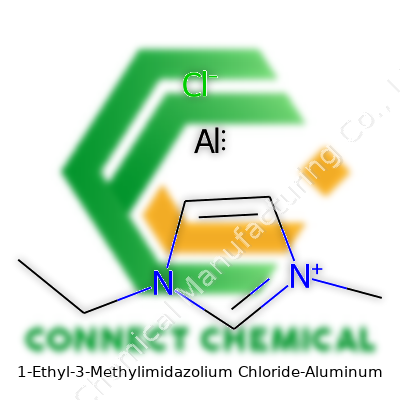

1-Ethyl-3-Methylimidazolium Chloride-Aluminum: An Extensive Look

Historical Development

Back in the mid-1990s, chemists started probing ionic liquids for their potential to replace volatile solvents. Research focused on 1-ethyl-3-methylimidazolium chloride-aluminum as a way to create new, safer electrolytes for aluminum deposition. Early studies explored how the imidazolium cation alters the chemistry of aluminum chloride, lowering vapor risk and boosting stability. Japan, Germany, and the US invested in making these systems more practical for energy storage and metallurgical uses. Technical literature from the early 2000s often cited the unique balance between ionic conduction and low volatility, unlocking non-aqueous aluminum batteries, advanced lubrication, and even niche catalysis away from water.

Product Overview

Chemists and materials engineers appreciate this compound for its properties. Blending 1-ethyl-3-methylimidazolium chloride with aluminum chloride brings out a molten salt at room temperature. It looks like a viscous, clear to yellow-green liquid. That physical form makes it different than the aluminum salts many folks picture in their heads. Most commonly, suppliers provide this ionic liquid as a premixed, stoichiometric solution tuned for electronic or surface processing needs. It’s gained ground in battery labs, pilot-scale aluminum refining, and organic synthesis units that need controlled Lewis acidity.

Physical & Chemical Properties

This material brings high ionic conductivity—often above 10 mS/cm—without the water-based corrosion many aluminum complexes suffer. Its thermal window stretches from below zero Celsius up past 100°C, supporting robust lab and industrial uses. Viscosity lands higher compared to water, so pump systems require more power. In terms of chemical stability, imidazolium-based ionic liquids often resist oxidation and hydrolysis unless strongly heated or exposed to wet air, where some degradation and hydrolysis risk appears. As workers shape new processes, they value the low vapor pressure: spills cause far fewer breathing issues compared to standard aluminum salt solutions or organic solvents.

Technical Specifications & Labeling

Most technical-grade samples contain a fixed mole ratio, such as [C2mim]Cl:AlCl3, often 1:1.2 or 1:1.5 depending on target reactivity. Certificate of analysis sheets detail major ions, water content (often kept below 500 ppm for electronics), color, and halogen balance. Repeated testing checks for metal contaminants using ICP-OES methods. Regulations in the European Union have led producers to add detailed pictograms and signal phrases for safe storage. Shipment containers must include batch numbers and preparation date so traceability never falters from synthesis to application site.

Preparation Method

Chemists usually synthesize this ionic liquid by slow, controlled addition of aluminum chloride powder into a cooled solution of 1-ethyl-3-methylimidazolium chloride under inert atmosphere. Exothermic reactions force the need for stirring and external cooling. Process scale-up moves from glovebox mixing to jacketed reactors fitted with moisture-free nitrogen blankets. Product forms after phase separation and repeated washing with dry solvents such as acetonitrile. Filtration removes excess solids, while vacuum stripping removes dissolved impurities. Analytical checks follow every step, as moisture or organic residues undermine both performance and shelf life.

Chemical Reactions & Modifications

Chemists working with this molten salt routinely tweak stoichiometry to modulate its behavior as a Lewis acid or base. More aluminum chloride sharpens acidity and shifts the ionic liquid closer to traditional metal halide chemistry. These mixed systems can act as both solvents and reactants, dissolving aluminum, forming organoaluminum complexes, or acting as a medium for electrodeposition. Addition of other metal chlorides, like FeCl3 or ZnCl2, introduces new ions for catalysis or alloying research. Sometimes, teams graft functional groups onto the imidazolium ring, tailoring viscosity or electrochemical windows for application-specific needs.

