1-Heptyl-3-Methylimidazolium Bromide: The Road from Discovery to Utilization

Historical Development

Chemists began studying imidazolium-based ionic liquids in the late twentieth century, searching for alternatives to volatile organic solvents. These liquids stood out because they rarely evaporate and they remain stable over a wide temperature range. In the 1990s, research groups started synthesizing and cataloging many alkyl-imidazolium salts, hoping to harness their tunable structures. By the early 2000s, interest in 1-heptyl-3-methylimidazolium bromide (often abbreviated as [Hmim]Br) rose sharply as researchers wanted longer alkyl chains for applications in phase separation, extractions, and beyond. I remember scanning countless articles during graduate studies, always stumbling across new variations of these ionic liquids in works focused on “green chemistry.” The surge in this research stemmed from ongoing public demand for safer, environmentally friendly solvents.

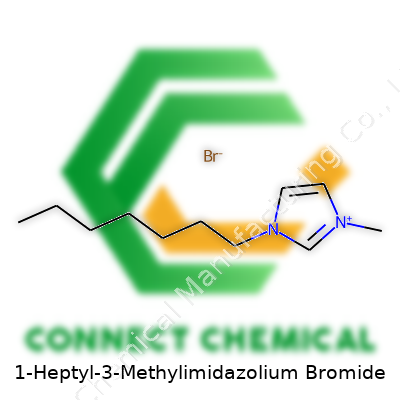

Product Overview

1-Heptyl-3-Methylimidazolium Bromide isn’t a household name, but it’s left an imprint on advanced materials science. What defines it is a bulky heptyl tail on one side of an imidazolium ring, a single methyl at the third position, and a bromide anion balancing charge. This structure offers a good mix between hydrophobicity and charge stabilization, which sets it apart from its shorter-chain siblings. Labs buy it as a crystalline, often waxy, solid or clear solution. Companies offer it in packages suitable for research as well as larger amounts tailored for manufacturing.

Physical & Chemical Properties

People who have handled 1-Heptyl-3-Methylimidazolium Bromide can quickly identify its striking viscosity. Pouring it from a vial in winter gives thick, syrupy ribbons, which isn’t surprising considering its high molecular weight and the long alkyl chain. The ionic structure grants it a high melting point, often well above room temperature, yet with enough heat, it flows and dissolves many organic and inorganic compounds. It fares well against water yet mixes with some polar solvents, thanks to the balance between the imidazolium head and the hydrophobic heptyl. This duality makes it polar enough to dissolve ionic species but nonpolar enough to act as a phase transfer medium. The bromide ion, quite reactive, often dictates the liquid’s behavior in coordinated reactions.

Technical Specifications & Labeling

Companies list purity as a key technical feature, and most demand at least 98%. High purity limits byproducts during sensitive reactions. Every batch comes with labeling that highlights the compound’s CAS number (171058-18-9), molecular formula (C11H21BrN2), and formula weight (261.21 g/mol). Regulatory information, including hazard statements and recommended storage, accompanies each shipment. This labeling, in my view, reflects hard lessons labs have learned over the years: careless handling or mislabeling, even with less “volatile” chemicals, makes for disaster. Storage recommendations focus on keeping it dry and out of light at ambient temperatures to avoid decomposition.

Preparation Method

To make 1-Heptyl-3-Methylimidazolium Bromide, chemists typically quaternize 1-methylimidazole with 1-bromoheptane under reflux. This reaction drives alkylation on the imidazole ring, gradually loading on the lengthy heptyl group. The mixture usually requires extensive washing with polar solvents to remove unreacted starting materials and byproducts. I found lab notebooks from my own research years are full of these salt syntheses — with purification often consuming more hours and resources than the initial reaction itself. Once isolated and dried, the product is checked for leftover solvents or unreacted reagents by NMR or chromatography.

Chemical Reactions & Modifications

With a lab bench full of imidazolium salts, it’s clear how minor structural tweaks can shift reactivity. Substituting the bromide for another anion, such as PF6- or BF4-, drastically changes solubility and thermal stability. Complex reactions, like catalytic hydrogenation, run differently in this medium. The cationic nature of 1-Heptyl-3-Methylimidazolium Bromide enables strong coordination with transition metals, stirring up interest among researchers hoping to tune reaction outcomes. The imidazolium ring resists breakdown across many conditions, opening up modifications around the alkyl chain without losing the core identity of the compound. In my experience, this level of structural control fuels both academic exploration and industrial applications.

