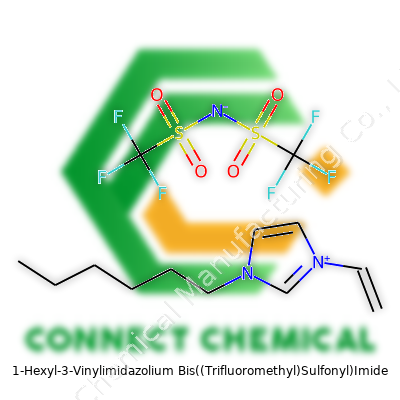

1-Hexyl-3-Vinylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: Behind the Chemical Formula

Historical Development

Rolling into the late 20th century, traditional solvents and salts reached their limits in select industries. Researchers started poking beyond the conventional boundaries, their attention turning to room-temperature ionic liquids. Among the molecules that came into focus, 1-hexyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide (often dubbed [HVIM][NTf2]) holds its spot. If you break down its roots, the imidazolium framework got popular because of its stability and versatility. Chemists tinkered with long-chain substitutions and functional vinyl groups, searching for molecules that offered better performance for batteries, electrochemistry, and organic synthesis. By the early 2000s, scalable syntheses had put [HVIM][NTf2] into more than just academic journals, handing it over for practical trials in several labs worldwide.

Product Overview

At its core, this ionic liquid carries a unique pairing—a long hexyl tail and a reactive vinyl group stuck to an imidazolium ring, coupled with the bis((trifluoromethyl)sulfonyl)imide anion known for hydrophobicity and chemical stability. This carefully chosen structure lets the compound blend attributes like solvent strength, low flammability, and the rare ability to tolerate extreme ions and temperatures. Most often, suppliers offer it as a pale yellow to colorless liquid, stored tightly capped to block reactions with ambient moisture or air. The balance in its composition makes it a valuable player where typical solvents or salts trip up, especially where traditional choices decompose or ignite.

Physical & Chemical Properties

Expect dense liquid at room temperature, slippery to the touch, with a relatively high boiling point and a melting point well below freezing—something that sets it apart from older salts that refuse to stay liquid. It’s non-volatile and tends to shrug off water, making it especially handy for water-sensitive chemistry. Electrochemical stability runs broad across roughly 4–5 volts in some applications, which means it doesn’t break down quickly under voltage stress. In my own work, equipment stayed cleaner and electrolytes didn’t break down as fast as with other more volatile and reactive options. Its viscosity feels higher than standard solvents, but brings advantages in applications like lubricants, electrolytes, and some catalysis systems. The fluorine-heavy anion keeps it resistant to oxidation and harsh conditions.

Technical Specifications & Labeling

Every bottle of 1-hexyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide should spell out its purity—typically offered upwards of 98%. Labels read out key info like molecular formula (C13H19F6N3O4S2), CAS number (unique among ionic liquids), batch and lot details, plus storage advisories. Experts recommend keeping it tightly sealed at room conditions. Certificates from major suppliers include spectroscopic analyses and confirm water content stays low, often beneath 0.2%. Unlabeled or ambiguous batches can create headaches; a solid supply chain ensures safer lab handling and consistent experimental results.

Preparation Method

Synthesis begins with alkylation of a vinylimidazole, typically using n-hexyl halides as alkylating agents, under controlled atmospheric conditions. Once the 1-hexyl-3-vinylimidazolium halide forms, it's met with a bis((trifluoromethyl)sulfonyl)imide source (often lithium salt) to swap halide for NTf2– anion through a metathesis reaction. Filtration and careful drying typically follow, since water and halide contamination compromise both product efficiency and safety. In several university labs I’ve visited, high-yield prep demands close attention during anion exchange—skipping thorough washing steps can leave impurities nobody wants in precision applications. The process, though developed in academic settings, is reliable and works for industrial scale-ups, owing to robust anion chemistry and stable intermediates.

Chemical Reactions & Modifications

The vinyl group creates a chemical handle ripe for further reactions. Grafting this cation onto polymer chains lays the foundation for ion-conductive membranes, an area gaining traction in advanced battery research. Crosslinking reactions using the vinyl moiety generate gels with outstanding conductivity and mechanical properties. Modified forms may interchange the NTf2– anion for other large, weakly coordinating anions when specific solubility or thermal features take priority. The NTf2– moiety shields the cation from decomposition, making it a practical solvent or component under harsh synthetic or electrochemical conditions. Over the past few years, chemists have tailored the cation by attaching other alkyl or functional tails, aiming for tweaks in viscosity, boiling range, or reactivity.

