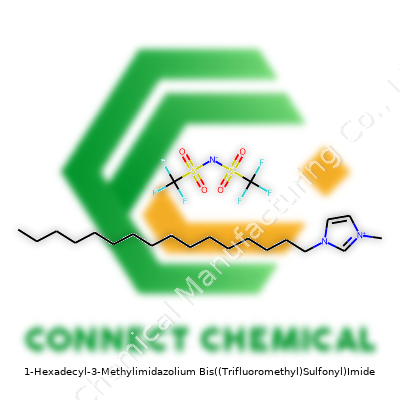

1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: A Practical Look

Historical Development

Chemists began looking to ionic liquid compounds in the late twentieth century, searching for solvents that don’t evaporate at room temperature or catch fire easily. Out of this push, substances like 1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, known in labs as C16MIM-TFSI, started to show up in the literature. The clunky name signals its design: experts mixed long hydrocarbon chains with imidazolium rings, then added a sturdy anion. Older ionic liquids tended to stick to glass and stank to high heaven. C16MIM-TFSI moved things forward with much less odor and stronger resistance to water, letting researchers tinker with battery electrolytes and industrial catalysts in ways that older chemicals couldn’t handle. Many university projects, research labs, and chemical companies over the last couple of decades documented the advances in using imidazolium compounds to handle demanding tasks where classic solvents failed.

Product Overview

Manufacturers usually list 1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide as an ionic liquid—meaning this salt melts to a sticky, oily fluid below the boiling point of water. The formula uses a methyl group and a super-long sixteen-carbon alkyl chain bound to an imidazolium core, balanced by a bis(trifluoromethyl)sulfonylimide anion, which gives it both stability and low volatility. You’ll see it sold either pure or dissolved in a solvent, often by specialist suppliers who focus on high-purity reagents for research and early-stage materials science. In the shipping documents, it sometimes appears as “C16mim-TFSI” or under synonyms linked to CAS numbers. This same compound anchors studies on lubricants, advanced separation membranes, and anti-static additives.

Physical & Chemical Properties

1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide comes as a viscous, nearly colorless liquid at room temperature and resists evaporation even in hot labs. The warmth in your hand can melt the solid to a thick syrup. My own handling showed how little odor comes off compared to a classic solvent like toluene. Its density hovers close to that of water, but the real power lies in a melting point far below most salts, an impressive electrochemical window, and high thermal stability. Try to dissolve it in water, and you see faint cloudiness—hydrophobic tails repel the water and cluster up, which helps in situations where chemists need to separate oily and watery layers. Importantly, this compound shrugs off acids and bases, lets ions move smoothly inside, and rarely serves as food for bacteria or fungi.

Technical Specifications & Labeling

Most bottles of C16MIM-TFSI bear labels with batch data and purity, generally listed at over 98%. You’ll find signal words warning users of minor skin and eye irritation. Safety data sheets spell out the formula C23H41F6N3O4S2 with detailed analytical results—HPLC retention times, NMR spectra, and melting points. Packaging uses thick glass or plastic vessels, never metal, with flat caps and tamper-proof seals to stop moisture and dust. The production standards meet regulations for research chemicals, focusing on consistency between batches, and every batch travels with a certificate showing results for water content, halide impurities, and heavy metal traces.

Preparation Method

Ionic liquids like C16MIM-TFSI usually come from quaternization reactions. Chemists start by mixing 1-methylimidazole with a hefty dose of 1-chlorohexadecane. Under controlled heating, the two snap together, sealing the long hydrocarbon chain onto the nitrogen of the imidazolium. Next, a metathesis swap brings in the bis(trifluoromethyl)sulfonylimide—from lithium or sodium TFSI salts—forcing the original chloride to jump ship and leaving behind the more inert, high-performance ionic couple. Drying and repeated washing remove traces of water and salts until the sample passes quality control.

Chemical Reactions & Modifications

This ionic liquid mostly resists breakdown, which often counts as its selling point. You can swap the alkyl chain for different lengths, though the C16 version stays popular for its surface-active traits—long enough to build structure but still fluid at ambient temperature. The imidazolium ring can accept further tweaks such as extra groups on the ring nitrogens, which dial up or tune down chemical reactivity. Chemists sometimes attach dyes or biomolecules through the methyl group, building functionalized materials for biosensors or smart coatings. One standout feature comes from mixing with other salts: the mixture still stays liquid, changing only its viscosity and conductivity—useful for customizing electrolytes.

