Commentary on 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride: Progress, Potential, and Cautions

Historical Development

Chemists first approached the synthesis of 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride with a growing interest in ionic liquids and imidazolium-based compounds. The late 1990s and early 2000s saw explosive growth in the study of functionalized imidazolium salts, steering research toward greener solvents and alternative chemical processes. Laboratories around the world experimented with modifications to traditional imidazolium frameworks, aiming for new reactivity and stability profiles. Reactivity studies soon pushed the limits on what these compounds could do, especially with the carbonyl functional group sitting in the side chain. The progress mirrored broader curiosity around sustainable solvent systems and the unique properties of charged organic species, setting the stage for a rich field of follow-up research.

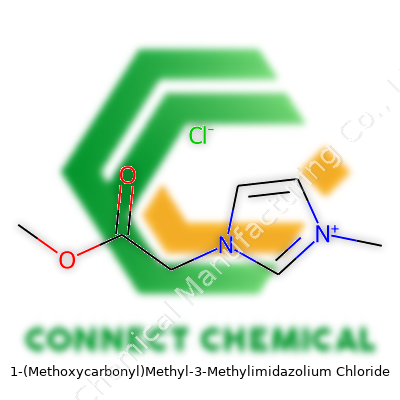

Product Overview

1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride belongs to the category of functionalized imidazolium salts, most commonly described as a hybrid between a room-temperature ionic liquid and an organocatalyst precursor. Synthetic chemists reach for this compound to push forward protocols in ionic-liquid catalysis, carbon-capture projects, and phase-transfer reactions. Its methoxycarbonyl group quietly expands its reactivity list compared to basic imidazolium chlorides. Many brands distribute it in tightly sealed bottles, favoring a moisture-free environment to avoid hydrolysis concerns. Chemical suppliers often underline its high purity, since trace fouling can complicate its intended use in sophisticated organic synthesis.

Physical & Chemical Properties

On the bench, this salt greets users as a white or slightly off-white crystalline solid. It dissolves well in polar solvents, including acetonitrile and water, which opens routes for homogenous catalytic tests. With the melting point typically landing between 150 and 160°C, chemists benefit from easy preparation of ionic solutions at moderately elevated temperatures without needing reflux. Its density measures close to 1.2 g/cm³, but more notable is the hygroscopic nature, demanding care to prevent caking or gradual decomposition. The compound radiates the chemical signature of an imidazolium core, ringed by functional groups that keep it stable at room temperature yet open to further modification.

Technical Specifications & Labeling

Manufacturers provide this compound under IUPAC-compliant names, issuing COA documentation with stated purity—usually upwards of 98%. Labels typically list CAS number, molecular formula (C8H13ClN2O2), and a clear batch identification. Packaging materials often show hazard symbols to underline irritant potential and urge the use of gloves and goggles in direct handling. Material safety data sheets consistently point to decomposition at higher temperatures with formation of potentially hazardous gases, putting extra stress on controlled conditions during waste disposal.

Preparation Method

I prepared this compound once in a research lab. The route builds from methylimidazole, which reacts with bromoacetate or methyl chloroacetate. Chemists exploit the reactivity of these haloesters for direct alkylation, introducing the methoxycarbonyl group to the methylimidazole ring under moderate heat. The resulting salt typically forms a viscous intermediate, eventually crystallized by antisolvent addition and dried under vacuum. If scaled to larger volumes, careful temperature control and dry-atmosphere protocols reduce impurity buildup. Analytical controls, such as NMR and mass spectrometry, confirm the structure before use in targeted reactions.

Chemical Reactions & Modifications

The standout feature rests in the methoxycarbonylmethyl group, which invites nucleophilic attack under mild to moderate conditions. Organometallic researchers have built on this site to create metal-ligand complexes, extending the reach of this “designer” imidazolium in the catalysis world. Modifying the substituents hanging from the imidazole ring, especially electron-donating or -withdrawing groups, changes the electron density and reactivity in noticeable ways. For those working in green chemistry, swapping the chloride anion to less-coordinating counterions can further tweak solubility, melting point, and interfacial tension, all without significant loss of performance.

Synonyms & Product Names

In supplier catalogs, this compound shows up under several names, including 1-Methoxycarbonylmethyl-3-methylimidazolium chloride and MCCMIM-Cl. Some research papers abbreviate even further, making reading the literature sometimes confusing; cross-checking with structure diagrams or CAS registry remains a practical step. Brand-name products rarely deviate in formulation, but smaller chemical suppliers often reference local inventory numbers for lab tracking rather than standardized language.

