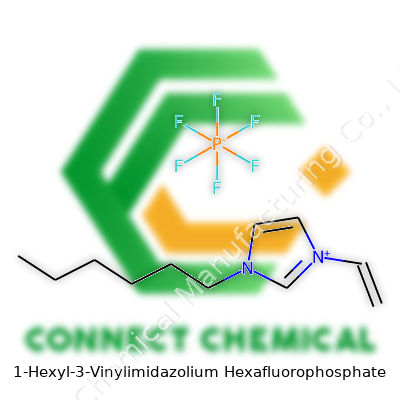

1-Hexyl-3-Vinylimidazolium Hexafluorophosphate: A Practical Look

Historical Development

The journey of ionic liquids started a few decades back, with researchers hunting for better solvents. Traditional organic solvents caused headaches for both workers and the environment. Then, chemists discovered imidazolium-based ionic liquids, opening doors for a new class of functional materials. 1-Hexyl-3-vinylimidazolium hexafluorophosphate stepped into the scene as the call for tunable, safe, and high-performance materials kept growing. Researchers found that swapping alkyl chains and tweaking side groups on the imidazolium ring could influence solubility, stability, and even reactivity, giving practical options for different lab and industrial uses.

Product Overview

1-Hexyl-3-vinylimidazolium hexafluorophosphate comes off the line as a specialty ionic liquid. Its structure blends a six-carbon hexyl tail and a vinyl group onto an imidazolium core, paired with a hexafluorophosphate anion. This mix of hydrophobic and reactive features gives it several unique tech perks. It doesn’t act like typical solvents; instead, it supports chemical reactions that struggle in water or common organics. Some chemists say it’s like a Swiss Army knife for labs: carrying the electrical conductivity and wide liquid range without the volatility that sends other chemicals into the air.

Physical & Chemical Properties

Pouring out of a bottle, you notice 1-hexyl-3-vinylimidazolium hexafluorophosphate’s slightly viscous nature. Its boiling point sits high and its melting point tends to stay low, but the most striking property comes from its lack of measurable vapor pressure under normal conditions. You don’t catch whiffs of fumes—less risk in cramped lab spaces. Chemically, the ionic bonds between cation and anion hold tight, but the molecule’s vinyl group brings a distinctive reactivity that smart researchers have learned to harness. It dissolves a range of organics and shows solid electrochemical stability, standing up even in the presence of aggressive reagents or strong electric fields. Its density, viscosity, and conductivity can change depending on temperature and impurities, something every chemist keeps in mind on the bench.

Technical Specifications & Labeling

Manufacturers supply 1-hexyl-3-vinylimidazolium hexafluorophosphate with batch purity usually over 98%. Specs on color, water content, and conductivity hit the data sheets. Labels list the CAS number, formula (C11H19N2PF6), and often include recommended storage below 25°C in sealed, moisture-free containers. Any researcher who has handled ionic liquids knows the frustration of small leaks or contamination, so suppliers ship it in sturdy glass or non-reactive plastic bottles. Safety and hazard warnings cover skin sensitization and possible toxicity, especially if mixed with water under the wrong conditions.

Preparation Method

Lab synthesis usually kicks off with 1-vinylimidazole and 1-chlorohexane. These react under controlled heating and stirring, producing 1-hexyl-3-vinylimidazolium chloride as an intermediate. To swap out the chloride, chemists add hexafluorophosphoric acid or potassium hexafluorophosphate. The mixture needs a solid phase extraction or repeated washing with organic solvents to remove residual salts. Once dry, the liquid gets vacuum-treated to clear out water, which ruins its key properties. Each step relies on careful temperature control and constant monitoring since even a small impurity disturbs the outcome, especially if a downstream application demands high conductivity or polymerizability.

Chemical Reactions & Modifications

The thing that draws synthetic chemists is the active vinyl group sitting pretty on the imidazolium ring. It opens up opportunities for radical polymerizations or addition reactions. You can stitch these cations into long polymer chains or functionalize surfaces, producing specialized materials for membranes, sensors, or even drug delivery. Another trick comes from tuning the anion: swapping out the hexafluorophosphate for a less hydrophobic anion shifts the solubility or compatibility with different reactants. Catalysis takes a leap when ionic liquids jump in, especially for reactions needing a stable, non-aqueous medium.

Synonyms & Product Names

Beyond its formal IUPAC name, this compound turns up as 1-hexyl-3-vinylimidazolium PF6 or simply as HVIM PF6. Some catalogs drop the numbers and call it hexyl-vinylimidazolium hexafluorophosphate. Depending on the source, the label can mix these up, so a careful read of the structure or CAS number helps. For polymer research, suppliers may include it under their specialty materials for advanced coatings or electrolytes.

