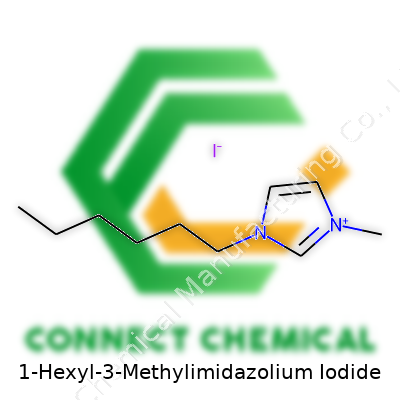

Exploring 1-Hexyl-3-Methylimidazolium Iodide: From Discovery to Impact

Historical Development

Long before anyone talked about green chemistry or sustainable solvents, chemists dabbled with ionic liquids in search of better conductivity and stability. Among these, 1-Hexyl-3-Methylimidazolium Iodide became a standout during the 1990s, when its unique capacity for charge transfer caught the eyes of researchers aiming to improve dye-sensitized solar cells. Early work revealed that imidazolium-based salts bring several benefits over traditional solvents. Later, a burst of research energy in Europe and Asia saw labs fine-tuning the alkyl chain length and tweaking purity. Over the last two decades, this compound went from a rare lab curiosity to a mainstay in countless electrochemical and photovoltaic explorations.

Product Overview

1-Hexyl-3-Methylimidazolium Iodide belongs to a growing class of room-temperature ionic liquids. Instead of the pungency and volatility typical of old-school solvents, it offers a scentless and stable alternative. In my own experience, its liquid range and robust ionic conductivity make it a versatile ingredient across applied and academic settings. Folks turn to it for its steady performance in both organic and inorganic systems, experimenting with batteries, catalysis, and solar cells. Some choose it for its ability to shuttle charge with less energy loss. Others take advantage of its chemical inertia and tolerance for harsh environments.

Physical & Chemical Properties

This salt stands out thanks to a handful of reliable physical and chemical traits. The compound appears as a pale yellow to colorless liquid under ambient conditions. With a melting point below room temperature and distinct viscosity, it offers practical advantages for those working on lab benches with temperature-sensitive reactions. The dense, non-volatile nature controls undesirable evaporation. High chemical stability against acids, bases, and many oxidizers allows it to endure extended testing cycles. Solubility leans toward water, acetonitrile, and several polar solvents. Iodide presence leads to a powerful nucleophilicity and strong affinity for heavy metals, which opens a door to separation and sensing technologies.

Technical Specifications & Labeling

These products, sourced through standard chemical suppliers, often display content purity above 98 percent, with water and halide impurities reported at trace levels. Labeling includes batch number, storage conditions—cool and dry, shielded from direct sunlight—and regulated transport codes to minimize risk. Material Safety Data Sheets outline shelf life, usually around two years, if kept tightly sealed. Suppliers specify chemical structure, molecular weight (286.23 g/mol), and the Chemical Abstracts Service number to avoid mix-ups with similar compounds.

Preparation Method

Most people in chemical manufacturing start with N-methylimidazole and 1-chlorohexane. By mixing these in a suitable polar solvent and heating with continuous stirring, one forms the core imidazolium structure with a hexyl side chain. Quaternization proceeds cleanly and leaves N-hexyl-N-methylimidazolium chloride as a crude intermediate. Subsequent anion exchange with sodium iodide, typically in aqueous solution, swaps the chloride for iodide. The mixture gets washed, dried, and filtered until only the desired ionic liquid remains. This hands-on approach yields high-purity 1-Hexyl-3-Methylimidazolium Iodide in volumes suitable for both academic and industrial runs.

Chemical Reactions & Modifications

Reactivity focuses on the imidazolium ring and its exchangeable iodide ion. Redox chemists appreciate the way this salt accepts or donates electrons without falling apart, which proves handy in battery and sensor development. The iodide ion participates in halogen transfer reactions, acts as a mild reducing agent, or supports metal ion extraction from waste streams. Side-chain modifications—like swapping hydrogen atoms for functional groups—help fine-tune solubility and conductivity, giving labs a custom approach to ionic liquid design. This adaptability leads to a vibrant space for patent filings and commercial partnerships.

Synonyms & Product Names

Depending on the supplier or region, this ionic liquid turns up under several names: HMImI, 1-hexyl-3-methylimidazolium iodide, or simply hexylmethylimidazolium iodide. Some catalogs abbreviate to [HMIM][I], referencing both cation and anion. These alternative names avoid confusion and aid in cross-referencing research papers, patents, and industry standard lists. Recognition across platforms ensures consistent sourcing and regulatory compliance.

