1-Heptyl-3-Methylimidazolium Hydrosulfate: An In-Depth Commentary

Historical Development

Over the past two decades, ionic liquids found their way into research labs and chemical manufacturing floors. Among these, 1-Heptyl-3-methylimidazolium hydrosulfate became popular during the early 2000s, as researchers looked to reduce environmental footprints in traditional chemical processes. Before then, solvents with high volatility and toxicity made many synthesis steps troublesome. The launch of imidazolium-based ionic liquids broadened the toolbox for chemists. Today, this compound stands as a testament to sustainable chemistry, moving from academic curiosity to regular spot in green chemistry protocols.

Product Overview

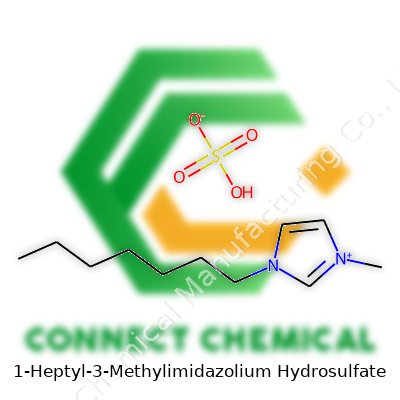

1-Heptyl-3-methylimidazolium hydrosulfate belongs to the family of imidazolium-based ionic liquids. The molecule pairs a seven-carbon heptyl group with a methylated imidazolium ring, which links to a hydrosulfate anion. The distinct structure gives it a unique stance among ionic liquids, especially regarding physical stability and solvent power. Chemists who search out solvents to handle awkward substrates appreciate the broad compatibility this molecule delivers, stretching from organic synthesis to electrochemistry.

Physical & Chemical Properties

This compound appears as a viscous, colorless-to-light yellow liquid at room temperature. Its negligible vapor pressure means fumes do not build up in labs, which anyone tired of headaches from classic volatile solvents regards as a practical improvement. The melting point sits below room temperature, giving flexibility in liquid-phase applications. Density, viscosity, and ionic conductivity range depend on temperature, but most labs report stable readings across a broad operational window, from sub-zero to around 100°C. Water-loving by nature, it mixes easily with water and polar solvents but pushes out non-polar organics. Chemically stable to acids and mild bases, it resists decomposition under most laboratory setups, though strong reducing agents or extremes of pH can break it down.

Technical Specifications & Labeling

Bottles of 1-Heptyl-3-methylimidazolium hydrosulfate often carry specifications such as purity (usually above 98%), water content (less than 0.5%), and trace metal content. Documentation lays out molecular weight (approximately 266.39 g/mol), and chemical formula (C11H23N2O4S). Labels warn users of the hygroscopic nature and recommend storage in airtight vessels in cool, dry places. Reputable suppliers deliver certificates of analysis with batch data for labs that run fine-tuned research protocols.

Preparation Method

Synthesis of this ionic liquid usually starts with 1-methylimidazole and 1-bromoheptane, which undergo a quaternization reaction to produce 1-heptyl-3-methylimidazolium bromide. This intermediate then reacts with sulfuric acid, swapping bromide for hydrosulfate to yield the final product. After reaction, extra purification steps like washing with ethyl acetate and drying under vacuum remove leftover reactants, unreacted acid, and water. Experienced chemists know careful temperature and addition controls keep the process smooth and maximize yield without making unwanted by-products.

Chemical Reactions & Modifications

The imidazolium framework handles tough reaction conditions. In organic synthesis, it can act as both solvent and sometimes even as a reaction promoter for cycloadditions, alkylations, or C-H activation steps. Under electrochemical conditions, its hydrosulfate anion participates in proton transfer, expanding what can be done during electrocatalysis. Some labs report modifying the alkyl chain length or switching anions for specialized needs, but the heptyl-hydrosulfate combo brings a reliable balance of hydrophobic tail and acid-leaning anion for regular lab work.

Synonyms & Product Names

Researchers and suppliers sometimes label this molecule as [HMIM][HSO4] or simply “heptyl-methylimidazolium hydrosulfate.” Older literature may reference it under its full IUPAC name. On the shelf, the common abbreviations—such as C7mim HSO4—speed up inventory tasks and standardize communication between manufacturers and end users.

Safety & Operational Standards

While this ionic liquid earned a reputation for being safer than volatile organic solvents, that does not mean careless handling works out well. Direct skin contact should be avoided since mild skin and eye irritation has been reported. Standard protocols suggest using gloves and goggles. Inhalation is rare due to low volatility, but handling in well-ventilated areas further reduces risk. Disposal practices require neutralization or controlled incineration, given the potential release of sulfur oxides. Emergency spill kits in facilities using this liquid help minimize exposure and environmental release. Material safety data sheets guide teams through first-aid steps and spill response.

