1-Hexadecyl-2,3-Dimethylimidazolium Chloride: A Comprehensive Commentary

Historical Development

Early pioneers in the chemistry of ionic liquids traced the development of imidazolium salts back to the mid-20th century. Scientists, searching for alternatives to volatile organic solvents, stumbled onto the stability and wide range of melting points in imidazolium cations. In time, longer alkyl chain derivatives like 1-hexadecyl-2,3-dimethylimidazolium chloride captured attention for their surfactant properties and ability to form self-assembled structures in solution. Today, laboratories across research institutions rely on this compound's qualities to drive innovation in areas spanning catalysis, material science, and green chemistry. I’ve spent years reading up on ionic liquids, watching their slow crawl from oddballs in academic circles to front-runners in sustainable technology. Much of this traction owes itself to the unique structure and versatile chemistry these salts provide.

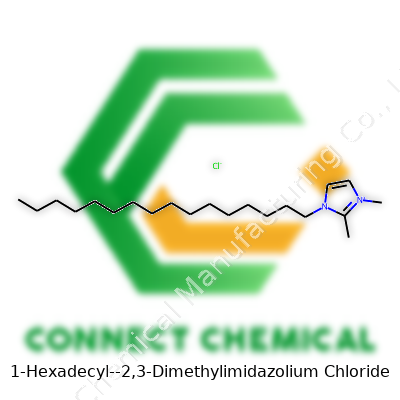

Product Overview

The molecule features a distinct imidazolium headgroup with methyl groups at the 2 and 3 positions, anchored to a 16-carbon alkyl tail. This gives the compound a strong amphiphilic character, meaning it behaves both as a surfactant and as a designer ionic liquid. Several commercial suppliers offer this chemical in powder or viscous liquid form, packed tightly to shield it from absorbing moisture from air. Laboratories bring this compound off the shelf for applications in nanomaterials, phase transfer catalysis, and as a medium for electrochemical processes. Researchers value the stability, purity, and batch-to-batch consistency from reputable vendors, and that trust enables successful replication and scale-up in most experiments I’ve seen or supervised.

Physical & Chemical Properties

The white to off-white solid holds a melting point hovering between 45 and 60°C, influenced by purity and trace contaminants. Its solubility profile demonstrates significant affinity for polar organic solvents, particularly alcohols and acetone, but it resists dissolving in nonpolar hydrocarbons. Density sits around 0.85-0.9 g/cm³. With a molecular weight in excess of 370 g/mol, the compound packs both mass and function into a single molecule. Electrical conductivity in solution ranks high among organic salts, a trait prized in electronics applications. The cation’s alkyl tail supports robust micelle formation in aqueous systems, which underpins its use in templating nanostructures and facilitating phase transfer.

Technical Specifications & Labeling

Packages list contents often above 98% in purity, backed by NMR and HPLC profiles from the manufacturer. Labels display the CAS number, hazard warnings regarding skin and eye contact, and recommended storage conditions—dry, cooled, and away from direct light. Shipments travel packed with desiccants and in chemically inert containers, often with a certificate of analysis to guarantee authenticity. From experience, labs enforce strict inventory tracking and handling protocols, carefully logging batch numbers and expiry to avoid cross contamination or accidental mix-ups during synthesis or experiments.

Preparation Method

Synthesizing 1-hexadecyl-2,3-dimethylimidazolium chloride follows a route involving quaternization of 2,3-dimethylimidazole with 1-chlorohexadecane in an aprotic solvent like acetonitrile or DMF. Reaction times can stretch to 24 hours under gentle heating, yielding a viscous, oily intermediate that precipitates in cold diethyl ether. Purification steps include repeated washing and dry vacuum to strip any unreacted starting material. Quality control checks on the isolated product by NMR, mass spectrometry, and FTIR ensure structural integrity before a compound earns its spot on the supply shelf. A good synthetic protocol delivers robust yields and, from my view, cutting corners on purification always leads to headaches down the line.

Chemical Reactions & Modifications

One sees the chloride ion exchanged for other anions, like PF6-, BF4-, or NTf2-, through metathesis reactions. These variants alter solubility, thermal stability, and electrochemical window, making the compound a core building block for custom ionic liquids. Functionalization of the alkyl tail or methyl substitution on the imidazole ring tunes interactions with biological or inorganic substrates, shifting micelle behavior or catalytic activity as needed. It’s typical for researchers to graft these salts onto solid supports for catalysis or sensing. Time and again, direct involvement in synthesis projects drives home how small structural tweaks open whole new application avenues, often with little more than a change of solvent or a new reaction partner.