Synonyms & Product Names

Commercial forms appear under names such as 1-hexyl-3-vinylimidazolium bis(trifluoromethanesulfonyl)imide, or more succinctly as [HVIM][NTf2]. Marketing teams sometimes label it by catalog numbers or legacy abbreviations—for instance, HVI-TFSI or HVIM-Tf2N. In research settings, shorthand names crop up for notes and presentations, but anyone sourcing for regulatory or safety reasons sticks with the full systematic name, keeping confusion at bay especially across suppliers and national borders.

Safety & Operational Standards

Handling standards keep evolving, mainly as more folks outside specialty labs take it up. While this ionic liquid rates as less flammable than many solvents, methylimidazolium salts have earned regulatory scrutiny regarding skin and eye irritation. Always wear proper gloves (nitrile wins for durability) and eye protection. The toxicological record remains slim but enough data suggest caution against inhalation or direct skin contact. Spilled material cleans up with inert absorbents and prompt disposal; water rinses do poorly due to low solubility. Thorough training and up-to-date safety data sheets (SDS) form the backbone for any operation. Modern labs underline closed-transfer setups, spill preparedness, and sharp oversight by lab managers familiar with both chemistry and evolving safety science.

Application Area

Interest boomed in energy storage fields using it as a component in lithium-ion and supercapacitor electrolytes. Its wide electrochemical window and non-flammable nature proved attractive for next-gen batteries and capacitors, especially in applications demanding high reliability. Another hotspot: polymer chemistry, where its vinyl group sets it apart as a monomer for ion-conductive gels, block copolymer synthesis, or solid thin films. Phases involving organic synthesis lean on the solvent’s resilience against strong nucleophiles, bases, and varying temperature. Over recent years, I’ve seen growth in green chemistry applications, trying to cut down on dangerous, volatile organic solvents while retaining reaction efficiency and selectivity. Industrial lubricants and even nanoscale separations round out its reach, leveraging both chemical resistance and hydrophobicity.

Research & Development

Market and scientific appetite for ionic liquids keeps growing, with this molecule often taking a starring role. Academic literature reports new derivatives almost monthly, chasing improvements in ionic conductivity, stability, or tailored reactivity for targeted processes. Researchers pilot blends of imidazolium liquids for safer, longer-lasting batteries, with some startups measuring cycle lives against traditional organic solvents. Material scientists test crosslinked versions in flexible electronics or actuators. Every year, more collaborations pop up, mixing industrial know-how with university research, speeding up the push for practical, cost-efficient production methods without performance trade-offs.

Toxicity Research

While ionic liquids once promised nearly zero toxicity, real-world testing unraveled that generalization fast. 1-hexyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide shares similarities with other long-chain imidazoliums: moderate environmental toxicity, mainly toward aquatic life. Recent studies point toward slow biodegradation, especially for the NTf2– anion. Chronic exposure leaves enough open questions for regulators, so disposal routes funnel spent ionic liquid into hazardous waste streams rather than going down the lab drain. Personal experience with eco-toxicology teams underscores the need for ongoing testing, transparent reporting, and designing chemical modifications that sacrifice little on performance while reducing persistence or bioaccumulation.

Future Prospects

As the world looks for safer, more sustainable alternatives in everything from energy storage to advanced manufacturing, this molecule’s story continues. Demand in high-performance sectors—think aerospace, portable electronics, grid storage—pushes next-generation electrolytes and specialty polymers. Chemists and engineers search for greener production routes and less toxic anions, testing dozens of small tweaks to maximize performance while keeping environmental footprints in check. Regulatory concerns about long-lived fluoro-compounds have pressured manufacturers to blend innovation with responsibility. New research directions experiment with biorenewable hyperbranched cations, or replacements for NTf2– that break down faster in the environment, hinting toward a more balanced future. If the chemical industry can harness these lessons, positives from early breakthroughs in 1-hexyl-3-vinylimidazolium chemistry will reach the mainstream—not just as a niche solution, but as a staple in safer, high-tech manufacturing.

Getting to Know the Structure

Through years working in a chemistry research lab, names like 1-Hexyl-3-Vinylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide became less intimidating. Sure, saying it quickly is a tongue-twister, but every part of the name helps explain what makes the compound unique. Looking at the cation first: the backbone comes from imidazolium, a five-membered ring with two nitrogen atoms. Stick a hexyl chain on position 1, and a vinyl group at position 3, and you’ve built a cation where one tail is oily, the other wants to link up during polymerization. That structural twist opens doors in both materials science and green chemistry.

