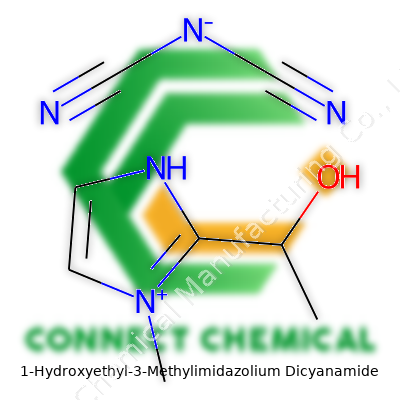

1-Hydroxyethyl-3-Methylimidazolium Dicyanamide: A Commentary

Historical Development

Chemists started exploring ionic liquids as solvents with unique properties several decades ago. The search focused on replacing harsh and volatile chemicals, and over time, a group of imidazolium-based ionic liquids caught wide attention. Researchers needed stable, low-melting compounds that could dissolve a range of substances without the environmental toll linked to old-school organic solvents. Out of this, 1-Hydroxyethyl-3-Methylimidazolium Dicyanamide grew in popularity not just in the academic world, but across labs focused on green chemistry. You’d see it called by code names in early literature, tested for its ability to act as both medium and reactant. With increasing regulatory scrutiny on toxic solvents, a safer alternative mattered more, and this compound fit the bill.

Product Overview

The compound presents itself as a pale liquid, sometimes with a bluish tint. It owes this to the dicyanamide anion, which also gives it distinctive chemical reactivity. The imidazolium cation carries a hydroxyethyl group, setting it apart from more common methylimidazoliums. Lab techs and process engineers appreciate that it flows easily at room temperature and doesn’t evaporate in open air. Packaging usually comes in amber glass or HDPE bottles, marked to indicate both moisture sensitivity and compatibility with most common labware.

Physical & Chemical Properties

1-Hydroxyethyl-3-Methylimidazolium Dicyanamide stands out with a melting point well below zero Celsius. You don’t have to heat it to use it in liquid-state processes. Its density sits near 1 g/cm³, which matches well with many organic solvents, so transferring protocols from classic to ionic-liquid systems doesn’t throw off balances. Solubility shows strong results with both polar and nonpolar organic molecules, and it has a dielectric constant high enough for serious electrochemical work. Viscosity, compared to some classic ionic liquids, doesn’t gum up stirring or mixing. It resists decomposition in both acidic and basic environments within a practical range, extending its shelf life.

Technical Specifications & Labeling

Spec sheets distributed by leading chemical suppliers list purity levels above 98 percent, often with water content less than 0.5 percent by weight. Impurity breakdowns usually include halides, residual solvents, and sodium, and reliable suppliers note batch-specific spectra (usually NMR and IR) for accountability. Regulatory compliance gets its due as labels must follow GHS and REACH frameworks. Each bottle bears a clear, hazard-coded identifier and QR code linking to digital SDS files, reflecting where modern inventory management has headed. This detail helps both in safe handling and in tracing batch history in research or process settings.

Preparation Method

You start by quaternizing 1-methylimidazole with 2-chloroethanol, yielding 1-hydroxyethyl-3-methylimidazolium chloride. This intermediate reacts with sodium dicyanamide, producing an aqueous solution from which the product gets extracted by dichloromethane or another non-reactive organic phase. Removal of volatiles under reduced pressure finalizes the purification, though several groups switch to ion-exchange resins to keep salt content low. Extensive drying in vacuo strips residual solvents and moisture, which, if left, could degrade long-term stability.

Chemical Reactions & Modifications

This ionic liquid has drawn attention mainly in catalysis, organic chemistry, and electrochemical systems. Its structure allows it to function as both medium and reagent because the hydroxyethyl side group can undergo further reactions, such as esterification or ether formation. The dicyanamide constituent reacts with electrophiles, leading to unique polymeric or triazine compounds under suitable conditions. Process chemists have leveraged this dual reactivity to cut down on catalyst or co-solvent waste, aiming for cleaner products and less post-processing. Even in multi-step syntheses, its reusability holds up for several cycles, which fits well into circular chemical production methods.

Synonyms & Product Names

You might see this compound sold as [HEMIM][DCA] by specialty stores or under system names like “1-(2-Hydroxyethyl)-3-methylimidazolium dicyanamide” or “Hydroxyethyl methylimidazolium dicyanamide ionic liquid.” Some catalogs shorten it for ease to HEMIM DCA. Regional labeling sometimes reflects the CAS number, but savvy buyers check structure to avoid confusion with other imidazoliums or unrelated dicyanamide salts. Some patent filings cite it as a key starting liquid in the context of advanced battery electrolytes or enzymatic catalysis, clueing industry insiders into new applications.