Application Area

In research and manufacturing, this ionic liquid shows up in dozens of scenarios. It dissolves cellulosic materials that stump petroleum-based solvents. Catalysis labs use it to run transition-metal-catalyzed couplings and oxidations. Electrochemists exploit its wide electrochemical window and ionic mobility for battery electrolyte research and electrodeposition experiments. Environmental labs find value in extraction work, where it can replace toxic solvents in separating organics from aqueous mixtures. Even pharmaceutical chemists get use out of it in crystallizations and purifications, sometimes improving purity with fewer washes. Given its ionic nature, it slows down evaporation and provides stable reaction conditions over longer timeframes.

Research & Development

Chemists keep pushing boundaries here. Studies look at how changing the length of the alkyl tail tweaks properties such as solubility, viscosity, and reactivity. Computational chemists model ion pairing and hydrogen bonding to tailor new analogs for specific reactions. Biotechnology fields examine its ability to solubilize biomass for next-generation refineries, hoping to scale up green processing without massive solvent loss or contamination. Collaborative projects run both bench and pilot-plant scales, searching for the holy grail of safer, scalable, and cost-effective ionic liquid-based chemical manufacturing.

Toxicity Research

No matter how safe an ionic liquid seems, the story is never that simple. Toxicity studies show this compound is less harmful to acute aquatic environments compared to classic solvents, but long-term data lags behind. Researchers studying its effects on cell membranes note limited acute toxicity in mammalian cells, but chronic exposure results remain scarce. Biodegradation tests suggest the heptyl tail and imidazolium ring slow breakdown rates in some ecosystems, hinting at bioaccumulation potential. Regulators demand ongoing research, calling on labs to build environmental fate profiles and test for unexpected side products. Responsible labs check literature and regulatory updates before releasing anything downstream.

Future Prospects

Looking forward, this ionic liquid stands poised at the intersection of green chemistry and industrial innovation. Academia and industry push for solvent alternatives in pharmaceutical and agrochemical manufacturing, and products like 1-heptyl-3-methylimidazolium hydrosulfate show up in those discussions. If future research verifies low eco-toxicity and sustainable lifecycle, even larger markets may open up. Advances in large-scale recycling and re-use could close the loop further, turning ionic liquids from specialty materials to regular fixtures in bulk processing. Ongoing R&D in catalytic systems, energy storage, and sustainable materials all suggest a growing role for this compound and its relatives in tomorrow’s chemical industries.

Why Does This Compound Matter So Much?

Right now, a growing number of researchers and industrial engineers are hunting for safer, more sustainable ways to transform how we process chemicals. 1-Heptyl-3-methylimidazolium hydrosulfate is an ionic liquid, meaning it stays liquid at room temperature, has no vapor pressure, and works as a powerful and sometimes eco-friendlier solvent. Unlike the old-school toxic solvents, this one doesn’t evaporate into the air, so you don’t breathe in fumes just by being nearby.

Solvent Power: Real Science, Not Sci-Fi

Chemists and chemical engineers have been getting creative with this compound. In the lab, it shines during catalytic reactions—breakthroughs in green chemistry love it. Picture teams working on pharmaceutical synthesis: they switch out petroleum-based solvents for this ionic liquid, and suddenly the reactions run faster, generate fewer byproducts, and limit exposure to hazardous waste. The compound’s molecular structure lets it dissolve a wild range of organic and inorganic substances. In the past, separating out a certain chemical from a complex soup of substances required some nasty, volatile liquids. Now, researchers grab 1-heptyl-3-methylimidazolium hydrosulfate, whip up their reaction, then recycle the solvent after use, slashing the piles of hazardous trash.

Heavy Industry Gets on Board

Pulp and paper production has a reputation for chewing through forests and fouling up rivers. In one pilot project I read about, engineers added this ionic liquid to digest wood pulp, breaking down cellulose into useful sugars without the caustic chemicals and high temperatures plants used for decades. Energy bills dropped and rivers ran clearer. Textile dye factories, always under pressure to clean up their act, have also dipped into this chemistry. With 1-heptyl-3-methylimidazolium hydrosulfate as a reaction medium, dyeing and finishing runs smoother, and wastewater loses a lot of its sting.