Synonyms & Product Names

Databases and chemical suppliers catalog the compound under several synonyms: 1-cetyl-2,3-dimethylimidazolium chloride, cetylimidazolium chloride, and its systematic IUPAC name. Fast searching for any of these designations brings up both academic literature and product listings, which helps smooth the transition from research table to industrial scale. I’ve seen ordering slip-ups due to name confusion, so cross-referencing with CAS and careful review of chemical structure drawings tend to save effort and money.

Safety & Operational Standards

Handling comes with risks. Direct skin contact causes irritation in most cases, with inhalation of dust posing mild respiratory hazards. I always emphasize proper PPE—gloves, splash goggles, and lab coats—along with working in a fume hood when transferring powders. Spills get swept with damp cloths or HEPA vacuums, with all waste routed to hazardous waste streams. SDS sheets push for detailed attention to storage away from moisture or acid, given the compound’s slow hydrolysis under moist conditions. Familiarity with your institution’s chemical hygiene plan, along with regular refresher training, keeps users safe and minimizes accidents or lost inventory.

Application Area

Researchers exploit the surfactant nature of 1-hexadecyl-2,3-dimethylimidazolium chloride for nanoparticle synthesis, self-assembly of mesoporous materials, and as a stabilizer for emulsions involving tough-to-blend components. In green chemistry circles, the ionic liquid serves as a non-volatile solvent for organic transformations, allowing reactions at higher concentrations with better selectivity and lower toxicity than traditional solvents. Analytical chemists use it to modify electrode surfaces, boosting sensitivity in biosensing platforms. Colleagues in polymer science turn to this compound as a soft template to organize block copolymers and shape new classes of responsive thin films. Its electrochemical stability makes it a favorite for batteries and supercapacitors looking to beat the old guard in energy density.

Research & Development

Academic groups study this molecule for its ability to direct bottom-up assembly of nanowires and mesoporous inorganic oxides. Collaborations between universities and industry labs push the compound’s boundaries, looking for cheaper or greener synthetic routes and tweaks to enhance biocompatibility without sacrificing function. Conferences in the last few years feature case studies leveraging these salts in water desalination membranes, CO2 capture, and solar energy conversion. My work brought home the need for fundamental data—viscosity, phase behavior, thermal decomposition profiles—since even minor tweaks ripple through large project teams. The robust body of published work blends synthetic discovery with practical feedback from end-users.

Toxicity Research

Laboratory studies point out moderate toxicity to aquatic organisms and bacterial cultures, which warrants care in disposal planning. Human exposure remains limited to occupational incidents, mainly mild to moderate skin irritation without systemic toxicity at standard lab concentrations. Regulatory bodies continue to assess long-term risks, requiring more targeted chronic studies. The compound’s cationic surfactant structure mirrors that of known irritants, so most in the field favor careful segregation and small scale handling until more toxicity data emerges. Waste streams, from synthesis to cleaning, route to controlled chemical disposal rather than direct drain or landfill application, part of good lab stewardship learned through daily routines.

Future Prospects

Interest grows as markets for ionic liquids in batteries, catalysis, and specialty coatings mature. Ongoing research focuses on lowering manufacturing costs and finding ways to tailor degradation pathways for safer end-of-life outcomes. Integration with bio-based feedstocks and green chemistry protocols promises a future where sustainable manufacturing meets high-performance materials. In my view, several hurdles stand in the way—chiefly scale-up costs and end-user education—but the underlying chemistry holds undeniable promise as industries look for safer, more efficient, and functionally adaptive compounds. Watching fresh graduates pick up these molecules and run experiments never gets old. Each discovery made with 1-hexadecyl-2,3-dimethylimidazolium chloride nudges materials science forward, one reaction flask at a time.

Real-World Uses of a Mouthful of a Chemical

In labs and factories, nothing grabs a chemist’s eye like a strong yet versatile ionic liquid. 1-Hexadecyl-2,3-dimethylimidazolium chloride, usually shortened to its initials or called an imidazolium salt, serves a real purpose well beyond just filling up space on a safety data sheet. My years in materials science have shown how often this compound pops up in research projects aimed at tackling big industrial problems, especially where regular solvents can’t keep up or break down too easily.

Why Industries Value This Stuff

This chemical steps up in places that crave strong surface activity or demand stability at higher temperatures. Its structure, with a lengthy hydrocarbon “tail” and charged imidazolium “head,” lets it grab onto surfaces and disrupt things at a microscopic scale. This action changes how water mixes with oil, how particles clump up, or how electricity flows across a surface. Researchers in chemical engineering know these traits as “surfactant” behavior and “ionic conductivity,” simple terms for very important jobs.