Synonyms & Product Names

Lab catalogs list this ionic liquid under several names including EMIM AlClx, [EMIM]Cl-AlCl3, or simply 1-ethyl-3-methylimidazolium aluminum chloride. Technical bulletins in Japan and Europe often abbreviate it as EMI-AlCl3 or EMIMAl. Patent filings from global battery firms sometimes describe it simply as a “chloroaluminate ionic liquid” or “imidazolium-based deep eutectic.”

Safety & Operational Standards

Safety data sheets stress the importance of moisture protection. Spilled droplets react with water, producing hydrochloric acid vapor and sometimes heat. Labs need both glove and face protection, along with splash-proof goggles during transfer or mixing. Storage plans rarely put aluminum chloride-based ionic liquids near moisture sources or food production lines. Employers offer targeted training that covers handling spills, neutralizing with sodium bicarbonate, and first-response rinsing for skin or eye exposure. Fume hoods and dry-boxes remain standard for opening fresh bottles or drumming larger volumes. While this compound lacks the acute toxicity of older aluminum solutions, labs document any breathing issues or skin reactions for occupational medicine records.

Application Area

Tech firms and research groups look to this ionic liquid for more than just academic curiosity. It long ago replaced traditional electrolytes in some aluminum electroplating processes, leading to smoother, more uniform metal layers without hydrogen evolution. In batteries, cell designers turn to it for robust aluminum-ion prototypes that cycle without gas formation or catastrophic leaks—a step ahead of older solvents. Fine chemical plants explore its use for Friedel-Crafts alkylations and acylations, cutting down hazardous waste streams. Some specialty lubrication blends use it for low-wear, non-evaporating behavior under high loads. As process engineers create new reactors, they appreciate its chemical tunability and long intervals between bath change-outs, which bring both productivity and cost savings.

Research & Development

Patent records and peer-reviewed journals show a clear surge in research since 2010. Battery consortia led by national labs in Asia and Europe now run multi-year programs to scale up aluminum-ion and even multivalent metal battery chemistries using this ionic liquid. Surface finishing research documents superior deposit morphology and energy efficiency for aluminum coatings on steel, copper, and semiconductors. Green chemistry groups dig deeper into catalytic cycles and reaction selectivity, finding new fits for pharmaceuticals and specialty polymers. Machine learning even helps crack structure-property relationships, searching for new cation or anion tweaks. As knowledge spreads, technical teams share insights on handling, recycling, and even upcycling effluent streams, aiming to make processes sustainable from start to finish.

Toxicity Research

Academic teams and regulatory bodies scrutinize this compound for chronic risks. Standard OECD testing on aquatic and mammalian cells tracks bioaccumulation and mutagenicity potential. So far, most research finds relatively low acute toxicity but flags moderate irritation and long-term environmental persistence as key points for monitoring. Workers exposed to mixed vapors in poorly ventilated rooms sometimes report throat and eye irritation, which usually resolves with prompt washing and airflow improvements. Longitudinal animal studies keep a close watch on any metabolic byproducts, particularly imidazolium ring cleavage or aluminum leaching, though sample sizes in these studies remain modest. As production scales, industry groups align with REACH and OSHA reporting protocols, supporting open science and promoting workplace surveys to catch emerging exposure risks.

Future Prospects

Commercial opportunities keep expanding for this adaptable ionic liquid. Startups experimenting with next-generation aluminum batteries believe it could break energy density bottlenecks, bringing cheaper, safer grid storage within reach. Research teams also mix this liquid with renewable feedstocks, using it for biomass reprocessing or rare earth recycling, an area sorely lacking efficient solvents. Production consistency and supply chain integrity still challenge new players, but pooling analysis data and open process benchmarks gives future buyers more trust. Industry, climate, and safety researchers maintain steady dialogue, sharing improvement roadmaps that weigh scale-up economics, energy costs, and end-of-life management. Over the next decade, the material’s success likely depends on how researchers and industry work together to address lifecycle safety, waste reclamation, and public transparency, while still fueling the innovations everyone demands from safer, smarter chemistry.