Safety & Operational Standards

A big draw of this compound lies in its low vapor pressure and nonflammability, cutting down safety incidents linked to inhalation or fire hazards. Gloves and goggles remain standard due to irritation potential upon skin or eye contact, especially when working with concentrated forms. Local exhaust ventilation keeps airborne droplets in check during large-scale operations. Disposal rules focus on preventing aquatic releases, since dicyanamide groups can disrupt microorganisms if dumped untreated. Spill protocols instruct staff to absorb with inert material and store waste in clearly labeled containers for regulated collection. SDS documentation covers first aid, fire fighting methods (typically CO₂ or dry agents), storage, and compatibility warnings.

Application Area

Industry and labs draw on this ionic liquid for separation science, biomass pretreatment, advanced battery prototypes, synthetic organic reactions, and enzyme-based catalysis. Process engineers champion it in CO₂ absorption, calling out how it captures greenhouse gases under mild conditions. Electrochemists test it as a conductive and stable medium in supercapacitors or rechargeable battery systems, particularly where water or classic organics underperform. Several research groups dissolve cellulosic waste in it, breaking down stubborn feedstocks more easily than with conventional solvents. Newer work includes pharmaceutical extractions and low-temperature polymerizations.

Research & Development

Academic and industrial labs keep running new tests to stretch the capabilities of 1-Hydroxyethyl-3-Methylimidazolium Dicyanamide. Studies focus on enhancing catalysis for fine chemical synthesis, looking into ways to merge reaction and separation steps within the same liquid phase. Multinational companies pour resources into testing for durability and recyclability, especially where regulations push for greener alternatives. A handful of startups boast pilot demonstrations in battery tech and biofuel production, counting on both technical performance and regulatory trends that favor low-carbon processes. Collaboration between chemistry, engineering, and materials science brings out fresh uses, sometimes by tweaking side-group chemistry or anion selection.

Toxicity Research

You find a mix of reassurance and cautious notes in the available toxicity literature. The dicyanamide anion, compared to classic imidazolium pairings with chloride or tetrafluoroborate, generally proves less persistent and bioaccumulative. Acute exposure studies show little impact at low concentrations, but the scientific consensus still urges controlled use, especially near open waterways. Chronic studies remain limited, so ongoing vigilance matters as the compound moves into workplaces and pilot plants. Guidelines suggest avoiding direct skin and oral exposures, and lab-scale waste goes through certified treatment streams to protect both staff and environment.

Future Prospects

Researchers expect continued growth in both the number and scope of applications. Fresh patents signal use cases in medical device coatings, controlled-release agrochemicals, and next-gen energy storage. Policy shifts around solvent emissions and circular manufacturing models amplify demand for safer, recyclable substances, placing this ionic liquid in a strong position. Scale-up work focuses on cutting both cost and ecological impact, especially through greener synthesis routes or co-product valorization. As the scientific community works out long-term performance and environmental impact, more companies can shift from pilot to full-scale operations, bringing greener chemistry from the lab to the market floor.

Tuning Solvents for a Changing World

1-Hydroxyethyl-3-methylimidazolium dicyanamide doesn’t roll off the tongue, but this ionic liquid has become a real workhorse for chemists and engineers. In my time working with chemical researchers, I’ve noticed a big shift: we see less of traditional, flammable solvents and more of these “designer” liquids. This one in particular stands out for its unique mix of low volatility, high thermal stability, and ability to dissolve a range of substances.

Most laboratories chasing after green chemistry use this compound for solvent extraction and separation. I’ve watched people ditch petroleum-based liquids in favor of it, especially in processes that need to limit toxic waste. Oil-removal from wastewater, precious metal recycling, or dye extraction from industrial streams—it shows up all over. There’s a sense of relief when you can recover valuable resources without making the planet pay the bill.

Supporting Industrial Catalysis

In real-world applications, this ionic liquid often plays the role of a reaction medium for catalysts. Transesterification reactions, often used to produce biodiesel, run smoother with its help. It brings out the best in transition metal complexes and enzymes, making these transformations more efficient. I’ve seen biofuel startups cut costs and boost yields simply by switching to this type of solvent.

Some teams in pharmaceuticals use 1-hydroxyethyl-3-methylimidazolium dicyanamide to enable tricky syntheses—ones that stall or fail in other media. This means more efficient drug manufacturing, cleaner products, and less cleanup. Its tune-able properties open the door for continuous processing, a big deal for making medicines faster and safer.