Synonyms & Product Names

Suppliers don’t always use one standard name. Catalogs list this compound as N-Heptyl-N'-methylimidazolium bromide, 1-Heptyl-3-methylimidazolium bromide, HmimBr, or even HMI-Br. Such variety sometimes complicates direct searches. Over the years, I’ve noticed confusion in orders, and sometimes delayed experiments, because two labs used slightly different naming conventions. Regulatory agencies often push for clarity, but everyday research still wrangles with overlapping synonyms as compounds cross between chemical, biological, and engineering work.

Safety & Operational Standards

Despite a “green” reputation compared to many organic solvents, 1-Heptyl-3-Methylimidazolium Bromide demands careful handling. Even small exposures can irritate skin and eyes; inhalation of dust or vapors irritates respiratory tracts. Protective gloves, glasses, lab coats, and fume hoods always stay close when working with any ionic liquid. Spills turn sticky and hard to wipe up — another reminder not to treat “low volatility” chemicals as harmless. Waste disposal follows rules for halogenated organic materials because bromide ions, with time, add up in effluent. Oversight by local safety committees enforces strict labeling and containment standards, and every new use requires risk assessment, building a culture of cautious, responsible handling.

Application Area

The biggest contribution of 1-Heptyl-3-Methylimidazolium Bromide is its role as a designer solvent and reaction medium. Chemical engineers use it in separations and catalysis; biotechnologists have probed its effect on enzyme stability and extraction. Extraction of rare earth elements, dissolution of cellulose, stabilization of difficult organometallic catalysts, and selective phase separations in multi-component mixtures all lean on this compound. Academic labs keep it on the shelf for test reactions involving hard-to-dissolve salts or as a model for ionic behavior. In one of my own collaborations, I saw its use in microextraction procedures deliver higher product purity than traditional solvents, speeding up the research workflow.

Research & Development

Current research focuses on expanding the utility of these ionic liquids while reducing their costs and environmental footprint. Adjustments to the alkyl chain, swapping out the halide, or combining 1-Heptyl-3-Methylimidazolium cations with different functionalized anions shifts not just solubility, but selectivity for specific tasks. Labs involved in green chemistry push for broad adoption in industry to replace volatile and toxic solvents. They also look at ways to recycle and reuse spent ionic liquids. Notably, emerging research into deep eutectic solvents sometimes leverages imidazolium compounds, aiming to sidestep the environmental costs of halides.

Toxicity Research

Toxicity sits under constant review as novel solvents appear on the market. Initial hopes painted 1-Heptyl-3-Methylimidazolium Bromide as benign, yet more recent animal studies and aquatic toxicity screens reveal moderate risk to fish and invertebrates, particularly at higher concentrations. Chronic exposure, in cell lines, shows membrane disruption and modest enzyme inhibition. This brings home a point: chemical structure determines not just performance but potential harm. Environmental groups and regulatory bodies demand more comprehensive testing, which often lags behind commercial enthusiasm. Developing less toxic analogues remains a major focus for chemical firms aiming for both performance and environmental stewardship.

Future Prospects

Looking ahead, the future of 1-Heptyl-3-Methylimidazolium Bromide hinges on green chemistry priorities and regulatory trends. Firms want affordable, recyclable ionic liquids for emerging industries like battery technology, pharmaceutical synthesis, and rare earth extraction. Researchers race to develop closed-loop systems that trap, purify, and reuse ionic liquids, easing pressure on supply chains and waste disposal needs. Competition from eutectic mixtures and bio-based solvents drives a steady push for innovation and risk reduction. The next decade will see progress through collaborations that blend academic creativity with industrial pragmatism, ensuring safer working conditions and real environmental gains.

The Shape of a Molecule Shapes Its Impact

Staring at a chemical name like 1-Heptyl-3-Methylimidazolium Bromide, I remember feeling lost in my undergraduate chemistry classes. Names tangled up with numbers, but each told a story about what the molecule looks like and, more importantly, how it behaves. The structure of 1-Heptyl-3-Methylimidazolium Bromide, commonly known in research circles for its shorthand [C7mim]Br, holds more importance than just its mouthful of a name.

Breaking Down the Structure

At its core, this molecule features an imidazolium ring—a five-membered structure holding two nitrogen atoms and three carbons. For 1-Heptyl-3-Methylimidazolium Bromide, one of those carbons wears a methyl (–CH3) group, and another carries a heptyl (seven-carbon, straight-chain) group. Picture a hexagon with a little stick and a long rod jutting out. Think of the methyl group as a speed bump, and the heptyl chain as a waterslide. On the sidelines stands bromide (Br–), balancing the positive charge on the imidazolium ring.

