1-Ethyl-3-Methylimidazolium Iodine: A Deep Dive into a Game-Changing Ionic Liquid

Tracing the Journey: Historical Development

The world first took notice of 1-Ethyl-3-Methylimidazolium Iodine during the early push into room-temperature ionic liquids in the late 1980s. Before this, most chemists struggled with highly viscous organic salts that barely solved much for electrochemistry or synthesis. The introduction of 1-Ethyl-3-Methylimidazolium-based salts, especially with iodine as the anion, kicked open new doors for researchers chasing alternatives to volatile organic solvents. Over time, its role grew from a laboratory curiosity to a staple in cutting-edge fields like dye-sensitized solar cells and high-efficiency batteries. What’s interesting is watching how the evolution of synthetic methods—think less water, cleaner lines, and more reproducibility—matched up with the real demand for safer, greener chemicals in labs and on commercial floors.

Getting Familiar: Product Overview

The compound often goes by the shorthand EMIM-I, and you’ll spot it labeled as 1-ethyl-3-methylimidazolium iodide or just EMIM iodide on most catalogs. This ionic liquid rises above traditional electrolytes for several reasons, and you’d notice its dark color and near-waterlike viscosity at room temperature straight away. EMIM-I finds itself at the heart of many electrochemical setups, always praised for its high ionic conductivity and impressive thermal stability. In the lab, it shows up as a deep brown liquid—easily mistaken for oxidized oil until you stir it up and watch it pour with that unmistakable smoothness. The growing market for EMIM-I keeps suppliers busy, with material sourced at varying purities, but the focus remains on top performance in sensitive electronic and energy projects.

What Makes It Tick: Physical & Chemical Properties

Pull up data sheets, and EMIM-I stands out for its low melting point, usually sitting just under room temperature, which lets it remain liquid in most laboratory and industrial settings. Its density registers near 1.6 g/cm³, and it boasts high thermal stability above 200 °C before it starts breaking down. As for solubility, EMIM-I blends well with lots of polar solvents—and mixes nicely with water, alcohols, and, less commonly, with non-polar media. What keeps people coming back is its wide electrochemical window and resistance against air and light for short exposures, making it practical even in rougher working conditions. Handling EMIM-I calls for decent ventilation—the iodine leaves a faint chemical smell that lingers if left open too long.

The Details: Technical Specifications and Labeling Demands

Suppliers mark EMIM-I with its CAS number (33119-31-8), clear chemical formula (C6H11IN2), and standard purity levels ranging from laboratory grade (≥98%) up to the rare ultra-pure variants for advanced research setups. Labels follow GHS guidelines, showing iodine’s characteristic hazard alerts even though EMIM-I behaves much safer than other halide salts in practice. Technical sheets usually include details like viscosity at 25°C, typical moisture content, and heavy metal traces, which help lab staff order the right material for sensitive synthesis or analysis. Requests for custom batches aren’t rare, especially for research groups focused on energy storage or catalysis, where slight changes in purity swing results in big ways.

Cutting Through: Preparation Methods

Crafting EMIM-I feels straightforward to those familiar with imidazolium chemistry. Most start with methylimidazole, hitting it with ethyl iodide under controlled heat and atmosphere. This result leads to a straightforward alkylation, often carried out in polar solvents or even under solvent-free conditions for those pushing toward greener protocols. Technicians then purify the salt through washes with ethyl acetate or other organic solvents, stripping away unreacted reagents and ensuring a crisp final product. Handling these raw reagents takes some care, given ethyl iodide’s toxicity and volatility, but good fume hoods and glove protection have made the process routine in many well-equipped labs.

