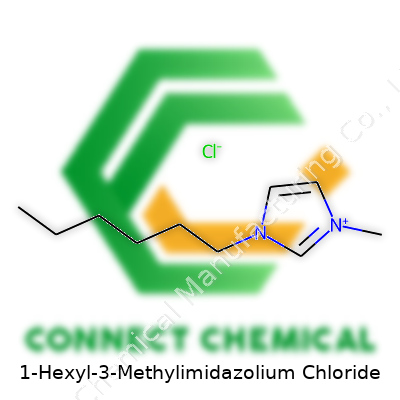

1-Hexyl-3-Methylimidazolium Chloride: A Comprehensive Perspective

Historical Development

Looking past traditional solvents, researchers in the late 20th century started to pay close attention to ionic liquids. Among them, 1-hexyl-3-methylimidazolium chloride (HMIM-Cl) drew strong interest. Early work focused on finding alternatives for harsh chemicals and searching for new reaction media that avoid flammability and volatility, known issues with routine solvents. The path 1-hexyl-3-methylimidazolium chloride followed owes much to this global push. As green chemistry matured, labs worldwide revisited these “room-temperature molten salts.” Chemists tinkered with the imidazolium core, substituting alkyl chains until they observed a suite of materials with tailored thermal, conductivity, and solubility traits. Over time, the hexyl derivative stood out for its melting point, stability, and its knack for dissolving an impressive range of substances—from specialty polymers to coordination complexes. What started as bench-scale curiosities evolved into small-batch commercial production, gradually shaping protocols in analytical chemistry, electrochemistry, and industrial catalysis.

Product Overview

HMIM-Cl forms a colorless to pale yellow liquid at room temperature as long as the space stays dry and free from contamination. The imidazolium ring ensures strong ionic character, while the hexyl group provides lipophilicity, making it uniquely amphiphilic. In the laboratory, a sealed vial of this material resists evaporation, and its hygroscopic nature means it eagerly soaks up water from the air, sometimes changing the outcome of experiments if not handled with care. Producers offer it in grades suitable for both industrial application and high-purity environments. Known by other names—such as 1-hexyl-3-methylimidazolium chloride or HMIMCl—one container of this substance delivers enormous flexibility in the hands of a synthetic chemist, electrochemist, or process engineer.

Physical & Chemical Properties

Set against water or typical organic solvents, 1-hexyl-3-methylimidazolium chloride behaves quite differently. It often presents a viscosity that can challenge pipetting, yet it flows easily with gentle warming. The melting point tends to hover just below room temperature, and the liquid state persists over a large temperature range. As a chloride-based ionic liquid, strong ionic interactions dominate the structure, keeping volatility low—a huge advantage in closed systems or environmental chemistry. Its water miscibility is moderate: below a threshold, aqueous and organic phases combine, but excess water can eventually produce two phases. Conductivity levels support use as an electrolyte, while moderate thermal stability puts it within reach for organic synthesis but just out of range for high-temperature applications. Purity drives performance; trace water or decomposition products influence how it interacts with substrates or electrodes.

Technical Specifications & Labeling

Suppliers market HMIM-Cl by purity (typically above 98%), with packaging that seals out humidity. Labels highlight the CAS number, batch and lot details, and hazard identifications under global guidelines. The glass or high-density polyethylene containers ward off moisture and prevent leaching from plastics. Product sheets specify pH, appearance, and residual solvents, giving users a way to match results whether they work at the gram or kilogram scale. Storage advice circles back to temperature and desiccator use, as well as avoiding direct sunlight. For scale-up, technical data on viscosity, specific gravity, and ion content support precise process control and documentation for quality assurance.

Preparation Method

Chemists rely on straightforward alkylation to make HMIM-Cl. The journey starts with 1-methylimidazole, mixed with a hexyl chloride in an inert solvent like acetonitrile or toluene. Under gentle heat, the reaction generates the ionic liquid, which crystallizes or separates as a viscous phase. Product recovery involves repeated washes with organic solvents to strip away unreacted starting material, while vacuum or azeotropic drying handles water traces. Scaled-up projects demand robust purification to dodge issues with residual halides or alkylated byproducts, which can interfere with subsequent chemistry. Yields tend to track close to theoretical predictions, barring operational mishaps or contamination concerns. With experience, the process stays manageable and reproducible, making it accessible for academic labs and specialty chemical manufacturers alike.