Safety & Operational Standards

Anyone handling ionic liquids with functional groups learns quickly that gloves and eye protection go from recommendation to requirement. I watched a colleague experience mild skin irritation after small amounts made contact during weighing, which matched the hazard warnings provided. Chloride salts, in particular, tend to have low volatility but can still irritate the airways if powders become airborne during transfer. It pays to use closed systems and proper ventilation, especially if working at elevated temperatures or in the presence of strong bases or acids. All waste enters halogenated organic waste streams for incineration rather than drain disposal, following both university and local environmental policies.

Application Area

Chemists prize these ionic liquids in catalysis, electrochemistry, and material science projects. I saw a team apply it as a supporting electrolyte in electrochemical cell assemblies, reporting strong conductivity and consistent electrode performance. The methoxycarbonylmethyl group lets researchers expand into biotransformations since it interacts with nucleophilic biological residues under controlled conditions. Some colleagues tested its merits for green solvent systems, exploiting its low vapor pressure and thermal stability, especially in microwave-assisted organic synthesis. Process chemists keep their eyes on these compounds as potential alternatives to classic chlorinated solvents because they limit emissions and enable new reaction designs.

Research & Development

Lab notebooks fill quickly with new tests using modified imidazolium salts. One thrust in research targets carbon dioxide fixation, with these functionalized ionic liquids acting as both solvent and activator for CO₂. Other groups focus on polymer electrolyte development, seeking options with high thermal stability and ionic conductivity as battery and fuel cell materials evolve. Another forward-looking area centers on enzymatic compatibility, trying to bridge the gap between organic and biochemical transformations. Patent filings related to these compounds continue to climb, which shows both the commercial interest and the still-untapped possibilities for further functionalization and application.

Toxicity Research

The toxicology of imidazolium-based salts sparks serious discussion in green chemistry circles. Early claims about eco-friendly credentials fall flat unless researchers take time to measure and report acute aquatic toxicity and persistence in soil. Initial studies link some imidazolium salts to moderate toxicity in algae and fish, though structure greatly influences the results. The methoxycarbonyl group may change bioaccumulation risk, so research actively compares breakdown rates under aerobic and anaerobic conditions. Acute exposure stays low in controlled lab settings, but accidental disposal into waterways triggers stricter handling. Research teams call for clear reporting of toxicity outcomes, not only to satisfy regulatory agencies but also to frame responsible development and commercialization strategies.

Future Prospects

Growth in sustainable chemistry demands new solvents that work efficiently while minimizing waste and hazards. 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride brings a versatile profile to the table, with its reactivity and physical stability opening footholds in advanced material design, catalyst recovery, and green synthesis pathways. Challenges remain with toxicity, cost, and lifecycle analysis, but its story looks far from over. If next-generation ionic liquids can combine tunable properties with lower ecological risk and better biodegradation, then what starts in the laboratory may soon drive real change in industry and academia alike.

Invisible Workhorse in Green Chemistry

Ask most chemists about ionic liquids, and you’ll hear about their ability to replace traditional solvents. 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium chloride fits well into this story. In my time working with organic transformations, the need for safer, less volatile solvents always comes up. Traditional options like acetonitrile or dichloromethane fill plenty of shelves, but stricter safety rules knock them down a peg. That’s where compounds like this one find their place—cleaner, more manageable, and far less toxic to work with.

A Solvent’s Job: Behind the Scenes

Solvents shape the pace and direction of chemical reactions. Using 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium chloride, researchers get more than just a vessel; they tap into its unique properties as an ionic liquid. It stands stable under a range of temperatures, doesn’t evaporate quickly, and resists breaking down under heat. In the lab, I’ve seen it open new doors for reactions that either fail outright or drag on too long with regular solvents. The controlled reaction speeds matter in industrial production, where every minute counts.

Cleaner by Design

Lab work comes with responsibility for its mess. Many common solvents end up as hazardous waste, drawing complaints for both cost and environmental damage. This chloride-based ionic liquid skips some of these headaches. It boasts low volatility, limiting toxic fumes. I’ve noticed the impact firsthand—less time in fumes hoods, fewer headaches at the end of the day, and lower costs to manage solvent disposal. In publishing research, journals increasingly prefer methods that skip harsh solvents; regulations inch toward rewarding this.

