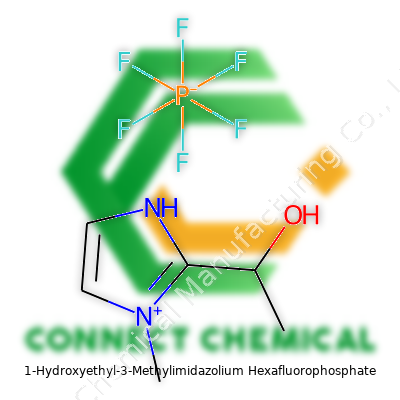

1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate: An In-Depth Commentary

Historical Development

Chemical discoveries leave an undeniable impact on industry, but not all get the recognition they deserve outside of scientific circles. 1-Hydroxyethyl-3-methylimidazolium hexafluorophosphate, often abbreviated as [HEMIM][PF6], started as part of the drive to find more stable, less hazardous alternatives to classic organic solvents. The imidazolium family gained attention thanks to their versatility, bench-stability, and relative environmental friendliness. Early research at the turn of the century revealed these "ionic liquids" could play a big role where water or volatile organic compounds caused problems, especially in sensitive chemical syntheses and green chemistry initiatives. It didn’t take long for the focus to turn specifically to [HEMIM][PF6], because its unique molecular structure solved problems that hindered other ionic liquids, especially in the realm of solubility and electrochemical stability.

Product Overview

People in chemistry labs turn to 1-hydroxyethyl-3-methylimidazolium hexafluorophosphate when traditional solvents complicate the process or pose health hazards. Packaged as a viscous, clear to pale-yellow liquid, this compound offers a low-melting alternative that handles a surprising range of applications. Its non-flammability takes some worries off the table and its high ionic conductivity opens the door to many electrochemical uses. Often you see it as “HEMIM PF6” or simply “ionic liquid PF6” on labels and in catalogs, so knowing these names helps with identifying the right product when comparing suppliers. Confidence in what you’re getting is as important as price or volume.

Physical & Chemical Properties

1-hydroxyethyl-3-methylimidazolium hexafluorophosphate earns its spot in labs for good reason. It typically appears as a colorless or slightly yellow, viscous liquid under room temperature. It refuses to evaporate the way classic solvents do, which cuts down on workplace exposure. With a melting point well below 100°C, high thermal stability up to about 200°C, and strong resistance to oxidation and reduction, it stands up to processes that would break down less robust materials. Water solubility depends on purity and preparation method, but generally it pairs with polar organic solvents more willingly than water. That balance of moisture tolerance and stability creates a lot of flexibility in chemical design and process engineering.

Technical Specifications & Labeling

Suppliers list [HEMIM][PF6] at purities upwards of 98%, but even small impurities can affect performance in sensitive syntheses. Purchase documentation and safety data sheets spell out CAS numbers, batch purity, and recommended storage conditions, since these factors play a key role in consistent results. Labels must follow regulatory requirements, showing signal words and hazard pictograms tied to its hexafluorophosphate group. These details, standardized by GHS and regional regulations, matter even for experienced chemists; it’s too easy to overlook ion-exchange risk or hydrolysis under lab humidity, which can lead to stubborn cleanup problems and contamination of valuable reactions.

Preparation Method

Chemists prepare 1-hydroxyethyl-3-methylimidazolium hexafluorophosphate through alkylation of N-methylimidazole with 2-chloroethanol. The resulting chloride salt undergoes anion exchange with potassium hexafluorophosphate, often in a two-phase system to keep inorganic byproducts out of the final product. Careful washing and drying steps follow, with vacuum treatment to remove trace water. Each step demands close attention to purity ― leftover ions or incorrectly dried intermediates can have outsized effects on ionic conductivity and final product yield. Green chemistry approaches now avoid heavy-metal catalysts, aiming to reduce both cost and downstream environmental impact.

Chemical Reactions & Modifications

Many see the biggest advantage of HEMIM PF6 in its flexibility for modification. Imidazolium-based ionic liquids accept tweaks to their alkyl or hydroxy groups, letting chemists tune solubility or viscosity for tailored performance. The hydroxyethyl arm supports hydrogen bonding, which affects how it solvates metal ions or organic substrates in catalytic reactions. Under controlled conditions, the compound resists decomposition by most strong acids or bases. Reactivity with nucleophiles and its ability to dissolve or stabilize certain organometallic complexes has inspired whole new branches of catalysis, especially in fields where water or standard organic solvents break down sensitive reactants.

