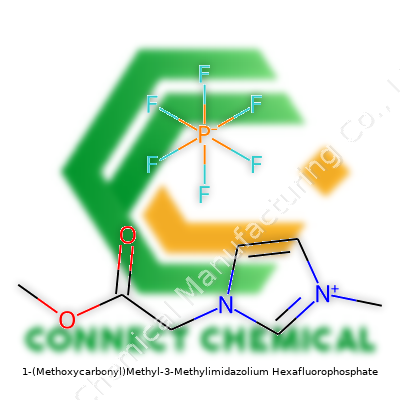

An Inside Look at 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate

Historical Development

The story of 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate traces back to the rapid growth of ionic liquid chemistry, where researchers sought salts that remain liquid at room temperature. The imidazolium backbone stood out in this hunt. Hexafluorophosphate, with its stability, became a natural choice as a counter-ion. Early studies from the late 1990s documented significant milestones, especially as scientists started tailoring ionic liquids to fine-tune solubility, conductivity, and safety. The introduction of functional groups, including methoxycarbonyl and methyl substituents, brought unique reactivity and physicochemical behaviors. Over time, chemists documented ways to strengthen stability and manage reactivity, setting the foundation for this compound’s broader role in lab and industrial settings.

Product Overview

1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate falls under the family of functionalized imidazolium ionic liquids. This class of chemicals delivers more than a simple liquid medium or solvent; it brings tunable chemical properties suited for advanced synthesis. Its core structure features an imidazole ring substituted with a methyl group and a methoxycarbonylmethyl group, paired with a hexafluorophosphate anion. This composition makes it distinct among the hundreds of ionic liquids available today.

Physical & Chemical Properties

From my lab days, you learn to respect imidazolium compounds for their robust thermal properties and low volatility. This salt typically presents itself as a colorless or faintly yellow liquid at room temperature. The presence of the methoxycarbonyl group affects solubility, nudging it toward moderate miscibility with polar organic solvents yet resisting water uptake. The melting point tends to fall well below 100°C—often around 50-80°C—depending on subtle synthetic details. Its moisture sensitivity remains moderate, not as touchy as some fluorinated analogs but requiring careful storage away from humid air. Stability holds up under rigorous reaction conditions, though you see some reactivity in highly basic environments. Its vapor pressure stays low, making it safer for open-bench work than typical organic solvents.

Technical Specifications & Labeling

Reputable suppliers guarantee a purity level above 98%, verified by NMR spectroscopy and ion chromatography. Sellers offer certificates of analysis for each batch, detailing residual chloride, moisture content (often below 0.1%), and trace metal impurities. Material shipped in sealed, amber glass bottles, with clear hazard labeling per GHS standards. The bottle label features chemical name, structure, batch number, CAS registry, and expiry date. A printed safety data sheet covers emergency measures, storage guidelines, and disposal rules. Buy from sources that offer batch-specific analysis and documentation, as trace contaminants influence sensitive reactions or electrochemical studies.

Preparation Method

Most researchers build 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate through a well-established quarternization approach. The synthesis starts with 1-methylimidazole, which reacts with chloromethyl methyl carbonate. The alkylation step typically proceeds under mild basic conditions, monitored by NMR to confirm full conversion. Purification employs solvent extraction, iterative washes, and sometimes ion-exchange to eliminate halide residues. Treatment with hexafluorophosphoric acid or a suitable PF6− salt then produces the target imidazolium hexafluorophosphate. A series of filtrations and drying under vacuum clears up the product. Yield often exceeds 80% on the lab scale, provided careful exclusion of moisture and efficient phase separation. This process adapts well to both gram-scale synthetic work and small-scale industrial settings.

Chemical Reactions & Modifications

Chemists value this compound both as a reactive intermediate and as a stable reaction medium. The methoxycarbonyl side-chain opens up possibilities for further functionalization through nucleophilic substitution or hydrolysis, offering entry points for tailor-made ionic liquids. The imidazolium core resists many common degradation pathways, such as oxidation and hydrolysis, under neutral to acidic conditions. Pairing with different anions—besides hexafluorophosphate—lets chemists fine-tune solubility or introduce new catalytic sites. In organic synthesis, this ionic liquid demonstrates unique phase behavior and can stabilize reactive intermediates, like carbocations or radical species. Its non-coordinating anion, PF6−, delivers reliable ion conductivity without interfering in catalytic cycles. Recent work explores its potential as a solvent in green chemistry applications, including transition metal catalysis and electrochemical processes.

Synonyms & Product Names

Outside of its full IUPAC title, expect to see shorthand like “(Methoxycarbonyl)methyl-methylimidazolium PF6”. Some catalogs list it under abbreviations such as MCMIm PF6 or MMC-Imidazolium Hexafluorophosphate. European suppliers sometimes prefer listings based on cation or anion priority, creating even more naming variations. Researchers working internationally should cross-reference chemical identifiers, like the CAS or EC numbers, to sidestep confusion in supply chains or publication data.