Pushing Boundaries: Chemical Reactions and Modifications

In terms of reactivity, EMIM-I plays the role of both a solvent and a participant in several organic transformations. It supports nucleophilic substitution reactions thanks to the iodide anion, which offers better leaving group ability than its chloride or bromide cousins. The EMIM cation’s unique structure also carves out space for exploring hydrogen bonding and π-π interactions, useful for catalysis and extraction. Researchers spend a lot of time tweaking the imidazolium ring and changing the side chains—sometimes swapping ethyl or methyl groups to tune solubility or ionic conductivity. Modifying the anion itself, shifting from iodide to other halides or functionalized derivatives, opens up new reactivity windows for EMIM-based ionic liquids in analytical chemistry and material science.

Names to Know: Synonyms & Product Names

You’ll come across EMIM-I under an assortment of catalog names. Most academic literature lands on 1-ethyl-3-methylimidazolium iodide, revealing its basic skeleton, but suppliers sometimes shorten this to "EMIM iodide" or even just "EMIM-I." Chemical databases might log it as N-ethyl-N’-methylimidazolium iodide or show older naming conventions depending on the country of origin. There isn’t much confusion as long as the CAS number backs up the listing, but it’s not rare for junior researchers to double-check stock bottles before starting a run.

Working Safe: Safety and Operational Standards

Handling EMIM-I safely calls for typical chemical hygiene: gloves, lab coats, and well-ventilated working areas. The primary concern always comes down to avoiding unnecessary contact and inhalation, mainly due to the iodine content, which can irritate the skin or lungs. Waste disposal needs some attention because iodine’s environmental effects raise concerns with regulatory agencies, so most labs collect spent material for specialized waste processing. On a larger scale, industries ramping up production invest in closed systems and regular training to cut accident risks. Storage works best in tightly sealed containers, in cool, dry storage rooms—limiting exposure to light and air keeps the material in good shape over longer periods.

Where It Belongs: Application Area

Most people working with EMIM-I head for research into electrochemical devices, especially dye-sensitized solar cells (DSSCs). It’s prized as an electrolyte in these cells, owing to its excellent ionic conductivity and compatibility with both organic and inorganic dyes. Beyond solar cells, EMIM-I finds strong footing in batteries—particularly lithium and sodium-ion systems—as a safer, more stable alternative to volatile organic carbonates. On the analytical side, chemists use it for liquid-liquid extraction and as a stabilizing medium in organometallic synthesis. Some even push its properties further in biochemistry, testing its gentle effects on tricky enzymes that struggle in harsh solvents. In each of these fields, EMIM-I represents a leap past legacy materials, making processes more efficient and sometimes even opening doors to new chemistry.

On the Cutting Edge: Research & Development

Current research digs deeper into the interplay between the imidazolium ring and the iodide ion. Scientists at energy institutes tried pairing EMIM-I with novel electrode materials to enhance charge transfer in high-efficiency batteries. In materials science, studies track how EMIM-I can dissolve difficult polymers or serve as an effective medium for nanomaterial synthesis. Some groups explore using EMIM-I for carbon dioxide capture, capitalizing on its chemical robustness and tunability. Over the years, grants and investment funds kept the research pipeline full, as industries from pharmaceuticals to energy storage banked on EMIM-I’s promise for scalable innovation. You don’t need to look far to find dozens of patents claiming new mixtures using EMIM-I for better performance under real-world operating conditions.

Staying Vigilant: Toxicity Research

Toxicity studies for EMIM-I tend to show low acute toxicity in comparison to traditional organic solvents, but long-term environmental research reveals lingering questions. The iodide component doesn’t break down quickly, raising flags for aquatic toxicity if released in significant quantities. In lab animals, high concentrations lead to thyroid disruption due to iodine overload, prodding regulators to urge controlled use and minimization of waste. Though no sweeping bans exist, safety data sheets urge careful handling and disposal to avoid unnecessary buildup in soil or water systems. Researchers responding to these concerns develop advanced filtration and recycling methods, cutting down the footprint left after each run. More transparent disclosure of test results and chronic toxicity studies helps everyone stay informed and adapt safer working practices.