Synonyms & Product Names

Reputable suppliers list this compound as 1-hydroxyethyl-3-methylimidazolium hexafluorophosphate, HEMIM PF6, and sometimes as [HEMIM][PF6] or 1-(2-hydroxyethyl)-3-methylimidazolium hexafluorophosphate. Knowledge of these synonyms and corresponding registry numbers helps avoid misorders and confusing paperwork, which anyone experienced in procurement knows can throw off a lab’s schedule.

Safety & Operational Standards

No one should underestimate the safety concerns with hexafluorophosphate salts. [HEMIM][PF6] does not ignite easily, but it can generate corrosive hydrofluoric acid if it reacts with water or undergoes thermal decomposition. Safe handling relies on proper PPE ― gloves, goggles, and a chemical-resistant apron as spill control. Good ventilation and storage away from acids, bases, and heat sources keep risks firmly in hand. In the event of spills, immediate cleanup with fluoride-specific adsorbents prevents lingering hazards. Safety data sheets from reputable vendors consistently update the recommended practices, but it pays to keep an eye on new regulatory findings related to ionic liquids.

Application Area

People look to this ionic liquid for its impressive performance in electrochemistry, synthesis, and materials science. Its strong thermal and electrochemical stability make it a natural fit in batteries and capacitors. Researchers developing next-generation lithium-ion or sodium-ion models often experiment with HEMIM PF6 to push ionic conductivity and safety higher than possible with traditional organic electrolytes. It plays a pivotal role in catalysis, especially for transition-metal complexes, sometimes making the difference in reaction selectivity or conversion yield. The world of cellulose processing, nanomaterial fabrication, and pharmaceuticals all benefit when protic ionic liquids like this step in where others fail.

Research & Development

Academic labs and industrial consortia treat ionic liquids both as solvents and as building blocks for even more complex “designer” molecules. R&D programs investigate improved synthesis routes for HEMIM PF6, hunt for greener anion exchange methods, and analyze degradation products to tighten safety standards. Material scientists measure how blending with other ionic liquids or tuning the hydroxyalkyl arm affects both chemical reactivity and lifespan in real-world applications. More recently, interest shifted to recycling and regeneration techniques to minimize waste after industrial or laboratory use, since both cost and environmental concerns drive sustainable chemistry forward. Most notably, these efforts often spill over into altogether new avenues—such as using HEMIM PF6 in drug delivery or as a matrix for advanced analytical devices.

Toxicity Research

You will sometimes hear “ionic liquids are green solvents,” but the reality requires a nuanced assessment. Toxicity tests show variable results depending on exact structure. For HEMIM PF6, studies indicate low acute toxicity toward rodents and aquatic species at concentrations typically used in the lab, but hydrolysis yields hexafluorophosphate, which carries much heavier long-term risks. Chronic exposure to PF6- anions raises legitimate concerns about persistence and bioaccumulation, especially if released to water systems. These findings highlight the need for robust spill response and waste management protocols rather than assuming that “low volatility” means “harmless.” Regulatory trends suggest closer scrutiny in upcoming years, especially as production volumes climb with broader industrial uptake.

Future Prospects

Even with increasing regulation, it’s hard to overstate how valuable a compound like 1-hydroxyethyl-3-methylimidazolium hexafluorophosphate remains. Manufacturers and researchers see plenty of growth potential in next-generation batteries, smart materials, and pharmaceutical synthesis. More advanced recycling and regeneration processes could extend its reach into areas once left aside due to cost or environmental concerns. Pushing boundaries with new anion or cation structures will keep ionic liquids like this in the spotlight, as chemists search for the right blend of thermal stability, conductivity, and toxicity balance. Partnerships across universities, manufacturers, and regulatory agencies will likely set the pace, ensuring continued innovation without letting safety or ecological responsibility slide into the background.

Beyond a Complex Name: What This Chemical Actually Does

The mouthful that is 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate often draws little attention outside academic circles. Yet, for chemists and engineers, this ionic liquid plays a crucial role every day. Its unique set of properties—non-volatile, thermally stable, and able to dissolve a wide range of materials—makes it a standout tool in fields that push chemistry to new limits.

Chemical Research Relies on Real Innovation

I’ve seen research labs struggle to find solvents that don’t evaporate or catch fire easily. Traditional organic solvents dry out or pose safety hazards, blocking progress in green chemistry and advanced material science. Here, 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate steps in. With its resistance to air and heat, scientists use it to develop clean synthesis methods and extract natural compounds from plants safely. Journal articles in Chemical Reviews and Green Chemistry have highlighted its role in moving beyond toxic, old-school solvents.