Safety & Operational Standards

Handling starts with gloves because this compound, like many ionic liquids, can pass through the skin. Goggles and fume hoods earn their place in any protocol, especially given the fluorinated anion’s risks if rice-milled with acids. Avoiding moisture extends not just shelf life but personal safety, since hydrolysis of hexafluorophosphate liberates hydrofluoric acid—a notorious danger. Disposal calls for specialized waste routes; dumping into drains leads to headaches for wastewater treatment. Training on handling and spillage reduces risk for everyone in the lab. As researchers, learning from those who worked with older, more hazardous solvents brings appreciation for safer substitutes but never invites complacency.

Application Area

Energy storage outfits use ionic liquids like this one in battery electrolytes, supercapacitors, or solar cells. The vinyl group allows integration into polymeric matrices, expanding options for flexible electronics or high-performance coatings. In my past collaborations with materials scientists, we leaned on its hydrophobicity for separation processes and extraction of organics. Chemical engineers test it in catalysis setups needing a stable, high-temperature medium. Some pharmaceutical research even investigates its potential in drug transport systems, though much of this remains exploratory.

Research & Development

Active labs across the globe take up work on new derivatives and modifications, seeking non-flammable electrolytes that cut fire risk or raise operating voltages. The latest journals show electrochemical tests, polymerization studies, and applications in optoelectronics. Partnerships between academia and industry speed the push to scale-up, looking past the bench to how easily these materials shift into pilot production. Grants often target green chemistry and sustainability, as ionic liquids help step away from volatile organics.

Toxicity Research

Limited animal and cell line studies exist for this individual compound, but the family of hexafluorophosphate-based ionic liquids has shown some concern for aquatic life and chronic exposure risks. Skin contact sometimes causes irritation. Inhalation data stays sparse thanks to negligible vapor pressure, but ingestion or environmental leaks raise problems by interfering with metabolic functions in exposed organisms. Regulators keep a close eye on new data, and responsible labs regularly consult evolving guidance for solvent replacement or waste handling.

Future Prospects

Practitioners in green technology circles and electronics research see a bright path for 1-hexyl-3-vinylimidazolium hexafluorophosphate. The chemical industry weighs cost against performance, looking to scale synthesis and drive prices down. New reactor designs might expand use in batteries, ultra-capacitors, or even light-emitting devices. Researchers continue to probe for less toxic, biodegradable counter-anions—hoping to merge performance with environmental responsibility. My own experience watching ionic liquids come off the bench and into pilot lines suggests demand will keep growing as energy tech and clean synthesis push into new frontiers.

A Liquid That Means Business in Chemistry Labs

People call ionic liquids the “future of chemistry,” and 1-Hexyl-3-Vinylimidazolium Hexafluorophosphate, or HVImPF6, stands out in this class. Stepping into any research lab working on battery tech, electrochemistry, or green solvents, you’ll see scientists placing their bets on these unusual liquids. If you haven’t poked around in these circles, you might not realize why—HVImPF6 doesn’t evaporate the way water or alcohol does, and it resists catching fire. These traits matter when dealing with volatile or dangerous experiments, which come up more often than most expect.

Pushing Electrochemistry Forward

The largest spotlight for HVImPF6 falls on batteries and supercapacitors. Standard liquid electrolytes used in lithium-ion batteries lose their edge at high voltages or temperatures—sometimes they even spark fires. HVImPF6 brings a stable, non-flammable barrier, which allows researchers to push the limits safely. This means denser, faster-charging batteries for devices we care about every day—phones that last longer or cars that charge in minutes.

Why Chemists Prefer This Over Conventional Solvents

Traditional solvents pollute ground water and often create difficult clean-up jobs. Unlike these, HVImPF6 hardly evaporates, producing fewer emissions. I once joined a project investigating chemical recycling, and this liquid’s low vapor pressure made everything feel less hazardous—no burning in the throat, no headaches from working fumes. These liquids also dissolve salts and organic compounds very well, opening doors for custom-designed reactions.

Making Polymer Science More Flexible

Industrial coatings and plastics shift gears with ionic liquids bearing a vinyl group like this one. HVImPF6 takes part in special polymerizations, connecting itself into longer chains under the right light or heat. Lab experiments show these ionic polymers boost the conductivity and mechanical strength of films. Companies eager for flexible electronics—think bendable screens or “smart fabrics”—lean into these materials for their unique properties. This push is backed by solid numbers: a 2022 review in ACS Applied Polymer Materials revealed that ionic liquid-containing polymers increased device lifetime twofold compared to standard films.