Safety & Operational Standards

Despite the promise of ionic liquids, safety remains a top priority. Material safety literature draws attention to irritation on direct skin or eye contact, so gloves and goggles form the front line of defense. Spills wash away with soapy water but disposal follows local hazardous waste protocols. During synthesis or analytical work, vapor and dust controls shield workers from accidental exposure. Storage recommendations stress low humidity environments and well-sealed containers, particularly since iodide can oxidize and degrade in the open air. Proper workspace ventilation keeps any accidental emissions down, aligning with occupational best practices.

Application Area

The reach of 1-Hexyl-3-Methylimidazolium Iodide stretches across industries and labs. It often rises to the top for those building dye-sensitized solar cells (DSSCs), where it acts as the redox mediator in electrolytes. The result translates to greater device stability and efficiency. Battery manufacturers include it for its thermal stability and low vapor pressure, tackling the need for long-lasting, leak-resistant units. Analytical chemists use its affinity for heavy metals to trap and detect trace contaminants from soil and water. Even catalysis R&D teams pull it for biphasic reaction setups and waste reduction, thanks to its recyclability and resistance to decomposition.

Research & Development

Across the globe, universities and companies test 1-Hexyl-3-Methylimidazolium Iodide in new processes that aim to outperform fossil-based solvents. Groups at national labs dissect ion transport and interfacial behavior, hoping to push the limits of battery and capacitor technologies. Scientific literature reveals studies on enzyme catalysis, where mild ionic environments extend enzyme lifetime and open new product routes. Some researchers note its role in improving old techniques, like phase transfer catalysis, by eliminating organic solvents and slashing hazardous waste. Teams partner with industry to push these findings out of the lab and into pilot plants, where scale-up means new energy storage or environmental cleanup solutions.

Toxicity Research

Safety assessments run deeper than just labeling or lab protocols. Studies on aquatic toxicity suggest moderate effects when exposure crosses certain thresholds, not surprising given the iodide component. Chronic toxicity remains under review, with work focusing on breakdown products and their interaction with living tissues. Some researchers point out the slow biodegradation rate, which turns into a concern for large-scale applications. Early reports show limited bioaccumulation in mammals, and routine cell culture assays find relatively mild cytotoxicity compared to classic organic solvents. Still, many urge ongoing research, especially as production scales up and wider environmental exposure starts to look likely.

Future Prospects

Given the growing concern about volatile and polluting solvents, 1-Hexyl-3-Methylimidazolium Iodide sits in a sweet spot for researchers seeking greener alternatives. Next-generation batteries, sensors, and even pharmaceuticals draw on its stability and electrochemical versatility. As synthesis routes become cleaner and cheaper, more manufacturers tilt towards ionic liquids for new product launches. The future likely holds smarter recycling programs, more detailed toxicology work, and modified chemical structures that cut costs and environmental impact. With strong backing from academic and industrial groups, this compound finds itself at the intersection of practical innovation and responsible chemistry.

Looking Closer at an Unfamiliar Name

Organic chemistry likes to surprise us with names that sound puzzling. Take 1-Hexyl-3-Methylimidazolium Iodide, for example. Unless you work in a lab, this name likely doesn’t ring any bells. Yet, it matters more than most people realize, especially in energy and electronics. I’ve worked with research labs that explore new battery technologies, so I know just how often chemists turn to compounds that sound like science fiction. Here’s a look at why scientists seek out this compound for real-world solutions.

What Makes It Worth Talking About?

1-Hexyl-3-Methylimidazolium Iodide falls into the category of ionic liquids. A fancy title, but all it really means is that the chemical stays liquid at room temperature. Unlike table salt, which only melts when you turn your oven into a furnace, this stuff flows much more easily. Being liquid and able to carry an electric charge gives it some unique superpowers—mainly as an electrolyte.

Key Role in Solar Cells

This compound appears most often inside dye-sensitized solar cells—commonly called DSSCs. Labs around the world have tested almost endless recipes to make better, cheaper solar panels. DSSCs are lighter and sometimes even work indoors or in cloudy weather. Standard silicone-based panels rely on thick, solid materials, but DSSCs need a liquid that can ferry charges between electrodes. That's where 1-Hexyl-3-Methylimidazolium Iodide comes in. It doesn’t evaporate as quickly as common solvents, so cells last longer and become less likely to break down after only a few months.