Safety & Operational Standards

Lab safety culture has evolved, especially around novel salts and ionic liquids. Despite its relative thermal stability, 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate requires gloves and goggles during handling. The hexafluorophosphate ion presents an HF-generation risk upon contact with strong acids or when exposed to high heat. Accidental ingestion, inhalation, or dermal exposure calls for standard first aid but also quick follow-up due to uncertainty around chronic effects. Labs rely heavily on fume hoods, tightly closed containers, and segregation from acids or water sources. Waste disposal involves collection in dedicated halogenated-organic containers, never simple drain disposal. Manufacturers provide detailed safety data sheets aligned with international standards, emphasizing accident prevention and spill response. Regular training and hazard communication stand as frontline tools in minimizing risks.

Application Area

Ionic liquids based on imidazolium, especially those functionalized with methoxycarbonyl sidechains, now anchor research in electrochemical devices, catalysis, and modern material science. In the lab, these compounds offer unique solvating power for organic molecules that typically challenge traditional solvents. Their low volatility and electrochemical stability support use in batteries, capacitors, and other energy storage devices. Some years ago, the rise of greener chemical syntheses pushed researchers to replace volatile organic solvents with ionic liquids, including those in this imidazolium family. Their use in CO2 capture technologies, separation science, and even drug formulation continues to expand, though every project demands a close look at toxicity and environmental impact before full-scale adoption.

Research & Development

Labs worldwide set their sights on optimizing ionic liquids for greener chemistry. Teams focus on tweaking this core imidazolium structure to enhance biodegradability, lower toxicity, and boost recyclability. Recent research tests its compatibility with biotransformations, aiming for hybrid systems that combine biological and chemical catalysis. In materials science circles, modifications of the methoxycarbonyl group seek new routes to tune hydrophilicity or push reactivity boundaries. Studies track interactions with advanced nanoparticle catalysts, uncovering new synergies that traditional solutions rarely achieve. Private sector R&D invests in scaling up synthesis, hoping to cut costs without sacrificing quality or purity, as stricter regulations hit the specialty chemical market. Every year, conference sessions and journal articles expand the collective knowledge, while collaborative networks help spread best practices on safe handling and application.

Toxicity Research

Most folks outside the lab overlook risk profiles, but toxicity drives real decisions in both research and industry. Early studies on imidazolium ionic liquids flagged concerns over ecotoxicity, especially in aquatic systems. While this particular derivative sidesteps the acute hazards seen in pyridinium salts, precaution figures heavily into its material safety regimen. Animal testing and in vitro studies suggest low acute mammalian toxicity, but chronic exposure data stays sparse. Some breakdown products, especially those relating to the PF6- anion, raise flags due to potential HF release and bioaccumulation. Environmental chemists continue to survey persistence in soil and water matrices, urging for more comprehensive lifecycle analysis before scaling up commercial use. Responsible labs either minimize use or recycle spent solutions through professional waste contractors, eager to avoid future regulatory pitfalls.

Future Prospects

The story of 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate hasn’t closed. Advances in separation technology, energy storage, and green synthesis fuel demand for ionic liquids that balance performance and safety. Teams look to new catalytic cycles using these liquids as both medium and reactant, leveraging unorthodox reactivity for cutting-edge chemistry. Regulatory pressure shapes product development, pushing innovation toward lower-toxicity anions and sustainable synthetic pathways. Industrial uptake hinges on reliable sourcing, third-party certification, and proven waste management strategies. Across academia and industry, researchers keep searching for clear toxicity answers and ways to recover, reuse, and recycle these advanced salts. Next-generation applications in electronics, pharmaceuticals, and environmental remediation could cement this class of ionic liquids as core tools—if society agrees on responsible risk management and efficient resource use.

The Building Blocks: Peeking at the Molecule

Chemistry always comes down to what sits on the molecular level. With 1-(Methoxycarbonyl)methyl-3-methylimidazolium hexafluorophosphate, the name alone hints at quite a bit. The main backbone is the imidazolium ring—a five-membered aromatic ring with two nitrogens. Two groups hang off this ring: one is a methyl group at the third position, which gets called the 3-methyl piece. The other, at the first position, is a side chain carrying a methoxycarbonylmethyl group. This is where the carbon chemistry brings color, with an ester (that’s what the methoxycarbonyl part signals) attached to a -CH2- linker.

Now for the counterion. Hexafluorophosphate (PF6-) stands out as a familiar face in the world of ionic liquids. It brings stability, low reactivity, and keeps the cationic (positively charged) imidazolium portion in balance. Pieced together, this ionic pair yields a salt with curious strengths.

The Real-World Gravity of Imidazolium Salts

Imidazolium salts like this have become fundamental in the world of green chemistry. They’ve proven themselves in labs as solvents that don’t evaporate away, can stand up to heat, and often dissolve even the most stubborn organics or inorganic solids. These salts have cropped up in my own trials—tackling stubborn separations or coaxing harsh reagents to play nice in new reactions.