What Lies Ahead: Future Prospects

Looking down the road, EMIM-I stands ready to play larger roles across chemistry, energy storage, and environmental remediation. Some predict rapid commercialization, especially as global demand for cleaner, safer energy production picks up steam. Improvements in preparation methods drive down production costs, while advances in purification set the stage for even wider application. Environmental researchers eye EMIM-I for new green chemistry projects, testing its limits in circular processes where nothing goes to waste. Forward-thinking teams in electronics hope EMIM-I can help unleash solid-state batteries and next-generation DSSCs. The more people learn about its strengths and pitfalls, the sharper our approach grows, balancing progress with thoughtful stewardship over this versatile compound.

More Than Just a Strange Name

Some chemicals slip right under the radar, even though they pop up in places that matter. 1-Ethyl-3-Methylimidazolium Iodine, known in labs as EMIM-I, fits that bill. Looking past the long name, it often turns up whenever people are trying to push the limits of batteries and solar panels. This compound’s big draw comes from its ability to dissolve and transport ions. It’s what scientists refer to as an “ionic liquid,” meaning it stays liquid at room temperature and doesn’t evaporate or catch fire like many traditional solvents do.

Breathing Life Into Dye-Sensitized Solar Cells

Solar technology used to rely heavily on crystalline silicon, but newer designs need something with more flexibility. EMIM-I stands out in dye-sensitized solar cells, or DSSCs for short. These cells need a liquid electrolyte that lets charged particles move efficiently. EMIM-I answers the call by remaining stable over long periods and supporting the movement of iodine ions—key ingredients for electricity generation in these devices. The main challenge many researchers hit: finding an electrolyte that won’t dry out or leak. Unlike volatile organic solvents, EMIM-I sticks around. Some published studies show its remarkable stability and low volatility helped boost DSSC lifespan and efficiency. If you’ve ever wondered why those flexible, colorful solar panels have crept into wearables or building façades, this kind of chemistry sits behind the scenes.

Opening New Paths for Advanced Batteries

Plenty of batteries struggle with electrolyte leakage or safety concerns, especially as devices shrink and expectations around energy storage rise. EMIM-I helps by providing what’s basically a non-flammable, long-lived medium for moving ions between electrodes. In lithium batteries, for instance, using EMIM-I means less risk of a sudden fire or chemical breakdown, especially in high-temperature conditions. Electrons move without overheating or clogging up the works. Real-world use isn’t widespread yet, but research labs and tech startups keep coming back to this compound whenever they design safer, more durable power sources for sensors, smartphones, or electric cars. The big sticking point is cost—for now, EMIM-I remains pricy to produce on a massive scale. Lowering production costs and proving long-term safety remain crucial steps forward.

Turning Old Challenges Into Fresh Ideas

One thing about EMIM-I: It keeps drawing out curiosity from folks in chemical engineering and clean energy spaces. People keep experimenting with its ability to dissolve difficult materials. For instance, researchers explore its role in extracting rare metals or recycling old electronics, allowing them to recover precious elements without toxic chemicals. On top of that, EMIM-I’s properties line up with “green chemistry” principles. With so many toxic industrial solvents out there, finding a liquid that dodges harsh fumes or explosions appeal to companies and communities alike. It’s not every day you find a solution that makes both innovation and environmental advocates happy.

What Stands in the Way

Wider adoption means looking at more than just chemical properties. Waste management, supply chain reliability, and long-term environmental impact need careful proof. The best future for EMIM-I likely lies in industries where its unique traits clearly outweigh the price tag and uncertainty. Collaboration between chemical producers, renewable energy companies, and regulatory bodies could help everyone figure out how much benefit there really is in shifting away from legacy solvents and older electrolytes. Above all, robust, peer-reviewed safety data will help shift opinion from theory to solid trust.

Putting Potential Into Practice

If the world wants energy systems that work smarter and cleaner, materials like 1-Ethyl-3-Methylimidazolium Iodine give us a running start. It shows that sometimes the best innovations don’t shout from the rooftop—they solve real-world headaches quietly, on the inside, until bigger change boils over.

