1-Heptyl-3-Methylimidazolium Acetate: An In-Depth Commentary

Historical Development

1-Heptyl-3-methylimidazolium acetate didn’t arrive on the scene overnight. The rise of ionic liquids, especially imidazolium-based salts, tracks back to the late twentieth century, when scientists began chasing alternatives to volatile organic solvents. Green chemistry started shaping policies and academic labs, and the family of 1-alkyl-3-methylimidazolium salts emerged as standout contenders. Researchers started stretching the alkyl chain lengths, hoping to find that sweet spot for stability, cost, and functionality. The heptyl derivative—balancing chain length with melting point and viscosity—gained its identity here. Adding an acetate anion built on what early ionic liquid research already knew: weakly coordinating anions help unlock powerful solvation, tunable polarity, and biodegradability, sidestepping the toxicity baggage carried by more traditional chlorides or fluorinated anions.

Product Overview

This compound steps onto the stage as a room temperature ionic liquid (RTIL), taking center position in labs hunting for benign yet robust alternatives to traditional solvents. Its key strengths fall in dissolving organic and inorganic substances, resisting water and organic solvent mixing, and holding up under thermal stress. Researchers and process engineers notice its versatility during catalysis, battery design, cellulose processing, and carbon dioxide capture. Its distinct composition—an imidazolium ring capped with a heptyl group, paired with the relatively mild acetate ion—offers a practical option for tackling problems where greener chemistry meets tough industrial demands. Applied researchers can see the difference this makes under real-world laboratory protocols.

Physical & Chemical Properties

A good look at 1-heptyl-3-methylimidazolium acetate reveals a pale to yellowish liquid, stable under air and moisture, with low vapor pressure and significant ionic conductivity. It packs a density just above water, typically ranging from 1.03 to 1.08 g/cm³, and keeps a melting point below room temperature—an attribute that matters in applications demanding continuous flow or ambient handling. Its viscosity trends upward compared to short-chain analogs, hovering between 100 and 400 centipoise at room temperature, influenced by the length of the heptyl tail and water content. Solubility runs high for polar organic molecules and many inorganic salts, bridging gaps where traditional solvents fail. Thermal stability holds into the 200-250°C range, making it a candidate for elevated-temperature synthesis and extraction.

Technical Specifications & Labeling

Quality assurance calls for tight specs: water content falls below 0.5% for most uses, and purity clocks in over 98%. The manufacturing, shipping, and usage often reference a CAS number, ensuring traceability across global supply chains. Clear labeling underscores hazards, shelf life, storage temperature—typically cool, dry, and sealed away from strong oxidizers or acids. Regulatory bodies push for detailed safety data sheets featuring hazard pictograms, clear disposal guidance, and emergency measures. For high-purity batches, residual halides, metals, and organic impurities get measured down to parts per million, supporting pharmaceutical or electronics-grade needs.

Preparation Method

Synthesis of 1-heptyl-3-methylimidazolium acetate usually kicks off with an alkylation reaction, where 1-methylimidazole and 1-bromoheptane meet in a polar aprotic solvent. The resulting bromide salt gets purified, washed, and dried before undergoing anion exchange with sodium acetate or silver acetate, stirring in water or methanol to help complete the swap. Careful drying under reduced pressure leaves behind the finished ionic liquid. What fascinates chemists here is the opportunity to tune reaction temperature, solvent, and washing cycles—each parameter influencing not only purity and color, but also performance in downstream processes. Large scale operations automate these steps, yet small tweaks remain vital for custom jobs in research or small-batch specialty chemical production.

Chemical Reactions & Modifications

This acetate-based ionic liquid holds strong in many reaction setups, from Diels-Alder to nucleophilic substitutions. Its slightly basic acetate anion can promote esterification, transesterification, and even select polymerization schemes. Modifying the cation side—such as introducing other alkyl substituents—alters physical and chemical properties, expanding its reach to tailored solubility or hydrophobicity. Researchers can swap out the acetate for other carboxylate anions, each change influencing solvation, ion-pairing, or hydrogen bonding patterns. In development labs, these modifications enable specific roles in catalysis, electrochemistry, and extraction, often outperforming legacy solvents for both selectivity and efficiency.

Synonyms & Product Names

The chemical literature and supplier catalogs list variants including 1-heptyl-3-methylimidazolium acetate, [C7mim][OAc], and HMIM Acetate. Suppliers may brand it under proprietary lines optimized for particular end-use sectors: electronics, cellulose pre-treatment, catalysis, or analytical grade standards. Its structure always comes back to the same core: a heptyl-methylimidazolium cation paired with an acetate anion, sometimes spelled out in full for regulatory documentation, other times shortened for ease in commercial or research communications.