Recycling and Recovery

Solvents don't just help build materials; they help take them apart. Think of waste plastics, metals, or electronics that pile up in landfills worldwide. This compound helps dissolve, break down, and extract valuable metals or polymers from all sorts of e-waste. By pulling out the useful stuff, recyclers can reprocess material instead of digging up new ores or pouring fresh petroleum into the system.

Not a Magic Bullet—Real Risks

No chemical comes without trade-offs. Runoff into waterways has biologists worried about toxicity to aquatic life, and proper disposal still costs. Some studies suggest the breakdown products from these ionic liquids could build up in nature, though more testing is needed to confirm what happens long-term. Supply chains for specialized chemicals often face disruptions, driving up costs and making access spotty, especially far from major research centers.

Building Safer Paths Forward

Industry and academia can't operate in isolation, so real transparency helps. Each new application of this ionic liquid needs a full look at environmental impacts. Regular toxicity screening, plus incentives for recycling and reuse, keep things on track. Companies should invest in worker training and disposal protocols, lowering the risk of spills or routine exposure. Governments can provide grants to deepen research on safer alternatives or ways to break down old ionic liquids, shrinking the environmental shadow. Cutting-edge chemistry doesn't have to happen at nature’s expense—and this new solvent stands at a crossroads for greener options in manufacturing and recycling.

Physical Traits Worth Knowing

1-Heptyl-3-methylimidazolium hydrosulfate, often called an ionic liquid, adds a new kind of flexibility to modern chemistry labs. Pour a little onto a glass plate, and you’ll see a clear to pale yellow liquid, usually at room temperature. The material doesn’t evaporate much because of low vapor pressure, so you won’t catch a strong odor — a welcome break from traditional solvents that sting the nose.

This liquid feels viscous. Try swirling it: it moves thickly, almost syrup-like, compared to water or alcohol. People who have handled it in experimental setups notice it's not flammable, not explosive, and doesn’t boil easily. Its melting point sits low, well below 100°C, and it stays liquid over a broad temperature stretch. Industrial partners care about stability, as fewer phase transitions mean it stays reliable during storage and use.

Chemical Behavior Outlined

This ionic liquid combines a bulky organic cation (the heptyl-methylimidazolium group) with a hydrosulfate anion. This pairing makes it highly soluble in water and gives it a strong ability to dissolve both organic and inorganic compounds — something petroleum chemists and material scientists talk about often. Its ionic nature also means the material conducts electricity, making it valuable in electrochemistry.

Imidazolium-based liquids, like this one, resist breaking down under normal lab conditions. They show thermal stability up to about 200°C. Chemists, especially those working on green solvents, often highlight the compound’s non-volatility and chemical inertness. It won’t react with acids or bases in most cases, and mixing it with strong oxidizers or reducers gets frowned upon because of the theoretical risks. Researchers have seen that it can absorb moisture from the air, so it should be capped tight once the bottle is opened.

Importance in Real Work

Ionic liquids have already carved out space in processes that once relied on volatile organic solvents. 1-Heptyl-3-methylimidazolium hydrosulfate stands out because it solves certain solubility problems that basic solvents cannot. During separation experiments or in extracting metals from ores, this compound offers a more sustainable approach — fewer emissions and less loss due to evaporation.

Chemists in my circle appreciate getting consistent results, which often leans on the unchanging nature of this solvent. The high boiling point helps prevent experimental losses, especially in reaction mixtures running at elevated temperatures. The substance’s thermal resilience means you can push reactions harder and longer, squeezing every drop of yield out of precious starting materials.

Concerns and Solutions

The green credentials of ionic liquids always spark discussion. While 1-Heptyl-3-methylimidazolium hydrosulfate reduces VOC emissions, the environmental factor depends on end-of-life management. Disposing of used liquids into regular waste streams threatens aquatic life because of their persistence. Some labs develop recovery methods: distillation and ion-exchange techniques recover most of the ionic liquid for reuse. Universities keep pushing projects to improve biodegradability without sacrificing performance, which shows a shift towards smarter chemistry.

Another challenge relates to purity. Impurities in starting materials or careless handling contaminate batches and affect reproducibility. Careful sourcing and airtight storage containers solve part of the problem. Labs that track quality through regular checks see fewer surprises in their experiments.

Final Thoughts

1-Heptyl-3-methylimidazolium hydrosulfate gives experimentalists an edge. Its physical stability, robust solubility, and green potential continue to win over both the academic and industrial crowd. Being thoughtful about its lifecycle, from procurement to disposal, ensures that the progress made in sustainable chemistry sticks around for the long run.