Chemical Reactions & Modifications

Many scientists treat HMIM-Cl as both a solvent and an active component in synthesis. Its ionic matrix hosts polar or charged substrates, supporting transitions that stall in nonpolar media. The material tolerates strong acids and bases up to a point, though exposure to superacids or highly nucleophilic species can trigger decomposition or undesired side reactions. Chemists swap chloride for other anions—such as tetrafluoroborate or hexafluorophosphate—using metathesis reactions to unlock different solubility or catalytic properties. The imidazolium ring's C2 hydrogen enables deprotonation, crafting N-heterocyclic carbenes, which play pivotal roles as ligands or organocatalysts. Modifications often follow routes that minimize extra steps and solvents, harmonizing with green chemistry principles. These approaches expand the material’s scope in catalysis, separation science, and advanced material synthesis.

Synonyms & Product Names

Suppliers and researchers refer to HMIM-Cl by several standard names: 1-hexyl-3-methylimidazolium chloride, HMIMCl, and in regulatory filings, the systematic IUPAC name. In the catalogs of specialty chemical companies, it pops up with product numbers, alternate spellings, or even abbreviated as [HMIM][Cl]. Literature sometimes splits on conventions—opting for either hexylmethylimidazolium chloride or simply imidazolium chloride (C6 variant). Whether you cite a catalog or a peer-reviewed paper, cross-checking identifiers remains crucial to avoid mishaps with other alkyl-imidazolium chlorides that look similar but perform differently.

Safety & Operational Standards

1-Hexyl-3-methylimidazolium chloride needs careful handling even though it sidesteps flammability and volatility. Skin contact or inhalation of aerosols brings risk, so labs require gloves and fume hoods. Regulatory standards from OSHA and REACH flag it as irritating to the eyes, and long-term studies link some imidazolium salts with toxicity if used carelessly or disposed of down the drain. Disposal uses designated waste containers—never sinks or open trash. Training falls to lab managers and safety officers, with regular audits to make sure storage, record-keeping, and ventilation remain up to code. Environmental health considerations factor into operational plans, particularly for facilities near water sources or farms, prompting periodic monitoring for leaks or improper disposal practices. As a part of the push for sustainable chemistry, tighter controls now cover both production and post-use handling.

Application Area

The usefulness of HMIM-Cl covers a wide range of research and industrial activity. Electrochemists prize its ionic conductivity for batteries, capacitors, and solar cells, where safer, longer-lived electrolytes mean fewer failures and less environmental impact. Organic chemists dissolve polar or poorly soluble substrates in it, leading to smoother reactions and new synthetic routes without the hazards of traditional solvents. Process engineers look to it for CO2 capture, supported by its selective solubility and recyclability, working toward a low-carbon future. Environmental scientists use it as a medium for pollutant extraction and the recovery of heavy metals. Polymer chemists test HMIM-Cl as a solvent for tough-to-dissolve engineering plastics or as a plasticizer for specialty films. In separation science, the unique blend of hydrophobic and ionic properties supports challenging tasks, such as extracting bioactive compounds from plant material or purifying proteins. Demand in these sectors grows as teams look for greener alternatives and higher performance from their favorite materials.

Research & Development

Development never stands still. Current research around HMIM-Cl races ahead in several directions. Teams probe nanomaterial synthesis, making metal nanoparticles inside the ionic liquid, where size and dispersity come under tight control. Enzyme stabilization remains a buzzword: some proteins retain activity longer or resist denaturation when dissolved in HMIM-Cl-based systems, hinting at applications in biocatalysis. Fundamental studies on solvent effects, thermal stability, and ion-pairing behavior churn out fresh data each year, refining mechanistic understanding and sharpening predictive models. Collaborations between academia and industry often chart new territory, searching for composite materials, advanced membranes, and improved catalysts powered by HMIM-Cl. Funding bodies invest in projects that promise energy savings, waste reduction, or expanded renewable resource use, tying the fate of this ionic liquid to the broader movement for sustainable technology. Conferences and journals serve as melting pots for these ideas, pushing the entire field forward.