Studies published in chemistry journals and renewable energy research show that using ionic liquids like this cuts down on leaks, fires, and fast degradation that plague more traditional electrolyte solutions. The solar industry is full of buzz about new electrolyte options, but most fade out because they can’t manage heat or last more than a season in the field. Ionic liquids carry the promise of fixing these headaches. This particular imidazolium salt offers both a good thermal range and stability, which matters in real-world outdoor conditions.

Spin-Offs in Batteries and Sensors

Batteries have the same problem as solar cells: they need a safe, reliable liquid for ions to move. Lab-scale experiments mix 1-Hexyl-3-Methylimidazolium Iodide into test batteries to see if it beats older formulas in how well it keeps up performance over hundreds of charges. Because it resists breaking down, researchers hope to create batteries that won’t quit after a year or swell up and crack electronics. Some electrochemical sensors also use this compound, mainly because it helps reactants dissolve and move freely, enabling faster and more accurate readings. I’ve tested similar ionic liquids in biosensors, and the ease of mixing important ingredients often becomes the difference between a working sensor and a dud.

Where Do We Go from Here?

If these ionic liquids can make solar cells and batteries safer and longer-lasting, that’s a leap for devices we use daily. To get there, cost must come down. Manufacturing these chemicals in bulk still eats up a chunk of change. Environmental impact can’t be ignored, either. While ionic liquids tend not to vaporize, what happens when thousands of panels or batteries need recycling? Researchers and companies will have to address end-of-life management. Early progress suggests that the future energy world could depend as much on creative chemistry as on flashy new gadgets, and compounds like 1-Hexyl-3-Methylimidazolium Iodide likely have a front-row seat in that story.

The Practical Stuff About Safe Storage

People working with chemicals like 1-Hexyl-3-Methylimidazolium Iodide quickly learn that storage isn’t some background detail. Mess it up, and you risk more than a ruined batch—you invite hazards that reach far beyond lab benches. I’ve seen too many minor mistakes turn into expensive cleanups, plus safety teams never look impressed when someone ignores basic chemical care. If there’s one thing professionals agree on, it’s that treating specialty chemicals like everyday table salt only brings headaches.

The Right Setting Matters

This particular compound—a salt used in research, batteries, and sometimes organic synthesis—catches moisture easily. Water in the air loves to creep into some chemicals, changing their quality and messing with research results. Every time a container sits open in a humid room for too long, that risk grows. Keeping 1-Hexyl-3-Methylimidazolium Iodide dry isn’t just a suggestion. I remember the first time someone scooped out a clumpy, half-dissolved sample from a poorly closed container. Suddenly, a promising project hit a roadblock. The fix turned out simple: airtight jars, desiccators, and, in some setups, those silica gel packets everyone ignores until a problem appears.

Temperature Talks

Heat brings another headache. This isn’t a chemical that bursts into flames with a little warmth, but higher temperatures speed up unwanted changes. Decomposition creeps up. Purity drops. The solution? Find a cool, dark shelf away from heat sources and sunlight, and stick to it. Regular room temperature in a climate-controlled space handles the job much better than a shelf above the radiator or the sun-baked corner of a crowded lab. Throw in a labeled container and consistent record-keeping, and small mishaps stay rare.

What Science Tells Us

Research sheds some light—ionic liquids like 1-Hexyl-3-Methylimidazolium Iodide usually last longer at lower temperatures. Most manufacturers suggest storage between 4–25°C, with drier environments getting the best marks. In some specialty labs, chemical stocks stay refrigerated—especially for long-term samples. Direct contact with acids and bases turns risky, too, so separating incompatible reagents makes a difference. Real-world lab audits dig up plenty of preventable slip-ups, and almost all revolve around storing salts in leaky bottles or next to strong reactants.

Looking Beyond the Label

Companies that set up smart chemical management systems worry less about product loss and potential exposure. Relying on secondary containment—those plastic bins or trays lining the bottom of storage cabinets—keeps spills from going anywhere dangerous. Regular checks beat any one-off fix, something every good lab manager schedules into the weekly routine. For anyone shipping or transporting this salt, sealed, moisture-resistant packaging should be standard, with clear safety data sheets attached. Improper storage often links back to skipped steps, not lack of instructions.

