1-Ethyl-3-Methylimidazolium Chloride: A Closer Look into an Ionic Liquid Shaping Industry and Research

Historical Development

Synthetic chemists searching for greener alternatives to traditional solvents have discovered 1-ethyl-3-methylimidazolium chloride (EMIM-Cl) over the past few decades. In the late 20th century, ionic liquids drew interest for their negligible vapor pressure and ability to replace volatile organic compounds. Researchers such as Wilkes and Zaworotko demonstrated the stability and unique solvent power of alkylimidazolium salts. This research fueled excitement and catalyzed the search for better ionic liquids. EMIM-Cl quickly stood out—its relatively simple synthesis, structural versatility, and remarkable solvating ability spurred adoption across academic and industrial sectors. With increasing regulatory and environmental scrutiny on volatile organic solvents, this compound’s influence continues to grow, shaping green chemistry standards and offering a model for designing functional fluids.

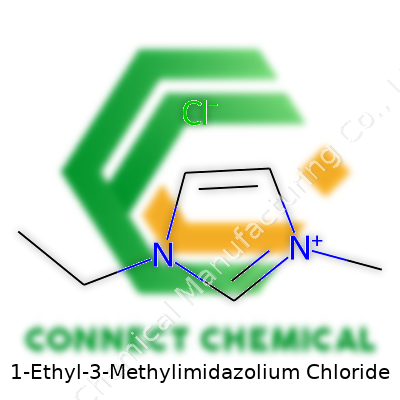

Product Overview

1-Ethyl-3-methylimidazolium chloride, often called EMIM-Cl, falls into the family of room-temperature ionic liquids—salts that remain liquid below 100°C. Its structure combines an imidazole ring with ethyl and methyl groups on the nitrogen atoms, paired with a chloride anion. Each substitution pattern brings subtle shifts to properties. Compared to traditional solvents, EMIM-Cl stands out because it doesn’t evaporate under standard conditions, remains stable for extended periods, and dissolves a wide range of inorganic and organic molecules, especially cellulose and carbohydrates. Organizations working with biomass conversion, electrochemical devices, or material synthesis turn to EMIM-Cl for its broad compatibility and durability under laboratory and manufacturing settings.

Physical & Chemical Properties

EMIM-Cl is a white to slightly off-white crystalline or powdery compound at room temperature, becoming a clear to pale liquid just above 80°C. With a melting point near 77–80°C and a density close to 1.15 g/cm³ in liquid form, it holds up under diverse handling environments. The ionic character leads to strong conductivity, often above 10 mS/cm at working temperatures. Its hygroscopic nature demands care during storage to maintain purity. EMIM-Cl dissolves easily in water, methanol, and acetonitrile. Its thermal stability stretches up to 240°C, though it decomposes at higher temperatures, releasing imidazole fragments and possibly toxic byproducts. Its strong ion-pairing helps break down hydrogen-bonded networks, enabling novel reaction environments for both dissolution and catalysis.

Technical Specifications & Labeling

A typical specification sheet for EMIM-Cl includes a minimum purity standard, often above 98%. Water content, measured by Karl Fischer titration, stays under 1.0% for most lab and industrial orders. Trace metal contaminants (sodium, potassium, iron) remain below 10 ppm, with halide impurities checked to ensure chemical consistency and avoid interference in sensitive reactions. Suppliers clearly label containers with the chemical name, CAS number (65039-09-0), batch number, manufacturing and expiry dates, recommended storage temperature (generally below 25°C, tightly sealed), and key hazard warnings. Accurate documentation supports regulatory compliance and simplifies auditing for companies and research labs.

Preparation Method

Industrial and academic labs use straightforward synthetic routes to make EMIM-Cl. One common method combines 1-methylimidazole with ethyl chloride in a closed reactor, often under mild heating and inert conditions. The alkylation yields EMIM-Cl and requires careful removal of unreacted starting materials and byproducts. Purification methods involve repeated recrystallization or dissolution in suitable solvents, followed by drying under vacuum. Quality control tests check for residual reactants using NMR or GC-MS analysis. Production scales from gram quantities for research to multi-kilogram lots for manufacturing. Fine-tuning the synthesis impacts cost, reproducibility, and scalability, which is why specialty chemical manufacturers invest heavily in process optimization and staff expertise.