What This Chemical Is and Where You Find It

1-Heptyl-3-Methylimidazolium Hydrosulfate belongs to the family known as ionic liquids. These substances tend to show up in laboratories and industrial plants where the goal is to avoid using regular solvents like benzene. Folks in research talk about their lower volatility, how they don’t catch fire easily, and their ability to dissolve many chemicals most regular solvents cannot. That gets attention, especially if someone wants “greener” chemistry — or at least a cleaner lab bench, less vapor in the air.

Health and Safety Concerns

Many people see “ionic liquid” and imagine a gentle solution, but experience with chemicals tells a different story. While some options are benign enough, others show clear toxicity, especially during long exposure. Evidence on 1-Heptyl-3-Methylimidazolium Hydrosulfate doesn’t fill entire shelves, but a few key studies point to causes for caution. This chemical can irritate skin, eyes, and airways; animal tests describe effects on cell membranes and living tissue. One study in Environmental Science & Technology in 2010 showed certain imidazolium ionic liquids, especially those with longer carbon “tails” like heptyl, damaged aquatic organisms more than the short-chain versions. The effect worsened with higher concentrations.

Anytime a chemical harms aquatic life, question marks rise for workers and researchers, too. No one wants the next generation of solvents to echo the mistakes made with tetraethyl lead or DDT — both introduced because people overlooked subtle health effects. A long aliphatic chain, like in 1-Heptyl-3-Methylimidazolium, means it often breaks down slower in water and may build up in living things. While scientists still argue how much risk this particular salt poses to humans with real-world exposure levels, the pattern demands respect, not dismissal.

Handling and Environmental Impact

Any laboratory I’ve worked in treats all ionic liquids as hazardous unless proven otherwise. Gloves, goggles, and installed extraction hoods don’t just look professional — they’re hard-won layers of protection. A single spill in the wrong place, and the janitors could be dealing with a burn or persistent contamination. Just because a chemical doesn’t have the choking fumes of old solvents doesn’t mean it lives up to “safe.” Studies hint this compound resists breakdown in wastewater, lingering on surfaces and in pipelines. Unchecked disposal means organisms in streams or ponds soak up these molecules, sometimes with fatal results.

Industry Response: Room for Improvement

Down the street at the chemical plant, a few responsible firms now demand comprehensive hazard reviews before trying a new solvent on large scale. Audits outline not just immediate toxicity, but any risks to water and wildlife. Some companies sponsor research to see if enzyme-based or bio-friendly versions get the same job done with less risk. Regulators, especially across Europe, already track ionic liquids as substances of higher concern. Registration and reporting got stricter last year due to studies showing potential for chronic toxicity.

What Needs to Change

Replacing dangerous bulk solvents doesn’t guarantee a free pass. Anyone working with 1-Heptyl-3-Methylimidazolium Hydrosulfate must pull up real safety data instead of sales brochures. Labs and plants benefit when staff know the long-term environmental record and push for tighter spill controls. Future chemists must develop clear checklists: Does this new solvent break down in a safe way? Is there solid proof it won’t build up in rivers or food chains?

Ultimately, smart use of this ionic liquid — or the next one to hit the market — comes from active skepticism, caution on exposure, and a habit of asking tough questions. The future stays healthier if we get ahead of potential hazards instead of scrambling after problems surface.

The Nature of the Compound

Working with chemicals over the years has taught me that organized storage isn't just a recommendation—it keeps people safe. 1-Heptyl-3-Methylimidazolium Hydrosulfate falls in the category of ionic liquids, a group that makes life easy in many labs thanks to their low volatility and high stability. This doesn’t grant a free pass to toss the bottle in any cupboard, though. Safety, both for people and for long-term data integrity, depends on respecting the specific traits of every substance we work with.

Understanding Risks and Reactivity

Hydrosulfate salts bring some unique challenges. Spilling this stuff on the floor probably won’t clear a room like hydrochloric acid, but splashing concentrated hydrosulfate on skin or in the eyes gets serious fast, so I make a habit of using gloves and safety goggles every time, even if I’m just transferring a few grams. Accidents happen, and tired hands in a cluttered storage area create most of the messes I’ve seen over the years.

Ideal Storage Conditions

Placing the container somewhere dry keeps the chemistry predictable. This salt absorbs water from the air, turning lumpy or sticky over time, so I avoid benches close to sinks or dishwashers. Screw-cap bottles, sealed tight, sit inside a clean, labeled box on a shelf, away from direct sunlight and away from heat. On a summer day, a warm shelf causes faster breakdown and corrosion, so I keep it in a climate-controlled chemical cabinet if there’s one available.