Batteries Get a Jolt From Ionic Liquids

Rechargeable batteries—especially lithium-ion models—demand electrolytes that won’t burst into flames or degrade too fast. Many of us remember hovering over a phone or laptop that felt too warm. By swapping in ionic liquids like this one, battery manufacturers reduce the risk of explosions and boost safety. A few studies from Advanced Energy Materials have shown how electrolytes using this compound extend the life of batteries and perform better under stress.

Sustainable Industry Needs New Solvents

Lots of industries still lean on chemicals that harm workers and the environment. 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate offers a way out—at least in some processes. Its structure helps dissolve metals, plastics, and even cellulose from renewable biomass, making recycling and biofuel production far easier. The ability to separate tough-to-handle compounds in one pot changes how factories think about waste. For example, the European Union has invested in projects using ionic liquids to recycle rare earth metals from discarded smartphones.

Challenges That Demand Attention

No chemical should be hailed as the magic bullet. People remain concerned about the environmental footprint of even the most promising solvents. The hexafluorophosphate part, in particular, raises flags: fluorinated chemicals might linger in soil and water. I’m no stranger to these debates, having listened to both industry scientists and activists warn about “forever chemicals” at conferences. No sustainable chemistry path feels complete without tough, unbiased testing and industry oversight to weed out hidden risks.

Practical Steps Toward Responsible Use

Regulators need thorough risk profiles before rolling out any new solvent across industry. Open data, transparent trials and strong collaboration between scientists, manufacturers, and watchdog groups provide the backbone for trustworthy chemical innovation. For anyone working in a lab or production line, training matters just as much as the tech itself. A chemical like 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate brings genuine improvements, but only if used with care, accountability, and a clear eye on future consequences.

Understanding the Risks

1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate grabs attention in labs for its use as an ionic liquid. My first brush with working around ionic liquids started in graduate school. The buzz around these materials centered on replacing traditional volatile solvents. They promise lower vapor pressure and, in theory, less air contamination. But the flip side is easy to overlook: safety risks hang around, sometimes in trickier ways than chloroform or acetone.

Most folks expect a chemical that smells sharp or evaporates quickly to pose more harm. Not with this stuff. It's easy to drop your guard around “stable” liquids, but hexafluorophosphate-based compounds bring their own dangers. Getting careless around the bench led one labmate to discover this: hydrolysis releases hydrofluoric acid, and that gets serious fast. A tiny HF exposure can cause deep tissue damage, bone problems, or worse. You won't always feel it initially, which sometimes fools people until the damage grows.

Realistic Safety Measures

Lab coats offer a little defense, but nitrile gloves resist this liquid far better. Splash goggles go on every time. I've worked next to researchers who lost partial vision because diluted acids splattered once and they thought their regular glasses gave enough coverage. Fume hoods play a major role with this class of chemicals; splashes and vapor build-up rarely get noticed in open air. Even if the vapor pressure seems low, any material containing the hexafluorophosphate anion can build up dangerous gases if you let moisture hang around.

My own routine includes checking that the hood’s airflow works before each session, not after. I saw early mistakes where folks used up their supply of chemical-resistant gloves mid-task and switched to standard latex—frustration followed when they noticed the gloves swelling or breaking down. Cotton does nothing for protection, and a spill soaks through in seconds. Doing a dry run without the liquid, setting up every tool beforehand, keeps hands from fumbling later and reduces dumb, rushed movements.

Disposal and Emergency Practice

Working in a busy teaching lab showed me what happens when people treat cleanup as an afterthought. Residue on a benchtop or glassware dries out, someone wipes it up with a generic paper towel, and that gets tossed in ordinary trash. Not long after, the waste bag started breaking down thanks to moisture, and inside that was a mild hydrofluoric sting on a technician’s fingers. Special hazardous waste bins solve this, with clear labeling and a secure lid.

I learned never to pour leftover liquid down a drain, no matter what someone online claims about water solubility. Laboratory waste services in most universities pick up halogenated liquids in separate containers. Forgetting to segregate this from other acetone or isopropanol waste usually brings an annoyed email from the safety officer and a longer training session.

One positive practice: emergency eyewash and shower stations nearby. During drills, we practiced blindfolded to simulate chemical splash emergencies. A real accident once forced someone to rinse a gloved hand for fifteen solid minutes. That long soak helped; HF exposure demands calcium gluconate gel too, and labs keep it stocked in visible, reachable spots. Quick access to first aid cuts risk but doesn’t take away the value of self-discipline and double-checking everything you touch or wear.