New Roles in Materials and Energy

In battery labs, this ionic liquid finds another home. Lithium-ion battery development has become crucial as electric cars pick up speed on our roads. Safety jumps up a notch once batteries drop flammable organic solvents. This particular compound helps keep things stable at higher temperatures, and researchers have managed to develop devices that avoid dangerous leaks or fires.

Membrane fabrication, including for gas separations or water treatment, gets easier with it, too. Instead of dealing with patchy membranes full of defects, engineers report smoother films that stop the right stuff and let the rest pass. Industries that rely on clean water or pure gasses can thank discoveries coming from this space.

Making Chemistry Friendlier

The real value of 1-hydroxyethyl-3-methylimidazolium dicyanamide emerges in how it chips away at old habits. I grew up hearing about chemical spills and inhalation hazards. These new ionic liquids turn that world on its head. They vaporize less, so there’s little to breathe or spill. Regulations get easier to meet, and byproducts can often be recycled or degraded more cleanly.

Challenges do remain. Large-scale production of the compound must improve, and toxicology tests and lifecycle studies need to keep pace with new uses. Industry groups, academic labs, and regulators all get a say in where this field goes. If more processes shift toward these liquids, we should see less reliance on petrochemicals, healthier workplaces, and a lighter environmental footprint.

Why Properties Matter in Real-World Use

People want to know more than just what a product claims on the label. They want the solid details—how it behaves, how it reacts, and whether it holds up in the environment where they use it. Physical and chemical properties offer these answers. Take density, for example. If you pick up a product that feels heavier than expected, you might hesitate to work with it. Heaviness affects storage, transportation, and even the way a material spreads or pours. Melting point, another common property, influences what happens during summer heatwaves inside a delivery truck or a warehouse. A product that breaks down or loses shape at lower temperatures can cause headaches for everyone involved along the supply chain.

Chemical properties shape trust in the product’s safety and performance. Flammability remains a top concern, especially for people working near open flames or electrical equipment. Nobody wants surprises that could lead to workplace accidents or product recalls. Reactivity follows close behind, especially if products mix during routine maintenance or cleaning. Most chemical reactions that people run into at home or work result from an accidental combination of materials, so honest documentation of how a product reacts with water, oxygen, acids, or other common substances means fewer ugly surprises down the line.

Supporting Claims with Facts

Let’s look at a few facts. PVC piping—common in construction—features a density between 1.3 and 1.45 g/cm³. This property influences the weight calculations for entire plumbing systems and how easily installers can manage it on taller buildings. Chemically, PVC resists most acids and bases, but can degrade under long exposure to sunlight, releasing harmful gases. Silicone bakeware handles temperatures up to 260°C without breaking down. That heat resistance builds trust in the kitchen, especially in professional food preparation where reliability matters most. Stainless steel owes its corrosion resistance to the addition of chromium, making it safe for surgical tools or kitchen knives exposed to moisture every day.

Customers and regulators demand transparent testing before a product enters the market. Reputable brands conduct third-party lab work to confirm melting point, boiling point, pH, and even odor. This builds public trust and gives industries a solid base for safe storage and disposal. The movement for more open data in technical sheets helps industries and consumers alike make better-informed decisions. With clear facts, companies find it easier to comply with environmental and safety laws.

Problems with Unclear Property Information

Many setbacks start with missing or incomplete property lists. A worker using solvent-based paint without knowing about its vapor pressure could risk headaches, fires, or even long-term health issues. Farmers using fertilizers without seeing the solubility values in water may see poor crop growth or pollute nearby rivers unintentionally. Even with “natural” cleaning products, knowing the exact pH can make the difference between something safe for sensitive surfaces and irreparable damage to countertops, appliances, or skin.

Practical Solutions for Better Transparency

Companies that want to earn trust need to put clear, honest property data front and center. That means plain-language technical sheets, safety data with real-world examples, and easy-to-understand infographics about storage and limits. Retailers can offer quick-access QR codes on packaging, leading to detailed online resources that get updated as standards change. Industry professionals and regulatory bodies could work hand in hand to develop common property labels, much like nutritional facts for food, guiding buyers both in-store and online. As demands for safety and reliability grow, transparency in physical and chemical property reporting turns from a regulatory requirement into an ethical responsibility.

