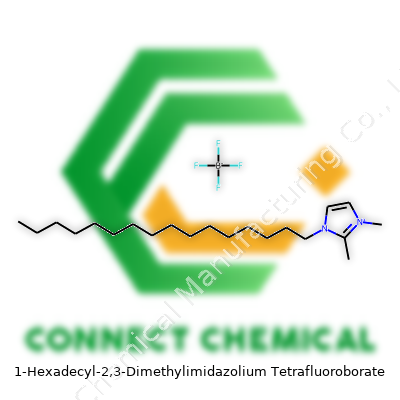

1-Hexadecyl-2,3-Dimethylimidazolium Tetrafluoroborate: Unpacking a Modern Specialty Chemical

Historical Development

Chemistry in the last few decades has delivered a steady stream of new materials with unique application niches. In the growing family of ionic liquids and imidazolium salts, 1-Hexadecyl-2,3-dimethylimidazolium tetrafluoroborate emerged from research targeting more stable, highly lipophilic agents. Early motivators sprang from efforts to move beyond volatile organic solvents toward safer, non-flammable options for extraction, catalysis, and advanced materials development. Researchers took cues from the structural backbone of imidazolium rings and began attaching longer alkyl side chains, including the C16 hexadecyl tail, aiming for compatibility with organic matrices and smoother interfaces in applied chemistry. The choice of the tetrafluoroborate anion often reflected a compromise, offering both reasonable moisture stability and ways to tune properties like viscosity and ionic conductivity. By refining alkylation and methylation methods, chemists found the right tweaks, pushing synthesis from benchtop curiosity toward scalable specialty production after the 2000s, right as demand surged in green chemistry and nanomaterials labs.

Product Overview

1-Hexadecyl-2,3-dimethylimidazolium tetrafluoroborate stands out as a member of the ionic liquid class — salts that, in many cases, don’t solidify at room temperature. Structurally, this molecule brings together a bulky C16 alkyl group, a methylated imidazolium ring, and a fluorinated borate anion. The design provides both hydrophobic and hydrophilic domains, which impacts its solubility and interactions with a broad swath of chemicals. In a lab or plant, you often find it serving as a phase-transfer catalyst, solvent, or surfactant—and chemists interested in manipulating nanomaterial surfaces or stabilizing ionic environments pick it out for these reasons.

Physical & Chemical Properties

With its long hexadecyl chain, the compound often appears as a waxy, light-colored solid or a viscous liquid depending on the precise temperature. Its melting point generally falls just above room temperature, but can shift based on slight tweaks in purity or preparation. The imidazolium core delivers ionic conductivity, although the degree lags behind the shorter-chain analogs due to enhanced hydrophobic aggregation. Like other fluorinated borate salts, it absorbs some water from the atmosphere but resists rapid hydrolysis under neutral conditions. Chemical stability holds up in mildly acidic and basic environments, and the molecule won’t volatilize easily, setting it apart from more hazardous, lower-weight solvents. Viscosity can be high, with handling that feels more like working with grease or honey rather than water or alcohols. Its density and solvating power allow it to dissolve nonpolar and polar chemicals in a single phase — characteristics valued in electroplating and nanoparticle synthesis.

Technical Specifications & Labeling

Producers typically ship 1-Hexadecyl-2,3-dimethylimidazolium tetrafluoroborate with clear labeling on purity, moisture content, and storage conditions. Purity above 98% remains standard for research and commercial orders, with residual solvents, acids, or alkylation by-products kept below trace levels. Single-use containers, such as amber glass or inert-lined drums, avoid contamination and shield the chemical from UV degradation or accidental reaction with atmospheric moisture. Labels mention the CAS number and reveal not just storage temperature but practical notes on required PPE, spill response, and first aid, helping users maintain safety and integrity from delivery through disposal.