Addressing the Toxicity and Stability Question

No new chemical gets a free pass. It’s true that the “hexafluorophosphate” part of this ionic liquid—while offering stability—also raises concerns about long-term toxicity and degradation. Governments in Europe and the US have started reviewing the environmental fate of such compounds. Safe lab practices remain crucial: wearing gloves, sealing off containers, and avoiding skin contact or spills. Researchers focusing on green chemistry now explore how to recycle or break down these ionic liquids at end-of-life, using photochemical or electrochemical processes.

Moving Toward Better Solutions

Real progress means not just swapping one solvent for another, but considering the full cycle—from raw ingredient to disposal. Chemists continue to test HVImPF6 in pilot projects, searching for less toxic counter-ions and scaling up re-use methods. Funding bodies like the National Science Foundation have made grants available for projects developing “benign-by-design” ionic liquids. For industry, making the switch requires more data on life-cycle impacts—but with more scientists examining the question from synthesis to recycling, the brightest uses of HVImPF6 may still be ahead.

Digging Into the Chemistry

1-Hexyl-3-vinylimidazolium hexafluorophosphate appears in research labs more now than ever. Its use in electrochemical setups and as an ionic liquid draws curiosity about its stability, specifically on crowded shelves and in real-world storage. Stability is not a small thing—it decides long-term costs, lab safety, and confidence in results. I spent years in university labs and chemical stockrooms, and the talk around the bottle always boiled down to, “Will this change on me?”

Hexafluorophosphate: An Old Friend with Warning Labels

The hexafluorophosphate (PF6-) anion offers good thermal and electrochemical stability, which led some to treat it as a gold standard among counter ions. Yet some hard facts stick with anyone who handles these salts: water breaks PF6- down. The hydrolysis can produce HF—a health hazard from both inhalation and skin exposure. Moisture finds its way into everything, from faulty bottle caps to that faint sheen inside desiccators after a rainy week. Unless stored bone-dry and tight, PF6-based salts cannot really be described as trouble-free.

The Imidazolium Cation: More Than Just a Passenger

Imidazolium rings with vinyl groups also attract questions. The vinyl function attached to the ring means you can expect higher sensitivity to light, air, and rapid polymerization if someone leaves the bottle open or on a sunny windowsill. A graduate student once left a sample on an exposed benchtop. After two days, a once-clear liquid grew cloudy—with sticky side-products confirmed by NMR. Polymerization and decomposition always linger around the corner when vinyl chemistry meets oxygen and light.

What Experience Shows in Storage

In dry, cool, and dark storage, 1-hexyl-3-vinylimidazolium hexafluorophosphate holds up reasonably well over a few months. My own test bottles, wrapped in foil and tucked with new desiccant, looked unchanged by visual inspection after six months at 4°C. Shift the scene to standard room shelves—ambient light, variable humidity, open-air atmosphere—and subtle breakdown creeps in. Chemical suppliers often recommend storing these compounds under argon or nitrogen, and desiccants are a basic must. If a cap sits loose or a bottle makes a round trip to the weighing bench too often, hydrolysis and slow vinyl polymerization come into play. No need to wave a panic flag, but regular checks and strict storage habits matter.

Scientific Backing

Several published studies confirm the risk. Analytical checks on aged samples often detect increased fluoride, byproducts, and deviations in conductivity. The hexafluorophosphate story has played out in battery labs, where electrolyte decomposition tanks performance, and in materials science setups, where trace contamination derails reproducibility. Peer-reviewed literature lays out these pitfalls, matching up with what many chemists observe in the real world.

Better Storage for Better Science

Storing 1-hexyl-3-vinylimidazolium hexafluorophosphate in tightly sealed, amber-glass bottles under inert gases isn’t just paperwork. It’s an insurance policy for your data. Log change dates and label all containers. Desiccators fight moisture, but adding indicator cards helps spot trouble early. For stockrooms without climate control, smaller-scale purchasing can save money, sanity, and reduce exposure to noxious byproducts. If decomposition sneaks up, proper PPE and vented fume hoods protect staff from possible HF release.

Balancing Safety and Practicality

No chemical pays rent on a shelf. Rigorous storage and vigil matter more than relying on standard shipping advice or best-case scenarios. Each step labs take—tighter capping, less exposure to air, and regular upkeep—extends the life and reliability of 1-hexyl-3-vinylimidazolium hexafluorophosphate. The chemistry world advances on the backs of careful hands, sharp eyes, and the lessons passed on from one stockroom to the next.