Safety & Operational Standards

Every lab or factory using this ionic liquid takes safety seriously. Although less volatile than many organics, this substance can still irritate eyes and skin. Proper gloves and goggles keep exposure down, and local exhaust ventilation reduces inhalation during large-scale transfers or mixing. Some experience in lab safety helps here—no one wants to skimp on handling protocols for a compound that resists easy removal with just soap and water. Spills soak up best with absorbent pads, and residues get rinsed with dilute alcohols before disposal in accordance with hazardous chemical waste rules. Safety data sheets summarize everything: incompatibility with strong oxidizers or acids, thermal decomposition risks, and storage recommendations away from light or heat sources.

Application Area

1-Heptyl-3-methylimidazolium acetate fits well in green chemistry, especially in dissolving cellulose for fiber spinning or biomass conversion. Its strong solvating power comes into play for chitin extraction from shellfish waste, helping push sustainable material sourcing. Electrochemical researchers load it into batteries and capacitors, harnessing its wide electrochemical window and stable conductivity. As a solvent for organic synthesis, it often outperforms older solvents by reducing byproduct formation and making product purification easier. In CO2 capture, it helps trap and store greenhouse gases more efficiently than many amine-based systems. Throughout academia and industry, the growing interest in less toxic, recyclable solvents keeps expanding how and where this ionic liquid shows up.

Research & Development

Research groups in universities and national labs focus on unlocking niche uses, tweaking the heptyl or imidazolium structure to fine-tune reactivity or selectivity. R&D projects often target biodegradable ionic liquids—an area where acetate anions pull weight thanks to their environmental profile. Collaborations with industries in textiles, pharmaceuticals, and fine chemicals run experiments to confirm benefits observed at bench scale before scaling up. Patent filings and journal articles document incremental advances: tweaks in synthesis, performance in challenging reactions, or improvements in recyclability. For anyone supporting product development, tracking these advances offers practical benchmarks and competitive insights.

Toxicity Research

Safety testing continues to examine the biocompatibility and breakdown products after disposal or accidental release. Early evidence suggests lower toxicity than fluorinated anions or aromatic solvents, but studies still flag eye and skin irritation and potential aquatic toxicity at high concentrations. Chronic exposure studies, both in model organisms and cell cultures, help define safe working limits and support claims for greener credentials. Engineered water treatment systems test how effectively municipal processes break down or remove ionic liquids from wastewater.

Future Prospects

The search for sustainable, high-performance solvents keeps the spotlight on compounds like 1-heptyl-3-methylimidazolium acetate. Market analysts track growing demand from sectors striving for environmental compliance without sacrificing throughput or performance. Researchers push for better data on environmental impact, long-term stability, and possible recovery or recycling schemes. New application horizons open as technology crosses with tradition—not just as a replacement for tired solvents, but as an integral part of designing processes with less waste, higher efficiency, and a smaller environmental footprint. Watching industry and policy shifts, the future for this ionic liquid rests on balancing innovation with genuine insight into lifecycle impacts and real-world safety.

Industrial Curiosity, Real-World Utility

Ask folks working in advanced manufacturing about 1-Heptyl-3-Methylimidazolium Acetate, and you usually get the real story: it’s the chemical that solves headaches others can’t. Researchers began looking at ionic liquids like this when the usual methods started running up against limits. Traditional solvents let off fumes, catch fire easily, and gum up delicate processes. This unusual compound comes in handy because it’s a liquid at room temperature, but it doesn’t have those old problems. It made a name for itself in labs before trickling into wider use.

A Straightforward Path to Greener Chemistry

Factories have to keep a close eye on environmental impact. Regulations keep getting tighter, and customers want to know where their products come from. 1-Heptyl-3-Methylimidazolium Acetate fits this new world. It works well as a solvent that won’t evaporate much, so it won’t fill the air with pollution. That quality made it popular with teams breaking down wood or food waste. In pulp and paper or biorefineries, this chemical pulls apart lignin and cellulose much faster and more smoothly than older choices.

Bridging Innovation and Cost

Not every factory wants to switch chemicals overnight. Process engineers have to weigh cost, performance, and safety. I remember an industry partner balking at the price years ago, but they paid attention when their solvent waste bill started climbing. 1-Heptyl-3-Methylimidazolium Acetate pays for itself in some settings because it lasts longer and can be recovered easily. Real-world use keeps proving chemistry textbooks right: brands stay interested when a product cuts expenses and does the tricky jobs. The cost balance always comes back to its reusability and low volatility, not just up-front expense.