Preparation Method

Lab synthesis builds from alkylation of N-methylimidazole with long-chain alkyl halides, using C16 bromides or chlorides, under heat and solvent. The reaction follows a straightforward nucleophilic substitution, running under nitrogen or argon to avoid water pickup, which could quench the chemistry or introduce side-products. Once formed, the imidazolium halide is purified by repeated washing and drying cycles, often requiring careful attention to solvent choice, since some by-products love to cling to the ionic core. Introduction of the tetrafluoroborate anion happens via salt metathesis, usually adding sodium or potassium tetrafluoroborate in aqueous or organic phase, prompting precipitation of the desired imidazolium tetrafluoroborate. Filtering, drying under vacuum, and careful storage deliver the finished material. At industrial scale, automation helps keep moisture and oxygen contact minimal—key to producing kilogram batches for larger projects or customers.

Chemical Reactions & Modifications

Chemists have explored several post-synthetic modifications with this molecule. Its imidazolium ring, while resistant to mild conditions, tolerates further alkylation or arylation on positions not already blocked by the methyl groups. Under high temperature or strong base, ring-opening can occur, though these reactions chiefly serve research rather than routine synthesis. The long alkyl chain gives space for further functionalization, opening the door to amine, thiol, or ether substitutions. These tweaks let researchers build bespoke surfactants or extractants fine-tuned for tough separation problems. In electrochemical cells or surface science, the material’s ionic nature helps it self-assemble on electrodes or nanoparticles, broadening its range of utility. Oxidation and reduction stability compare favorably with other ionic liquids, but over time or at high temperatures, slow decomposition of the tetrafluoroborate may release trace fluoride—a factor when planning long-term device stability.

Synonyms & Product Names

Walk through catalogs or technical papers and you may see alternative names for this chemical. Common variants include Hexadecylmethylimidazolium tetrafluoroborate, C16MIM-BF4, or 1-Cetyl-2,3-dimethylimidazolium tetrafluoroborate. Certain brands add proprietary codes or abbreviations, especially in multi-component formulations. Careful reading of chemical registries and supplier documentation sorts out these synonyms, reducing chances of confusion in cross-reference or procurement.

Safety & Operational Standards

Like many ionic liquids and specialty salts, 1-Hexadecyl-2,3-dimethylimidazolium tetrafluoroborate brings safety needs you can’t ignore. Direct skin contact may lead to irritation, so lab practice always involves gloves and goggles. Inhaling fine powders or vapors, though unlikely at typical room temperatures, isn’t something anyone wants—the compound can cause mucous membrane irritation and in rare cases, sensitize users after repeated exposures. Waste disposal lines up with rules for organic halides and fluorinated salts; incineration in facilities equipped with acid gas scrubbing offers the best route. Storage in a cool, dry spot with containers tightly sealed wards off moisture absorption—a small amount of water can lead to hydrolysis and, over time, affect the chemical’s stability. Safety data sheets bring all this together, and most labs keep a clear log of storage, use, and disposal, both for safety audits and accident tracking.

Application Area

1-Hexadecyl-2,3-dimethylimidazolium tetrafluoroborate plays several roles in emerging industries. In the field of catalysis, its structure lets it serve as a highly effective phase-transfer agent, especially for alkylation or nucleophilic substitution in biphasic systems. The long alkyl chain helps solubilize reactants in organic phases, upping yield and selectivity in industrial reactions. Over in nanotechnology, researchers use it as a stabilizer in nanoparticle synthesis and as a surfactant for dispersing carbon nanotubes or graphene sheets. Certain batteries, supercapacitors, and electroplating baths require precisely these kinds of ionic liquids to achieve desired ionic conductivity and film uniformity. Analytical chemistry labs benefit from its unique polarity balance in extraction processes, especially when trace organic pollutants or pharmaceuticals hide out in tough matrices. Water treatment, lubricants, and even cosmetics have all seen experimental work, since the tailored hydrophobicity lets formulators break away from older, more environmentally troublesome surfactants.

Research & Development

Teams in both academia and industry devote significant benchwork to extending the reach of these functional salts. Focus often lands on tailoring the length and branching of the alkyl tail, or swapping the counterion, to change melting point, toxicity, or solubility for targeted applications. Surface science groups dig into self-assembly on metals, semiconductors, or nanostructures, measuring conductivity and charge mobility. Chemical engineers model these behaviors for scaled-up separations, aiming for cleaner extraction from reactions or environmental samples. Synchrotron and NMR studies track the subtle organization of the liquid at the molecular level, capitalizing on the unique amphiphilic nature for next-gen supported catalysts or membranes. Funding in Europe, China, and North America pushes this family of molecules toward both green chemistry goals and broader industrial adoption.