Catalyst and Reaction Tuner

Beyond acting as a solvent, this compound sometimes steps in as a catalyst. Certain organic reactions—cross-coupling, alkylations—get a helpful boost. In practice, that can mean bigger yields or less energy needed for the same result. I’ve worked on projects where tweaking salt-based reaction components made old pathways finally work. Even small improvements at the lab scale can snowball once a process moves into commercial production.

Room For Growth

Like any lab tool, this chloride compound isn’t perfect. Price tags run high, and sometimes purification turns into a hassle. Researchers run into challenges scaling up but keep pushing because the upside pulls hard. Stronger industry adoption will depend on both better supply chains and continued proof that these ionic liquids make a difference in real-world settings.

Future Steps in Safer Chemistry

Putting safer solvents such as 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium chloride into more labs won’t solve every issue, but small shifts make big waves. Pushing for greener chemistry can start with these swaps. Investment in better waste handling and improved synthesis routes makes these options more approachable for smaller research teams. It’s worth keeping an eye on the new generation of solvents for both the sake of efficiency and the health of the people handling them every day.

Why Smart Storage Makes a Difference

1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride doesn’t always sound like a substance to take lightly—any chemical built for research or lab work calls for respect. Keeping it in good shape usually traces back to three things: temperature, moisture, and light. The chemical community doesn’t thrive on guessing games, so clarity matters.

Temperature Isn’t Just a Recommendation

Heat speeds up reactions and can scramble the expected traits of a compound like this. At room temperature, microbial growth stays limited, crystals don’t merge, and decomposition risks stay low. My own time in basic chemistry labs drove home the lesson fast—leave heat control out of the equation, and shelf lives shrink. Chemistry researchers and manufacturers tend to park this type of chloride at 2–8°C. Cool conditions shield against slow breakdown, avoid color changes, and fend off contamination.

Moisture: The Silent Spoiler

With hygroscopic salts like this, pulling water from the air comes easy. Even trace humidity leads to clumps or crystal shifts. Sealed containers offer the best bet for dryness. In practice, vacuum-sealed bags, thick glass vials, or polymer containers with tight lids win out. Desiccators—dry boxes with moisture-absorbing packets—create a backstop against water sneaking in. One wrong step with exposure, and purity questions pop up right away.

Light Sensitivity and Degradation

Plenty of organic salts grow unstable when exposed to strong light over time. Yellowing and loss of effectiveness come next. Opaque or amber-colored containers do most of the heavy lifting here. Light-blocking cabinets finish the job. Even if the literature doesn’t highlight the risk for this chloride specifically, the risk never falls to zero, especially where the stakes revolve around reproducibility or pharmaceuticals.

Safer Storage Pays Off

Lab safety officers don’t make rules just to fill time—their playbooks often focus on limiting accidents to zero. Storing this chloride secure and labeled makes retrieval safer. Gloves and eye protection aren’t a luxury. Lids and seals should get checked before and after every use.

Supply Chain and Contamination Risks

Most chemical mishaps never make headlines. Chemical supply companies and university stockrooms who set and follow strict storage routines see fewer ruined samples. Open bottles get relabeled with date and initials. Compounds stored near strong acids or organics run the risk of cross-contamination. Labs that really care keep log books by the shelves.

Solutions and Practices That Stick

Cold storage units with automatic humidity controls cut risks fast. Color-coded bins help staff never mix up two similar bottles in low light. Silica gel packs dry out containers before storage—no mystery there. Even teaching undergraduates proper storage teaches good habits for the rest of their careers.

No One Succeeds Alone

Trust builds from transparent storage routines. Regulatory guidelines from the likes of OSHA and ISO roll in clear expectations. Proper training and checklists stand out as a real-world fix many forget. Not every step requires a budget blowout, but sloppiness usually leads to wasted chemicals and lost time. In the end, the right storage protects more than just inventory—it shields reputations and results, too.

What Are We Talking About?

1-(Methoxycarbonyl)methyl-3-methylimidazolium chloride sounds like something you’d only find in a research lab. It pops up in academic papers and niche chemical catalogs, usually listed as an ionic liquid. The thing about ionic liquids—especially those from the imidazolium family—is they have built a reputation for being less volatile than many classic solvents people used to reach for in organic chemistry. That lower volatility gets a lot of applause, mostly because you lose less to the air and breathe less in. But volatility isn’t the only thing worth watching.