Surface Tension, Grease, and Clean Energy

This compound finds work in detergents and emulsifiers. In plain language, it helps oily gunk dissolve in water for easy washing, used for tough industrial cleaning or where traditional surfactants just don’t go far enough. Because its ionic part stays stable in many environments, it’s also useful for making things that need solid, lasting performance, like coatings or lubricants.

Battery makers and green energy researchers look to this salt for safe, stable electrolytes in fuel cells and lithium-ion devices. I once worked on a team trying to squeeze out extra firepower from prototype batteries; we saw that traditional liquids broke down far too early, especially as devices heat up under strain. Using imidazolium-based salts boosted our operating window—less runaway heating, fewer breakdowns under real-world use.

Getting Tough on Water

Water treatment plants look for tools that pull out heavy metals and grease. The long alkyl chain plus charged head in this chemical latch onto dirt and grease, bunching them up for removal. Wastewater treatment relies on this, especially in industries like textile manufacturing where oily runoff just doesn’t budge for water alone.

Safety and Environmental Concerns

Widespread use always brings up health and environment questions. People following green chemistry trends point out that not all ionic liquids break down cleanly. If companies use more of these chemicals in the future, the next challenge centers on breaking them down without hassle, or designing them to degrade naturally. During a project with a hazardous waste team, I saw the headaches that come from pulling long-lasting chemicals out of groundwater—no one needs that job to get harder.

What Needs to Happen Next?

R&D leaders already experiment with tweaking the side chains to make the next generation friendlier to the planet and to people. At big conferences, scientists trade results on what modifications pull out more grime, conduct current even better, or wash away without leaving a mark. Progress runs on teamwork here, linking chemists, engineers, and environmental watchdogs around a shared vision of cleaner, smarter chemistry.

Anyone who’s handled a sample knows that good lab practice stays crucial. Gloves, goggles, and proper labeling keep workers safe no matter how promising a new chemical looks in the journals. Keeping an eye on regulations and pushing for greener tweaks stands as the best way to make sure this family of ionic liquids brings more good than harm as their use grows.

A Practical Look at Keeping Chemicals Safe: Lessons from the Lab

1-Hexadecyl-2,3-Dimethylimidazolium Chloride sounds unusual, but to many in research, it’s simply another ionic liquid with a job to do. Like other specialty chemicals, it deserves respect and responsible handling. Leaving a compound like this exposed or poorly stored gets expensive and dangerous fast. Anyone who’s seen a neglected shelf of reagents that turned into a sticky mess knows this all too well.

Moisture and Contamination: Protecting Purity

Air humidity builds up in many chemical storage rooms. Imidazolium-based salts often soak up moisture if left uncovered, which then can throw off results in any future experiments. Even a little water can slowly change the product. My colleagues and I learned early to take care with hygroscopic substances: never just screw the cap on and call it a day. A tight, sealed container is the first step, preferably glass or plastic that won’t react with the compound. Toss in a silica gel packet, and you've added a reliable line of defense against creeping dampness.

Temperature Matters More Than You Think

Temperature swings in old storage rooms do more than make you sweat. Many specialty chemicals degrade faster as the ambient temperature climbs. Ideally, 1-Hexadecyl-2,3-Dimethylimidazolium Chloride stays cool and stable—below 30°C usually does the trick—but not frozen. Keep it away from direct sunlight and radiators. On my team, if we had any doubts, we reached for the refrigerator meant for chemicals, never food. That move preserves shelf life and reduces the risk of unexpected changes.

Avoiding Light and Reactive Chemicals

Light speeds up breakdown. Over time, a bottle left in the open will lose its reliability. Opaque or amber bottles keep things simple. If the only containers available are clear, a dark cupboard shields against UV and visible light. Mixing storage areas with volatile acids, oxidizers, or strong bases creates chaos; labels might fade, but cross-contamination does not go away quietly. Always give a dedicated spot, far from incompatible substances. One mix-up can mean ruined stock or worse, a hazardous reaction.

Labeling and Documentation: Why They Matter

Missing dates and mystery jars haunted my grad school days and caused plenty of headaches. Label every bottle clearly—product name, date received, supplier, and your own initials. This simple act keeps work transparent and safe. Update the chemical inventory often and check for discoloration or odd smells. A good process cuts down on wasted money and reduces the risk of accidents.

Handling Waste Responsibly

Even leftovers or degraded stock need attention. Never pour unused chemicals down the drain or toss them in the trash. Workplaces and universities train staff to put spent or degraded chemicals in marked waste containers for professional disposal. This habit protects not only people but the environment.

