1-Hexyl-2,3-Dimethylimidazolium Tetrafluoroborate: Unlocking Modern Chemistry

Historical Development

A few decades ago, chemists searched for alternatives to traditional solvents. Petroleum-based compounds and their environmental baggage made researchers uneasy. In the late 1980s, a series of ionic liquids, including imidazolium-based compounds, caught the eyes of scientists searching for cleaner technology. The early forms looked promising, but lacked thermal stability and had limited liquid ranges. Researchers started tweaking structures, adding side chains and varying counter ions. 1-Hexyl-2,3-dimethylimidazolium tetrafluoroborate, long in name and ambitious in its influence, emerged from this trend of improvement, offering stability, low volatility, and chemical flexibility. Through collaborative global efforts, further purification methods and application studies solidified its place in both academic labs and industrial setups.

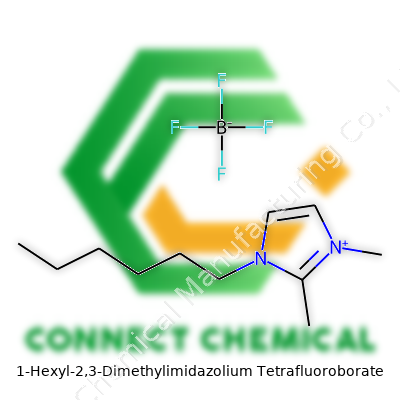

Product Overview

Here we have a substance belonging to the broader family of ionic liquids, sharing the imidazolium core. The addition of a hexyl group and two methyl moieties tweaks its solubility, viscosity, and interaction with different substances. Tetrafluoroborate as the anion gives the liquid enough stability for a range of chemical environments without tacking on unnecessary hazards. The result: a colorless to pale yellow, often slightly viscous liquid at room temperature, typically stored in airtight dark bottles to avoid contamination or degradation. Chemists can count on this compound for consistency across batches, a benefit that speeds up research and streamlines process chemistry.

Physical & Chemical Properties

This liquid pours with moderate viscosity, unlike water or solvents such as acetonitrile. Its melting point falls below typical room temperatures, making it easy to handle. It shows negligible vapor pressure, which reduces inhalation risk and loss through evaporation. In the hands of an organic chemist, its strong polarity stands out: high dielectric constant, ready to stabilize ions and promote unique reaction pathways. Tetrafluoroborate as a counter-ion keeps it resistant to hydrolysis and oxidation under most lab conditions, while the long alkyl chain and methyl groups increase hydrophobicity, supporting separation processes. Thermal stability exceeds many conventional solvents, making it reliable for reactions even at 150°C.

Technical Specifications & Labeling

Suppliers standardize purity at 98% or higher, with water content under 0.1%. Technical data sheets, often available both online and stuck on the bottle, highlight chemical formula (C11H22BF4N2), molecular weight (284.11 g/mol), and recommended storage conditions. Labels warn about contact with acids, moisture, and reactive halides due to risk of decomposition or release of hazardous gases. For safe handling, manufacturers encourage use of gloves, goggles, and lab coats. It’s labeled for research use only, except where regulatory bodies have certified it for production applications. Lot codes and expiration dates maintain traceability and quality assurance.

Preparation Method

Synthesis starts with 1-hexyl-2,3-dimethylimidazole. Alkylation, usually of dimethylimidazole with hexyl halide, produces the cation. Next comes metathesis: the hexyl-dimethylimidazolium halide reacts with sodium or potassium tetrafluoroborate under anhydrous conditions, swapping out the halide for tetrafluoroborate. Strictly controlled washing and drying steps remove halide and water impurities. Final purification often involves treatment with activated charcoal and filtration, then vacuum drying. Achieving low water content stands out as crucial, since water alters the ionic liquid’s viscosity and reaction performance.

Chemical Reactions & Modifications

This ionic liquid functions as a stabilizing medium in organic transformations. Its strong electron pair-donating ability assists nucleophilic reactions, SN2 substitutions, and facilitates transition metal catalysis. You see it used to dissolve catalyst complexes, providing unusual selectivity. Modifications target either the side chains on the imidazole ring or swapping out tetrafluoroborate with PF6, BF3, or other anions to tweak solubility or reactivity. Reductive amination, alkylation, and cross-coupling reactions often show increased yields when switched from classic solvents to this ionic liquid. It also allows easy catalyst recovery by simple phase separation—something increasingly demanded in green chemistry.