New Chemicals, Old Questions

Anyone working in a lab for a few years learns that the latest chemicals always carry a mix of excitement and caution. 1-Hydroxyethyl-3-methylimidazolium dicyanamide, known in some circles as a designer “ionic liquid,” has caught the attention of researchers in everything from battery technologies to green solvents. It looks promising on paper, but just because a chemical helps science move forward doesn’t mean it’s safe for everyday use. As someone who’s handled more labels with hazard symbols than I can count, doubts about toxicity always stick at the front of my mind.

Hazards Lurking under Innovation

This substance, being an ionic liquid, doesn’t evaporate easily. That sounds safer than something you might accidentally inhale, but the story isn’t so simple. Researchers from the University of York published evidence suggesting that dicyanamide-based ionic liquids can break down in water to release cyanide ions. Cyanide blocks cells from using oxygen, making it dangerous even in small amounts. I remember stories from my graduate days, learning that some “green” solvents used in early fuel cell work could turn hazardous after a few weeks exposed to moisture. Safety data sheets warn about toxicity to aquatic life and potential harm if released outside controlled settings. For folks without hazmat suits, even a small spill spells trouble for soil or surface water.

Worker Exposure and Lab Lessons

In lab settings, curiosity meets caution. Gloves and goggles are mandatory, but accidents still happen. Splash a bit on your skin, you face irritation or worse; ingest a little by accident, you’re looking at acute toxicity. It’s not the sort of thing to take lightly, even with modern ventilation and safety showers. The type of risk reminds me of older industrial chemicals—useful, but requiring respect. Families of ionic liquids can differ, but many share stubborn toxicity traits, especially when their breakdown products get into water systems. Long-term exposure isn’t well documented, yet cautious researchers treat these substances as potential carcinogens until proven otherwise.

Environmental Impact: The Unseen Risk

I remember working near a wastewater outlet at an old plant and watching what runoff did to nearby streams. Even years later, the ecosystem struggled. The persistence of dicyanamide compounds in the environment means they don’t break down as easily as, say, salt or ethanol. Fish and aquatic plants suffer even at low concentrations. Data from ecotoxicology studies point out that ionic liquids with dicyanamide groups show moderate to high toxicity to algae, daphnia, and fish. So, while a chemist inside the lab feels safe enough with gloves, wild organisms can’t put on protective gear.

What Can Be Done Better?

Better monitoring helps, but at the end of the day, process changes prevent accidents. Limiting the discharge of these chemicals to waste streams pays off later by protecting rivers and drinking water. Researchers now push for ionic liquids that break down into harmless pieces. Lab managers invest in better training for handling spills, not just relying on the old “wash it down the drain” mentality. Public agencies and journals have begun tightening disclosure rules, demanding a closer look at toxicity before new compounds show up outside controlled settings.

Bottom Line

New materials bring hope for progress, but hope isn’t a substitute for caution. Anyone working with 1-hydroxyethyl-3-methylimidazolium dicyanamide needs to respect the risks—both for themselves and the wider world. The more transparency, the better, both in the lab and outside it.

Practical Storage Tips

Storing chemicals like 1-Hydroxyethyl-3-Methylimidazolium Dicyanamide feels like one of those dull lab tasks, but it keeps everything running safely. This compound doesn’t set off alarms with the general public, but anyone who spends time in a research lab will want to keep it dry and cool. Moisture and heat often lead to surprise reactions, and nobody wants to be that person who sets off the fire alarm or ruins a batch of hard-earned material. Glass bottles with airtight lids usually do the trick. I’ve seen people tuck reagents in plastic containers, but glass always gives that extra security — no leaching, and fewer mystery contaminants at the bottom.

What Actually Goes Wrong?

Put this material in a humid spot and the integrity of the compound starts drifting. Chemical bonds break down faster than you’d think. If you try to save time and leave it on a lab bench, it can start pulling water from the air, which messes with purity. If dicyanamide-based liquids mix with strong acids, you face toxic gas risks. Rogue spills—especially anywhere near organic solvents or acid bottles—can turn a safe lab into a scene no safety officer wants to see.

Personal Safety Counts

Beyond storage, the gear someone uses when handling this stuff makes all the difference. After years around synthetic imidazolium salts, latex gloves and eye protection become second nature. It’s tempting to let your guard down with something that doesn’t smoke or smell strong, but complex organics can irritate skin and eyes on contact. Goggles don’t feel stylish, but they save a trip to the ER. Nitrile gloves work better than basic latex for longer handling, just from a comfort and protection angle.

Labels Save Time—and Nerves

Labels never feel glamorous, but every time someone leaves a beaker or flask on a shelf without naming it, some poor soul has to guess later. Proper labeling, including hazard warnings, expiry dates, and concentrations, keeps the workflow clean and stops accidents before they start. It feels tedious until you’ve actually witnessed a mix-up over an unlabeled bottle. The best labs have clear, big print, and color-coded stickers that no one can ignore.