Understanding Material Risks

Everyday products often include chemicals or materials most folks hardly think about. Long stretches in a warehouse or time on a garage shelf can turn something ordinary into something risky. One small example is paint thinner. At home, I once helped my dad stain an old bookshelf, and he left the can uncapped just a bit too long. The fumes gave us both a nasty headache. That day stuck with me. Even simple items ask for respect.

Storage Practices Matter

Most containers display pictograms or warnings for good reason. Paint, solvents, pesticides, even cleaning sprays—none belong near kids, pets, or open flames. Warm garages invite trouble. I’ve seen products swell or leak after a classic July heatwave, which can lead to dangerous spills or even fire. Survey the home or workspace twice a year. Keep breakable containers off top shelves and away from sunlight or heat vents. A lockable cabinet saves a lot of stress down the line.

Personal Protective Equipment

Simple choices make a big difference. Gloves, goggles, and masks cost little compared to medical bills from skin burns or inhaled dust. Last summer, a friend pressure-washed his deck using a heavy-duty cleaner. He skipped gloves—his hands blistered, tough lesson learned. Your eyes and lungs need protection too. Ventilation turns a risky space into a safer one, whether it means cracking a window or running a fan.

Using and Disposing Responsibly

Misuse often starts with ignoring instructions. That little printed manual or sticker has tested steps for a reason. Never mix chemicals, even if the labels don’t seem to warn against it. Mixing bleach and ammonia, for example, creates toxic gas. I’ve seen folks try odd combinations, thinking it’ll clean faster, and regret it. Stick to one product at a time.

After the job, don’t pour leftover liquid down the drain or toss it in the trash. Most communities list hazardous waste drop-off days and specify where to bring cans, batteries, and spent cleaners. Safe disposal prevents ugly surprises downstream, like pollution or sewer backups, which hit nearby neighborhoods before anyone realizes it. As a kid, I watched city crews scoop an oily mess from a creek after someone dumped antifreeze. That mess lingers for years.

Emergency Ready

Accidents happen, even with the best plans. Keep the number for Poison Control, a fire extinguisher, and a first-aid kit close by where chemicals are stored or used. Read emergency guidelines before starting a task, not during. I once saw someone fumble for the antidote directions after splashing their arm, wasting precious time. Quick response makes the difference between a minor scare and a trip to the hospital.

Keeping Others Safe

Kids and pets won’t understand the risks—doors and locks matter. Take a minute to explain house rules about strange bottles or sprays. Young friends won’t always ask questions before experimenting, and teens might ignore warning labels. In my own house, I started a rule: If you don’t know what it does, you don’t touch it. Not once has someone gotten hurt since.

Understanding what you bring home, store, and use guards everyone’s health. Look at every container as an opportunity to prevent a problem before it starts. Good habits weigh less than regret.

The Stakes Behind Purity Levels

If you have ever worked in a research lab or managed a chemical process, you know just how much purity matters. I’ve spent far too many hours troubleshooting mysterious results only to trace the issue back to a reagent not being quite as clean as promised. 1-Hexyl-3-vinylimidazolium hexafluorophosphate isn’t just a mouthful—it’s a high-value ionic liquid that finds use in advanced electrochemistry, photovoltaics, catalysis, and even green chemistry. Purity controls experiment outcomes, equipment safety, and product consistency.

What Purity Levels Look Like

Typical suppliers peg the purity of this ionic liquid between 97% and 99%. Anything lower introduces risks. Take the story of a postdoc I knew who set up a fancy electrochemical cell for months, only to discover the trace impurities in the electrolyte shifted reaction rates and product selectivity. The documentation from most chemical distributors usually provides a certificate of analysis, but you need to dig deeper. Small differences in percentages reflect big changes in contamination. Tiny bits of unreacted starting material, solvents, or byproducts can cause color problems, leave residue, and interfere with spectroscopy or conductivity measurements.

Why the Number Matters

Skepticism toward supplier claims serves researchers well. My own experiments have taught me that high-purity reagents aren’t just a technical ideal—they help avoid wasted time and questionable data. With 1-hexyl-3-vinylimidazolium hexafluorophosphate, a purity rating over 98% unlocks its full potential in applications like battery research, where contaminants can alter redox chemistry. Even a limited number of studies exist showing that trace water or organic impurities drop ionic conductivity, increase viscosity, and throw results into chaos. These aren’t just headaches for researchers—manufacturers lose batches of material, money, and face supply-chain headaches if the product doesn’t match a trusted level.