Digging Into Toxicity and Hazards

Now, some people argue that just because a compound doesn’t go airborne easily, it’s automatically safer. I’ve run experiments in busy teaching labs, and nobody wants to be around the old-school solvents that evaporate before you can recap the bottle. Still, toxicity goes beyond just breathing fumes. Studies of imidazolium-based compounds keep turning up evidence they can irritate skin and eyes. I read case notes from researchers who, after splashing similar liquids, needed a rinse and trip to campus health. It’s not just contact risk, either; many ionic liquids, this one included, bring concerns about chronic effects and environmental persistence.

Digging through safety data sheets, you won’t always find detailed human toxicity numbers. That’s a problem with rare research chemicals—their risks get less attention because they’re not sold by the truckload. For this specific chloride, animal studies have pointed to moderate aquatic toxicity. Even if the toxic dose in people sits higher than in classic solvents, the fact remains: their breakdown in nature drags out for years. Leaving a couple of drops down the sink can damage water systems long after the experiment wraps up.

What Makes This Important?

People tend to cut corners once a chemical gets labeled “green” or “safer.” In reality, a “safer” label sometimes just means a different kind of risk. Imidazolium liquids resist burning, which sounds great, but many have toxicity profiles matching or outpacing standard organic solvents if you get enough on you, or if the dose stacks up over time in waste. Regulators still classify many of these ionic liquids as irritants, and several regions restrict their use in commercial products until more is understood. In the world of chemistry, it takes a lot longer to prove something’s harmless than it does to prove it’s dangerous.

As somebody who’s guided new lab workers, I’ve seen firsthand that safety attitudes shift based on labels. A new solvent shows up, called “eco-friendly,” people forget their gloves. They wash glassware with it at the sink. It’s a real risk, especially when the gap between known and unknown hazard is wide. Ionic liquids keep cropping up as environmentally persistent, with this methylimidazolium derivative being no different. In real-world water toxicity studies, they can hurt micro-organisms that ecosystems rely on.

Solutions the Community Can Use

Solutions start with education. Universities and companies handle ionic liquids like hazardous chemicals—not just based on flammability but on health effects and long-term persistence. Simple changes reduce risk: Always wear gloves and goggles. Use a dedicated waste container for used or leftover solutions; treat it the same way as you would suspected hazardous organic solvents. Push for clear labeling and updated safety data sheets that address aquatic toxicity and chronic exposure, not just immediate symptoms.

Some research teams are synthesizing new ionic liquids with built-in biodegradability. Until those become reliable and affordable, sticking with common-sense, strict handling approaches can prevent a lot of troubles before they begin. Just because a solvent’s modern doesn’t mean it’s risk-free—and only open communication based on evidence keeps everyone safe.

Understanding Purity and Its Impact in Research and Industry

Walk into any research lab, and you’ll hear discussions about purity all day long. The chemical purity of compounds like 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride shapes the reliability of results. This isn’t just academic—errors in purity can cause experiments to fail or push scale-up processes off track. The molecular structure of this ionic liquid features an imidazolium core, a methyl substituent, and a methoxycarbonylmethyl group, making it a versatile material. Chloride anion brings its own reactivity. Scientists use this compound in advanced synthesis, catalysis, and even electrochemical devices. Impurities can introduce unpredictable side reactions, change yields, and force researchers to question every data point.

Looking Beyond the Label: What Purity Grades Mean

Vendors often sell this compound at a stated purity level, measured as a percentage. You might see “98%,” “99%,” or “99.5%” on the bottle. That decimal point matters. In real-world settings, that extra half percent can mean the difference between a failed drug candidate and a breakthrough. Trace metal contaminants, moisture, and organic leftovers can all sneak into the mix during synthesis or storage. For industrial chemists, small amounts of certain ions might not bother a robust process, but in precision manufacturing—electronics or pharmaceuticals—tiny flaws can spell disaster. I’ve seen projects grind to a halt because a batch contained a mystery impurity just above the usual detection threshold.

Why Experience and Reliable Data Trump Price

Plenty of buyers chase chemical deals online, focusing solely on cost. Sourcing from trusted suppliers with transparent QC data turns out to be a smarter move. Certificates of analysis help, but the most reliable labs run rigorous methods like NMR, HPLC, and elemental analysis. These techniques flag even minor contaminants. Not every academic budget stretches far enough for the highest grades, so teams often weigh the benefit against their risk. For teaching purposes, lower-grade samples hold up under most conditions. For a clinical application, even a trace of residual solvent could shut down an entire production run. After years in the field, I learned to ask for spectral data along with every order, checking firsthand for unexpected signals and double-checking against supplier claims.