Making Improvements Count

Decent chemical hygiene pays off every time. Encourage team members to double-check lids, rotate stock, and record the condition of containers each time they dip in for supplies. Anyone managing a teaching lab, research group, or manufacturing site feels how small gaps in storage practice lead to wasted funding or lab downtime. Teaching storage by example creates longer-lasting inventories and safer workplaces—no lecture or printed guideline beats seeing best practices in action.

Understanding the Chemical

1-Hexyl-3-methylimidazolium iodide sounds intimidating. This chemical belongs to the family of ionic liquids—salts that stay liquid at room temperature. Labs use it to transport ions in solar cells, batteries, and sometimes as solvents for tough reactions. The name alone can raise eyebrows, especially for those of us used to everyday products with ingredients that end in “-ate” or “-ide.”

Looking at Safety and Toxicity

Curiosity about toxicity is fair. Most people hear “imidazolium” and think of something you’d never want near your morning coffee. Safety data on 1-hexyl-3-methylimidazolium iodide remains limited compared to old-timers in the chemical industry. Unlike table salt or vinegar, you don’t see risk reviews on local news. Still, some reports have trickled in from research and industry.

Scientists have tried to pin down how risky it actually is. Testing in labs did not reveal the kind of acute toxicity you’d get from cyanide or mercury. That said, its chemical relatives sometimes show moderate eye, skin, and respiratory irritation. Breathing vapor or splashing the liquid could wind up harming sensitive tissues. Chronic exposure still needs more study—nobody’s spent decades living near a manufacturing site that handles this stuff.

Inside living cells, some ionic liquids disrupt cell walls and stress out enzymes. A few studies involving 1-hexyl-3-methylimidazolium iodide on aquatic life showed changes in fish and algae health, but not outright devastation. Long-term buildup in the environment could sneak up on us. Right now, regulators in Europe and the US don’t put strict restrictions on its use, but any chemical that finds its way into water supplies carries potential risks.

Why It Matters

Once, I spent an afternoon touring a battery lab. The engineers told me that switching to ionic liquids like 1-hexyl-3-methylimidazolium iodide brought down the flammability of their prototypes. Safety matters, especially with the electronics we tuck into bedrooms or carry in backpacks. Unfortunately, this improvement can distract us from hidden dangers that slowly catch up with regular exposure or careless disposal.

Compared to classic solvents like benzene—which everyone agrees is a carcinogen—ionic liquids look better on paper, yet still belong on the “handle with care” list. Some folks argue that since a chemical has no proven deaths or spectacular accidents, it must be fine. That’s a risky mindset. In reality, long-term harm often escapes attention until it lands in a river, a landfill, or someone’s lungs.

Choosing A Safer Path

Good practice keeps trouble at bay. Store 1-hexyl-3-methylimidazolium iodide in clearly marked containers, behind proper ventilation. Gloves and glasses don’t just sit in labs for show—they make it less likely to end up with purple stains on hands or a cough that lingers. Waste should go to dedicated chemical processors, not the local drain.

It’s tempting to chase new tech using chemicals like this, gambling that benefits outpace risks. Responsible companies invest in clear safety training, honest risk assessment, and try to swap out anything questionable for greener rivals. Consumers and researchers push for more data. Only careful eyes on both the hazards and the rewards make sure promising innovations don’t turn sour with time.

Why Purity Matters

In chemistry labs and industrial settings, the purity of a compound shapes both its performance and reliability. With 1-Hexyl-3-Methylimidazolium Iodide, or HMIM-I, purity comes up as a key checkpoint, not just a number on a data sheet. Anyone who has spent time troubleshooting failed reactions will tell you that sketchy purity specs translate into wasted time, wrong results, and, sometimes, expensive failures. HMIM-I gets used widely in electrochemistry and organic synthesis, so knowing its purity spec can save plenty of headaches.

Typical Purity Levels Found in the Market

Most HMIM-I offered for laboratory use lists a purity between 98% and 99%. That 1% gap might not seem huge, but it could mean a world of difference, especially for sensitive applications or electronic research where even tiny contaminants can wreck a controlled system.

Sigma-Aldrich, one of the more reliable suppliers in the research space, labels its standard HMIM-I product at a minimum of 98% purity. Some high-end grades can reach up to 99.5%, mostly for analytical or advanced battery work. Purity here refers to the percentage of the main compound, not counting water or other residual solvents. These numbers matter because every impurity—sometimes leftover starting materials or other ionic salts—may interfere with its use, especially in devices or large-scale processes.