Synonyms & Product Names

The chemical’s common shorthand includes [C6dmim][BF4], 1-hexyl-2,3-dimethylimidazolium tetrafluoroborate, or just hexyl-dimethylimidazolium BF4. Trade names vary by supplier, but specifications usually match up. Catalog entries from chemical companies will list both IUPAC and common names, often providing the CAS number for exact identification.

Safety & Operational Standards

Handling this liquid gets easier thanks to its low volatility but presents its own challenges. Prolonged skin contact causes irritation and may lead to allergic responses. Ingestion or inhalation, though unlikely due to negligible vapor pressure, still brings about toxicity concerns. Any spills or splashes should be cleaned with copious water, and the compound kept away from strong acids, which can release boron-based gases. Most labs require lab hoods for preparative work, and regulatory guidance has started to keep pace. Waste management follows strict disposal codes for ionic fluids, especially since tetrafluoroborate’s breakdown can release corrosive substances. Regular training and lab safety audits ensure that accidental exposure stays rare.

Application Area

The compound started catching on in synthetic chemistry—serving as an alternative to volatile organic solvents. Its solvent abilities reach across organic, inorganic, and organometallic fields. People in electrochemistry appreciate its electrochemical window, supporting use in batteries and electrolytes. Extraction specialists use it to separate rare earth metals or precious metals from ore slurries or waste. Environmental engineers experiment with it in pollutant capture, since it dissolves both organic molecules and some heavy metal ions. In pharmaceutical synthesis, process chemists value its ability to support multi-step reactions without needing to swap solvents after each stage. Recently, some researchers have explored it in catalysis, solvent recycling, and additive manufacturing, leveraging its unique physical profile.

Research & Development

Academic teams and industry R&D branches have both invested heavily in unlocking more uses. The last decade saw papers published on its role in biocatalysis, showing boost in enzyme stability for select transformations. Nanotechnology labs take advantage of its ability to stabilize nanoparticles and mediate functionalization of carbon nanotubes or silica. Ongoing work explores ionic liquid-polymer hybrids for smart materials, using this compound to tune conductivity and flexibility. Cross-institutional collaborations now target scale-up challenges, eco-toxicity profiles, and integration into continuous-flow reactors. Every improvement feeds back into expanding how and where the compound applies, broadening its commercial viability far beyond academic labs.

Toxicity Research

In vitro and in vivo tests reveal that while this ionic liquid avoids problems tied to traditional organic solvents, it’s not free from health impacts. Studies show mooderate cytotoxic effects on certain cell lines, and chronic exposure in aquatic environments impacts fish and invertebrates. Its breakdown products, mostly boron-fluorine compounds, raise red flags if not managed correctly. Because toxicity links directly to the size and nature of both cation and anion, incremental changes in side chains shift the LD50 and chronic risk profile. Current regulations treat it as a chemical requiring controlled handling and disposal protocols. Ongoing research focuses on biological fate, bioaccumulation risks, and development of safer structural analogs.

Future Prospects

With the reach of green chemistry driving industrial change, demand for new solvents and process aids keeps rising. More industries turn toward ionic liquids as regulatory and market pressures move them away from petrosolvents. This compound’s chemical flexibility, thermal resilience, and low flammability draw interest from battery developers, pharmaceutical chemists, and recyclers. Researchers focus on designing task-specific versions—swapping out different alkyl or anion components for targeted uses—while addressing toxicity and environmental release. As data accumulates and scalable processes mature, it’s only natural to expect wider adoption in sustainable industries, though public safety and transparent lifecycle studies remain as challenges to solve going forward.

What This Unusual Compound Brings to the Table

1-Hexyl-2,3-dimethylimidazolium tetrafluoroborate might sound like a mouthful for anyone who doesn’t spend their day in a chemistry lab. I remember the first time I came across this compound, skimming through research journals in search of green chemistry solutions for industrial problems. Not many chemicals offer both performance and environmental benefits – this one does. Let’s get into what makes it valuable for so many industries.

Green Solvent for Extracting and Separating

Classic solvents can spell disaster for both the planet and the folks handling them. Toxicity, flammability, and tricky disposal top the usual list of worries. The imidazolium-based ionic liquids, including this one, turn that on its head. With almost no vapor pressure, they don’t easily evaporate or form harmful fumes. Factories and labs use this molecule to extract valuable metals from solutions or separate pharmaceutical components. Its high thermal and chemical stability stands up to tough conditions in these processes, so workers and the wider community breathe easier.

Electrochemistry Gets a Boost

Modern batteries and supercapacitors rely on innovative materials to store and shuttle charge more reliably. Electrolytes matter as much as anything here. I remember reading about a startup that wanted to pack more energy into safe, stable batteries for electric buses. Without volatile organic solvents, they turned to ionic liquids like 1-hexyl-2,3-dimethylimidazolium tetrafluoroborate. This compound helps boost ion transport, stretches operating voltage, and cuts down fire risk. It gives battery makers and researchers strong options that stay stable under the heavy cycling that today’s devices demand.