Toxicity Research

Rigorous work on HMIM-Cl toxicity began once its potential spread beyond the lab bench. In vitro and in vivo studies show it can disrupt biological membranes and interfere with enzyme systems, especially at concentrations higher than those typical for environmental exposure. Ecotoxicology draws a line: water organisms, plants, and soil microbes can suffer if release happens without restraint. Chronic exposure brings developmental and reproductive risks for aquatic life. Regulatory agencies take these findings seriously, setting strict discharge limits and requiring proof of fate and transport prior to approval for large-scale use. Human safety tests highlight the need for eye and skin protection in regular lab and plant environments. As a result, safety data sheets evolve, matching the pace of published research, and new biocompatible derivatives start to emerge as possible alternatives. That said, the chemical holds promise when handled appropriately—education and vigilance set the boundary between benefit and hazard.

Future Prospects

Looking ahead, 1-hexyl-3-methylimidazolium chloride stands at a crossroads. Its clean lab record, tuneable properties, and track record in tough chemical environments attract researchers and industry planners. Next-generation batteries, green synthesis, and environmental remediation projects all carve out opportunities. Progress depends on improving lifecycle assessment, scaling up cost-effective production, and developing recycling methods that return spent ionic liquids to the supply chain. The growing push for non-toxic, sustainable materials challenges chemists to tweak the molecule further, minimizing impact without sacrificing utility. Multidisciplinary teams merge expertise in computation, synthesis, toxicology, and engineering to build safer, smarter materials. By closing research gaps and keeping communities informed, HMIM-Cl can play a pivotal role in shaping chemical technology for decades to come.

An Ionic Liquid Changing the Way We Solve Problems

Plenty of folks outside the lab ignore chemicals with long names, but if you’ve spent time in research or manufacturing, you know how certain compounds can shake up the status quo. 1-Hexyl-3-Methylimidazolium Chloride—commonly called HMIM-Cl—belongs to the group of ionic liquids that look like they might belong in a science fiction story but have landed in some practical corners of industry and science.

Green Chemistry and Solvent Replacement

The old style of solvents like benzene and toluene might help get a job done, but they bring along toxic fumes and lots of environmental baggage. HMIM-Cl enters the scene with much lower vapor pressure, almost no smell, and less flammability. Using it in labs or industrial scale production means safer working conditions and fewer headaches from regulatory compliance. Fact: Research from chemists at the University of Alicante shows HMIM-Cl can dissolve cellulose—a tough, fibrous plant material that’s hard to break down with water or alcohol. This opens doors for making greener plastics and textiles, cutting reliance on fossil-fueled feedstocks.

Catalysis and Chemical Synthesis

Anyone who's tried to scale up a chemical reaction knows about bottlenecks: purity problems, yield drops, or sluggish reaction rates. HMIM-Cl acts as both a powerful solvent and a catalyst for some organic reactions. In pharmaceutical development, this double-duty can mean fewer steps and purer output. For instance, scientists at the Indian Institute of Technology have used HMIM-Cl to speed up reactions that turn raw molecules into next-generation drugs or efficient dyes. These aren't just small wins—saving time and reducing chemical waste makes medicine more accessible and less costly in the long run.

Electrochemistry and Energy Storage

Old batteries use materials and liquids with a track record of leaks, fires, or limited durability. HMIM-Cl’s ionic nature helps shuttle electric charge with remarkable stability, and it doesn’t evaporate or corrode parts the way pasty electrolytes do. Researchers at Argonne National Lab report that batteries and supercapacitors built with this compound keep their strength after hundreds of charging cycles, making electric tools and vehicles more reliable. The push towards renewable energy needs safer, longer-lasting storage, and HMIM-Cl plays a part in that journey.