Chemical Reactions & Modifications

EMIM-Cl’s ionic nature and stability allow it to serve as both a solvent and reactant. It dissolves cellulose directly, opening up new pathways for biomass processing and biopolymer derivatization. Mixing EMIM-Cl with metal salts often leads to in situ complexation or formation of new ionic liquid phases. Its chloride anion can be swapped using metathesis reactions for other anions such as tetrafluoroborate or bis(trifluoromethylsulfonyl)imide, yielding ionic liquids with different physical properties. Chemists covet EMIM-Cl’s ability to support organic transformations, like alkylations and cyclizations, without acting as an interfering solvent. Electrochemists exploit its wide electrochemical window for battery and capacitor designs, adjusting the cation or anion structure to fine-tune conductivity and stability.

Synonyms & Product Names

EMIM-Cl often shows up under several aliases, leading to confusion for early-career researchers. Some common alternatives include 1-ethyl-3-methylimidazolium chloride, EMICl, and EMImCl. Commercial distributors sometimes market it by catalog codes. Careful attention to molecular structure and CAS number reduces misidentification risks during procurement, especially with so many imidazolium-based liquids circulating globally. Project teams that streamline procurement with consistent naming conventions cut down on costly ordering and regulatory mistakes.

Safety & Operational Standards

EMIM-Cl requires careful handling practices. Contact with moisture may lead to hydrolysis and possible decomposition, so tightly sealed containers and an inert atmosphere prevent product degradation. If inhaled or swallowed, it can irritate mucous membranes and result in mild toxicity symptoms. Gloves, goggles, and lab coats serve as a basic barrier in all settings. Emergency showers and eye-wash stations need to be close by in larger industrial installations. Waste solutions, especially after chemical reactions, fall under regulated hazardous waste and require systematic disposal through qualified vendors. Fire risk from EMIM-Cl stays low, but thermal decomposition generates toxic gases. Training and access to safety data sheets lower accident rates and keep regulatory audits smooth.

Application Area

Research into new materials and green chemistry keeps turning up new uses for EMIM-Cl. Biorefinery processes depend on its remarkable ability to dissolve lignocellulosic feedstocks, leading to new cellulose-based films, fibers, and composites. Catalysis experts leverage its thermal stability and low volatility for fast, selective reactions. Analytical chemists trust its solvating power to extract, separate, or process complex mixtures without volatile solvent contamination. Companies building next-generation batteries, supercapacitors, and electrodes take advantage of its ionic conductivity, using EMIM-Cl to improve cycle life and reliability. Labs turning pressed waste biomass into biofuels or high-value chemicals see significant gains in efficiency with this solvent, shrinking energy bills and chemical footprints. Polymers, active pharmaceutical ingredients, and even nanoparticles all benefit from the tailored environments EMIM-Cl provides.

Research & Development

Dozens of R&D programs focus on improving EMIM-Cl’s production efficiency, purity, and environmental impact. Synthetic chemists work toward greener alkylation and recycling strategies for both the liquid and any byproducts. Analytical teams refine methods for detecting impurities, microtraces of metals, and anion contamination. Efforts to model the solvent-molecule interactions at a molecular level, using supercomputers and in situ spectroscopic probes, provide deeper understanding of EMIM-Cl’s behavior, feeding back into process or reactor design. Collaboration between academic centers, government labs, and private industry ensures robust technical knowledge transfer and keeps safety practices up to date. Pilot facilities scale new production techniques, closing the loop on solvent recovery and fostering cross-disciplinary innovation.