Ensuring the Product Matches the Label

Most reliable producers share detailed analytical data, including NMR, FTIR, and even small-molecule crystallography results. If your order comes without proof, it’s asking for trouble. Running a quick proton NMR in the lab or sending a sample out for elemental analysis provides an extra layer of trust. Once, a friend received what looked like perfect ionic liquid but discovered later that a batch contained significant chloride ion contamination. A simple ion chromatography test could have prevented weeks of wasted work, faulty sensors, and hours explaining things to a frustrated supervisor.

Building Confidence in Sourcing

Customers need more than a number. A solid supplier builds trust by providing transparent, up-to-date documentation. They respond to questions about their purification steps and batch tracking. No one benefits from hiding information. Reputable brands understand that openness wins returning customers and keeps projects on track. Years working with tricky chemicals have shown me that investing in thorough upfront checks avoids costly surprises. It’s always a smart move to ask suppliers about recent production runs, impurity profiles, and how they verify claims. Third-party validation gives extra peace of mind. If a vendor pushes back on these requests, look elsewhere. Precision, clarity, and communication matter as much as technical quality.

Why Storage Methods Matter

Handling chemicals takes care and respect. If you’ve worked in a lab for any amount of time, you know accidents usually happen less from big disasters and more from small oversights. Stuff like where a bottle ends up, how tightly it’s capped, and whether it sits near a heat source often determines how your day unfolds. 1-Hexyl-3-Vinylimidazolium Hexafluorophosphate—a mouthful to say, and no friend to casual storage practices—demands this sort of attention. Everyone from students to seasoned chemists has stories about what goes wrong if bottles wait too long on the wrong shelf or end up with moisture sneaking inside.

Keep the Enemy in Sight: Moisture

Having spent quite a few mornings drying out reagents and salvaging expensive stock, it’s easy to see that this compound dislikes water. Hexafluorophosphate salts pull water out of the air, which can kick off decomposition into hazardous gases. I’ve seen ruined batches and ruined gloves by not sealing bottles tight enough or forgetting a drying agent. Room air may feel harmless, but it spells trouble for ionic liquids like this. Buying a desiccator or using a glovebox means fewer replacement orders and fewer headaches.

Light and Heat Invite Trouble

Imidazolium-based ionic liquids won’t just wig out from air. Exposure to sunlight and warmth over time eats away at structure and purity—not just some academic concern, but real dollars lost for storeroom budgets. Direct sun by a window can turn something pure into something unpredictable. Plenty of chemists have stories of opening a cabinet to bad smells or strange colors after leaving chemicals too close to a radiator or vent. Keeping bottles in dark cabinets at room temperature makes storage less risky. For higher purity or long-term storage, a cold room avoids issues that come from fluctuating temperatures in a crowded shared lab.

Containment and Spill Control Count

Spills with this compound travel fast. You wipe up the liquid, but you end up with sticky hands and an oily spot that doesn’t wash out. Secondary containment—simple trays lined with absorbent material—gives you more than peace of mind, it means spills stay local and easy to clean. Anyone who’s tried to wipe a spill off shelving knows how chemistry can stick around, floating into the next experiment or onto unsuspecting elbows. Good labels, sealed containers, and quick action on drips and leaks matter most when things get busy.

The Small Print—Health and Safety

People don’t always read safety datasheets, but ignoring toxicity and corrosion risks can end badly. Hexafluorophosphate salts can burn skin or, worse, breathe out toxic fumes if they react with moisture. Using gloves, goggles, and lab coats keeps you out of trouble. More than once, I’ve caught students trying to zip through cleanup without gloves or with lab coats unbuttoned, only to see them dealing with burns or rashes. Chemical fume hoods aren’t just for show—the filter catches what might otherwise fill up your nose or lungs.

Smarter Solutions for Storage

Putting all these habits together takes more than a supply order or a new label printer. Every workplace can set up standard operating procedures and actually enforce them. Regular training goes a long way, since it reminds users that storage isn’t only about following rules, it’s about making sure tomorrow’s work can start without awkward calls to the supplier or health clinic. Keeping clear instructions near storage cabinets and regular checks on stock help avoid forgotten containers or outdated, leaky samples.

Looking Forward

Science doesn’t stop for poor storage practices, but accidents and contamination do set back experiments and morale. Paying attention to where and how chemicals like 1-Hexyl-3-Vinylimidazolium Hexafluorophosphate live means safer labs and better data. Following storage principles isn’t just following the book—it’s what keeps you, your team, and your research moving forward.