Why This Structure Matters in the Real World

I once watched a Ph.D. candidate spill a vial of this stuff in the lab. She wasn’t worried about the mess much as she was about the solvent properties. Unlike most table salt, 1-Heptyl-3-Methylimidazolium Bromide is an ionic liquid at room temperature. The long heptyl chain plays bodyguard, crowding the molecules, making it tough for them to form a rock-solid crystal. Instead, the liquid acts like a clever solvent.

That soft, oily texture means researchers working with sensitive reactions don’t have to wrestle with flammable organic solvents or messy water-based systems. The structure isn’t just lining up on research posters; it’s steering real choices in green chemistry, pharmaceuticals, even battery science. Changing a side chain—swapping the heptyl for something shorter—can tweak melting points, viscosity, and even toxicity. It’s like switching the wheels and frame on a bike; the ride changes for every user. Structures that look small move the levers on how safe, sustainable, or scalable a chemical becomes.

Risks and Responsible Choices

The longer carbon tail, as seen in the heptyl group, usually ramps up hydrophobic properties. That can mean lower solubility in water and higher potential to stick around in the environment. A study from the mid-2010s out of Germany raised questions about the fate of these ionic liquids in aquatic environments, noting their persistence compared to shorter-tailed cousins. So, organizations focused on responsible chemistry are pivoting toward designing and testing molecules that strike a balance between performance and environmental footprint.

Solutions in Development

Green chemistry researchers are digging into how to swap out long-tailed chains or introduce biodegradable tweaks. Some are even pushing for closed-loop recycling setups in the lab, where spent solutions of 1-Heptyl-3-Methylimidazolium Bromide flow back to recovery tanks instead of drains. Educators, too, are nudging the next generation to check both structure and consequence—reminding students that every chain, ring, or side group eventually meets the real world.

Few things in life are truly isolated. One lab accident or one new solvent recipe carries a ripple you don’t see coming. Understanding the structure of a molecule like 1-Heptyl-3-Methylimidazolium Bromide means knowing how it moves, how it lingers, and where it leaves its mark.

A New Face in Chemical Applications

Chemists are always looking for materials that help get reactions moving more efficiently, safely, and in a cleaner fashion. One new name on the block is 1-heptyl-3-methylimidazolium bromide, known to researchers as a type of ionic liquid. These liquids hold a lot of value since they often swap out traditional organic solvents, which come with their own set of problems.

Why Ionic Liquids Grab Attention

Back at university, many of us dreaded dealing with organic solvents. They smell, evaporate quickly, and raise safety concerns. Laboratories working with greener chemistry now reach for ionic liquids because they don’t evaporate as easily and bring better thermal and chemical stability. This means labs generate less hazardous waste, protect workers from fumes, and often see better yields in reactions. A study by Rogers and Seddon in Science (2003) outlined how using ionic liquids helped reduce toxic waste in pharmaceuticals by up to 50%.

Main Uses in the Lab

1-Heptyl-3-methylimidazolium bromide shines in catalysis. Its unique structure helps dissolve a range of compounds, so chemists use this feature to run reactions more smoothly. Often, the ionic liquid operates as a supporting player, holding onto catalysts and even letting scientists recycle them. In one industrial process, this cuts both waste and costs.

This compound also supports extractions. Traditional solvent extraction often gets messy and loses product or purity. By using ionic liquids in this sort of task, folks working with medicinal plants or rare earth elements keep more of their yield and stay away from environmental headaches.

This Liquid and Renewable Energy

Batteries and fuel cells rely on materials that conduct ions without leaking or degrading fast. Some ionic liquids, including 1-heptyl-3-methylimidazolium bromide, improve these systems by resisting water, acids, and high temperatures. A 2021 study in Electrochimica Acta showed these liquids let certain battery cells reach longer cycle lives and stay safer under stress.

Stepping into the World of Biomolecule Handling

Researchers handling delicate DNA, proteins, or enzymes often face breakdown once samples hit a chemical bath. Some groups started using this ionic liquid to help keep biomolecules intact during analysis. In one reported experiment, enzyme activity held steady at higher temperatures, letting companies process food and biopharmaceuticals at bigger scales. This hints at both better quality control and less waste.

Challenges and Honest Hurdles

No chemical fixes everything. For example, sometimes ionic liquids linger longer in the environment than expected. Some manufacturers scramble to find solutions, like tweaks to the molecular structure or new recycling protocols. The price can also frustrate researchers, so scale-up will only catch on once economics tip in the right direction. There’s a call for more real-world toxicity studies before these compounds see routine field use.