Toxicity Research

Safety and environmental performance drive current research agendas just as hard as new applications. Toxicity for 1-Hexadecyl-2,3-dimethylimidazolium tetrafluoroborate tends to run higher than shorter-chain relatives, owing to increased bioaccumulation potential and impacts on aquatic organisms. Fish and invertebrate studies report membrane disruption and behavioral changes at fairly low concentrations, so wastewater management and accidental spills present real risks. Mammalian toxicity seems moderate, with direct ingestion or skin contact generating irritation but not acute systemic toxicity at the quantities usually handled in labs. Long-term exposure studies, however, remain thin, especially on the impacts of breakdown products or chronic low-level contact through environmental routes. Regulatory agencies monitor ongoing publication, and as the market expands, comprehensive risk assessments must keep pace with demand and deployment.

Future Prospects

Future prospects for this material and its analogs lie at the intersection of green chemistry, nanotechnology, and sustainable industrial processes. With ongoing revision of manufacturing protocols, researchers anticipate blending lower-toxicity, biodegradable counterions to cut environmental foot print without losing performance. In electronics and energy storage, tweaking the chemical structure could unlock higher temperature stability and enhanced longevity, helping to replace hazardous electrolytes in batteries or supercapacitors. Environmental remediation, from recalcitrant dye extraction to advanced oil recovery, could see new use-cases as tailor-made ionic liquids prove their mettle where traditional surfactants fall flat. Success in these fields requires committed cross-sector research partnerships, clear reporting of health and safety data, and open channels between scientists and policy makers—a model that’s overdue across the specialty chemicals industry.

Peeling Back the Layers: The Formula and Frame

Chemistry sometimes feels intimidating, but diving into a molecule like 1-Hexadecyl-2,3-Dimethylimidazolium tetrafluoroborate, the mystery starts to clear up. This compound’s chemical formula is C21H43N2BF4, which sounds technical, but every part tells a story. It’s built with a long chain of 16 carbons—hexadecyl—stuck to a five-membered ring called imidazolium. Methyl groups branch off at the 2 and 3 positions on that ring. Imagine a sturdy backbone for the organic side, versus the slick, polar BF4- for its anionic companion.

What Difference Do These Parts Make?

The hexadecyl chain stretches out like a molecular tail. This length gives the molecule unusual physical properties. Substances like this turn heads in research circles for their ability to dissolve oils and fats that typically shun water-based environments. I’ve seen graduate students at the fume hood chasing ionic liquids for their “designer” solvent abilities, and this one’s bulky tail means it won’t behave like a simple salt. Its structure helps it stay liquid over a wider temperature range than smaller salts or traditional solvents.

A molecule like this with that imidazolium core—and dimethyl branches—won’t just interact with other molecules using simple attractions. Instead, it brings strong interactions through its ring and the positive charge. The methyl groups push out, giving it bulk, which can prevent unwanted packing together. This helps the substance stay liquid and easy to mix. The imidazolium ring’s nitrogens play a big role too, as they help stabilize the charge and bridge interactions with the counterion.

What’s the Role of Tetrafluoroborate?

On the flip side, the tetrafluoroborate anion (BF4-) rides shotgun. This group doesn’t just provide electrical balance. In practice, BF4- usually brings stability to reactive mixtures. In the lab, I watched ionic liquids with tetrafluoroborate hang in there, staying stable while other, more common salts fell apart or reacted with moisture or acids. The presence of four fluorine atoms, all around boron, beefs up its resilience and makes it fairly inert.

Where Does It Matter Outside the Lab?

Ionic liquids like 1-Hexadecyl-2,3-Dimethylimidazolium tetrafluoroborate aren’t science fiction anymore. They pop up in electrochemistry experiments and get used for separating tough mixtures, even pulling water out of oil in challenging chemical processes. I’ve seen colleagues work to add them to batteries and fuel cells, where their stability and unique ionic balance can make or break performance. An electrolyte with a long alkyl chain and robust tetrafluoroborate core resists evaporation and breakdown, extending device lifespans.