Synonyms & Product Names

Besides the mouthful on each bottle, suppliers list the compound as C16MIM-TFSI, 1-hexadecyl-3-methylimidazolium NTf2, or with catalog names that throw the CAS number in (CAS 890380-03-5). “NTf2” stands for the bis(trifluoromethyl)sulfonylimide part, which often pops up in abbreviations on chemical shopping sites. These label variations don’t change the molecule, but they can trip up new buyers trying to cross-reference suppliers or academic papers. Once used in a project, the shorthand terms become almost a language between chemists, smoothing over much of the jargon.

Safety & Operational Standards

Years of lab practice showed me that C16MIM-TFSI feels less risky to handle than many solvents, so long as you respect safety basics. It doesn’t ignite easily, spills don’t cause a stink, and short-term contact rarely leaves a mark. Still, every material deserves respect. The safety sheets note possible irritation—especially if splashed straight into the eyes or onto fresh cuts. Gloves, safety glasses, and smart habits (no pipetting by mouth, no careless storage) prevent nearly every accident. Waste disposal follows standard procedures for organic chemicals. I’ve found it helps to run small-scale tests in a fume hood before scaling up to prevent any reaction mishaps.

Application Area

C16MIM-TFSI plays a real role in electrochemical devices, from batteries and capacitors to sensors and fuel cells. Its ability to dissolve salts and promote smooth ion motion appeals to engineers designing energy storage solutions that need to operate above room temperature or in the absence of water—think electric car batteries exposed to summer heat, or sensors tucked into tight, hot spaces. In the advanced lubrication world, people use it to keep machinery moving under punishment where classical greases burn off or degrade. Researchers also reach for the compound when developing membranes for water treatment or solvent extraction, since it bridges gaps between oil-loving and water-loving molecules. Analytical chemists sometimes include it in chromatography or as a separation medium, since the unique structure sorts out molecules by both size and solubility.

Research & Development

Labs worldwide push the understanding of imidazolium ionic liquids further each year, and C16MIM-TFSI lands a fair share of that attention. Studies probe how minor tweaks—different tail lengths, added groups on the ring—change thermal and conductive properties. Experimental battery cells get built, torn down, and rebuilt with this liquid in every possible weather condition to map its limits. Work also looks at environmental impacts, with researchers checking on decomposition pathways and searching for clues about breakdown in soil or wastewater. Teams aiming for a commercial breakthrough stress-test the liquid under cycling and storage, looking for drift or slow reactions that could wreck device longevity or power delivery. Nearly every big leap in electrochemical storage since the late 2000s brought up new ionic liquids, with each advance measured partly against C16MIM-TFSI standards.

Toxicity Research

Early tests treated all ionic liquids as green alternatives, but later studies, including those using C16MIM-TFSI, uncovered mixed results. This compound avoids most of the headaches caused by solvents like benzene but still resists breakdown in the wild—microbes simply can’t digest long imidazolium chains or the stubborn TFSI anion. Animal studies hint at low acute toxicity when used sensibly, but long-term fate remains under investigation. Wastewater treatment specialists question whether residues could persist or move up food chains, so engineers build closed-circuit procedures to recover and recycle this liquid after use. To keep things safe, responsible handlers never dump it after experiments, but treat or burn it using approved waste streams.

Future Prospects

C16MIM-TFSI could shape the next wave of green chemistry, especially in energy and environmental technology. Improvements in synthetic methods could bring down the cost, letting more companies upgrade battery and fuel cell systems. Work on catalysis and material science holds plenty of promise—adjusting the molecule or blending with other ionic liquids might lead to new uses in drug delivery or pollution capture. Regulatory agencies will pay close attention to disposal and recycling, with stricter product stewardship and “greening” of both starting materials and by-products. As labs and factories learn from each round of results, the practical toolkit will get bigger and more sustainable, moving beyond curiosity toward true industry uptake.

The Hidden Powerhouse in Modern Chemistry

Staring at a chemical name like 1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, most folks outside of a research lab might zone out, but this ionic liquid has backed some of the quieter revolutions in tech and industry. Lab benches and pilot plants have seen its thick, almost syrupy limelight, carving a reputation for handling jobs that regular solvents would give up on.

Keeping Things Green and Efficient

My experience at a materials science lab taught me about the headaches caused by volatile organic solvents—heavy fumes, long cleanup, and disposal nightmares. This imidazolium-based ionic liquid barely evaporates, which means it can hang around longer and cut down on emissions. In green chemistry, that’s gold. Chemical engineers love using it to build new catalysts because it lets them skip the tough balancing act with heat and pressure. Instead, experiments chug along gently, saving both time and energy.