Disposal—Don’t Take Shortcuts

No one should ever wash this stuff down the drain. Local regulation tends to be strict for good reason. Many universities and companies keep separate organic liquid waste for imidazolium salts or cyanamide derivatives. It’s cleaner and safer to batch up used material for a registered chemical disposal service. I’ve learned the hard way that shortcuts always lead to more headaches—especially once auditors start sniffing around or pipes start clogging. Most labs use logbooks to track disposal, and it brings real peace of mind.

Training Goes Beyond Formal Rules

Many labs run safety briefings, but real safety sticks when teams talk openly about mishaps. People trust each other more when they share stories about what went right—or wrong—at a bench. A culture of openness beats a laminated sign any day. Every person who works with 1-Hydroxyethyl-3-Methylimidazolium Dicyanamide should feel comfortable asking questions, double-checking procedures, or flagging weird smells or unexpected colors.

Reliable storage and smart handling of 1-Hydroxyethyl-3-Methylimidazolium Dicyanamide don’t just protect the chemistry—they protect everyone who walks into a lab.Pursuing the Right Purity

Purity stands as a sort of baseline in any commercial chemical supply. Many buyers don’t realize how much this detail drives everything else, from pricing to safety protocols to performance in a lab or a factory. Based on my experience with suppliers across several sectors, the bulk of industrial and laboratory chemicals arrive at purities ranging from 95% up to 99.9%, depending on the task at hand. Specialty markets—the ones hunting for electronic-grade silicon, biomedical reagents, or high-end pharmaceuticals—regularly push for numbers closer to or above 99.99%.

A decent example would be solvents like ethanol: labs often require 99.8% purity, since trace water can spoil reactions or distort data. In contrast, crude industrial processes get by with lower purities, letting them save money and still get the job done. The issue comes up most sharply in highly regulated environments, such as semiconductor manufacturing, where a single ion of contamination can write off an entire run of wafers worth tens of thousands of dollars. These folks order “five nines” (99.999%) and trust only suppliers with strong provenance, backed by certificates of analysis and batch traceability.

Purity often isn’t just about chemical cleanliness. Heavy metals, particulates, or biological contaminants draw serious concern for buyers in biotech, medical research, and food production. This is one area where experience counts: longtime buyers tend to stick to the same reputable sources after a single bad batch poisons a week’s work or ruins pilot-scale production. I’ve learned over time how a small trace impurity can sneak up and cause massive material loss or even prompt product recalls.

Packaging Sizes That Actually Work

Most folks picture chemicals arriving in drums or bottles, but it’s actually a wide world out there: barrels, bags, vials, cans, super sacks. Typical packaging reflects end-user habits and handling safety as much as the nature of the substance itself. In my time with industrial clients, bulk solids like sodium carbonate or urea showed up in 25 kg bags or 1000 kg big bags. Liquids such as acetone or acetic acid went out in 200-liter drums or, for the bigger players, as much as 20,000-liter tank trucks.

Labs and small-batch manufacturers have a different rhythm. They tend to order in 500 mL, 1-liter, or 5-liter bottles, while researchers needing just a bit for analysis grab 100-gram jars or ampoules. It’s not only about convenience; smaller containers reduce risk, especially for reactive or toxic reagents. Many suppliers also offer tamper-evident seals and inert gas fills to keep air-sensitive goods safe.

Every packaging type brings its own headaches. Poor sealing, weak labels, or nonstandard sizes pile up waste or spark confusion on the floor. I’ve seen entire projects stall because a drum of reagent showed up in an impossible-to-handle tote. It pays to check compatibility up front, especially with hazardous goods, where local regulations can dictate approved container types and labels.

Why Standards and Relationships Matter

No shortcut replaces the value of longstanding relationships with trusted suppliers. Standard purity and packaging solutions won’t always fit niche needs. That’s why close communication with manufacturers and an appetite for reading technical documentation mean the difference between steady supply and costly downtime. Some companies solve repeat packaging headaches by negotiating custom container sizes or agreeing on shipment calendars that line up with downstream processes.

Regulatory compliance shapes choices, too. Certification under ISO, GMP, or REACH helps buyers avoid surprises and keeps shipments flowing across borders. Suppliers who offer detailed batch records or participate in third-party audits stand out in a crowded market. Out in the field, a little extra legwork up front saves pain down the line. Trust and track records guide most companies far more than glossy marketing brochures ever will.