Toxicity Research

Long-term health and environmental impact studies on EMIM-Cl keep building an important data backbone for regulators and industrial safety officers. Animal studies show moderate acute toxicity by ingestion, with most symptoms resolving in under a week. EMIM-Cl causes skin and eye irritation with prolonged contact, so robust PPE protocols reduce risk significantly. Environmental models predict slow biodegradation under normal soil or water conditions, raising questions about disposal routes and lifecycle end-points. Some work explores EMIM-Cl’s effects on aquatic organisms, pushing the chemical sector toward better wastewater treatment and containment practices. These toxicity and fate studies shape laws, encourage facility upgrades, and steer research into designing safer, more degradable analogues.

Future Prospects

EMIM-Cl’s path forward looks promising, fueled by the search for non-volatile, recyclable alternatives to petrochemical solvents. Tightening emissions laws in Europe and North America already nudge companies toward ionic liquids, and years of practical experience support reasons for optimism. Research teams keep investigating structure-property links, designing new imidazolium-based salts with even lower toxicity or better biodegradation. Electrochemical engineers eye these liquids for safer batteries, water treatment modules, and renewable energy devices. Pulp and paper mills as well as agricultural biotech startups gravitate to EMIM-Cl for cost-effective, efficient conversion of renewable feedstocks. The challenges of mass production, waste management, and product stewardship invite young chemists and engineers to shape better protocols. Mentors passing down practical safety and sustainable use insights will shape the way researchers and the chemical industry deploy EMIM-Cl and its cousins.

Dissolving Cellulose for Greener Chemistry

Ask anyone working in advanced materials about dissolving cellulose, and they’ll bring up ionic liquids like 1-ethyl-3-methylimidazolium chloride. It grabs attention because it can break down natural plant fibers into manageable parts without relying on strong acids or heavy metals. In practical terms, this means researchers and industries get to skip some nasty chemicals when making materials like bio-based plastics or specialty papers. This shift matters, since fewer toxins in manufacturing leads to a safer workspace and fewer headaches over wastewater treatment.

Electrolytes in New-Age Batteries

Battery engineers keep searching for salt blends that last longer and put up with some heat. 1-ethyl-3-methylimidazolium chloride lands in their hands not for tradition, but for its ability to act as a tough, non-volatile electrolyte. Lithium batteries and supercapacitors require materials that don't break down or burst into flame under stress. Choosing a salt like this one increases battery stability and opens doors for safer devices in cars and backup power supplies. Researchers sharing real-world data on improved cycle life and performance support its adoption, especially in the push for renewable energy storage.

Catalysis and Organic Synthesis

Chemists get excited when they can skip petroleum-derived solvents in complex reactions. 1-ethyl-3-methylimidazolium chloride provides an alternative, especially for reactions where water doesn’t help. Synthesis of pharmaceutical intermediates, natural product extraction, and catalytic transformations all benefit from this liquid salt. In pharmaceutical labs where every gram and every byproduct gets scrutinized and regulated, picking a method that reduces toxic solvent waste boosts both efficiency and safety. The fact that this compound can often be cleaned up and reused speaks to ongoing improvements in chemical process sustainability.

Metals Processing Without Acid Fumes

Metal finishing shops and recyclers need better ways to extract valuable metals from complicated ores or scrap. This imidazolium salt works as a leaching agent that avoids the chlorine gas and sulfuric acid clouds of older approaches. Whether recovering rare earths for electronics or copper from wiring, plant managers have more control and spend less on corrosion protection. Better selectivity in dissolving certain metals, backed by peer-reviewed data, signals real progress in both worker safety and cost savings.

Challenges and What Comes Next

Switching over to new chemicals always stirs up practical questions. Cost and availability put limits on scale-up, with markets sometimes facing shortfalls of produced ionic liquids. Researchers keep pushing for more eco-friendly ways to make these salts from cheaper and renewable raw materials. Safety also can't be ignored—anyone in a lab knows handling ionic liquids requires gloves and good ventilation, and companies must test for toxicity before large deployments. I’ve seen success grow when lab results get verified in pilot plants, helping bridge from experiment to production line.

Looking Forward

Years of lab work and industry trials show that 1-ethyl-3-methylimidazolium chloride isn’t a miracle fix but does solve a handful of stubborn problems in several fields. Its use points chemists and engineers toward processes with less environmental impact, more control, and less risk. Sustainable progress always depends on hard data, honest review, and collaboration between researchers and industry leaders.