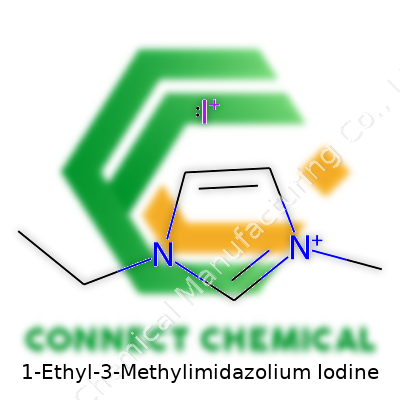

Breaking Down the Building Blocks

Chemistry unlocks secrets in tiny steps, and ionic liquids like 1-ethyl-3-methylimidazolium iodine (EMIM I) show just how creative this field can get. The basic structure features a five-membered imidazolium ring with two tailored "sidearms"—an ethyl group on the first nitrogen atom and a methyl group on the third nitrogen atom. These little modifications seem simple, yet they control the liquid's personality: solubility, stability, viscosity, and the ability to transport ions. What you get is a cation, [C6H11N2]+, paired with an iodide anion (I−).

Why Chemists Choose EMIM I

One thing stands out: this ionic liquid doesn't play by water's rules. It stays liquid at room temperature, doesn’t evaporate the way ordinary solvents do, and reliably transports both organic and inorganic components. In my university lab days, we worked with ionic liquids to sidestep the volatility of traditional solvents. No more headaches from fumes, and far less worry about handling or environmental release. The EMIM family, in particular, offers a stable framework, with the imidazolium ring favoring high conductivity and thermal reliability.

Understanding the Chemistry

Visualizing this compound begins with its imidazolium core. Ethyl and methyl groups give the molecule just enough bulk to block tight crystal formation, which explains why the material flows so easily. Attach the iodine anion, and solubility in both polar and non-polar settings opens the door for chemistry that once demanded hazardous materials. Because each ion can move independently, this blend can boost ion transport in battery electrolytes or solar cells.

The cation does more than sit around—its electrons play an active role in stabilizing charged intermediates. The large, loosely held iodide helps balance things out, making EMIM I resistant to oxidation and able to dissolve diverse compounds, from simple organics to unstable transition metal complexes. Research out of academic labs and industry alike shows EMIM I as a go-to choice for electrochemical setups, with efficiency and safety improving along the way.

Connecting Chemistry to Real-World Progress

Why does all this matter? Portable electronics and renewable energy storage depend on robust, adaptable substances. The focus shifts to materials like EMIM I, which support green chemistry by cutting down on toxic waste and energy costs. Electrolytes based on these ionic liquids last longer than aqueous ones, rarely catch fire, and stand up to wide temperature swings. As someone who's seen the struggle to find replacements for flammable, corrosive solvents, I recognize the value in a liquid that's tough, safe, and versatile.

Scientists keep pushing for better conductivity, lower production cost, and full recyclability. EMIM I provides a solid platform. Scaling up comes with challenges: purity standards, large-scale synthesis, and ensuring stability over a device’s life. Collaboration between university and industry researchers brings fresh ideas for tuning these chemicals and testing new applications.

Looking Ahead

The story of 1-ethyl-3-methylimidazolium iodine runs deeper than its formula. It signals a quiet revolution: less hazardous chemistry, more powerful devices, and a step toward a sustainable technological future. These choices reflect careful design—molecular tweaks that shape progress. Each advance helps take another step toward safer labs, greener factories, and longer-lasting technologies.

The Real Deal with This Chemical

Every lab worker or chemist who’s ever handled 1-Ethyl-3-Methylimidazolium Iodine understands that good storage is more than just a matter of keeping bottles on a shelf. This ionic liquid pops up in solar cells research and high-level electrochemistry. It stands out for its power to dissolve stuff most solvents can’t touch, but it also has a knack for picking up water out of the air. From my own days sweating over reagent shelves, I’ve seen firsthand how moisture can mess with iodine salts, turning a solid research plan into a messy headache.