What Makes 1-Ethyl-3-Methylimidazolium Chloride-Aluminum Special?

Step into any advanced chemistry lab and glass vials of ionic liquids often catch the eye. Among them, 1-Ethyl-3-Methylimidazolium Chloride paired with Aluminum Chloride stands out. This combo forms an ionic liquid that doesn’t act much like the typical oily or watery stuff seen at home. I remember the first time I worked with it — the thick, amber liquid stuck to gloves and glassware. Later, I found out that researchers and manufacturers both keep close watch on how this mixture behaves.

Shaping the Future of Batteries

Development of rechargeable batteries doesn’t slow down. Scientists hunt for electrolytes that stop batteries from catching fire and lasting longer on a single charge. Here, this ionic liquid finds its spot. The blend conducts ions without evaporating quickly or catching fire, giving battery makers a new way to store power safely. Research papers from the past few years keep pointing to this mixture for aluminum batteries that pack more energy and use abundant raw materials. One study published in Nature Communications highlighted this electrolyte’s ability to keep working over hundreds of charge cycles.

Aluminum Electroplating without Toxic Fumes

Factories once relied on dangerous or flammable chemicals to coat metals. People on factory floors had to handle fumes and corrosive liquids, sometimes taking those problems home on their work clothes. With this ionic liquid, plating shops can deposit aluminum much more cleanly. Melting points drop, fumes vanish, and the overall process gets safer for workers. The thick liquid can flow around complex shapes, leading to even coatings that last longer than before. This isn’t futuristic — several commercial lines in Asia and Europe already use this process.

Organic Synthesis and Catalysts

Chemists always hunt for better solvents and reagents. Standard organic solvents evaporate fast and pollute the air. Using 1-Ethyl-3-Methylimidazolium Chloride-Aluminum lets teams run sensitive reactions without open flames or heavy-duty ventilation. Some synthetic steps even work faster or yield cleaner products. Having tried it myself in college, I found separating products from this ionic liquid easier than scraping sticky gunk off glassware. This reduces waste and trim costs, giving small labs the same edge as industrial giants.

So What’s the Catch?

While this compound brings a lot to the table, disposal and recycling raise some eyebrows. Ionic liquids do not break down easily. Spills can linger, harming water supplies or local wildlife. I’ve seen colleagues spend weekends filtering and reprocessing used liquid to avoid waste and keep costs down. Industry needs to set tighter standards for collecting, treating, and reusing this mixture. Some companies now reclaim and recycle, but not enough follow the best practices. Training, strong policy, and investment in recovery tech will tip the balance.

Moving Forward with Smart Choices

In the end, the success of 1-Ethyl-3-Methylimidazolium Chloride-Aluminum rests as much on smart use as technical merit. Safer batteries, cleaner metal coatings, and modern synthesis push research forward. Putting the right safety nets in place, from worker training to chemical management, lets everyone reap the rewards without trading away health or environmental quality. In my experience, openness in sharing know-how and lessons learned speeds up progress — and keeps accidents a memory, not a headline.

What’s Behind the Formula?

1-Ethyl-3-methylimidazolium chloride-aluminum doesn’t roll off the tongue, but it packs a punch in the chemical world. This name speaks to a hybrid type of salt called an ionic liquid. The chemical shorthand for 1-ethyl-3-methylimidazolium chloride is [EMIM]Cl. Start pairing that with aluminum chloride, and you get a family of compounds, usually written as [EMIM]Cl–AlCl3 or [EMIM][AlCl4], depending on how much aluminum chloride jumps into the mix. The result looks like [C6H11N2]Cl·xAlCl3, with x often around one or more. You end up with a material that’s not just salty, but also stays liquid at room temperature — pretty unusual in the world of salts.