Getting to Know the Formula

The chemical formula for 1-ethyl-3-methylimidazolium chloride reads as C6H11ClN2. This looks like a mouthful, but it’s not as mysterious as it appears. The structure holds an imidazolium ring, which is a five-membered ring with two nitrogen atoms spaced apart. At one nitrogen, there’s a methyl group (CH3), and at the other, you’ll find an ethyl group (C2H5). Chloride, a simple Cl- anion, balances the positive charge that the imidazolium cation carries. Put simply, the cation settles into the liquid’s heart while the chloride anion circles around it.

Structure That Makes a Difference

Chloride’s story feels basic at first glance, since it’s just a Cl- ion. But 1-ethyl-3-methylimidazolium shifts the plot. If you sketch it out, the ring forms the core, one carbon with a methyl tag, another with ethyl, and the rest as part of the ring scaffold. Both nitrogen atoms share the ring but take on different neighbors: one sticking with an ethyl, the other with a methyl. The rest of this molecule builds on simple organic chemistry, but these tiny tweaks in side chains—and the presence of chloride—produce a salt that stays liquid at room temperature. That’s a standout quality, setting it apart from traditional salts we meet daily.

Why the Structure Matters in Real Life

Experience in the lab shows how this imidazolium salt behaves. For years, chemists have faced challenges dissolving cellulose, managing hazardous organic solvents, or finding greener reaction conditions. 1-ethyl-3-methylimidazolium chloride offers a way forward. This ionic liquid dissolves plenty of substances that typically resist common solvents. Its unique structure builds physical properties like low vapor pressure and impressive thermal stability into the recipe.

With so many industries working to shrink their environmental footprint, safer and reusable solvents draw attention. I remember trying to separate organic layers in a stubborn reaction mix, only to discover that certain ionic liquids like this one can do the job, cleanly, without a strong solvent odor or fire hazard. In rechargeable batteries and electrochemistry, this salt avoids water-induced breakdowns, keeping things more stable.

Real-World Potential and Room for Improvement

Scaling from the lab bench to industry brings questions about cost, sourcing, and safe disposal. Reports put imidazolium-based ionic liquids above average in cost, making them out of reach for routine, large-scale chemistry unless recycling or streamlined processes keep waste down. Research keeps pushing for bio-based routes to salts like 1-ethyl-3-methylimidazolium chloride, tapping renewable feedstocks and less energy-intensive synthesis. Scientists scrutinize toxicity too, since greener chemistry rings hollow if byproducts or spent salts harm aquatic life or disrupt soil health.

Improving recycling rates matters for making these chemicals more sustainable. One practical approach involves designing recovery systems that grab the ionic liquid after reactions, filtering out spent reagents and impurities for reuse. Universities and industry groups have begun collaborating on standards for this. Finding biodegradable analogues with similar properties would also keep waste streams safer in the long run.

Summary

Understanding the formula and shape of 1-ethyl-3-methylimidazolium chloride goes beyond textbook chemistry. Real-world reactions, new green technology, and industrial needs give this molecule its importance. The structure drives the function, and the opportunities it opens for safer, cleaner processes keep researchers coming back, looking for ways to make these compounds even better for future applications.

Understanding the Material

1-Ethyl-3-Methylimidazolium Chloride has caught the attention of researchers in labs across the world. People want to use this ionic liquid for its ability to dissolve a wide range of compounds, especially cellulose. Its chemical makeup brings unique benefits, but it also creates some risks in handling and storage.

Storage: Keeping Chemicals Secure and Stable

Leaving this chloride in an open container on a lab bench never ends well. The material picks up moisture from the air quickly, which can lead to unexpected chemical changes. I learned the hard way, with a half-used bottle turning clumpy after a weekend. Tight seals matter. Using air-tight, chemical-resistant containers such as glass with threaded caps keeps the product dry. Dense lids prevent the absorption of water, so the liquid performs as expected.