Creating Reliable Labs Through Smarter Storage

Safe storage and careful documentation build trust in results. Reliable chemicals mean fewer repeat experiments and more useful data. Labs with poor habits see more accidents and less funding because mistakes get expensive. Habits forged in school or early training stick around; these details hold the difference between an efficient lab and a chaotic one. 1-Hexadecyl-2,3-Dimethylimidazolium Chloride isn’t a common household name, yet the principles behind safe storage apply across the board–keep it dry, keep it cool, and treat every bottle as the valuable resource it is.

Learning About Chemical Safety

Anytime I see a long name like 1-Hexadecyl-2,3-Dimethylimidazolium Chloride, my first thought goes to the chemical’s purpose and the risks tied to it. Found in some industrial solvents and ionic liquids, this compound often pops up in research but isn’t what most folks have ever handled outside a specialist’s lab. So the question of hazard or toxicity isn’t just for scientists―it matters for workers, students, and anyone reading a safety sheet.

What Science Says About the Risks

Scientists study these chemicals because many show unique properties useful in extraction, material science, and catalysis. Yet, research and regulatory sources give us reason to pause before reaching for a bottle. From what’s been published, 1-Hexadecyl-2,3-Dimethylimidazolium Chloride shows moderate to high toxicity in aquatic life. A 2020 study found marked effects on freshwater organisms, particularly small crustaceans. Over time, imidazolium-based ionic liquids have shown the potential to bioaccumulate, which means their risks don’t vanish after a single use.

For people, the data remains limited. Inhalation or skin exposure could irritate, and some sources suggest it may cause allergy-like symptoms. My own time researching chemicals taught me to treat all unknowns as suspect; an assumption of safety would be reckless until testing says otherwise. Most manufacturers assign it recognizably strict hazard labels: avoid breathing dust, keep out of skin contact, and use well-ventilated spaces. Fire departments would know it as a chemical they fight with special gear, not water alone.

How Exposure Happens

Labwork, manufacturing, and waste handling raise exposure risks. Spills, poor storage, or accidental mixing with incompatible materials can prompt chemical reactions. Protective gear―nitrile gloves, goggles, and fume hoods―act as the frontline defense. Students new to lab rules tend to cut corners, so training stays essential. From my experience, the best labs drill safety and make sure all staff understand emergency protocols, not just the postdoc or chemist in charge.

Safe Handling and Solutions

Prevention stands out every time. Anyone using 1-Hexadecyl-2,3-Dimethylimidazolium Chloride needs full access to safety data sheets. Lock down storage, keep chemicals labeled, and never let non-trained folks handle containers. Factories benefit from clear signage and proper waste channels―the kind that separates harsh chemicals from general waste. Teams should review procedures regularly and run drills, not assume a dusty binder on the shelf is enough.

Research teams answer these challenges by designing safer alternatives where possible. Green chemistry has made solid gains, developing less toxic molecules to do similar jobs. Universities, national labs, and industry groups share updates on new models and screening tools so businesses can cut risks before they surface.

Fresh studies are needed. Regulatory agencies in the U.S., E.U., and Asia check incoming data and update rules, giving workers and communities better protection. The internet brings key info fast—so long as you know where to look and can sort facts from fluff. More companies start putting full chemical transparency forward, which helps create a culture where safety doesn’t take a backseat to profit or speed.

Worth the Attention

No chemical deserves blind trust. 1-Hexadecyl-2,3-Dimethylimidazolium Chloride, while valuable for research and some industries, comes with clear warnings for health and the environment. Folks working with it must take those risks seriously and push for safer substitutes whenever possible.

Chemical Formula and Molecular Weight

Understanding chemicals often circles back to their formula and weight. 1-Hexadecyl-2,3-dimethylimidazolium chloride goes by the formula C21H43ClN2. The molecular weight clocks in at 359.03 g/mol. Each piece of that code tells a story about the substance—how many carbon, hydrogen, nitrogen, and chlorine atoms it boasts, and how these interact during research, industry use, or in a lab notebook.

Why Knowing the Structure Matters

Back in college, pouring over molecular models, I realized: properties hang on types and numbers. The long hexadecyl chain in this one gives it a fat tail, the sort that impacts how it mixes with water and organic solvents. That imidazolium ring, methyl groups sticking out, plays a role in ionic behavior. Not every chemical formula sticks out in memory, but the minute detail makes it possible to predict or explain real-world outcomes—like how this salt dissolves, how stable it stays on a shelf, or how it interacts during a reaction.

Real World Impact

This salt falls into a class known as ionic liquids. Researchers gravitate toward these for several reasons. Many possess low volatility and can stay liquid even at room temperature, which means fewer fumes mess up the air in a lab. It’s not a green solution for all problems, but some point to ionic liquids like these as an alternative to older, hazardous solvents.