The anion part—bis((trifluoromethyl)sulfonyl)imide or “Tf2N”—is a heavyweight in ionic liquid chemistry. This anion balances the cation’s charge, but more importantly, it resists breaking down and plays nicely across a broad temperature range. That feature matters a lot to scientists looking for new solvents that won’t fall apart under stress. The chemistry here isn’t just textbook—it’s practical.

Why Such Molecules Matter

In a time where sustainability in chemistry draws so much focus, substances like this one stand out. Ionic liquids featuring extensive fluorination, like the bis(trifluoromethylsulfonyl)imide family, caught my eye back in grad school for their ability to leave behind almost no vapor. Compare that to classic organic solvents that stink up labs and pose health risks. The low volatility means less exposure for workers and reduced emissions to the air. As someone who values both practicality and safety, these properties can make or break the decision on what to use for important reactions.

The vinyl group attached to the imidazolium ring offers a way to build even bigger molecules. I watched colleagues blend this kind of molecule into new polymers for batteries and sensors. The vinyl group acts like a handle, letting scientists graft the ionic liquid onto polymer backbones. That flexibility brings better stability, mechanical properties, and often improves how fast ions can move in a device—big pluses for technology that needs to last.

Seeing the Challenges and Opportunities

Nothing in chemistry is perfect. Engineering and sourcing highly fluorinated reagents creates environmental headaches, with potential persistence in soils and water. These concerns pop up every time chemists discuss new “green” replacements. Experience taught me to ask questions about how we dispose of leftover chemicals, especially anything with so many fluorines. The chemical stability that keeps ionic liquids from falling apart also means they can linger in the world longer than expected. Factoring in life cycle and safe disposal can’t be an afterthought once a process gets upscaled.

One path forward that’s gaining traction in my network involves tweaking the recipe: reduce the reliance on long, fluorinated tails without giving up performance. Some research teams now design hybrid anions, blending just enough fluorine to deliver crucial properties but balancing with more degradable pieces. In the lab, we’ve tried micronizing these ionic liquids for easier handling, cutting down on worker exposure and improving waste collection.

With the chemical structure clear, the spotlight now turns toward smarter design, safer practices, and a bigger push to factor in environmental cost early. Scientists, industry professionals, and regulators have to keep asking if the next advance checks off all these boxes.

Smart Solutions in Green Chemistry

Lots of people talk about moving toward a greener way of doing chemistry. I’ve seen genuine progress only when chemists grab new tools with both hands. 1-Hexyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide—typically called an ionic liquid—stands out in this journey. Its main claim to fame: swapping out volatile organic solvents that often end up polluting our air and water. Many labs have used it to make solvent processes safer and cleaner, cutting down on chemical waste and handling risks. In synthesis, its stability and low vapor pressure have lightened the pressure on exhaust systems and labs overall.

Electrochemical Devices

Anyone with experience tinkering on batteries or supercapacitors knows that the liquid inside the thing matters just as much as the casing or the electrodes. This ionic liquid came into its own in research labs and pilot projects that push the limits of lithium-ion and sodium-ion batteries. The ability to handle extreme voltages without corroding or breaking down gives engineers peace of mind. It won’t catch fire the way standard organic electrolytes sometimes do. That’s a big plus when you’ve ever seen battery accidents up close.

Another place I’ve noticed it pop up: dye-sensitized solar cells and other next-generation photovoltaics. Compared to more old-fashioned electrolytes, this salt handles heat stress without falling apart—a key little detail for rooftop solar projects in sunniest parts of the world.

Advanced Separation Techniques

Industry folks running into headaches with hard-to-separate chemicals know that distillation and extraction can be both energy-hungry and leaky. This ionic liquid helped short-circuit some problems through an edge in selective extraction. Applications range from removing heavy metals in wastewater streams to purifying complex product mixtures in pharmaceuticals. The “green” part matters, but so does the bottom line. Lower energy costs in separation translate straight into profit, and the reduced hazard profile means less training and fewer spills.

Catalysis and Polymerization

One friend of mine in academia pushed ionic liquids into the limelight with some clever catalysis. The vinyl group on this specific compound acts as a point where chemical reactions can latch on, making it a flexible co-catalyst or stabilizer. Some chemists use it to host transition-metal catalysts, making certain reactions run faster and with fewer unwanted byproducts. The story doesn’t end with academic curiosity; polymer chemists build tailor-made plastics by using this salt during controlled polymerizations, tuning properties like flexibility or conductivity in final products.