Ambient temperature often gets overlooked. This ionic liquid does not catch fire easily, but heating could break down the chemical structure. Labs without climate control may see swings, leading to degradation over time. A cool, dry spot—away from sunlight and fluctuating heat—makes a noticeable difference. I’ve seen corrosion on shelves from forgotten spills, so using solid trays and proper labeling helps people avoid accidents.

Handling Precautions

Skin contact may seem harmless with this compound, but after a few careless encounters, a recurring rash convinced me otherwise. Even if the data sheets don’t scream danger, gloves make a big difference. Nitrile gloves resist the chemical and any residue washes off easily with soap and water. Never use bare hands, not even for just a second.

Goggles protect eyes from accidental drops or splashes. No one expects a splash, but awkward bottle angles and slippery gloves make it more likely than most people admit. Tongs or spatulas work better than improvising with glass rods. Always work in a well-ventilated area, such as a fume hood, especially during transfers or mixing. Ionic liquids may not have many fumes, but getting used to proper ventilation pays off if something unexpected happens.

Disposal and Spill Response

Small spills seem like no big deal, but these liquids spread out into thin, stubborn films. Absorbent pads and neutral materials such as baking soda will soak up the bulk. Always collect waste in a labeled container, separating it from standard chemical waste. I once watched a janitor place a contaminated rag in the trash, which led to an uncomfortable conversation later. Sharing clear procedures—and posting reminders near chemical storage—saves time and headaches.

Large spills need more than a single person and a quick wipe. Bring in additional help, ventilate the area, and follow lab protocols. Alert waste management teams if the spill reaches drains or common spaces. Regularly review safety data sheets and keep updated emergency contact numbers at arm’s reach.

Building Safe Habits

Training goes further than instructions printed on a bottle. I’ve seen teams cut corners during busy weeks, which often backfires. Short safety meetings help everyone recall best practices. Proper storage and careful handling protect not only the experiment, but also the people who do the work. A safe workplace allows innovation without unnecessary risks or cleanup nightmares.

The Science Behind the Chemical

People often treat the names of chemicals like 1-Ethyl-3-Methylimidazolium Chloride as a warning label on their own. Throw “chloride” into the name and alarms start to sound. This organic salt commonly lands in research and manufacturing spaces for its use as an ionic liquid, especially in fields chasing green chemistry. The logic says, if it helps replace volatile solvents that stink up the lab and pollute the air, it must be an improvement.

From personal experience reading piles of chemical safety data sheets in the lab, the feeling of caution is justified. Even chemicals paraded as safe alternatives can carry risks that go unnoticed until problems show up years down the road. I checked the Safety Data Sheet and official hazard statements. This specific chloride won't burst into flames, but it will irritate your skin and eyes. Inhalation causes respiratory discomfort. There isn’t much evidence showing cancer risk, but allergic reactions and chronic health complaints haven’t been ruled out. I’ve seen students treat it like table salt, and that confidence misses the underlying risks.

Environmental Impact: More Than Just a Lab Story

We keep hearing that ionic liquids like this one don’t evaporate easily. That earns them the “green” label, but the full story often gets lost. Nature isn’t a perfect recycling machine, and dumping persistent chemicals into waterways brings real consequences. Research out of environmental chemistry journals points to some toxicity toward aquatic organisms. Even at low concentrations, these compounds damage the cells of water fleas and algae. It doesn’t take long for these ripples to affect larger animals in the food chain, let alone people drawing water downstream.

I remember sitting with environmental scientists in conference halls where the room buzzed about these “designer solvents.” They saw value, but they didn’t ignore the lack of long-term data. I learned that something non-volatile isn’t automatically non-toxic. Just because the air doesn’t smell doesn’t mean the harm isn’t there, quietly building up in riverbeds and sediments.

Solutions and Smart Approaches

Here’s where the conversation gets practical. Labs and chemical manufacturers can’t wave a wand and disappear the need for specialty solvents, but they can use smarter risk management. Closed systems cut down on worker exposure. Good ventilation in workspaces keeps chemical vapors from building up and stressing out lungs and eyes. Gloves and eye protection aren’t luxury accessories — a splash is all it takes for regret to set in. Training newcomers goes a long way. The times I saw careless handling usually followed a poor safety briefing, not just careless habits.