Hurdles and Hopes Ahead

Sometimes, these long-chained molecules can pose challenges. They might show up in aquatic environments and raise eyebrows because they persist in water. Chemists keep an eye out for ways to recover and recycle them, or tweak the structure for better environmental compatibility. Alternatives with shorter chains or different counterions can be swapped in—as research keeps pushing boundaries, it’s worth tracking how molecular tweaks reshape both performance and environmental impact.

Chemistry likes to hide secrets in plain sight, but each piece of a molecule’s frame shapes what it can do. By examining what gets attached to the ring, what trails from the backbone, and which ions keep balance, we can predict and tweak how compounds like this might shape safer, smarter chemistry.

The Backbone of Agriculture

Farming has changed a lot in the past hundred years, and this compound stands out for its role in helping crops grow. I’ve talked with a few local farmers who use it to boost yields and protect against common plant deficiencies. A report from the Food and Agriculture Organization points out that fertilizers have nearly doubled global food production since the 1960s, and this compound is one of the linchpins of that boost. Whether you’re talking wheat, corn, or rice, it helps feed families by nourishing the plants at the root.

A Key Ingredient for Clean Water

Treated water isn’t just a city thing—it matters to anyone who wants to avoid getting sick or seeing fish die off in local streams. Municipal utilities use this compound to help clean drinking water and reduce harmful stuff like bacteria or heavy metals. In high school, I visited a water treatment plant and watched as a handful of these grains cleared cloudy water so folks could safely pour a glass at home. Federal data show that nearly 90% of communities in the U.S. use additives like this to guarantee safe tap water.

Healthcare Benefits Most People Don’t Realize

Hospitals aren’t just sterile places with white walls. This compound helps keep things that way. Manufacturers put it in some intravenous fluids and antibacterial solutions. These applications lower infection risks and help save lives. According to the Centers for Disease Control and Prevention, simple steps like disinfecting surfaces with the right cleaning agents—including compounds like this—cut hospital-acquired infections by up to 30%.

Essential in Food Processing

If you’ve ever seen bread stay soft or cheese resist mold for a week, there’s a good chance this compound made the difference. Food companies use it as a preservative, and it stabilizes flavors and textures in products from deli meat to dairy. After touring a local bakery, I learned bakers have relied on this compound since the 1930s to offer bread that lasts more than a day on the shelf.

Industrial Uses No One Talks About

From construction sites to car factories, the footprint of this compound stretches far. It goes into making glass, dyes, detergents, and even paper. In my first job at a paint store, we stocked buckets of it to help pigments spread evenly across batches. Industry statistics from the American Chemistry Council estimate that U.S. manufacturers use more than a million tons each year, proving it shows up in things you touch every day.

Solutions That Address Future Risks

Heavy use brings challenges. Runoff from fields and factories risks harming lakes and rivers. Real progress means using smart management—precision application for farming, improved filtration at treatment plants, and investments in alternatives where possible. Groups like The Nature Conservancy have demonstrated that cover cropping and buffer strips near waterways cut chemical loss by more than half, preserving benefits without the side effects.

Final Thoughts

Whether you care about what’s on your plate, the water in your tap, or the jobs in your community, the uses of this compound run deeper than most people realize. From food to healthcare, and from fields to factories, it shapes daily life in ways that deserve attention and thoughtful stewardship.

What’s Behind Solubility Questions

Curiosity about whether 1-hexadecyl-2,3-dimethylimidazolium tetrafluoroborate dissolves in water or various organic solvents points straight to the heart of modern chemistry’s focus on practical results. Many researchers step right into the lab with a fresh compound and quickly face the challenge: will this salt go into solution where and how we need it?

With ionic liquids like this one, things can get puzzling. The imidazolium part brings a touch of water-friendliness because of its polar nature, but a lengthy hexadecyl tail stands out—not for affinity to water but for its undeniable draw to oils and other non-polar things. Experience in synthesis tells me: the longer the alkyl chain, the less inclined the salt becomes to mix with water, and this one boasts a sixteen-carbon chain.