The Road Ahead

No silver bullet exists in advanced chemistry, but it’s possible to push toward greener, safer, and more efficient production by lining up the right molecular tools. Wider commercial adoption means seeing more field studies, not just lab tests. Work remains to lower costs and scale up production. Growing up around folks who managed industrial plants, I learned that good tech travels best when it pays off in practice, not just on paper. Supporting research, sharing real-world data, and focusing on safety build trust in these next-generation solutions.

No Place for Shortcuts with Modern Ionic Liquids

Labs keep turning to chemicals like 1-Hexyl-3-Vinylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide. It's got a long name and a reputation for unique properties, finding uses in electrochemistry, advanced materials, and catalysis. But working with substances like this brings some responsibility, especially when toxicity data isn’t as full as we'd like. I’ve worked around compounds just as new or unfamiliar, and it's clear: confidence in the safety sheet never outruns common sense and experience.

Understanding What We’re Dealing With

This ionic liquid won’t boil away like water. It tends to persist—low vapor pressure, which limits inhalation risk at room temp, but also means spills can linger. Reports link similar compounds to mild skin and eye irritation, and sometimes worse if mishandled. The imidazolium-based liquids in particular like to sneak through gloves that aren’t resistant enough.

Researchers document the environmental persistence of perfluorinated groups, which here show up as the bis((trifluoromethyl)sulfonyl)imide part. These have turned up in environmental samples long after labs stopped using them, and authorities raise eyebrows at their bioaccumulation potential. This tells me to avoid any careless drain disposal—the price of convenience runs high if persistent chemicals get out.

Personal Experience: The Difference PPE Makes

I've watched people skip double-gloving "since it’s just a small volume," then regret it after splashing an imidazolium-based compound. I stick to nitrile gloves, and always check them for chemical compatibility. Splash goggles don’t go back on the shelf until the bottles are sealed and work area wiped clean. I’ve noticed lab coats shield my arms but don’t help much if someone’s wearing shorts—it pays to suit up fully. A certified fume hood isn’t optional. Even without strong odors, breakdown products can produce fumes, especially with heating or ultrasonication. Any open manipulations or transfers happen behind glass.

Funding the Right Waste Disposal

Most municipal waste networks aren’t built for chemical cocktails like this one. We collect any liquid or solids contaminated with this compound in separate, tightly labeled waste containers. Decades-old advice from waste contractors still holds: seal, segregate, and track. University safety offices can help with batch pickups, but small companies sometimes have to pool disposal to make it affordable. Cleanup with disposable towels or absorbent pads followed by appropriate solvent means less residue, but never a reason to skip final wipes with water or alcohol-based cleaners.

Better Safe Than Sorry

Experience shows that the most uncomfortable PPE moment still beats the long-term mess of a chemical exposure. People learn safety culture faster by watching what happens when shortcuts fail. A transparent lab notebook, regular hazard reviews, and treating every new chemical as a little more reactive than expected—this attitude protects both laboratory staff and the environment. As more regulatory agencies scrutinize fluorinated chemicals, attention to disposal and spill response won’t just keep people safe. It will also keep doors open for innovators.

Why Purity Matters in Raw Materials

High purity in a product points straight to quality and reliability. In my own background working in labs as well as industry, I’ve seen projects break down because of impurities, even when they’re measured in fractions of a percent. Take pharmaceutical work for example. If a raw ingredient drifts below 98% or 99% pure, downstream processes turn unpredictable. Reactions slow, unwanted byproducts show up, and at the end of the day, people’s health is at stake. Analytical tools like high-performance liquid chromatography (HPLC) and gas chromatography (GC) pull their weight here, narrowing in on these small impurity levels. Reputable suppliers know that showing data from these tests earns trust and keeps production lines running smoothly.

Physical Form Shapes How a Product Works

The way a product looks and feels says a lot about its function. In agriculture, a powder or granule dissolves in water and spreads evenly over a field, getting right to the roots. In my time working on water-conditioning projects, the physical form dictated how easily we could measure, mix, or apply a product safely. Powders kick up dust and can be tricky, so suppliers tighten up particle size controls and packaging. Flake and bead forms handle better and pour with less loss or waste.

Industries lean toward what works best for their process lines. Laboratories want fine powders or crystalline solids, because weighing and dissolving happen more precisely. Painters and plastics manufacturers often reach for pellets, which flow through automated systems without clogging or clumping. Purity holds steady here because the source material sets the standard, but handling, storage, and convenience all come into play once form enters the discussion.