Beyond the Lab: Why the Formula Matters

Many people haven’t brushed up against “ionic liquids” unless they spend time in a chemistry lab. Yet, these mixtures deserve attention outside of textbooks. Compared to water or oil-based solvents, they don’t evaporate easily. I remember the first time I spilled a beaker of this stuff during a college lab and noticed it didn’t leave the sharp, stinging smell most chemicals carried. Later, I learned this comes from their low vapor pressure and chemical stability. That turns out to be a big advantage for cleaner chemistry, as fewer fumes end up in the air — a direct gain for anyone working in tight lab spaces, or larger plants aiming to keep their workers safe.

Real-World Chemistry: What Do People Actually Use This For?

In the past decade, these compounds have moved far beyond niche projects. One of the most noted uses for 1-ethyl-3-methylimidazolium chloride-aluminum comes up in aluminum electroplating and battery research. Traditional aluminum smelting uses harsh molten salts and eats up heaps of energy. With this ionic liquid, aluminum can be deposited at lower temperatures, cutting back on energy demands and even greenhouse gas emissions. A study featured in Journal of Power Sources (2020) highlighted how these ionic liquids unlocked new paths for rechargeable aluminum batteries, potentially replacing more toxic, short-lived battery chemistries.

Environmental and Safety Questions

The story isn’t all rosy. Like any advanced material, safety and sustainability questions surface quickly. Ionic liquids often get praised for being “green solvents,” but not all formulas earn that badge. Some byproducts can still end up leaching into waterways. Responsible manufacturers need to assess biodegradability and toxicology, especially with aluminum in the picture. From my own graduate research years, chasing the perfect “green solvent” meant trading off between solvency power and environmental footprint. Unless upstream sources focus on cleaner inputs and downstream users recycle the ionic liquid, we risk creating a new generation of stubborn pollutants. Fact-checking studies, such as a 2019 review from Chemosphere, show that proper waste management and process design keep the actual risks low.

What Can Move Us Forward?

It helps when regulators, chemists, and engineers collaborate from the start. Rather than swinging between miracle-worker and environmental headache, these hybrid salts will need stricter labeling, tracking, and recycling incentives. More labs could share real-world spill data and life-cycle studies, making it easier for new startups to follow best practices instead of cutting corners. Solutions won’t look like quick fixes, but with solid science and some honest industry self-regulation, this family of chemicals could drive innovation, not just complication.

The Promise and Perils of Modern Chemistry

The rise of ionic liquids like 1-ethyl-3-methylimidazolium chloride-aluminum has sparked a new era in laboratory and industrial research. This compound, known as an EMIM-Cl-AlCl3 mixture, sets itself apart by staying liquid at room temperature, offering impressive conductivity, and showing promise as an alternative to more volatile solvents. These traits explain its growing popularity in battery research, metal recovery, and electroplating.

This isn’t some harmless salt you find in a kitchen cupboard. Its ingredients—an imidazolium salt and a chunk of aluminum chloride—come together to build a solution with a strong habit of reacting with skin, water, and air. In the lab, I once cracked open a glass bottle and got a whiff that felt sharp and metallic, setting off alarm bells about its interaction with moisture in the air. I’ve watched thin wisps of vapor dance from an open beaker, hinting at what even a small spill can do without proper care.

Dangers Lurking in a Clear Liquid

This compound might look harmless, but its parts tell another story. EMIM-Cl doesn’t give much trouble on its own, but mix it with aluminum chloride and the result can eat right through skin and delicate tissue. Any water in the mix triggers a reaction, producing hydrochloric acid fumes—a surefire ticket to burns, irritation, or even lasting lung damage. The scientific literature backs this up, with toxicity data indicating serious concern for both skin and inhalation exposure.