The Electrochemistry Advantage

Electrolyte researchers often rave about ionic liquids for their stability and unique electrical properties. This particular salt can shuttle ions across electrodes in batteries and supercapacitors without the fire and explosion risks a lot of classic electrolytes bring. Some of the latest research points to better-performing lithium-ion and sodium-ion batteries when this ionic liquid steps in. It seems expensive, but over the full lifetime of a device, it actually saves money, because batteries last longer and require less hands-on maintenance.

Nanotechnology’s Secret Sauce

Applying this chemical in nanomaterials synthesis, I saw how it played almost a dual role. On one side, it acted as a solvent, dissolving the reactants. On the other, it stayed involved, controlling the size and shape of the nanoparticles that formed. Without its stabilizing touch, it’s tricky to keep nanoparticles from clumping together or breaking down. That’s part of what keeps it high up on the shelf in every advanced materials lab.

Solving Extraction and Separation Problems

Metal-mining operations and recycling centers have started bringing this ionic liquid into their process streams—especially for extracting rare metals and precious catalysts from electronic waste. It strips metals from complicated mixtures with more selectivity than old-school acids and bases, often at room temperature. A friend working in environmental remediation mentioned that it cuts down on hazardous by-products, making overall waste management less daunting.

Pushing for Widespread Adoption

Any commentary on ionic liquids has to mention cost. For a long time, the price tag kept most companies away, especially outside of niche research. That’s slowly changing. More industrial players have been figuring out recycling tricks—recovering and reusing this stuff across batches. With scale-up, the entry cost drops, opening doors across battery plants, pharmaceutical labs, and chemical facilities.

As more engineers and scientists share their ways of recycling and reusing this ionic liquid, expect it to pop up far outside universities. Losing the fumes of old solvents and gaining robust new products, that’s real progress. My own view: no one compound saves the world, but 1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide shows how smart chemistry cuts through bottlenecks, leading the push into safer, cleaner, better-performing technology.

Why Chemical Stability Holds the Key

Anyone who has ever found an old bottle of medication in the back of a cabinet knows that chemical stability affects everything. The reasons stretch beyond dated warnings. Chemical stability tells us whether a product holds up over days, months, or years, in the face of light, air, water, or unpredictable temperatures. Skipping stability studies risks harming both businesses and anyone relying on the product.

Pharmaceutical giants, paint manufacturers, food companies—everyone confronts this question, in some way or another. If a chemical compound changes too quickly, it either loses its power or becomes potentially dangerous. That alone proves chemical longevity is not a box to tick for regulators, but a baseline for trust.

How Environment and Packaging Impact Shelf Life

My own chemistry coursework showed the real nitty-gritty of product longevity. Toss a well-sealed vitamin tablet and a paper-wrapped bar of soap into a muggy bathroom, and watch which one degrades first. Humidity, oxygen exposure, and even the color of the container play their part. Clear bottles let in light and spark reactions; amber glass blocks ultraviolet rays, cutting down on breakdown. It’s a difference you can see with faded versus fresh vitamins—testing really does matter.

Manufacturers use stabilizers and antioxidants to slow decay, but the best trick I ever saw was proper sealing and dry storage. People ignore “Store in a cool, dry place” at their own risk. That’s what shelf life warnings are getting at: don’t expect a chemical to outlast its enemies forever.

Shelf Life: Beyond Expiration Dates

An expiration date gives a target, but it’s built on accelerated aging tests and real-world observation. A pharmacist once told me, “Everything comes down to how you store it.” Old aspirin, for instance, famously smells like vinegar over time due to chemical breakdown—it still might work but won’t meet expected potency. So shelf life becomes a guarantee the compound will deliver as promised up to a certain month and year, assuming you follow storage directions.

Food, drugs, and industrial chemicals lean on similar science, even if the media focus falls on lifesaving drugs. Vitamin C drinks, cleaning sprays, glues—they all degrade. Those faded labels and strange smells? That’s the result of time at work on molecules.

Building Trust with Testing

Folks in quality control labs run thousands of stability trials each year. They subject samples to harsh temperatures or light for weeks or months, measure active ingredients, and check pH levels. Businesses invest in this because customers need to know what they’re getting today will do the same job months down the line. Regulatory auditors look for this data in every industry.

Transparency and clear storage instructions help everyone make safer choices. Digital tracking systems, tamper-proof seals, and easy-to-read expiration dates make a difference. Sharing stability science publicly lets people judge risk and avoid guesswork.

How to Improve Shelf Life Moving Forward

To lengthen shelf life, companies rely on smarter packaging, new preservation additives, and temperature control—especially in shipping. For small-scale projects or DIY formulations, it pays to mimic these pros: keep things sealed, cool, and dry, and always respect the clock on the label.