Extraction and Separation

Mineral-rich ores and complex mixtures challenge engineers to pull out valuable elements cleanly. Traditional solvents struggle with selectivity or safety. HMIM-Cl steps in for extracting rare earths, heavy metals, and even some precious metals with less environmental fallout. In wastewater treatment, it helps remove toxic ions, reclaiming water for reuse and slashing disposal costs. Actual field studies from environmental consulting groups show less sludge and cleaner water compared with old-school approaches.

Personal Take: Room for Growth

Back in grad school, I watched researchers switch from volatile organic solvents to HMIM-Cl for tough reactions. The room got safer, and the work got faster. Still, not every problem gets solved overnight. The price tag for ionic liquids runs high, and recycling HMIM-Cl hasn’t reached perfection yet. Greater investment in recovery tech and larger production scales could drop costs and boost adoption, letting more people benefit from these clever chemicals in the years ahead.

The Real Significance of High-Purity Chemicals

In any lab, purity shapes the outcome of experiments and the reliability of the results. Using 1-hexyl-3-methylimidazolium chloride, most research teams expect no less than 98% purity. Anything below that turns small mistakes into big problems. Synthesis errors, side reactions, or unnoticed contaminants put a whole project at risk and make data hard to trust.

What Researchers and Manufacturers Typically Offer

The market usually provides this compound at a minimum of 98% purity. Some vendors push it a notch higher, advertising 99% or above for especially sensitive work. A lot of chemistry hinges on that small difference. Analytical chemists, electrochemists, and material scientists often chase that last 1% for a reason. Impurities interfere with catalyst performance, reduce battery efficiency, and muddy up spectroscopy data.

The Health and Environmental Stakes

Every contaminant in a bottle has a way of sneaking into the process flow. Lab safety officers keep a close eye on purity certificates, as solvents or starting materials can introduce irritants or toxic byproducts. Green chemistry pushes for ionic liquids as a sustainable alternative to volatile organics, but a dirty sample undermines that promise. High pure 1-hexyl-3-methylimidazolium chloride can limit waste streams and lower the risk to workers and end users alike.

Insisting on Transparency and Quality Control

Reliable suppliers back up purity claims by providing actual HPLC or NMR data. Certificates of Analysis need to be more than a standard document — they show what unexpected residues might be present. Some labs have learned the hard way: a missing or vague certificate means a higher chance of failed syntheses and repeated experiments. It’s not enough to trust a label. Chemists with experience tend to verify purity through independent measurement or reputable third-party labs.

The Money Factor: Cutting Corners Never Pays Off

Price differences between grades attract buyers, but cutting corners often means paying more in the long run. Low-purity samples mess with catalysts, damage valuable equipment, and waste months of research effort. Anyone who’s had to troubleshoot a failed polymerization or battery cell, only to trace it back to a contaminated batch, comes to value upfront investment in quality chemicals.

Better Sourcing Solves More Than Just Technical Issues

Sourcing from established suppliers, asking sharp questions about batch-to-batch consistency, and demanding open disclosure makes a big difference. Transparent distributors with solid reputations help create confidence in the materials entering a process. If research moves toward industrial scale, documentation and traceability become more than a formality — they’re a line of defense.

Raising the Bar as an Industry Standard

Progress in materials science, batteries, and pharmaceutical research keeps purity in the spotlight. More companies and academic groups are asking for cleaner, better-documented chemicals. Industry-wide standards, combined with audits and real data sharing, push the whole field forward. Trust in any finished product starts with what goes into the flask. High-purity 1-hexyl-3-methylimidazolium chloride sets the tone for real, trustworthy progress.

Stability Takes Real Effort

I’ve seen plenty of specialty chemicals lose their punch before their time, all because someone didn’t bother with good storage habits. 1-Hexyl-3-methylimidazolium chloride isn’t some magic stable molecule, either. Humidity changes it, and light can react with it. Leaving a bottle on a bench or stuffing it in a non-sealed box invites all kinds of headaches down the line.