Supporting New Sustainable Materials

Research keeps pushing the limits of plastic recycling and biopolymer production. This chemical has shown real value in dissolving tough plastics and turning agricultural waste into something useful. For scientists developing new polymers or trying to upcycle waste, finding a tool that doesn’t damage what they want to keep or generate new toxic by-products means fewer setbacks in the lab. When working on some lignocellulose projects myself, the switch to ionic liquids sped things up and improved the yield on biofuels, which felt like a small breakthrough in a stubborn field.

What Needs Fixing?

Widespread adoption still hits a few hurdles. Large-scale use raises questions about what happens at the end of life. Some ionic liquids can hang around in water if spilled, so managers can’t afford to skip handling protocols. Better commercial supply chains help ease bottlenecks, but scaling up responsibly demands tight controls on process waste. Learning from the challenges faced by early adopters makes a difference, and more industries have started putting money into recycling technology for these special solvents.

Where Do We Go Next?

As demand for efficient and green chemistry grows, companies push chemistry experts to go beyond familiar territory. 1-Heptyl-3-Methylimidazolium Acetate fits right into that story. It carries weight beyond the lab bench; it’s changing how industries tackle tough wastes and improve sustainability metrics. Its story isn’t done yet—next steps will come from how fast industries can lower risk, control costs, and make room for new ways to solve old problems.

Getting to Know Imidazolium-Based Ionic Liquids

In the fast-moving world of green chemistry, new compounds keep showing up with interesting properties. 1-Heptyl-3-methylimidazolium acetate, often shortened to [Hmim][OAc], stands out as a kind of ionic liquid. The name looks complicated at first, but a closer look reveals every part of it matters.

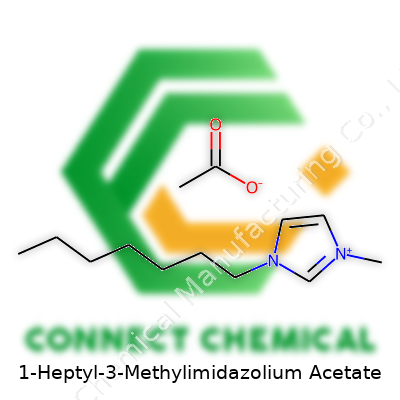

On a practical level, the chemical formula for 1-Heptyl-3-methylimidazolium acetate is C13H25N2.C2H3O2 or, written together, C15H28N2O2. You get this by combining 1-heptyl-3-methylimidazolium cation (C13H25N2+) and acetate anion (C2H3O2–). Both components play distinct roles and give the compound its signature characteristics.

What Makes the Structure Special?

The heart of this compound starts with the imidazolium ring—a five-membered structure containing two nitrogen atoms. One spot carries a methyl (CH3) group, while the other hosts a heptyl (C7H15) chain. That chain, longer than typical alkyl groups in simpler ionic liquids, changes how the substance interacts with water, organic materials, and even with cellulose. The acetate part, on the other hand, comes from acetic acid and brings a touch of biocompatibility. These building blocks form an ionic liquid that leans toward lower volatility and environmental impact.

Why Does the Formula Matter?

Lots of people working in labs want direct, clear facts. This formula, C15H28N2O2, sums up not just what makes up the compound, but also hints how it behaves in practice. Researchers find that ionic liquids like this handle cellulose much better than typical organic solvents. They can break tough bonds in plant material without creating toxic waste most solvents do. That promise led to deeper exploration in paper pulping, biofuel creation, and sustainable chemistry innovations. The acetate anion helps dissolve a range of materials without sharp odors or dangerous vapors. The heptyl group softens the melting point and can change solubility profiles. So, the formula carries practical weight—pick a different alkyl chain, or swap out the anion, and suddenly everything shifts.

Lab Experience and Daily Use

Anyone who has mixed, measured, or recovered samples in a lab knows: working with ionic liquids like this feels different. Oiliness, low odor, and stability come through right away. My own work with [Hmim][OAc] centered on dissolving plant fibers for green process trials. The results opened doors, not just in yield, but in fewer safety hazards, easier cleanup, and less stress around air quality. The chemical stability means less breakdown under gentle heating, so you don’t get nagging breakdown byproducts. Researchers watching for trace contamination or evaporation losses also appreciate having C15H28N2O2 in the toolkit. Choosing the right material often cuts energy use, accident risks, and waste costs—and this formula delivers on those fronts.