1-Hexadecyl-2,3-dimethylimidazolium chloride doesn’t just lounge on a shelf, either. Labs use related compounds as surfactants, antimicrobial agents, or as parts of new materials. Adding a long alkyl chain to the imidazolium ring changes surface activity and can make it more effective against certain microbes or better at stabilizing nanoparticles.

Environmental Responsibility

Every chemical brings risks. Ionic liquids sometimes parade as eco-friendly, but safety stories tell a fuller tale. Not every ionic liquid is safe for aquatic life, and reports paint a mixed picture about biodegradability. In my own lab work, every time a bottle with a long chemical name arrived, a safety sheet came with it—and for good reason. Responsible use means checking toxicity, local regulations, and making sure that chemistry helps, rather than harms, outside the lab walls.

Balanced Progress

Innovation takes a nudge from facts and an eye on consequences. New compounds aren’t magic bullets. For 1-hexadecyl-2,3-dimethylimidazolium chloride, research continues into greener synthesis, easier disposal, and lower toxicity versions. Chemists collaborate across specialties to solve tricky synthesis problems. Teams keep developing better ways to break down these compounds post-use, so they don’t stick around in the environment longer than they’re welcome. Looking at molecular formulas and weights might seem like desk work, but these details echo through larger conversations—across labs, industries, and policy rooms.

Supporting Reliable Science

Reviews in journals like Green Chemistry and studies on ionic liquids highlight real risks and propose alternatives. Facts published in the Journal of Hazardous Materials or by the American Chemical Society back up claims about toxicity or reactivity of imidazolium salts. The European Chemicals Agency updates safety profiles and listings, with access open for public scrutiny. Drawing from these sources makes it easier to trust that a chemical isn’t just new, but responsibly understood and handled.

What We Face with This Compound

1-Hexadecyl-2,3-Dimethylimidazolium Chloride shows up in labs searching for strong surfactants or ionic liquids. This stuff doesn’t belong in the category of everyday chemicals you can wash down the drain. I spent days studying how ionic liquids re-shape solvents, and I’ve seen some bad habits with how people store and throw out these specialty compounds. Most folks focus on how well it works and forget how some of these compounds hit the environment or human health.

Direct Experience: Day-to-Day Laboratory Practices

Every time someone moves this imidazolium salt, gloves come first. Room ventilation matters. Inhaling its powder or getting it on the skin leads to irritation, so nobody gets careless by skipping personal protective equipment. Fume hoods aren’t just for show—opening the bottle inside one keeps clouds or dust in check. In the rush of experiments, it’s tempting to leave containers uncapped for a second, but spills and leaks bring more cleanup than anyone wants to deal with.

Some see it as a generic surfactant, but its long alkyl chain and ionic head group create risks not always printed in bold on the bottle. I’ve spoken with safety officers who share case studies where spills cause slippery floors or chemical burns if handled with bare skin or poor eye protection. Even if exposure seems minor, repeated contact builds up over time.

Trusted Methods for Disposal

No university or industry lab should ever allow dumping this compound down the drain or tossing it in the regular garbage. Ionic liquids like this one resist breaking down in natural water and soil ecosystems. If poured away carelessly, they end up harming aquatic life or pump up chemical loads in water treatment plants.

Best practice involves using designated hazardous waste streams. That means putting used gloves, pipette tips, and wipes in a labeled solid waste container. Spent solutions and pure leftovers go into a sealed liquid waste container. Each gets a clear hazardous waste label. My own lab always coordinates pickup with licensed hazardous waste handlers who follow federal and state regulations, so this stuff doesn’t slip into public landfills or sewer systems.

Why It Matters for Health and the Environment

Toxicity information on some ionic liquids remains incomplete. Some labs treat these as greener options compared to traditional solvents, but assumptions can cause trouble. Persistence in the environment means traces stick around long after disposal. It doesn’t take much to skew water quality or upset delicate systems in rivers and lakes. Strict handling and disposal keep the risk low for everyone in the building as well as the communities downstream from any lab or industrial site.

Moving Toward Safer Chemical Culture

Direct experience shows that ongoing training keeps people sharp on the small details, like double-bagging waste or double-checking labels before disposal. The culture develops best when everyone, from students to senior scientists, commits to the habits—reporting spills, logging waste, inspecting storage areas. Collaboration with environmental specialists remains essential to update protocols if new research reveals deeper risks or new treatment technologies.

It’s not enough to focus on the convenience of new chemicals. True expertise means managing the risks all the way through, making sure the safety net never drops as chemistry pushes forward.