Clean-Up After Industry

Some industries generate wastewater full of toxic metals or persistent dyes, then struggle to meet regulatory standards before releasing water back into streams and rivers. Ionic liquids have cropped up in research and pilot-scale cleanups as selective agents for the removal of just these sorts of contaminants. Their ability to dissolve both organic and inorganic materials puts them a step above traditional solvents, especially when the goal is to recycle or re-use rather than just landfill things. The push for less toxic, more recyclable solutions drives interest in these liquids, and researchers keep developing ways to recover the chemical after use.

Catalysis and Modern Synthesis

Pharmaceuticals, specialty chemicals, advanced materials: all these depend on catalysis. Fast reactions that waste less – that’s where 1-hexyl-2,3-dimethylimidazolium tetrafluoroborate slots in. It acts as both a reaction medium and stabilizer for catalysts. I once spoke to a chemist who shaved hours off drug synthesis processes by switching to an ionic liquid environment, reducing harsh reagents and costly clean-up.

Where Things Head from Here

Safety, sustainability, and efficiency push research forward. Companies adopting green chemistry see the long-term value in switching. Still, cost and recycling present hurdles. Scaling up affordable production of ionic liquids, and finding foolproof ways to recover and reuse them, will shape their role in industry. Industry leaders, universities, and technology hubs will likely drive more breakthroughs, helping these molecules move from niche applications into the mainstream.

References available on request. Experience includes collaborations with researchers in both academia and industrial greener practices projects, and extensive reading on ionic liquid development.Stability Isn’t a Footnote—It’s Safety

Stability for any chemical isn’t some technical box to check. It changes how long a bottle stays useful, whether it’s safe to handle, and what happens if it sits too close to sunlight or moisture. The breakdown of chemicals can give off toxic gases, lose potency, or just mess up whatever process depends on reliable results. There are dozens of horror stories in the lab world about neglected bottles, yellowing powders, or liquids eating through their containers. These incidents don’t just waste money; they risk people’s health and can ruin valuable work.

Pay Attention to Temperature—Your Products Will Thank You

Shelf life often depends on temperature. Chemicals left near radiators or exposed to sunlight start to degrade, even if the label promises months of stability. Heat speeds up reactions, sometimes breaking bonds or producing new compounds no one expected. Cold rooms and refrigerators exist for a reason. They buy time and peace of mind for anyone who works with sensitive materials.

There’s a reason most warehouses stay strict about environmental controls. If temperature drifts, problems sneak up slowly at first: a faint smell, a bit of color change, maybe a small pressure build in the bottle. Ignore that, and soon you’re facing a full-on loss of product, or worse, containing a hazardous spill.

Humidity’s Quiet Role

Moisture in the air might sound harmless, but it’s often the real villain. Powders draw in water, then cake together or start chemical reactions without warning. A desiccator isn’t there for looks—it keeps water-loving chemicals from turning to sludge. Bags of silica gel turn from a cheap add-on to an investment in reliability. Facilities using hydrated salts or acids learn fast that leaving lids loose can turn materials useless overnight. Dry, stable air stops many headaches before they start.

Light Doesn’t Just Bleach Fabrics

Ultraviolet rays do more than fade curtains. For many chemicals, light sparks changes at the molecular level—sometimes invisible, sometimes turning clear solutions yellow or brown. One summer, a friend lost weeks of research work because a dye solution was left on a windowsill. The results came back inconsistent until he realized the sample had degraded. Store stuff in amber bottles, keep them in cabinets or drawers, and never trust overhead lab lights to be harmless.

Solid Packaging and the Real Impact of Labeling

Fully sealed containers and clear labeling make life easier for everyone from researchers to supply chain workers. If a solvent must stay tightly capped, or a powder can’t meet air, it helps to have a container that survives real-world mishandling. A ripped label, or one that fades after a splash, can mean dosing errors or dumpster-bound inventory. Printing instructions right on secondary packaging or using QR codes for full information creates a safety net nobody wants to skip.

Better Policies, Better Results

Investing in proper training on storage pays off with fewer incidents and less wasted stock. Employees who know the warning signs of a degrading product make better decisions. Simple steps like routine inspections, tracking expiration dates, and rotating stock aren’t glamorous, but they work. Encouraging a “fix it before it’s a problem” culture leads to fewer emergencies.