Building Safer Habits

Taking chemicals like 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate seriously means more than just reading the SDS. Everyone working with it benefits from knowing how the real hazards play out in everyday lab work. Nitrile gloves, face protection, working in ventilated areas, and keeping aid supplies within reach stand as simple yet strong shields. No shortcut replaces planning your moves and staying alert, especially since accidents rarely give second chances.

Looking Beyond Labels: Understanding What Chemicals Really Demand

I’ve seen enough lab incidents to know how ignoring storage conditions brings trouble to your doorstep. Shelving a volatile solvent near a sunny window might seem harmless—until you witness a bottle crack from pressure build-up or a slow leak lead to a costly cleanup. The conditions we give these substances aren’t just about keeping up appearances or satisfying paperwork. The hazards are real, and responsible storage forms the backbone of chemical safety.

Temperature Swings: A Real-World Risk

Fluctuating temps can turn certain chemicals into ticking time bombs. Hydroperoxides, for example, love to decompose if the mercury climbs, and you never want to see vapor pressure spike in a sealed drum. In my early days, the thermometer in a storage room hit 30°C one summer weekend—and that simple oversight cost us an entire case of spoiled reagents. Most chemicals last longer and stay stable when kept cool and shielded from sunlight. If you’ve got a fridge or temperature-controlled area, reserve it for your most sensitive stock.

Humidity and Moisture: The Silent Enemy

Moisture sneaks in and causes more trouble than most newcomers realize. Water-reactive substances don’t just fizzle; they can explode or give off toxic fumes. Even hygroscopic powders draw in enough dampness to clump or degrade, leaving you with useless material. Well-sealed containers, silica gel packs, and well-maintained dehumidifiers best serve chemicals that can’t tolerate humidity. If you leave them exposed, you gamble with both safety and the reliability of your results.

Keeping Hazards Apart: Segregation Saves Lives

You wouldn’t want bleach anywhere near acids. A friend once mixed incompatible leftovers in a storage closet, thinking the small volumes wouldn’t matter. A week later, the sharp stench hinted at a reaction that could have gone far worse. Oxidizers and organics, acids and bases—all ought to live on different shelves or, better yet, in separate cabinets. Most chemical suppliers include clear guidance on compatibility. It pays to read up or risk learning the hard way.

Labeling and Documentation: Accountability in Action

Labels fade or fall off, but strict records clear up confusion when something looks suspicious or starts to degrade. Every bottle should display its contents, hazards, date received, and—this matters—the storage requirement straight from the supplier’s sheet. I’ve learn that strangers walking into a well-labeled storage area need little training to avoid disaster.

Regular Checkups: Maintenance Isn’t Just for Equipment

Expired chemicals don’t ask for permission to become unstable. Regular checks keep surprises to a minimum. Slow leaks, bulging containers, evaporated solvents—all point to storage conditions falling short. In my experience, monthly walk-throughs catch warning signs before they spiral out of control.

Better Storage, Better Outcomes

Safe, controlled environments protect health, research, and investment. National agencies like OSHA and the EPA underline the importance of proper storage because every year, communities pay the price when someone gets careless. If budget or space runs tight, prioritize the most dangerous materials for the best storage. Smart storage habits prevent injuries, keep projects on track, and show respect for the environment and fellow workers. Building a culture that takes chemical storage seriously pays off every single day.

What Happens When Science Meets Everyday Life

Standing at the edge where chemistry touches daily living always leads to an interesting puzzle, especially with ionic liquids like 1-hydroxyethyl-3-methylimidazolium hexafluorophosphate. On paper, it packs an impressive name and a curious set of properties. In classrooms and laboratories, people often wonder what’s so special about these imidazolium-based salts, and more specifically, whether one can mix them with water and expect them to dissolve.

Does It Blend? Testing the Waters

After a few tries in the lab, watching this salt interact with water teaches an important lesson about chemical intuition and real-world observation. Many ionic liquids hold the label "designer solvent" because they open doors in green chemistry and materials science. Yet, their behavior in water doesn’t always follow what you’d expect just from looking at their structure.

From both workbench experience and a scan through published chemical databases, 1-hydroxyethyl-3-methylimidazolium hexafluorophosphate usually resists dissolving in water. The hexafluorophosphate anion tends to stay away from polar environments since its fluorine atoms pull electrons tightly and create a shell that water molecules don’t easily penetrate. This stands out since the hydroxyethyl group on the imidazolium ring loves water, but the anion overrules it, blocking the way for effective mixing.