What Purity Specification Really Says

Asking for a certificate of analysis (CoA) is more than just a formality. The CoA lets buyers see the real breakdown: percent composition, water by Karl Fischer titration, residual chloride, and sometimes trace metals. At least a couple suppliers report water content below 2% and limit chloride ions to under 0.02%. Any extra traces could derail measurement in ionic conductors or upend reproducibility. If you’ve ever had a sensitive electrode process pick up interference, you know exactly why those numbers get scrutinized.

How Purity Affects Research and Industry

Researchers and manufacturers make some real-life calls based on purity data. Folks in energy research, for example, rely on HMIM-I with top-end purity to make sure nothing gets in between their ions and the final charge-discharge curve of a battery. Others working with organometallics see unpredictable side reactions crop up from unlisted contaminants. Even a relatively small impurity level—say, a leftover halide—can invite unplanned corrosion or catalyze reactions that shouldn’t happen.

Skipping the step of checking purity or buying off-brand material often means paying later. It’s not only about the initial performance. Impurities tend to build up in long-term systems, slowly shifting results in ways that aren’t obvious until much later.

Raising the Bar with Better Practices

Labs and factories don’t need to live with mystery chemicals in their materials. The best way forward often comes from pushing for transparency from suppliers: always insist on up-to-date analytical results, avoid cutting corners on trusted sources, and push for full impurity profiles, not just the headline purity number. Running a quick NMR or IR scan in-house, if possible, gives a bit of backup, especially for critical projects. Simple attention to the purity spec lets teams work with more confidence, cutting out avoidable errors and keeping focus where it matters—on chemistry, not troubleshooting.

Understanding the Everyday Reality of Ionic Liquids

Anyone who handles chemicals for research or industrial work knows that packaging isn’t an afterthought. 1-Hexyl-3-methylimidazolium iodide, a member of the popular imidazolium-based ionic liquid family, brings that lesson home. This compound shows up in labs and cleanrooms across universities and solar startups thanks to its ability to conduct ions and support various reactions. Yet every chemist instinctively asks: is it a solid, a liquid, or sold as a solution?

Physical Properties Drive Supply Form

Call it personal experience, call it a professional habit—whenever I’ve ordered 1-hexyl-3-methylimidazolium iodide, it lands on my bench as a solid, usually a powder or crystalline granules. Its melting point sits comfortably above room temperature at around 52–55°C, which keeps it stable in a warehouse or during shipping. There’s no urge to bottle it up as a thick liquid unless the temperature jumps up.

Solids store better for most chemical laboratories. A powder needs only a dry, dark cabinet and a tightly-capped container. Packing the compound as a liquid would mean worrying about leaks and degradation, which gets expensive both for vendors and scientists. We want certainty in composition and performance, not a mystery of what’s evaporated or mixed in transit.

Why Not Ship It in Solution?

Some specialty chemicals make sense in solution, especially if immediate use or dilution reduces risk or accelerates processes. For 1-hexyl-3-methylimidazolium iodide, every extra milliliter of solvent means extra weight, extra shipping fees, and less control over the end product’s purity. Universities, solar cell developers, and battery research teams usually want to pick their own solvents for precision work, so a dry form stands as the favorite.

I’ve watched lab budgets bleed because a liquid or pre-diluted product didn’t fit the intended application, so more costs hit later for redistillation or extra purification. That hassle alone would push anyone to order the pure, unmixed solid.

Quality Assurance and Authenticity

Outfits like Sigma-Aldrich, TCI, and Alfa Aesar—big names in chemical supply—list this chemical as a solid. Not only does it let researchers weigh out exact quantities, it also takes the guesswork out of storage and transport. Glass bottles, foil-lined packages, and desiccators serve their role for a reason.

The stakes run high in energy storage, photovoltaic research, and organocatalysis. A bottle of murky liquid could spell weeks of troubleshooting or invalidate hard-won results. The solid form means fewer impurities, more reliable storage, and real confidence in experimental repeatability—a crucial part of trustworthy science.

Improving Supply Practices

There’s always some room for better information sharing between suppliers and users. Clear labeling, documentation about moisture sensitivity, and handling advice help new researchers sidestep rookie mistakes. If anything, suppliers can build trust by keeping certificates of analysis transparent and making explicit not just the purity, but the way the solid was dried and packaged.

Chemicals like 1-hexyl-3-methylimidazolium iodide shape the future of batteries and solar panels, but their true impact starts in the supply drawer. The more reliable the form, the smoother the path from bottle to breakthrough.