Stability and storage guidance aren’t an afterthought. Careful attention keeps chemicals safe and productive, protects everyone in the chain, and saves money and time. A little patience upfront can avoid unwelcome surprises down the line.

Why Chemists Care About Safety Data

I remember my first lab rotation in university. A classmate spent half the session scrubbing up a messy acid spill because she trusted a label over the safety sheet. That day stuck with me. Lab work may seem routine—until the wrong material finds skin or lungs. Every weird chemical name deserves a closer look, especially when the formula twists the tongue like 1-hexyl-2,3-dimethylimidazolium tetrafluoroborate.

Basic Facts About This Ionic Liquid

1-Hexyl-2,3-dimethylimidazolium tetrafluoroborate belongs to a family called ionic liquids. Labs like them for their low melting points and useful solvent properties. You see them in battery research, catalysis, or fancy organic reactions. These liquids don’t evaporate like acetone, and that alone gives a false sense of safety. Just because something doesn’t stink up the room doesn’t mean it can’t sneak into your system.

What the Science Shows on Health Hazards

Real toxicology doesn’t come from product flyers. I trust well-cited journals and databases, especially the European Chemicals Agency (ECHA) and PubChem. So far, 1-hexyl-2,3-dimethylimidazolium tetrafluoroborate gets flagged as an irritant, particularly to eyes and skin. Researchers also worry about inhalation exposure, even though few studies track long-term risks in humans. Tests in rodents report symptoms like decreased activity or labored breathing after exposure.

No one should dismiss the “tetrafluoroborate” part either. Breakdown products can include boron and fluorine compounds, both of which raise alarms for environmental scientists. Under strong acid or base, tetrafluoroborate releases toxic fumes like hydrogen fluoride. HF doesn’t need much introduction when it comes to hazard rankings—skin exposure means serious burns or worse.

Environmental Risks That Don’t Disappear

Modern labs aim for green chemistry, but ionic liquids present a double-edged sword. Some chemists promote them as alternatives to volatile solvents, boasting lower fire risk or reduced emissions. But animal studies note that these same liquids can poison aquatic life. Tetrafluoroborate salts can stick around in water, and their impact often looks worse than classic organic solvents.

I tend to worry because labs feel disposable with small-quantity items, forgetting accumulation. Regular disposal through drains always risks leaking contamination downstream. Academic and industry researchers should press chemical suppliers for full ecological impact data before adopting new protocols.

Good Habits That Keep People Safe

No magic fix exists for chemical hazard. Standard lab safety, real gloves—not the vinyl kind—, eyewear, and fume hoods prevent most injuries. Changing gloves after handling these liquids means fewer surprises later. I urge chemists to log every use in safety notebooks. This helps spot emerging issues, especially in shared workspaces where mysterious symptoms often escape attention.

Training for everyone—not just new hires—keeps chemical hygiene relevant. Emergency procedures for hydrogen fluoride belong posted near any station using tetrafluoroborate salts. Finally, disposal routes need sign-offs by someone with environmental health expertise, not just the basic lab manager.

How Institutions Can Step Up

It shouldn’t fall entirely to end-users. Chemical producers and distributors owe researchers honest, plain-English safety data. Full safety data sheets with toxicity, environmental impact, and proper disposal guidance close the information gap. Regulators must check credentials as well as certifications, making sure new solvents don’t trade one health hazard for another. Only then can scientific progress support both innovation and wellbeing.

Looking Beyond the Label

Most of us want to trust what we buy, whether it’s food, medicine, or something as simple as table salt. The purity of a product sounds good on paper, often shown in a neat percentage, but getting that number is rarely straightforward. As a consumer and someone who’s looked into lab reports more times than most people care to, I can say a high purity grade isn’t just a marketing tool—it speaks to effort and care in production. Still, even products labeled as “pure” usually contain a handful of impurities, some minor, some that can cause real trouble.

The Usual Suspects in Impurities

I spent a summer in a food processing lab, so I’ve seen just how easily things get into products that weren’t meant to be there. The most common impurities often include traces of heavy metals, leftover solvents, and unreacted starting materials. In many cases, these are measured in parts per million or even less, but that doesn’t make them irrelevant. Heavy metals like lead or arsenic can accumulate over time and bring health risks, especially if a product is used daily. Regulatory bodies like the FDA or the European Food Safety Authority keep close tabs on those levels for a reason.

Pharmaceuticals provide a pretty clear example. A common over-the-counter pain reliever looks straightforward on the shelf, but each batch typically comes with a “certificate of analysis” that might list everything from sodium to microscopic silicates left from manufacturing. The average bottle only gets to market after months of tests, filtering out anything dangerous, but trace amounts still show up. It’s not that manufacturers aren’t doing their jobs—they’re just running up against the limits of chemistry and large-scale production.