Keeping Science Accountable

Consistent transparency around results, long-term safety, and honest supply chain assessments help ensure advances like 1-heptyl-3-methylimidazolium bromide support both industrial progress and health. Collaboration between academic labs and industry partners brings better scrutiny, more data, and honest debate—key points anyone working in chemistry can take to the bank.

Making Sense of Chemical Safety in Everyday Labs

Working in labs long enough, you pick up a sixth sense about which bottles stay out on the bench and which deserve a special spot in storage. 1-Heptyl-3-methylimidazolium bromide doesn’t belong with the everyday solvents or snacks in the office fridge. It’s a specialized ionic liquid, often described in papers exploring catalysis or green chemistry. It raises questions beyond simple shelf space—namely, about keeping researchers and the work environment safe.

Why Storage Choices Matter

This compound holds a place in labs aiming to swap out volatile organics for safer options. Its low vapor pressure offers a break from fumes, but the bromide anion tells a story of possible corrosion and reactivity risk. The imidazolium ring brings its own profile—some studies point to moderate toxicity if handled carelessly, though nothing you’d compare with classic benzene hazards. That doesn’t excuse taking shortcuts.

Practical Storage Steps

Safe storage for 1-heptyl-3-methylimidazolium bromide begins with a dry, cool, and well-ventilated cabinet. Humidity can mess with the quality of many ionic liquids, leading to clumping or unexpected reactions. From experience, desiccators prove handy—silica gel inside zaps stray moisture, and it becomes a habit to swap out desiccant packs every couple weeks. Leaving the lid cracked or the bottle uncapped, even for a short time, lets air and water sneak in. Glass containers, preferably amber, help control light exposure, while plastic may react or leach, especially over long months in storage.

Some labs go a step further and restrict liquid storage to corrosion-resistant shelves. Bromide ions love to rust out plain steel—it ate through an old shelving unit back at the university, teaching staff to move anything salt-based clear of metal. Any spill calls for gloves and goggles, with the cleanup kit close by, not buried in a distant storeroom.

People Make Mistakes; Clear Labels Prevent Trouble

Confusion in chemical storage often starts with a missing or faded label. Permanent marker won’t cut it when solvents and humidity eat away ink. Spend a little extra for laminated, printed labels; add the date, concentration, and any hazard warning. More than once, old sample bottles mixed up with active reagents led to spoiled runs and headaches in the lab. Marking the container with its hazard class forces even the busiest researcher to pause and check their handling.

Thinking Beyond Your Own Bench

A big part of chemical safety comes from not working alone. Share tips about how to handle less-common items—pass on the trick with silica gel or which shelf stays safest. Share those MSDS sheets and keep them close, not hidden in a folder on some forgotten desktop. If you see a bottle sweating or leaking, replace it, report it, and track how long bottles sit unused. No one wants a surprise from an aging, half-evaporated compound months after the original user moved on.

Solutions That Stick

Building good storage habits outpaces any fancy monitoring system. Double-check bottle closures, keep incompatible chemicals apart, and never let containers block vent fans. Routine inspection—say, once a month—catches little mistakes early. If a container looks odd or a smell builds up, treat it seriously straightaway.

Storing 1-heptyl-3-methylimidazolium bromide safely boils down to common sense, teamwork, and a refusal to let small risks pile up. Most people in science respect these rules once they’ve seen what goes wrong. It’s all about protecting people and the work they pour themselves into every week.

Looking at the Hazards in the Lab

Anyone who’s spent time working with chemical compounds will tell you: the devil hides in the details. On paper, 1-Heptyl-3-Methylimidazolium Bromide falls into the family of ionic liquids—salts that usually stay liquid at room temperature. That family built a reputation for replacing volatile organic solvents in green chemistry projects. Still, that green halo dims when you peer closer at health and safety data.

Material Safety Data Sheets for 1-Heptyl-3-Methylimidazolium Bromide flag several red flags. Contact with skin and eyes triggers irritation. Breathing in dust or vapors presents risks for workers, especially in confined or poorly ventilated spaces. There’s not enough research to say this compound is a definite carcinogen, but lack of proof isn’t the same as proof of safety. Anyone handling large quantities wears gloves, goggles, a lab coat, and works under a fume hood for good reason.

Toxicity: What the Studies Say

Reports about toxicity come in pieces. Some studies point out imidazolium-based ionic liquids mess with aquatic life. Fish and algae don’t do well after exposure, even at lower concentrations. These problems often tie back to the length of the alkyl chain—the “heptyl” part in this compound leans toward the toxic side compared to shorter chains. Chalk up another mark for “handle with care.”

