmth speeds up degradation and sometimes leads to unexpected byproducts—anything above 30°C starts raising risk. Nobody wants to rerun a full synthesis just because the storage room got toasty over a summer weekend.

Don’t stack this stuff near acids, bases, or anything super reactive. Imidazolium salts aren’t weaklings, but neighboring volatile acids or bases bring up corrosion and contamination problems. Use a dedicated shelf in your chemical storage cabinet—cross-contamination ghosts have a way of sneaking into even the most careful workflows.

Labeling—The Overlooked Safety Tool

Good labeling saves more than arguments. Write out the full name, concentration if relevant, and the date you bottled it. Too many labs run on the “black sharpie, half a code” system until someone grabs the wrong thing for a reaction, trashes actual work, or triggers a near miss. One close call pushed me to double-label every ionic liquid; that habit stuck and paid off multiple times since.

Backup Moves: Use and Reuse

Reusing from a bulk container looks tempting, but every scoop invites a new risk of contamination. Pour working amounts into a secondary vial, work from there, always recap fast. Any leftover should go back into the main supply only if it stayed uncontaminated and dry. Labs focused on safety and sustainability often keep a small desiccant pouch—think silica gel or molecular sieves—in storage cabinets, trimming down moisture pickup dramatically.

Summary of Simple Habits

Care with storage isn’t just red tape or bureaucracy. Proper storage—airtight brown glass, away from sunlight, moderate temperature, low humidity, no acid or base neighbors—backs up years of reliable research and avoids dangerous surprises. Skimp here, and every lab project sits on shaky ground.

Looking at the Potential

Over the years, I’ve noticed that people tend to overlook the stories behind the compounds used in the lab. Many times, folks get excited reading headlines about some new “wonder material,” but skip digging into the details of whether that material actually works as promised, especially for electrochemical or catalytic setups. Anyone who spends time at a lab bench learns quickly that shelves stock dozens of promising bottles, but only a few live up to their early hype. Whether a compound does the job in electrochemistry or catalysis really depends on its chemical heart, its stability, and a track record confirmed by folks outside the original team.

Real Experience at the Bench

A compound’s star power rises the second it proves stable under tough conditions. Take nickel phosphide — I’ve watched a friend spend months running test after test, tracking whether the stuff flakes out under voltage swings. Other people in the next bay tried out organic frameworks hoping for hydrogen generation, but the materials would break down or leach metals. The best candidates, in my view, are the ones that power through cycles, showing up every day like a reliable coworker who doesn’t call in sick, not just once in a well-controlled article, but over and over in setups from different labs.

Stability isn’t the only story. Activity really matters. Doesn’t do much good if a catalyst shrugs off the toughest acids but barely nudges the meter. Platinum scrapes every electron from hydrogen so smoothly because its surface energy helps, even if it’s outrageously expensive. Ordinarily, groups try to swap in cheaper metals like iron, hoping for the same spark. There’s almost always a tradeoff. The dream is low cost, high punch, and a shelf life that won’t embarrass itself on scale-up.

Environmental and Safety Realities

No one can steer clear from health and safety. In my time, I’ve seen labs forced to ditch great-yielding molecules just because regulators step in. Compounds that work like a charm often bring side effects: environmental hazards, toxic byproducts, or tough disposal issues. For instance, many perfluorinated chemicals performed like magic in old batteries, only for environmental impact to rear its head. These stories push research teams to think about cradle-to-grave impact long before roll-out.

Lessons from Industry

Scale-up reveals true colors. Small batches in a research university can look promising, yet once larger reactors come into play, trouble appears. Raw material cost, reproducibility, and waste all spike as headaches, and sometimes a compound just gets too tricky or expensive to justify. I’ve seen plant managers toss out pilot runs and pivot to older, less flashy substances because they simply work without drama. Accountants can kill a compound faster than a bad toxicity report.

Finding a Path Forward

No magic bullet solves every pain point for these compounds. The honest approach means teaming up – chemists talk to engineers, environmental experts flag the pitfalls, and policy folks weigh in before big investments roll out. In one project, our team took regular feedback from the shop floor. That grounding saved months of heartache. Practical solutions usually appear when smart people step outside the literature, try things themselves, and report failures honestly.

Research and development teams will keep at it because better, safer, more affordable compounds still matter. What makes a true breakthrough is not just the right molecule, but also honest tests, safe handling, and a willingness to adapt the game plan when reality checks come in.