Chemical stability isn’t an afterthought—it’s the backbone of safe and reliable products in medicine, food, and beyond. Relying on well-studied stability data and good storage habits keeps products working the way they should, building trust between makers, sellers, and the public.

Understanding What’s on Your Bench

In any lab, you run into chemicals with names that stretch across two lines on a bottle. 1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide belongs on that list. It’s a mouthful, but thrown around where ionic liquids turn up, whether you’re dissolving tough polymers or separating metals.

Folks familiar with this compound see it as a room temperature ionic liquid. Unlike many older lab solvents, it barely evaporates, doesn’t emit sharp fumes, but can throw off anyone not paying attention. The fluorous part of its name hints at strength—the type of strength that can sometimes bite back if you ignore it.

Storage Wisdom: Beyond “Cool, Dry Place”

Let’s be honest, “cool, dry, and well-ventilated” has turned into wallpaper advice in labs. In reality, you want more than labels. Keep bottles sealed tight. Humidity acts like an invitation for ionic liquids to soak up water from air. Extra water can change the way your whole experiment runs—reaction speeds, solubility, even the way the liquid acts when you touch it.

Sunlight and fluctuating temperatures create chemical headaches over months. I’ve stashed bottles away from windows and radiators, even tucking them into ziplock bags as double-seals sometimes. Cold rooms can get too cold. Room temperature stays safest; I’ve seen crystallization cause label confusion when people leaned on the freezer unnecessarily. Avoiding cross-contamination can be as simple as not storing acids, bases, or strong reducing agents in the same cabinet.

Practical Handling: Gloves, Goggles, and Mindful Moves

Anyone who’s handled ionic liquids quickly learns gloves aren’t optional. I stick with nitrile or neoprene—I once saw latex start to yellow and fall apart after some spills. Not dramatic, just inconvenient, but repeated exposure probably isn’t doing anybody’s skin favors. It acts as a mild irritant, and while you won’t find people keeling over, regular contact brings its own risks. Always avoid distractions while pouring; drops roll everywhere, and that slipperiness lingers on benchtops.

Eye protection isn’t up for debate. Once, a splash during a weigh-in left me flushing my eye for a paranoid ten minutes. Even liquids that don’t sting at first can do long-term harm; the fluoro and sulfonyl parts make this one worth the caution. Use a spatula or pipetter instead of fingers, and always double-check that nearby containers are out of the spill zone.

Ventilation, Clean-Up, and Waste

Fume hoods deserve more respect than they get. Even if you don’t notice an odor, breakdown or reaction products sometimes surprise you. For messy bench spills, I lean on absorbent pads followed by detergent and a generous rinse. Getting every last trace off glassware stops problems that might pop up later.

Waste disposal trips up beginners. Dumping down the sink causes big problems both inside and outside the lab. Ionic liquids sometimes break down in the environment into tricky by-products. I prefer labeled, dedicated containers for waste, stored safely till the next pick-up. Local rules about ionic liquid disposal change, so check every few months for updates.

Caring for People, Tools, and Experiments

Labs work best as places where nobody hesitates to flag up a spill or mislabel. I keep clear records—labels, dates, and safety data handy. As part of any lab team, sharing personal tips and reminders about safe chemical handling matters. With complex-sounding chemicals, simple steps save headaches. Working thoughtfully with 1-Hexadecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide keeps both people and projects running smoothly.

Real-World Stakes with Purity Levels

I’ve seen labs lose weeks of work all because one shipment didn’t hit the mark for purity. Most research teams don’t take a jar of white powder at face value. Purity tells you what you're really working with. If a researcher orders sodium chloride, and the supplier promises 99.9% purity, everyone expects only trace water or sodium sulfate to sneak in. Anything lower brings risk that goes beyond numbers on an analysis sheet; contaminated compounds can throw off reactions, shut down production lines, or even cause health problems if the compound ends up in food, meds, or personal care products.

Defining Typical Purity Specifications

For active pharmaceutical ingredients, people in the industry look for at least 99% purity, validated by accredited labs. Impurities above 0.1% appear in the certificate of analysis. In food additives, 98% often cuts it, but the expectations keep rising because so many people depend on what goes into food. Tech-grade or industrial chemicals can land around 95–97%, though it depends on where they end up. You won’t want electronics-grade solvents near a circuit board unless their impurity profile is well-documented and falls below parts per million for things like metals or water.