Humidity Ruins the Show

This compound draws in water from the air. Any open container starts pulling in moisture the minute you open it, which slowly knocks out its purity. Water contamination kicks off unwanted side reactions, and that can make research data unreliable or industrial batches inconsistent. The facts don’t lie: ionic liquids that absorb even moderate amounts of water start acting differently, throwing off ionic conductivity or melting points. I’ve watched carefully measured batches swing out of spec due to sloppy storage.

Seal It Right, Store It Cool

Glass bottles with solid, screw-on lids do more than look the part. They keep air and its pesky vapor away. Plastic sometimes reacts or lets small molecules through over time. Some labs use dedicated desiccators with silica gel or molecular sieves to keep things bone-dry. It pays off, since you don’t have to re-test material every time you want to use it. Sticking to a cool, dark shelf (in a well-ventilated chemical storage room, away from heat sources) keeps the material stable much longer. Direct sunlight isn’t your friend, and temperature swings weaken seals and encourage decomposition.

Health and Safety Stand at the Front

This chloride doesn’t have a dramatic hazard symbol, but it’s not something to be casual with. Vapors aren’t common, though spills and skin contact can still cause irritation after repeated exposure. I once watched a student try to clean up a bottle accident with bare hands. The rash was immediate. Nitrile gloves cut out that risk, and a set of goggles stops accidental splashes. Keeping the material in labeled, dedicated containers helps everyone know what to expect if there’s ever a spill.

Track Shelf Life and Breakdown

Every chemical ages, and ionic liquids are no different. Regular checks—writing open dates and doing small sample tests—avoid nasty surprises over time. Once moisture creeps in, batch composition slides, so a dry-store reminder posted above the chemical cabinet helps keep everyone on track. If doubt pops up about purity or performance, use a fresh bottle. It costs less than re-running a failed experiment.

Practical Steps That Stick

The right storage comes down to discipline, not expensive gear. Use glass, keep lids tight, put bottles in dry zones, post reminders, and double-check inventory dates. These simple moves protect against lost work, spoiled batches, and safety risks. In the end, smart storage proves itself by saving time and trust—because no one wants to question whether their reagent still works when the pressure’s on.

Understanding the Chemical

1-Hexyl-3-methylimidazolium chloride isn’t your average household chemical. It falls under the family of ionic liquids, which often get used in laboratories and certain industrial settings for their ability to dissolve a wide range of materials and help run chemical reactions in a more sustainable way. The green claims sometimes get overblown, since “friendly to the environment” can mean lots of things, especially if basic safety is ignored.

What the Science Says About Its Toxicity

Researchers have dug into the safety profile of this ionic liquid. They tested it on organisms ranging from bacteria to fish. Their results pointed out that this compound, despite being interesting for chemists, doesn’t exactly treat living cells kindly. Studies show it can cause strong irritation—skin, eyes, even the respiratory tract if dust or vapors get into the air. Experiments on aquatic life, like zebrafish or algae, show quite a bit of sensitivity, with toxicity levels high enough to cause trouble at relatively low concentrations (sometimes in the low mg/L range). The risks aren’t theoretical for people who handle this material regularly, especially without solid ventilation or gloves.

Like a lot of ionic liquids, this one doesn’t evaporate easily, but it hangs around if spilled because it breaks down slowly in the environment. The slow pace means that over time, the stuff can build up in soil or water. Some studies have flagged up that compounds like this can stick around long enough to mess with microorganisms, which leads into issues that aren’t always easy to spot without a microscope and some patience. These kinds of invisible shifts sometimes only show up much later, and researchers are still sorting out exactly how dangerous that can be.

Handling and Exposure Risks

Lab regulars know not to treat unknown chemicals lightly, but even experienced folks cut corners sometimes. I remember seeing a graduate student splash some on his glove and wipe it off like nothing happened. Within a day, irritation and redness showed up on his skin. Real-world contact, even brief, can leave a mark. I always suggest double-gloving and keeping a bottle of eyewash nearby. For those working in industry outside the clean comfort of a research building, proper storage and spill procedures become critical—for their own safety and everyone else nearby.