Why Humidity and Light Spell Trouble

Water vapor loves to sneak into open bottles left on the bench for “just five minutes.” With ionic liquids like this one, exposure to air spells trouble. Moisture in the air triggers decomposition, and a brown mess in your flask means wasted time and wasted grant money. If the storage space sits under bright lights or gets hit by sunlight, the problem doubles. Photochemical reactions may slowly change the mixture inside, which leads to unexpected results when students or researchers try to replicate experiments. Moisture and light—these are two enemies anyone working with modern solvents dreads.

What Real-World Storage Looks Like

Experience in the lab teaches that a dry, cool cabinet with minimal temperature swings stands as the best defense for keeping chemicals in line. If I had a dollar for every time someone stuck a bottle right near a window, I could buy a new fume hood. Some researchers use a desiccator jar packed with silica gel or those blue-beads packets that turn pink when full of water. Desiccators aren’t just old-school—they stop the slow water creep and keep hygroscopic chemicals dry. For longer-term storage, the best option comes down to tightly sealed amber bottles. These dark bottles guard against both moisture and UV rays, which together keep 1-Ethyl-3-Methylimidazolium Iodine stable.

Not Just About the Chemistry

Safety walks hand in hand with storage. A spill of this iodine compound on the wrong bench can stain skin, corrode surfaces, and start an argument with the safety officer. Labels on bottles should be clear and honest—no peeling tape or barely readable ink. Hazard signs and inventory lists help prevent that frantic search for a missing reagent, and they keep everyone in the loop. From years helping train undergrads, I can say that chemical chaos breeds accidents.

Solutions for a Safer Lab Life

Simple steps go a long way. Always cap bottles right after pouring and wipe off any drips. After restocking, slide bottles into the far side of the cabinet, away from that one coworker who always leaves the door open. Keeping specialized containers on hand for problematic chemicals allows workers to respond quickly if things go sideways. Order chemicals only as needed, never in bulk “just in case”—expired stock causes more problems than it solves.

Why It Matters

At the end of the day, anyone working with 1-Ethyl-3-Methylimidazolium Iodine learns that haphazard storage costs more than just time and money. Poor storage undercuts safe research and piles extra risk onto an already tough job. Lab safety, solid chemical protocols, and a little common sense keep these powerful compounds doing what they do best—fueling new discoveries, not causing new problems.

Looking Deeper at a Modern Industrial Chemical

Lab benches didn't look quite so complicated before ionic liquids like 1-ethyl-3-methylimidazolium iodine showed up. This mouthful of a substance promises less volatile emissions and cleaner chemistry. Still, every time a bottle with a new label lands on the shelf, chemists wonder about risk, both to people and the planet.

Getting to Grips with Hazards

I have spent years around solvent cabinets, and most bottles didn’t pose much threat when handled correctly. With 1-ethyl-3-methylimidazolium iodine, you notice it lacks the strong odor you get with traditional organic solvents. That tricks some people into dropping their guard, thinking low vapor pressure means low risk. The compound doesn’t flash off at room temperature. Spills won’t fill the air with dangerous fumes, and you won't see sudden chemical burns typical of caustic acids. That doesn't mean careless hands are safe.

As of 2024, precise human toxicity data on this ionic liquid runs thin. The structure looks tame next to some alkyl halides or aromatic solvents, but you can’t forget it contains iodine and an organic ring. Chronic effects are a big question mark, with some animal studies flagging long-term exposure as a source of concern. A 2010 publication in Green Chemistry noted that imidazolium salts can trouble aquatic organisms and cells when they leak out, disrupting biological functions. Any substance that shows this much enthusiasm for dissolving stuff isn’t always harmless to tissue or the broader ecosystem.