Solving Challenges and Looking Ahead

Many labs worry about cost, recycling, and disposal with new chemicals. [Hmim][OAc] still costs more than conventional solvents, but as manufacturing scales up and green regulations tighten, demand continues to rise. Researchers have mapped out recycling loops and life cycle impacts, aiming to close the loop on waste. Down the road, refining production tech and building greener supply chains will make compounds like this even more attractive. Building skills in ionic liquid chemistry pays off for students and pros alike. Knowing this formula—C15H28N2O2—means working smarter and safer, with a longer view toward health and the environment.

Getting Real About Chemical Safety

Chemical names can look intimidating. Anyone working in a lab or around manufacturers probably feels a little wary when a name like 1-Heptyl-3-Methylimidazolium Acetate makes its way onto a work order or research note. People hear “ionic liquid” or see something ending in “acetate,” and safety alarms start ringing. So it’s fair to ask: is it toxic? Is there a real hazard in using it?

Looking at the Facts

Instead of throwing guesses, I dig through studies and safety sheets before tossing on the gloves. According to the research, ionic liquids like 1-Heptyl-3-Methylimidazolium Acetate are supposed to be “greener” options. Compared to old-school volatile solvents, they don’t catch fire easily and don’t evaporate into the air as fast. The story doesn’t end there, though.

Some ionic liquids look great on paper but carry a bunch of hidden risks if people get careless. This isn’t household vinegar, but labs sometimes treat it that way out of habit. Published studies have shown that long-term impact on aquatic life can be pretty harsh, especially for fish and algae. Researchers found the imidazolium-based liquids can disrupt cell membranes, throwing off growth and development at pretty low concentrations. In humans, direct exposure on the skin or accidental splashes can trigger irritation, redness, maybe burns if you can’t wash it off quickly enough.

OSHA isn’t ringing alarm bells specifically for 1-Heptyl-3-Methylimidazolium Acetate, but workplace safety rules for handling chemicals like this line up with general guidelines: goggles, decent gloves, and a fume hood keep headaches far from reality. Some folks read that, feel safe, and carry on—a recipe for complacency.

Personal Take: Why Paying Attention Matters

Over the years, I’ve watched colleagues let toxic warnings bounce off them, and learned the hard way that careful trumps confident. We all want replacements for harsh organic solvents. But jumping on the “greener” bandwagon can trip you up if you don’t read beyond the marketing claims. Even substances with less vapor and lower risk of explosions can build up in water systems since normal wastewater treatments can’t always break them down. So you end up trading obvious danger for slow, sneaky harm to the environment.

Pushing for Smarter Handling

I’m not looking to scare anyone away; 1-Heptyl-3-Methylimidazolium Acetate can play a solid role in research and better processes. What needs to happen is simple: full disclosure on safety data, clear labeling, and regular reminders to every person working with ionic liquids. Short safety huddles or even checklists go a long way. Outdated MSDS in the bottom drawer never saved anyone’s skin.

Strong practices—like not dumping leftover liquid down any old sink and calling up a trained waste service—matter more than any glossy brochure about sustainability claims. Requiring accountability and routine reviews keeps both workers and the planet out of harm’s way. Even so-called green options can hide risks, so it’s on each of us to double-check, speak up, and push for solutions that make sense outside a brochure.

Recognizing the Realities of Handling Ionic Liquids

Anyone who’s worked with chemicals like 1-Heptyl-3-Methylimidazolium Acetate knows the storage step can easily slip into an afterthought. The task feels as routine as flipping the lights off on your way out. Yet, this chemical throws a few curveballs worth noting. It’s one thing to check the label and see "store in a cool, dry place," and another thing to actually keep those conditions consistent—especially in a lab packed with project leftovers and hasty inventory.

Why Moisture and Air Matter

Some people only remember to seal the bottle tightly, but this acetate-based ionic liquid tells a different story. It pulls in water from the air, turning from a relatively stable compound into a messier, potentially less useful product. Open containers in a humid room? You’ll notice the contents get sticky over time and the purity drops. Those small changes in water content affect how well it dissolves things, its electrical properties, and even the results in your experiments. I’ve learned the hard way that just a little carelessness makes a bottle nearly worthless for applications needing reliable performance.

Shelving and Temperature

Room temperature storage seems easy until summer rolls in, or your building’s thermostat sputters out for a weekend. Heat speeds up chemical changes, so leaving this liquid in a hot spot—on top of an instrument, near a window, or in direct sunlight—invites decomposition or slow reactions you might not notice until your yields drop. A climate-controlled cabinet beats any open shelf or cardboard box stacked on top of a radiator. People sometimes forget how quickly a simple shelf swap saves money and headaches in the long run.