Folks in the field talk about its knack for drawing water out of the air, pulling it in to generate acids. Set that on an ungloved hand or near an unprotected face, and you risk much more than a minor rash. There’s a real reason seasoned chemists keep this material tightly sealed and stored inside gloveboxes or under dry nitrogen. Even quick mistakes—removing a stopper too fast or cleaning up a few drops sloppily—can end in burns or a mad dash to the emergency shower.

Shortcuts Don't Exist Here

Complacency leads to accidents. I remember a colleague dismissing safety data, thinking gloves and goggles would be enough. One day, a splash caught him on the wrist. His gloves slowed the reaction only slightly, but a patch of reddened, painful skin developed anyway. Between incident reports and real-world stories, patterns emerge: those who respect the dangers stay healthy, and those who ignore protocols invite trouble.

Research from peer-reviewed studies and industry guidelines continues to warn: treat EMIM-Cl-AlCl3 with the precautions you’d bring to handling corrosive acids. Wear face shields, chemical-resistant gloves, and lab coats. Work inside fume hoods to pull any fumes away from people. Double-check that containers stay closed outside of gloveboxes.

Smarter Handling and Safer Labs

Institutions and companies can’t leave safety to chance. Training needs to focus on more than just reading a data sheet. Hands-on (and gloved) practice using this liquid in real setups helps keep accidents from happening. Emergency stations such as showers and eyewashes belong within arm’s reach. Waste from experiments has to go in marked containers, never down the drain. Regular checks for leaks, drips, or failed seals help too. Putting people before productivity creates a safer workplace and saves on costly injury claims.

The bottom line stays the same: EMIM-Cl-AlCl3 deserves careful respect. Anyone thinking about using it should get familiar with real-world incidents, straight-talk safety tips, and proven best practices. Labs thrive when everyone puts caution before convenience.

Understanding Why This Matters

1-Ethyl-3-methylimidazolium chloride-aluminum brings value to labs and industries aiming for cutting-edge battery chemistry, high-performance catalysis, or advanced electroplating. But it’s a unique ionic liquid that doesn’t play by the same rules as table salt or tap water. Its reactivity with moisture and vulnerability to air means a spill or misstep could undermine research, cause corrosion, or put people at risk. I learned early in my own lab days that treating specialty chemicals with routine care only invites headaches down the road.

Moisture and Air: Not Friends Here

This compound doesn’t just dislike water; get a little humidity in contact, and you’ll see hydrolysis or corrosion creep in. In practical terms, it needs storage in a spot that keeps dampness and stray air out. I’ve watched too many research projects take a hit because a cap wasn’t tight or a desiccator got overlooked on a busy day. Airtight, non-reactive containers are a baseline. Glass with PTFE-lined caps have never let me down. Going further, a glove box with an inert atmosphere, such as nitrogen or argon, goes a long way in stopping accidental moisture exposure—especially if your lab’s climate control isn’t perfect.

Room Temperature Isn’t Always Good Enough

In most settings, you can set this compound aside at room temperature, but only after making sure light and fluctuating heat stay away. I keep mine in amber bottles to block out light, tucked away in a chemical storage cabinet that doesn’t see much foot traffic or temperature change. While 1-ethyl-3-methylimidazolium chloride-aluminum won’t freeze in a chilly storeroom, big temperature swings can break down these sorts of chemicals over time. It saves trouble to check for air conditioning vents or hot water pipes nearby.

Labeling, Documentation, and Spill Readiness

Good habits save lives and budgets. Labeling bottles clearly and keeping updated inventory records sound tedious, but confusion leads to double-handling or worse: dangerous mix-ups. In my experience, good documentation habits protect not only the current team but also anyone who inherits your stash of specialty chemicals down the road. Plus, accidents still happen. Chemical absorbents designed for ionic liquids and PPE—gloves, goggles, and lab coats—end up essential during cleanup. A dry, dedicated spill kit stored a few steps away is more than a check on a safety form; it's peace of mind.