Reasons Purity Causes Headaches

Some folks might think minor impurities don’t matter, but the strange things that show up can change the entire outcome. Imagine someone working on a new medication. If a compound brings along trace iron or copper, those metals can trigger unwanted side reactions, sometimes creating toxic byproducts or ruining months of testing. The same goes for making polymers or specialty plastics. Unlisted impurities can destroy party-popping yields or compromise the strength and safety of the final product.

Verifying Claims with Trusted Data

You want more than just numbers on a spec sheet. Reliable companies provide chromatograms and spectra, either from HPLC, GC, or NMR, to back their claims. If a supplier says their material hits 99.5% purity, most chemists and quality managers look for batch-to-batch consistency and a real certificate signed by a qualified technician. Mistakes and cut corners show up in returns and recalls. My own experience taught me to ask questions and get more than a sales brochure. Trusted relationships with suppliers keep mishaps at bay.

Making the Case for Transparency

It feels safer when ingredients, batch numbers, and impurity profiles are openly disclosed. That’s not just nice for paperwork. Clear standards help hold everyone accountable, lower the risk of product recalls, and protect the end-user, whether it’s a scientist in a university, a nurse giving medicine, or someone eating a bowl of cereal. It’s not enough to talk about a number; context matters—what makes up the other 0.1% could mean everything.

Paths to Consistent Purity

Sometimes, simple solutions work best: ask for certificates, dig into test results, and run your own checks. For high-stakes applications, people frequently demand documentation from start to finish. On the manufacturing side, batch monitoring and quick feedback loops tighten those standards. Real improvement needs investment in staff training, clear protocols, and a stubborn focus on what the end-product will touch—people, machines, or the environment.

What’s at Stake Beyond the Lab

Years ago, I came across a case where a manufacturer ignored a “small” impurity. That little oversight led to an expensive recall and made real people sick. Standards around purity aren’t just about ticking regulatory boxes—they’re about trust and safety in a world that depends on molecules doing exactly what they’re supposed to do.

Why Product Safety Means More Than Just Labels

Reading a label can give peace of mind, but real peace comes from understanding what sits behind those words. Whenever something is used at home, at work, or in schools, most people expect it to be safe. That assumption doesn’t come from nowhere—years ago, families stopped using lead paint and asbestos after learning what those did to health. Stories like these show why it’s important to question what’s inside every product, and not take claims at face value.

Real Issues—Not Just Numbers on a Data Sheet

Science tells us that some ingredients, though approved for use, can still cause trouble if handled carelessly. Take cleaning agents, which sometimes contain compounds that irritate skin, trigger asthma, or release fumes indoors. Laws often set exposure limits, yet minor spills or repeated use can affect kids, pets, or workers long before legal thresholds get crossed. According to the CDC, around 2,000 children in the US require emergency care daily due to household product poisoning. These aren’t rare accidents—they prove that packaging and “child-safe” caps only do part of the job.

Cosmetics stir up a different set of concerns. As a consumer, it's easy to trust that hyaluronic acid or plant extracts do no harm, but even products that avoid banned substances can sneak in questionable extras: microplastics, fragrances, formaldehyde-releasing preservatives. EWG’s Skin Deep database routinely flags popular lotions and soaps for ingredients linked to hormonal changes and skin reactions. A close friend of mine developed eczema after trying a new “gentle” hand cream, only to learn it contained methylisothiazolinone—a known allergen banned in the EU, still legal elsewhere.

Who Bears Responsibility?

Safety demands more than hope and caution. Manufacturers must do more than check regulatory boxes. They own a duty to test products as real people use them—wild temperature swings in a delivery truck, high humidity, a three-year-old squeezing half a tube on herself. Companies should share results from toxicity tests and data on how ingredients behave over time, not just at launch. The FDA and EPA play key roles, but their recall databases show they often catch problems after people fall sick.

End-users own some responsibility, too, but clear guidance matters. If warnings only say “seek medical help if swallowed,” they ignore eye contact, skin exposure, and what mixing with other cleaners might do. Honest, readable labels go much further than jargon or symbols that leave folks guessing. Sales pitches about “natural” or “eco-friendly” mean little without backup from third-party certifications or batch testing.

Protecting Ourselves and Each Other

Education stands out as a proven solution. Schools and workplaces need to update their safety trainings regularly. At home, more families turn to phone apps that scan barcodes and flag ingredients linked to toxicity or allergy risk. Small actions—like storing products out of reach, better disposal, or venting a room—cut risks, too.

The push for safer products picks up steam only when everyone stays vigilant and asks questions. My own routine now includes looking up ingredients, checking recent news for recalls, and talking to friends who work in health care. That willingness to stay informed may prove more effective in the long run than any warning label.