What Science Says About Solvent Choices

Open a polar solvent’s bottle, like water, and try dissolving a hefty, hydrophobic molecule like this—results don’t shine. The big hydrocarbon pushes water molecules away and clings to itself, so just a trace will go in before crystals settle back out. Lab manuals and researchers studying ionic liquids confirm that hydrophobic ionic liquids like this barely budge in water.

Organic solvents stand on firmer ground here. Chloroform, dichloromethane, toluene, and even hexane often show better dissolving power for such molecules. There’s a reason: like dissolves like. The tail’s affinity for oily environments becomes an advantage. Try it out: drop a pinch of this salt in dichloromethane and watch it disappear. Colleagues working with imidazolium salts in green chemistry projects have told stories of reactions going smoothly in these organic phases, where water-soluble salts would flop.

Why Solubility Profiles Matter for Real Applications

The solubility story isn’t just a chemistry curiosity. Many teams in catalysis or electrochemical applications look for just the right environment to steer their reactions. An ionic liquid that won’t dissolve in water might keep reactions water-free, which helps when moisture causes problems in the final product or where selectivity matters. In my own work on soft material synthesis, getting solvents right has cut hours off of purification and reduced losses of expensive materials.

Folks in pharmaceutical research keep an eye on solubility for similar reasons. Some drugs stay inactive if delivered with the wrong solvent system. Scientists dealing with organic extractions, phase-transfer protocols, or ionic liquid-mediated separations need to know this stuff cold.

Addressing the Knowledge Gap

Researchers sometimes rush into projects by guessing at solubility based on rough structural analysis. But data from resources like ACS or RSC, as well as hands-on tests, spell out results clearly—1-hexadecyl-2,3-dimethylimidazolium tetrafluoroborate shows low water solubility, but mixes well in non-polar and certain polar aprotic organic solvents. If solvent compatibility becomes a bottleneck, folks can modify either the cation (shorter alkyl chains promote water solubility) or tweak the anion. Pioneering research teams in ionic liquids often engineer their own salts to fine-tune how and where these compounds will work.

Moving Toward Smarter Choices

Direct lab experience and a survey of published results match up: picking solvents for ionic liquids takes more than a hunch. Checking the structure and matching it with solvent properties saves money and trouble. The focus on selecting or designing the right molecule for the job will only grow as more labs adopt green chemistry and resource-conscious frameworks.

Understanding the Risks

Handling any chemical product or industrial material, big or small, demands attention. I have watched colleagues brush off basic safety measures only to end up with irritated skin, eyes that wouldn’t stop watering, or in worse cases, emergency room visits. Certain products can provoke reactions from mild rashes to serious respiratory problems. Some solvents, for instance, linger in the air long after the job wraps up, catching you off-guard. Taking the time to learn what you’re dealing with before you start pays dividends. That label stuck to the side isn’t just legalese—it offers life-saving clues.

Personal Protective Gear Matters

Strapping on gloves and goggles is more than routine for anyone in workshops or labs. There’s a reason old-timers insist on these basics. Protective gloves shield your hands from caustic burns, while eye protection keeps splashes out. A splash of solvent to the eye registers as a sharp burn you don’t forget. Current science recognizes that some vapors stick to skin or enter through breathing. Simple gear—a mask fitted for the job, a lab coat, real shoes (not sandals)—blocks most hazards right at the source.

Good Ventilation Equals Good Health

Fresh air often gets overlooked. Once I worked in a storage room with sealed windows; pretty soon, minor sniffles turned into a team-wide cough. Fumes from even small containers build up quickly. Opening a window or running a ventilation fan changes everything. Research says long-term exposure to airborne chemicals increases risks for asthma and other lung troubles. If the fumes sting your nose or eyes, more air flow is overdue.

Safe Storage Keeps Problems Away

Tossing bottles under the kitchen sink or piling drums in a corner won’t do. Products with strong chemicals can break down if they get too much heat or direct sunlight. Fire departments report dozens of garage blazes from folks leaving flammable cans out in the summer heat. Chemicals deserve their own secure, labeled spots, away from food or kids’ reach. I’ve learned to never trust a faded label. A quick permanent marker note settles any doubt for next time.