Ventilation and Storage Location

It’s tempting to store unique materials alongside common reagents, but with reactivity and possible fume issues, I keep this compound separate. A ventilated storage cabinet, away from acids or bases, helps limit accidental cross-contamination or unwanted reactions. No one wants to discover a nasty crust or unpredictable cloud in their workspace.

Practical Takeaways for Safer Labs

Stored right, 1-ethyl-3-methylimidazolium chloride-aluminum gives long shelf life and reproducible results. Neglect the basics, and you invite chemical breakdown, damaged equipment, or safety hazards. Airtight containers, dry storage, good labeling, and a sensible location make a world of difference. These aren’t just best practices from a safety manual—they come from seeing a little care make research smoother and lab life safer for everyone.

Real Stuff, Not Just Theory

I first crossed paths with 1-ethyl-3-methylimidazolium chloride-aluminum—often called EMImCl-AlCl3—years back during a summer lab program. Most folks outside chemistry circles don’t come across this liquid often, but its role in research and industry definitely deserves some attention. Unlike common table salt or simple solvents, this material brings some unusual behavior to the table.

A Liquid with a Personality

EMImCl-AlCl3 behaves less like a regular chemical compound and more like a mixture with a twist. In solid form, the individual parts—EMImCl and AlCl3—act nothing like the resulting liquid when combined in the right ratio. Once mixed up, instead of turning into a powder or salt, you get a clear, almost oily-looking liquid at room temperature. This isn’t just neat to observe; it actually matters for work in batteries, electroplating, and even organic chemistry.

The viscosity stands out most when you try to pour or stir it. At room temperature, EMImCl-AlCl3 resists motion more than water, but not nearly as much as syrup. Its flow makes it easy enough to handle with normal lab tools. That smooth, slow-moving consistency plays a big role in how the molecules inside interact. This property reflects its nature as an “ionic liquid,” a term used for salts that stay liquid at much lower temperatures than most people expect. Regular salts, like sodium chloride, don’t melt until hundreds of degrees Celsius; EMImCl-AlCl3 is already liquid at 20°C, making it much less demanding to use safely.

No Strong Smell, But Watch Your Hands

I don’t pick up any distinct odor from EMImCl-AlCl3. Sometimes, not having a strong scent signals lower risk—but not here. It’s hygroscopic, grabbing moisture from the air and sometimes decomposing if left exposed. This affects not just storage, but also performance in real-world settings. Any researcher handling this liquid will tell you: gloves are a must, and air-tight containers help keep the mix stable.

It Drives Technology—At a Cost

This isn’t a chemical people find at home, but industries and labs rely on it for good reason. Its ability to dissolve metals, especially aluminum, makes it valuable for electroplating. The same property brings hurdles. Aluminum from the liquid can corrode certain metals, and even glassware sometimes suffers especially with acidic mixtures. Using plastics or special glass minimizes risk of damage, but adds expense.

Inevitably, safety stands as a big concern. Studies suggest EMImCl itself is less toxic than many popular solvents, yet mixing in AlCl3 changes the story. The mixture can irritate skin and eyes and causes more severe effects if inhaled. Nothing beats good ventilation and protective equipment during experiments or any sort of larger-scale usage.

Solving the Practical Issues

One barrier for greater adoption remains stability in humid or open-air environments. Solutions often involve pre-dried glove boxes and nitrogen or argon gas atmospheres. Research groups and manufacturers keep searching for additions or tweaks—sometimes swapping out EMImCl’s functional groups—for improved robustness while keeping the prized physical properties.

EMImCl-AlCl3 brought ionic liquids into mainstream research and even into some emerging battery technologies, especially for aluminum-based storage systems. Academic and industrial teams want to craft safer, cheaper, and more resilient alternatives, building on what EMImCl-AlCl3 brings to the table. Whether those efforts replace it in the future or not, this stubborn, clear liquid keeps finding its way back into advanced labs and pilot factories.