Practical Handling and Everyday Risks

People who work in battery labs or dye-sensitized solar cell research often handle liters at a time. In these spaces, you’ll find fume hoods in regular use and gloves swapped at the first sign of a tear. I watched a junior chemist develop eczema after repeated, careless skin contact with an imidazolium salt solution. The lesson stays with you: gloves, goggles, and lab coats aren’t overkill—they are common sense until more data clears the air.

The chemical resists burning, so explosion or fire from vapor doesn’t worry most users. Storing this substance in airtight containers, away from heat and direct sunlight, prevents it from decomposing or changing color. Most disposal teams treat this compound as hazardous waste out of caution. Labs usually keep spill kits with absorbent pads. If a bottle tips, nobody pauses for a committee meeting—they clean up, wipe down, and call the waste pickup.

Building Safer Habits in the Workplace

Regulations still catch up to new materials like this one. Safety data sheets advise avoiding inhalation, skin contact, and eye exposure. From experience, short briefings and posted reminders do wonders: someone always forgets their gloves in a rush. Regular training helps people respect chemicals they consider ‘green’ or ‘modern.’ Using dedicated glassware and segregating waste keeps cross-contamination in check.

Better options for the environment and user safety exist, but they’re rare. Some research groups look for less toxic ionic liquids. Broader industry always benefits from careful substitution, routine risk assessment, and treating everything not proven benign as riskier than it seems. 1-ethyl-3-methylimidazolium iodine brings cleaner processes, but not without responsibility at every step from bench to bin.

Understanding What’s in the Bottle

The chemical 1-ethyl-3-methylimidazolium iodine often lands in researchers' shopping carts. Before opening that bottle or trusting a label, people want to know exactly what’s inside. Purity and molecular weight aren’t just numbers for the sake of scientific flex. They help answer two very practical questions: “Is this stuff pure enough for my experiments?” and “Am I measuring out the right amount for my reactions?”

Why Purity Matters—From the Lab Bench to Real Life

Most suppliers advertise purity of 1-ethyl-3-methylimidazolium iodine of at least 97%. Good labs can push it higher, even up to 99%. Anything lower could mean extra junk tagging along in your chemical. I’ve seen folks struggle with research that ran off-track because their chemicals weren’t as pure as they thought. Traces of moisture, leftover solvents, or even unwanted ions can shift results, corrode equipment, or waste grant money.

For anyone trying to create batteries or improve solar cells, small impurities can short-circuit months of work. In teaching labs, students often expect messier results, but the absence of purity information turns learning into a guessing game. Trust kicks in when a supplier shows clear certificates of analysis and matches them batch after batch.

Tracking Molecular Weight—It’s All in the Numbers

On the molecular scale, 1-ethyl-3-methylimidazolium iodine weighs in at around 252.07 g/mol. That number does more than fill a space in a table. It guides reactions, planning, and safety. If you don’t know the weight, stoichiometry calculations fall apart, and so do experiments, sometimes in dramatic fashion. People often rely on reference databases like PubChem, which lists the formula C6H11IN2. Double-checking numbers pays off before trusting a fresh bottle, because even a small error multiplies fast in a busy lab.

Academic and industrial protocols demand accuracy. Consistency across suppliers levels the playing field for collaboration. A recipe in one location should work just as well on the other side of the world, as long as people start with the same pure compound and weighted amounts. Companies with global reach insist on this kind of foundation for safety, scaling, and innovation.

Improving the Situation—Better Reporting, Simple Verification

Labs can ask for clear proofs of purity for every batch, especially for sensitive work. Chromatography, melting-point tests, and spectroscopy offer ways to double-check. Some companies now include QR codes linking to online certification for each bottle, helping researchers save time and trust the product.

Publishing purity from independent testing, not just company claims, steers the field toward open science. Journals and grant agencies can keep pushing for full transparency, so nobody gets tripped up by impurities hidden in the fine print. Proper labeling, careful documentation, and building relationships with reputable suppliers go a long way in making chemistry more robust, less wasteful, and a whole lot safer for everyone involved.