Clean-Up and Disposal

Leftover solvents and broken containers can turn a small spill into a community hazard. Dumping liquids down the drain harms local water supplies and creates fumes in confined spaces. City waste management often posts safe drop-off days for hazardous stuff—information worth bookmarking. Cleaning hands and tools right after use stops future contamination and protects anyone who comes after. In my own shed, using a sealed container for soaked rags lowers the chance of a slow burn or a trash fire.

Training and Familiarity Pay Off

Most workplace injuries trace back to taking shortcuts or skipping basic training. OSHA reports repeat that regular safety briefings slash risks more than any single rule. Even veteran workers forget steps when they get too comfortable. Re-reading product instructions or reviewing the safety data sheet takes minutes but saves hours lost to accidents. If needed, asking a supervisor or supplier for clarification doesn’t show weakness—only real concern for everyone’s well-being.

Staying Ahead of the Risks

Every step above draws a line between routine work and a visit to urgent care. By recognizing the dangers, investing in real protective gear, keeping up with fresh air, handling products with focus, and staying sharp on best practices, daily jobs stay safe. Good habits stick for life, protecting you and anyone nearby from mistakes that last much longer than a single shift.

Why Storage Conditions Influence Everything

1-Hexadecyl-2,3-Dimethylimidazolium Tetrafluoroborate isn’t a household name, but those dealing with specialty chemicals learn quickly that a mistake in storage can mean lost data, ruined experiments, wasted spending, or worse — potential harm. This ionic liquid is popular for its stability, but improper storage can test the patience of any lab worker. I’ve seen things go sour when even the most robust compounds are left in the wrong environment.

Simple Rules: Low Moisture and Air-Tight

Chemicals like this one rarely forgive moisture or oxygen intrusion. Water snuck into a vial means unpredictable reactions, lower yields, or messy cleanups. Tetrafluoroborate salts, even in ionic liquid forms, can hydrolyze in damp conditions, throwing off the very properties that make them useful. A tightly sealed glass bottle, preferably packed under dry nitrogen, cuts down exposure. Desiccators with fresh drying agents offer extra insurance. Room temperature is typically enough, just keep it out of sunlight and away from heat sources that build up over time.

Label Everything and Record Dates

Expiration dates don’t always match real shelf lives. Most vendors promise stable properties for up to two years if bottles stay sealed and properly stored. Once that seal gets broken, patience isn't a virtue — use it sooner rather than later. Date the label at each opening and watch for changes in color or viscosity. I’ve seen even high-grade materials drift out of spec in less than a year, especially if folks get lazy with closing bottles or let the atmosphere creep in.

Why Quality Drops After Exposure

It doesn’t take much — a bit of water from humid air, or careless transfers, means the tetrafluoroborate may start breaking down. Byproducts often don’t get noticed until reactions start failing or analysis shows contaminants. Purifying contaminated ionic liquids adds cost and headaches, sometimes outweighing the price of a fresh order. Keeping a log of storage conditions and usage helps spot issues before they spiral.

Lab Safety: Respect the Risk

It’s easy to overlook how these salts can react. Tetrafluoroborate ions produce toxic gases if they meet strong acids or heat. Good airflow and clear labels help prevent surprises. Standard nitrile gloves, lab coats, and goggles — basic, but not optional. Chemical compatibility charts come in handy, especially in busy labs where mistakes can stack up fast.

Solutions: Training and Accountability

Chemicals don’t get safer through wishful thinking. Sustainable storage comes from training — every new staff member learns the rules about air-sensitive materials. Rotating stock reduces the risk of accidental use of expired or compromised material. Digital inventory tools help spot unused items before they turn to waste. Vendors usually offer technical data sheets with storage guidelines, and sticking to those specs saves money and time.

Summary Table: Clear, Practical Guidance

| Condition | Practice | Reason |

|---|---|---|

| Moisture | Store in dry, sealed containers with desiccant | Prevents hydrolysis and unwanted reactions |

| Air | Purge bottle with nitrogen, close tightly after each use | Reduces risk of oxidation and contamination |

| Temperature | Store at room temperature, away from heat | Maintains stability and shelf life |

| Shelf Life | Up to 2 years unopened in optimal conditions | Ensures reliable performance |