Why Solubility Matters

Solubility shapes so much more than textbooks claim. It drives separation processes, impacts waste treatment, and shapes how manufacturers pick chemicals for specific reactions. In real lab work, running into an insoluble salt can mean lost time and extra steps—pumps clogged, beakers full of separated layers, and some very real frustration for anyone who expected a smooth blend.

Researchers wishing to use this ionic liquid as a catalyst or reaction medium in water-based systems have to pivot quickly. I remember the scramble in the research group when we hit this wall. Instead of swapping solvents every week, the team explored making small shifts to the structure—changing the anion, or opting for a different imidazolium modification. Suddenly, swapping out the hexafluorophosphate for a chloride or acetate turned water from enemy to best friend. It’s a lesson in tweaking, not forcing, molecular relationships.

Looking Toward Smarter Design

This challenge underlines why researchers push for "task-specific ionic liquids." Instead of relying on trial and error, chemists now use computer models and iterative synthesis to predict how these advanced salts react with everything from water to proteins. Some teams at national labs have shared data showing that tweaking the alkyl group or introducing other polar moieties into the molecule can flip solubility almost overnight. This focus on design has become a key step for safer, more efficient industrial and green chemistry.

It goes to show: digging into solubility isn’t some dry technical hurdle. It connects practical lab work, environmental goals, and tough chemical engineering. Getting it right involves community trust, transparency about materials, and robust research. There’s no shortcut, just the steady, collective work of science—one complex salt at a time.

Understanding Purity in Ionic Liquids

A bottle of 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate usually features a purity specification of 99% or higher. In a lab, especially one that handles anything from green chemistry experiments to materials science work, this level of purity is essential. Any lower, and you start seeing unreliable NMR spectra or side reactions cropping up. You might think a percentage point or two shouldn’t matter — but in chemistry, the smallest impurities can trigger larger problems.

Why Purity Sets the Tone for Chemical Reliability

I’ve sat around a lab table with colleagues who’ve lost days because a batch of ionic liquid contained 97% active compound and 3% mystery. If there’s an extra half-gram of by-product in a project focused on battery electrolytes, the results can be misleading or even useless. High purity matters when researchers want to count on everything they put into a test tube. From catalysis to solvent development, each percent up in purity means fewer contaminants, better repeatability, and safer scaling.

Relevant Facts on Manufacturing & Quality Control

Most manufacturers run the raw 1-Hydroxyethyl-3-Methylimidazolium Hexafluorophosphate through several purification cycles. This Châlons-en-Champagne-style thoroughness comes from strict controls: high-performance liquid chromatography for organics, ion chromatography for PF6- content, and Karl Fischer titration for water. The short answer: expect a moisture content below 0.5%, halide content less than 50 ppm, and organic residue barely registering.

Risks Posed by Lower Purity Grades

I’ve watched new grad students buy cheaper 95% grades and then spend five times as long cleaning up their experiments. The main impurity, often water, can hydrolyze hexafluorophosphate to give up hydrofluoric acid — nobody wants that eating through their glassware or lab gloves. Trace acids corrode contacts in electrochemical cells. Even faint organic contaminants mess with strong-field NMR interpretation or mask key IR peaks. If a product consistently fails to reach the 99% mark, customers invest more in troubleshooting than real research.

Why Producers Must Communicate Specifications Clearly

Strong producers send a certificate of analysis with every batch. This doesn’t just list a purity figure, it breaks down what test validated the content: NMR spectrum, measurement of conductivity, report on trace metals. Trust builds when suppliers keep traceability open and data easy to read. I always ask to see a complete assay report before switching source for such a key chemical.

True Solutions: Better Testing and Third-Party Audits

Lab managers and purchasing teams should ask suppliers about every test method they use and whether any lot comes with a third-party review. It’s worth investing in products from sources holding ISO accreditation or who allow customer-initiated batch tests. Low-cost overseas sources attract by price, but good paperwork separates a smooth project from weeks of after-the-fact troubleshooting.

Helping the Research Community Move Forward

A purity higher than 99% brings peace of mind that research data reflects what is supposed to happen, not what accidental contaminants cause. Reliable, transparent specifications free scientists from debugging supply chain issues and let them focus on discovery, whether applying ionic liquids to battery, pharmaceutical, or green chemistry development.