Material Choices for Containers

Reusing random glass bottles or plastic jars doesn’t work with aggressive liquids. Many plastics start to break down or leach unwanted chemicals after sitting for a few weeks with this solvent inside. I’ve thrown out more than one project because of weird contamination that traced back to a cheap vial. Amber glass works best for blocking light and holding up against reactive materials. Air-tight screw caps with PTFE linings don’t swell or leak, so leaks and evaporation get cut way down.

Labeling with Details

Rapid turnover in labs means forgetting what was purchased last year and what was opened two months ago. Labels matter more than most admit. Each bottle needs clear details—purchase date, date opened, concentration, and special warnings. The habit of scribbling quick notes saves headaches months later during audits or after someone tries to repeat a result with compromised material.

Safe Handling and Longevity

1-Heptyl-3-Methylimidazolium Acetate shouldn’t sit near food, acids, or strong bases. Absorption accidents in crowded fridges or cluttered storage areas happen more often than anyone plans for. Keeping everything separated and creating a spot away from standard traffic protects both the chemical and the people using it. If small labs invest in desiccators or dedicated storage fridges, the investment almost always pays off in reliable results and fewer replacement costs.

Solutions From Experience

Routine checks don’t cost much time. Opening each bottle for a quick look during monthly inventory stops surprises down the line. Silica gel packs or molecular sieves make a big difference by keeping storage humidity low, even if the main lab gets a bit damp. Training new team members on these simple habits prevents a slow creep of questionable results. Spending a little extra on proper storage means fewer frustrations, steadier results, and far less waste.

From Lab Bench to Practical Application

1-Heptyl-3-methylimidazolium acetate lands on the chemist’s table with a reputation for being more than just a pretty molecule. It sits in a glass vial as a colorless to slightly yellow, oily liquid. Most people who pour it will notice right away how thick the stuff feels compared to regular solvents. Calling it viscous is an understatement—think more maple syrup than water. This property alone makes it a game-changer in how folks handle and store it, not to mention what kinds of jobs it can take on in the world of chemistry.

Melting Point and Handling Surprises

We don’t get snowflakes from this salt—its melting point slides in low, near -12°C. In a cold room, it may still flow, unlike older salts that form crystals if you breathe on them the wrong way. No sharp crystals or clumps, which is a real win when you’re aiming for a smooth reaction. The low melting point means you can start reactions at lower temperatures without waiting for anything to dissolve, saving both energy and patience.

Physical Properties Shaping Its Use

What sets 1-heptyl-3-methylimidazolium acetate apart comes down to what you see and feel. That oiliness goes hand in hand with stubborn stickiness. Clean it off glassware and you’ll see what stubborn really means. Density hovers between 0.9 and 1.1 g/cm³ depending on the temperature, keeping it less dense than saltwater but heavier than gasoline. Lighter molecules evaporate, but this ionic liquid stays put—barely any vapor pressure to speak of, even at a hot 100°C. That's a relief in labs where anything flammable and smelly raises eyebrows and causes health concerns.

Why Do These Features Matter?

Working with solvents, you don’t just care about calculations on paper. You remember the bite of acetone in a poorly ventilated room. You recall cleaning spills that refuse to fade from memory. Here, the lack of strong odor and low volatility means safer handling and less worry about breathing in chemicals all day. You pour some into a beaker, and it just sits there. No need for fume hoods on full blast, no headaches at the end of the day. That matters in real, practical terms for everyday lab work.

Facing Practical Challenges

This isn’t an all-purpose solution. That stickiness? It complicates cleaning. These liquids cost a fair bit too, so nobody wants to throw away contaminated samples. Adding simple filtration steps can reduce product loss. If cleanup after experiments takes longer than the experiment itself, productivity drops. In our workflows, we’ve learned to adjust. Glassware gets pre-treated with compatible surfactants or washed with warm ethanol to strip lingering residue. Increased awareness and staff training make sure everyone handles and stores these ionic liquids without accidents or wasted material.

Potential for Greener Chemistry

Green chemistry aims for less waste and reduced exposure to toxins. This particular liquid doesn’t evaporate like the old volatile solvents. That’s progress, especially in labs that value worker safety and environmental impact. It keeps more chemical inside the beaker instead of releasing it into the atmosphere. As researchers, we keep pushing for new designs that avoid tough cleanups while keeping the low volatility and handling safety that make these ionic liquids so appealing in the first place.

Looking Forward

Every lab worth its salt can benefit from safer, more manageable chemical alternatives. Understanding the physical quirks of 1-heptyl-3-methylimidazolium acetate makes that possible. A careful balance between the ease of use, reliable measurements, and environmentally friendly practices shapes its future even as challenges remain on the cleanup front. Solutions come from sharing practical experience and real fixes, not just waiting for a better molecule to show up.