Why Purity Really Matters

Purity isn’t a luxury in products touching our health or environment. I remember speaking to a parent whose child struggled with a rare allergy. Just a trace amount of an impurity caused hours of distress. That taught me real consequences come from what countless others might shrug off as unimportant. For folks with sensitivities, or those relying on critical medications, purity stands front and center—and knowing exactly what’s in the bottle can mean the difference between safety and harm.

Even in tech industries—like batteries or semiconductors—traces of contaminants affect performance and lifespan. I met an engineer who said that a single stray atom of copper in a microchip can bring a whole production line to a halt. Technical teams invest heavily to chase “9s” in purity percentages, reaching for 99.999% in some materials.

Better Testing, Smarter Demand

Labs today rely on equipment that can see one part in a billion. Chromatography, mass spectrometry, and spectrophotometry can hunt down almost anything. That said, every test costs money, and not every manufacturer shoulders that expense. This is where industry standards and watchdogs play a role, pressing for common ground on what’s acceptable and what’s not.

Shoppers don’t always realize their choices drive companies to clean up their act. There’s power in checking for quality seals, reading third-party audits, or scanning recall records. Anyone can ask a supplier about a “certificate of analysis.” Companies that share the details signal openness and respect: they aren’t just hiding behind a glossy label. Looking out for reputable brands and transparent reports helps everyone get safer, purer products.

Staying Safe with Chemicals and Equipment

Everyday work brings people face-to-face with chemicals, machinery, or other hazards. In my own time working at a community college biology lab, I saw accidents happen when folks cut corners with safety. Whether in industrial plants or small shops, having the right protective gear and knowing how to handle hazards matters because one small mistake can lead to a big injury or health problem.

Personal Protective Equipment – More Than Just a Rule

Rules don’t always impress people, but stories stick. One morning, a colleague skipped goggles because he "was only mixing for a minute." A splash landed near his eye, sending everyone into a panic for the eyewash station. Thankfully, quick action worked. That moment changed how our team viewed protective gear—not as a nuisance, but as non-negotiable.

Gloves, safety glasses, lab coats, and masks aren’t just for show. Take nitrile gloves, for example: they help protect skin from acids, solvents, and irritants that can do real damage. Face shields and goggles go beyond keeping out dust—these block splashes that can burn eyes or blind someone for life if caustic chemicals strike. Coveralls or aprons guard against spills that could cause burns or rashes. Respirators or simple masks keep lungs safe when powders, fumes, or sprays linger in the air. Each item blocks a path that harm might travel, and skipping even one step puts a person at risk.

Thoughtful Handling Makes a Difference

Rushing—or assuming all chemicals are equally harmless—shortens careers and can threaten lives. From my experience, reading the label before opening any bottle helps tremendously. Some seem harmless but release dangerous vapors, or react with water, or need darkness to stay stable. One scientist I worked with always preached: “Respect everything until you know what it does.” He once wore gloves to handle what he thought was harmless powder, only to learn it could burn skin on contact. Common sense, paired with knowledge, saves skin and jobs.

Storing materials away from heat, moisture, and incompatible substances matters. I’ve seen storage rooms crammed because someone “just needed to make space.” That habit once caused acid to tip and eat through two shelves before anyone noticed. Good habits—returning chemicals to the right spot, sealing lids, and logging each use—don’t take much time but prevent disasters.

Training and Teamwork: The Backbone of Safety

Clever policies mean nothing if workers lack training. My own safety habits clicked into place through hands-on coaching—not just reading rules, but practicing spill response or learning to remove gloves the right way. In smaller shops or labs, everyone picks up habits from the people they work with. That’s why strong safety culture relies on people speaking up when shortcuts happen, not just management laying down rules.

Mistakes happen, but sharing stories, owning up to close calls, and running regular refresher courses keeps risks top of mind. Safety equipment lasts longer, works better, and protects more people if everyone commits to looking out for each other. Experience doesn’t just make work faster; it keeps people safer, too.

Building Smarter Solutions Together

Engineered solutions like splash guards, ventilation, or automatic shutoffs offer extra layers of protection. But even the best gear can’t fix poor habits. Starting with honest conversations and clear expectations, plus giving staff authority to stop unsafe activities, goes further than any sign on the wall.

Every safe day relies on equipment that fits, routines that make sense, and a work culture built on looking out for one another. The best solution comes from everyone taking ownership, sharing knowledge, and choosing to prevent harm—long before an accident tests the system.