Regulatory Context and Practical Steps

No global agency yet puts 1-hexyl-3-methylimidazolium chloride on a high-risk blacklist, but agencies like the European Chemicals Agency include it on watch lists because of the mounting lab evidence. Material Safety Data Sheets stress the need for good ventilation, protective gear, and prompt cleanup for spills. If a spill moves beyond the lab, local water utilities might not have the tools to treat it, so responsible disposal really matters.

Companies that use or produce ionic liquids can prioritize basic training, invest in good ventilation, and support regular air and surface monitoring. They can push for more research into not just immediate hazards, but also chronic impacts on people and the surrounding ecosystem. Alternative solvents, like some bio-based ones, might take the edge off some risks, though effectiveness varies case by case.

Being Proactive With Emerging Chemicals

As more specialty chemicals enter all corners of research and industry, the lesson is clear: Don’t just trust green-sounding buzzwords or assume the new stuff is automatically safer. Bridging the gap between innovation and responsibility needs people ready to look past the surface, respect the data, and make smart day-to-day choices—on the bench and beyond it.

Understanding the Options

1-Hexyl-3-methylimidazolium chloride isn’t rare in research, and you run into it whenever ionic liquids come up. Anyone spending hands-on time in the lab knows packaging size bumps right up against budgets, shelf space, and safety. Ordering too much creates chemical waste and takes up space. Too little means wasted time in reordering, waiting on suppliers, and maybe even holding up the rest of the project. From personal experience working in academic and commercial labs, juggling packaging sizes gets overlooked more than it should.

Commonly Offered Container Sizes

Most chemical vendors, from Sigma-Aldrich to TCI, carry this compound in a range of volumes. The smaller labs pick up 5-gram or 10-gram bottles, usually glass or HDPE to limit leaching or contamination. This fits projects that need precise weighing for small syntheses, or for method validation. For mid-scale trials, suppliers offer 25, 50, or even 100-gram bottles, giving some flexibility without the headache of storing large drums.

Industrial settings step up to the kilogram scale. Package options for 1-Hexyl-3-methylimidazolium chloride can go over 1 kg, sometimes delivered in plastic drums or heavy-duty bags. Years ago, I helped with a scale-up process where 5 kg containers made deliveries manageable for regular use, but still small enough for handling in a single day’s run. The right size keeps things efficient and safe in the workplace—no one wants to wrestle with a fifty-kilogram drum unless the storage and handling plan keeps up.

Labeling and Regulations

Larger packaging runs into more serious compliance. Safety labeling, documentation on purity, and batch tracking ramp up in importance. This is not just a paperwork burden: one missing detail can send a whole shipment sideways at customs or force a recall during an audit. Laboratory containers carry hazard labels, while industrial drums demand clear transport regulation info.

Protecting Chemical Integrity

Once you open a container, air and moisture want to get involved. In my lab, we would never rely only on the original cap or seal after the first use, especially with hygroscopic chemicals. Smaller containers mean fewer exposures and less risk of spoiling the entire lot. This gets critical when a project spans months: a dozen single-use bottles outlast a single big bucket, pure and simple.

Balancing Waste and Value

Waste management affects both cost and environmental impact. Opening the largest bucket for just a spoonful seems smart to the procurement office, but leftover chemicals often get tossed by the end of the year. The same thing frustrated me working with grant-funded labs that don’t have a streamlined disposal plan. Sizing orders to your workflow saves money and helps avoid chemical waste headaches.

Choosing the Right Size

Selecting a container comes down to real-world planning: project scale, purity needs, storage capacity, handling routines, and disposal policies. Reliable vendors spell out available sizes online and offer custom packaging for unique demands. Buyers should always request certificates of analysis and purity documentation, especially at larger scales, to make sure what’s inside matches the work ahead.

Moving Toward Greener and Safer Chemistry

There’s a slow shift away from wasteful ordering and inefficient packaging. Some suppliers now offer recyclable containers or return policies to recycle used drums and bottles. Responsible procurement isn’t only about the environment—it saves real money and reduces hazardous waste headaches down the road. In my experience, lab managers who pick sizes with the future in mind always fare better when audit season rolls around or budgets tighten.