Setting the Right Standard

Consistency is valuable. Suppliers use certificates of analysis to detail not just overall purity, but other chemical and physical checks. Every batch comes with these numbers: percentage of key ingredient, trace element limits, moisture content, sometimes even specific surface area. Customers then match those values with their Specification Sheets. In my past work as a buyer for a research group, these sheets served as the final checkpoint before acceptance. No match, no deal.

Dry powders, crystalline chunks, pellets—each supports particular needs. Electronics manufacturing, for example, demands ultra-high-purity materials (often more than 99.999%) because microscopic contamination wrecks tiny circuits. On the other hand, a cleaning product manufacturer might not need such extreme precision; a product containing 95-98% can fit the bill, as long as it dissolves fast and leaves no residue.

Moving Toward Better Solutions

Purity and form go hand in hand with safer, cleaner, and more efficient results. Handling and transportation improve with solid consistency. Technological progress keeps improving the way we measure purity, lowering detection limits and catching contaminants companies a decade ago might have missed. More manufacturers now invest not just in better raw ingredients, but in smarter packaging and transport. Tamper-proof seals, clear labeling, and batch traceability all help keep the chain of custody intact.

Transparency brings confidence. Companies that share their test reports openly, explain their quality control steps, and support their claims with published data become real partners for buyers in critical fields. If every producer, supplier, and end user prioritizes solid purity and the right physical form, customers benefit from performance that matches expectations, whether that’s in a farm field, a medical lab, or a circuit board plant.

Understanding Why Storage Matters

Ask anyone who has spent time in a chemistry lab, and you’ll hear plenty of cautionary tales about what happens when storage protocols get ignored. In my own experience, small lapses—leaving a bottle out too long, ignoring the recommended temperature—create big problems. Expensive materials lose their integrity, or worse, react in ways you can’t predict. That makes attention to detail more about safety than just rule-following.

1-Hexyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide falls under a class of ionic liquids prized for their stability, but that doesn’t mean you can set them aside and forget them. Each lab material comes with its quirks. Here, both the imidazolium cation and the bis(trifluoromethylsulfonyl)imide anion bring their own set of sensitivities.

Key Factors that Affect Shelf Life

Improper storage doesn’t just inconvenience scientists; it drains budgets. I remember a costly episode when environmental moisture ruined a specialty chemical, turning a promising research batch into hazardous waste overnight. With this compound, moisture is a particular enemy. Even trace water can start hydrolysis or cause slow degradation, especially over months.

Oxygen ranks up there with moisture. The vinyl group can react with atmospheric oxygen, especially under light, and this leads to unwanted polymerization or breakdown of the compound. Experiences like seeing a clear solution take on a yellow tint or grow cloudy highlight how critical oxygen control remains even outside high-stakes industry labs.

Temperature and Light Matter More Than You Think

Manufacturers often suggest cool, dry, dark conditions for a reason. For 1-hexyl-3-vinylimidazolium-based ionic liquids, consistent refrigeration—usually between 2–8°C—slows chemical reactions. From practical experience, even brief spells at higher room temperatures can shorten shelf life. Direct sunlight not only introduces heat, but tends to speed up photochemical changes. In my own early laboratory days, failing to shade a sensitive reagent meant watching it gradually degrade from a pure compound into something almost useless within a season.

Packaging Choices Make a Real Difference

Original packaging from reputable suppliers provides the best start. Airtight, amber-glass containers work, offering a barrier to both moisture and UV light. Laboratory-grade desiccators add another layer of defense, targeting humidity that sneaks in after frequent bottle opening. Adding packet-style desiccants absorbs residual water vapor, extending the period before you see deterioration.

Shelf Life and Practical Advice

With proper storage, most ionic liquids like this one keep their quality for one to two years, sometimes longer. I’ve stretched shelf life to nearly three years with controlled refrigeration and careful resealing after every use. Each time the container pops open, the content faces small exposures—rushing to withdraw the amount needed minimizes this risk.

Routine Monitoring: A Simple Step with Big Payoff

Simple checks—like noting color shifts, changes in viscosity, or any unusual odor—tell you a lot. Running occasional purity assessment with NMR or IR spectroscopy catches problems invisible to the naked eye. My own habit is to mark the date of first opening directly on the bottle—no fancy tracking system, just a pen and a clear label. This simple act makes it easier to rotate stock and avoid using questionable material on a big experiment.

Final Thoughts on Responsible Storage

Following these guidelines not only maintains product performance but keeps projects on track and safe. With a little extra care at each step, labs can keep costs down and research up to standard. These lessons—learned through both success and error—matter more than any line in a safety manual.