People sometimes ask, “If it’s so dangerous, why use it?” That comes from the promise of ionic liquids in making chemical processes cleaner. They offer low vapor pressure, so spills stay at the site instead of moving through the air. But these same qualities mean a spill sticks around in soil or water unless someone actively cleans it up. Without intervention, the compound might persist and harm local microbes and animals.

Regulation and Safe Handling

Look for 1-Heptyl-3-Methylimidazolium Bromide on big regulatory lists like REACH or OSHA, and you’ll see it doesn’t always show up. Many ionic liquids aren’t old enough or widely used enough to appear in every regulation. That puts extra pressure on labs and manufacturers to set strict self-regulation. Labeling, proper storage in sealed containers, and access to spill cleanup materials help. Training workers, testing for leaks, and keeping only the amounts you need on hand all cut down risk. Engineers can install extra ventilation and spill catch basins in work areas as a backup.

What’s Next for Safety

Safer chemistry doesn’t come from one “green” label. My time experimenting with ionic liquids showed me that each new compound asks for fresh safety work. Testing for toxicity with local species in wastewater and soil helps. Developers can make new ionic liquids with shorter alkyl chains, or build biodegradable versions, to protect workers and the environment. Funding more studies to fill the gaps in what we know creates a foundation for smarter decisions and stricter rules down the line.

Researchers want alternatives to volatile organic compounds for a reason, but swapping those out without clear health data just shifts the problem. Holding manufacturers to higher transparency and tougher in-lab rules keeps progress honest. The more experience and facts labs share, the better the chance the next “green” solution lives up to its promise, without hidden dangers for people or the planet.

Looking Beyond the Label: Why Purity Matters

Lab work and industrial processes both demand consistency. Whenever I hear about someone struggling with results that don’t match the theory, impurities in chemicals usually lurk somewhere in the background. The true value of a chemical like 1-Heptyl-3-Methylimidazolium Bromide stands or falls with its purity.

Researchers, students, and technicians know that a reagent’s stated purity makes the difference between success and wasted hours. Most suppliers ship this ionic liquid in purities ranging from 97% up to 99%. In practice, 98% is common for research, while someone working at scale may hunt for even cleaner product.

Digging Into Specifications

Taking a closer look at the specification sheet can feel like picking through a long grocery list. Key values usually show up on the certificate of analysis: melting point, water content, chloride content, and color. For 1-Heptyl-3-Methylimidazolium Bromide, the melting point lands around 60-65°C. Moisture can be a headache—less than 0.5% counts as a decent level, though stricter applications aim lower.

Some specs point to deeper purity checks. Nuclear magnetic resonance (NMR) results show whether the desired chemical structure truly dominates the sample or if unexpected by-products turned up. If the NMR looks clean, you won’t need to worry about stray alkyl chains or leftover precursors.

Bromide purity goes beyond a single tally. Reputable sources often list halide balance, total halide content, and even trace metal limits. Nothing undercuts ionic liquid performance like a heavy metal spike from poor production or sloppy storage.

Practical Experience: How Impurities Wreak Havoc

A colleague once shared her frustration with a batch sourced from a new vendor. The label promised 99% purity, but reproducibility flopped. After some heated hours, Karl Fischer titration and IC revealed water and excess bromide, both slipping under the radar. These microscopic flaws amplified side reactions and forced reruns.

In my own work, the agony of inconsistent results led me to double-check purity, drying procedures, and batch traceability. Transparency from suppliers became a must. Real trust builds on upfront documentation and independent verification, including melting point checks, HPLC, and elemental analysis.

Quality Control: Supporting Claims With Facts

Over the past decade, demand for pure ionic liquids like 1-Heptyl-3-Methylimidazolium Bromide keeps growing—from green chemistry applications to advanced extraction processes. Researchers found that lower water and chloride levels cut error and enhance yield consistency. The ACS Green Chemistry Institute, for instance, stresses that even a half-percent impurity causes unexpected shifts in reaction pathways and product yields.

Many top journals demand that authors report detailed purity data alongside their results. This peer expectation keeps the bar high and helps stop the spread of ambiguous claims.

Improving the Specification Landscape

Some simple steps can drive improvement. Lab teams should push vendors for audit trails, not just standard certificates. Running their own checks—Karl Fischer for water, HPLC for trace impurities, and regular retesting of old stock—saves time in the long run. Standard protocols for storing and handling hygroscopic chemicals also help. Investing a small bit of effort up front means fewer headaches and cleaner results down the line.

1-Heptyl-3-Methylimidazolium Bromide may seem like one ingredient among thousands, but its specs shape everything that comes after. Finding a source with solid transparency—backed by reliable analysis and real people on the phone—makes research faster, cleaner, and far less stressful.