Pushing for Higher Standards

The chemistry community demands higher purity now than ever. Regulations around trace impurities keep tightening, after some highly publicized recalls and safety scares. Public health and environmental risks from overlooked contaminants force everyone to pay more attention. Researchers working with this imidazolium salt face expectations that barely existed a decade ago, from detailed impurity profiling to full traceability. Automation and digital tools make these checks faster, but don’t replace careful human review.

Solving the Purity Puzzle

Achieving greater purity starts during synthesis. Cleaning glassware, selecting pure reagents, and application of up-to-date purification steps all matter. Labs with tighter protocols use ion-exchange, careful drying, and custom recrystallization to squeeze out every trace of impurity. Some groups collaborate directly with suppliers to tailor purification methods, refining processes for the needs of a specific project. Open conversation between buyer and supplier—sharing intended use, sensitivity to various contaminants, and necessary assays—cuts down on costly surprises.

Final Thoughts

Demand for rigor never lets up. The purity of chemicals like 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Chloride spells success or failure in research, industry, and public safety. People working with these compounds shape progress in science and technology one cleaned flask at a time.

The Growing Interest in Specialty Ionic Liquids

1-(Methoxycarbonyl)Methyl-3-methylimidazolium chloride doesn’t usually pop up in dinner conversations, but in the world of specialty chemicals, it’s made some waves. This compound sits under the ionic liquids family and people know it for physical and chemical properties that make a difference in catalysis, biomass processing, and as solvents in modern labs. The problem I ran into years ago as a postgrad wasn’t finding exotic molecules for a gram-scale experiment. It was accessing them when a project or pilot demanded more than just a vial or two.

Bulk Availability: A Real Issue for Labs and Industry

Trying to scale up from a test tube to a kilogram of this ionic liquid brings some real questions. Most catalogs of chemical suppliers carry complex imidazolium compounds in small bottles—enough for research, not for manufacturing or pilot lines. I’ve seen researchers and procurement teams spend weeks on the phone or firing off quotes to suppliers, just to hear there’s a 12-week lead and an eye-watering price. That’s not just an inconvenience; it slows down R&D and makes feasibility studies shaky.

This availability problem can be traced to irregular demand and synthesis hurdles. Making ionic liquids like this isn’t as simple as producing hydrochloric acid. The synthesis requires controlled conditions and high-purity reagents. It discourages most distributors from holding onto large lots—nobody wants to tie up cash and fridge space for something that might not sell for months.

The Role of Custom Synthesis and Made-to-Order Production

Sometimes, academic and industry groups work closely with custom synthesis labs. These partnerships mean a company produces a molecule only after a purchase order hits their inbox. That reduces overhead on both sides, but most buyers I’ve talked to prefer an off-the-shelf inventory, even at a slight premium. Long waiting times and unpredictable yields complicate project timelines.

The main challenge here isn’t just money—though prices easily hit four figures for bulk orders. It’s uncertainty. It’s one thing to wait a month for a custom batch; it’s another to walk into a meeting without knowing when or if your delivery can actually keep up with your deadlines. This sort of bottleneck can push companies to switch solvents or shelve innovations that depend on the unique characteristics of ionic liquids.

Why Bulk Supply Matters Beyond Just Price

Having bulk options goes far beyond saving on unit costs. The presence of a steady supply chain reassures investors and helps projects cross the messy gap between lab benchtop and pilot plant. In my own experience, the decision to use or substitute specialty chemicals isn’t driven just by a technical advantage. Desktop-scale science often means nothing unless the market can deliver the material in real-world quantities, plenty of times.

Right now, larger players in specialty chemicals manage some buffer inventory, but only for high-demand compounds. Suppliers tend to shy away from building up stocks unless there’s a clear, ongoing commercial user—usually in pharmaceutical or materials science pipelines. For labs and startups tinkering with ionic liquid breakthroughs, that leaves them trading certainty for flexibility and sometimes facing dismal time-to-market.

What Would Fix This Mess?

Regular dialogue between buyers and producers unlocks visibility into future need. Setting up framework agreements or partnering with local toll manufacturers could start shifting the equation. As green chemistry and advanced materials grow, I see opportunity for chemical suppliers who are willing to carry modest but scalable inventories of uncommon but promising materials. Better forecasting and shared risk could ensure fewer stops and starts for companies chasing the next big thing.

In the end, whether you’re a lone researcher or a mid-sized industrial group, real progress comes from knowing you can buy what you need—when you need it. That’s not the entire story, but for the world of 1-(Methoxycarbonyl)Methyl-3-methylimidazolium chloride, bulk availability matters more than most folks outside a lab would ever guess.