Waste disposal stands out as the next front. Pouring leftovers down the drain adds to the cocktail moving through wastewater plants. Treatment systems often fail to break down these ionic liquids fully. Companies should partner with waste specialists or advocate for better breakdown technology. Green chemistry can’t just mean “less smelly” — it should result in genuinely low-footprint solutions. This means not just focusing on immediate convenience, but weighing persistence and toxicity across the product’s life cycle.

Transparency in labeling helps. If chemical suppliers share not just basic hazards but also persistence and aquatic toxicity data, researchers and buyers make smarter choices. I’ve seen peer pressure inside scientific communities shift practices faster than regulations. Open conversation lets users compare chemicals with real-world impacts in mind, not just shiny new safety claims.

Tackling a Demanding Chemical Market

As someone who has spent years bouncing between research labs and chemical procurement offices, I’ve seen the challenge of tracking down specialized reagents like 1-Ethyl-3-Methylimidazolium Chloride. This ionic liquid might seem niche outside of academic or industrial circles, but its role in everything from catalysis to electrochemistry has pushed more scientists and engineers to include it in their arsenal. When you need it, you don’t have time for games—you want to know where it’s sold, how pure a product you can secure, and what the trade-offs are.

Main Suppliers and Sourcing Pitfalls

In today’s marketplace, reliable sources for this compound include longstanding giants like Sigma-Aldrich, TCI, Alfa Aesar, and Thermo Fisher Scientific. These companies keep inventory for a wide range of chemical users and have earned reputations for quality and traceability. Specialized outfits, such as IoLiTec and Proionic, focus even more heavily on ionic liquids, often offering more packaging and purity options.

Chemical distributors vary widely in service and pricing, especially for customers outside North America or Europe. Buying directly from manufacturers or official distributors matters—gray-market sellers on general ecommerce platforms present risks. Lax storage or documentation can turn a promising deal into a research headache. If you’re representing a lab or a business, sticking with a vendor that guarantees proper labeling and freshly sealed containers will pay off every time.

Pushing for High Purity and Why It Matters

For regular synthesis and experimental work, purity isn’t a side issue—it shapes everything. Most commercial supplies of 1-Ethyl-3-Methylimidazolium Chloride approach 98% to 99% purity, which handles many needs in research and prototyping. Higher-grade versions, sometimes listed as “ultra pure” or “electronic grade,” push up to 99.5% or greater, especially when low water and low halide contamination are critical. Your choice depends less on labeling and more on lab realities: trace metals or moisture can derail sensitive electrochemical tests or disrupt delicate organic transformations.

Some labs, including ones I’ve worked with, take the extra step and test each new batch coming in. Even from the most trusted suppliers, it’s routine to run a quick NMR or water-content assay. This isn’t excessive—project deadlines and hundreds of dollars in reagents hang in the balance. Bad batches can waste person-hours and grant money, sparking a scramble to identify and isolate the problem.

Safeguarding Quality and the Need for Transparency

The market has improved since the wild west days of opaque supply chains. Today’s best suppliers provide certificates of analysis and adequate safety data, but some outfits don’t. If a vendor dodges questions about batch analysis, shelf life, or contaminant levels, that’s your cue to walk away. Scientists have pushed the industry to open up about provenance and handling, and the result is a more transparent process—most of the time. For critical projects, ask for the latest analysis. If the number looks loose, move to a supplier willing to commit to quality on paper.

Solutions for the Next Wave of Technical Buyers

For anyone stepping into procurement for the first time, don’t rush to the cheapest or fastest option. Lean into forums, professional networks, or colleagues who have blazed the trail. Shops that understand both chemical manufacturing and the needs of end users tend to take extra care, and their reputation is built on each shipment. Keep emails and batch information—tracking quality issues depends on paper trails, and vendors respond faster to buyers who know their rights. Above all, insist on openness. Your research and your safety depend on it.