Labeling matters much more than folks sometimes admit. I’ve sorted through enough mismatched jars to know the headache of unclear marks. I print the full chemical name, concentration, hazard warnings, and date received. Missing details can put someone in real trouble during inspections or emergencies.

Separation from Incompatibles

Ionic liquids get along with many compounds, unlike some volatile chemicals that react at the drop of a hat. But acids like hydrosulfate don’t mix well with strong bases, reducing agents, or oxidizers. Ammonia gas, bleach, or even some metals kick off dangerous reactions—smoke and fumes in the worst cases. Drawing from past mistakes, I no longer let acids and bases share the same shelf. Segregating chemicals doesn’t require a big space, only solid habits and a few secondary containers to keep shelves organized.

Disposal and Emergency Considerations

No matter how tidy the storage, spills and bottle breaks crop up. A spill kit sits close to any spot where these kinds of chemicals live. I keep absorbent pads, neutralizer, and a couple pairs of extra gloves on hand. Spilled hydrosulfate needs prompt cleanup, not five minutes later when it’s spread out or already eaten into the surface.

I’ve seen people pour unwanted residues down the drain—costly errors. Proper disposal at approved facilities avoids costly environmental harm and, more importantly, keeps the workplace in line with local waste regulations. Ignoring these details brings heavy fines, and worse, broken trust among coworkers and in the scientific community.

Building the Habit

Most accidents around 1-Heptyl-3-Methylimidazolium Hydrosulfate never start because the chemistry is tricky; they start because someone rushes, improvises, or skips a label. Safe storage, to me, feels like an extension of professional respect. Each time I close a bottle, store it dry, and double-check the shelf, I'm making the next workday—and next worker—just a bit safer. Not flashy, just smart.

Unlocking Chemical Efficiency

Stories about specialized chemicals often sound distant. But take 1-Heptyl-3-Methylimidazolium Hydrosulfate, a type of ionic liquid—this compound quietly supports big changes in how industries manage both energy and pollution. I’ve seen specialty chemicals like this change workflows dramatically, especially for those of us working around research labs or sustainable tech companies. Ionic liquids don’t evaporate easily, which cuts down the risk of toxic fumes compared to old-school solvents. This alone puts them at the center of safer, more responsible chemical engineering.

Cleaner Processing for Industry

Chemical manufacturing, textiles, and the energy sector all rely on efficient catalysts. This specific ionic liquid steps up as a catalyst in organic synthesis. Think about making essential molecules for things like pharmaceuticals, perfumes, or polymers. Traditional solvents create a lot of waste and emissions. With the right ionic liquid, companies see higher yields and purer results, cutting cleanup costs and environmental headaches. The pharmaceutical side often gets the most press, as green chemistry is a selling point when producing life-saving drugs with fewer toxic leftovers.

A Push for Better Biomass Handling

In the biofuel and renewable energy world, breaking down plant material without harsh chemicals matters. Industrial teams have started making use of this ionic liquid to dissolve lignocellulose—that tough, woody part of plants that usually resists ordinary solvents. This step turns straw, wood chips, or food waste into sugars for fermentation, leading to bioethanol and even specialty chemicals. The old processes used to chomp through a ton of acid and result in a lot of sludge. Now, the process leaves less waste behind and recycles more starting material.

Smoother Metal Extraction

People rarely talk about the chemicals used to separate metals from electronic waste or ores. Still, in labs and pilot plants, engineers mix ionic liquids like 1-Heptyl-3-Methylimidazolium Hydrosulfate right into the process. Traditional metal recovery often creates caustic byproducts or involves hazardous smelting. With ionic liquids handling the extraction, yields go up and dangerous emissions drop. That means less mess for workers and the land, plus cleaner recycling for growing piles of electronics.

Tuning Up Electrochemistry

Battery research, coatings, and advanced sensors all rely on stable electrolytes. I once watched an R&D team switch to ionic liquids for battery prototypes. Their goal: safer, non-volatile systems that keep running smoothly in tough conditions. This compound’s thermal stability helps push beyond what water or volatile organics can handle. Machines and devices relying on them become safer, and failures from overheating or chemical leaks decrease.

Straightforward Steps Forward

Applying this chemistry more widely doesn’t just come down to science. Prices and regulations shape who gets to tap into the benefits. Academic-industry partnerships, open data on life-cycle impacts, and tighter workplace safety rules all smooth the transition from bench to factory floor. As more data comes in about long-term impacts, industry teams keep refining protocols and scaling up recycling to cut both costs and environmental footprint. Broad adoption starts from real-life wins and the steady grind of improving small steps.