Take a look through the chemical literature, and you’ll see this structure popping up in catalysis, electrochemistry, and materials science. The cation’s bulky side chain and the non-coordinating PF6- anion let it dissolve plenty, but they also keep impurities in check, a boon during sensitive syntheses.

Safety and Sustainability Concerns

The downside with these finely-tuned ionic liquids always circles back to safety and sustainability. Hexafluorophosphate has carried a reputation for stability, but that comes with real trade-offs. If it encounters strong acids, PF6- can produce toxic HF gas, which sets off alarm bells for anyone conscious of laboratory health and environmental safety.

In my experience, handling ionic liquids based on PF6- meant double-checking vent hoods and re-thinking cleanup. They don’t break down quickly; disposal options lag far behind those for conventional solvents. Labs must track waste flow for these salts carefully, especially as environmental frameworks grow tighter every year.

Potential and Pathways Forward

Many chemists realize that the molecular structure of 1-(Methoxycarbonyl)methyl-3-methylimidazolium hexafluorophosphate gives it unique abilities—thermal stability, tunable polarity, and resistance to breakdown. Those have opened doors in catalyzing reactions more efficiently and with less waste.

Still, stewardship counts. Green chemistry goals push researchers to focus on less persistent anions, or to recycle these ionic liquids after use. That means new blends and alternatives are already under study. For any researcher embracing these chemicals, safety training, full lifecycle planning, and a steady review of byproducts shape responsible practice.

Chemistry has never stood still. Structures like 1-(Methoxycarbonyl)methyl-3-methylimidazolium hexafluorophosphate prove that with the right insights, old molecular tricks become part of smarter, safer, and more sustainable innovation.

Modern Chemistry Needs Reliability, Not Mystique

Lots of folks hear a chemical name like 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate and imagine a lab full of glass flasks, goggles, and maybe some white coats. My own route through applied science hasn’t been glamorous, but I can tell you this compound offers more than intimidating syllables. It plays a real part in how we solve day-to-day challenges in laboratories.

Chemical Labs See Ionic Liquids as Workhorses

This substance belongs to a group called ionic liquids. Green chemistry keeps chasing after materials that work without creating piles of hazardous waste. I’ve watched teams swap out classic organic solvents, like toluene and benzene, for ionic liquids in both research projects and small-scale production. The hexafluorophosphate option catches attention due to its resilience and low volatility. In practice, scientists reach for it when running difficult organic reactions or pushing electrochemical studies further.

A clear example pops up in metal catalysis. Early on, I saw graduate students wrestling with catalyst waste and poor yields from precious metal routines. Adding this ionic liquid, improvements followed—not just cleaner reactions, but catalysts recycled multiple times, lowering costs and headaches for the whole group.

Electrochemistry Counts on Consistency

Electrochemical devices, from batteries to supercapacitors, don’t just need a working electrolyte—they need one that stays stable. I learned pretty quickly in energy storage labs how often developers chase after ionic liquids with strong thermal and electrochemical windows. 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate doesn’t break down as easily as other materials, even when voltages run high. Researchers use it as a solvent or as an electrolyte that stands up to stress, letting them focus on testing new electrode materials instead of babysitting ingredient breakdowns.

Green Synthesis and Recycling Matter More Than Ever

People talk about sustainability, but you really see its importance in the pile of chemical waste left after a single experiment. My short time clearing out old solvent drums drove the point home—legacy processes generate messes that nobody wants to tackle. With this ionic liquid, chemists have published methods for recovering products and reusing the liquid across several runs. It supports a shift in culture, where reusability isn’t a vague goal but an everyday choice. There’s growing data on lower toxicity, reduced evaporation, and improvements in recyclability compared to old-fashioned solvents.

Core Problems Still Demand Fresh Eyes

Working with advanced materials always brings a mix of promise and stubborn problems. Not every solution is perfect. Ionic liquids usually cost more and sometimes slow reaction rates. My mentors showed me workarounds, like combining trace amounts of water or adding simple co-solvents to offset these issues. There’s still a tradeoff—improved safety and recyclability at the expense of speed or price. Ongoing studies keep exploring new ways to lower costs and make manufacturing easier, especially as demand grows in advanced batteries and specialty chemical sectors.

Outlook Calls for More Shared Experience

As researchers keep pushing boundaries, familiarity with these materials pays off. Talking to industry chemists, most agree that knowing how to handle, recover, and recycle makes the difference between an experiment that ends in frustration and one that sparks innovation. Training future scientists in these practical, sometimes unglamorous, details—how to measure viscosity, what to do with leftovers—matters as much as the headline breakthroughs. That’s where real progress takes root, one experiment at a time.

Personal Lessons from the Lab

Having spent time working in a university lab, every chemical bottle brought a story. The sharp smell of acetone, the weight of a flask of nitric acid, always kept you grounded in the present. Safety goggles weren't just a box to check; they're the barrier between sharp shards and your eyes on a bad day. One unexpected splash and you'll never shrug off safety gear again.

Why Labels and Data Matter

Before even unscrewing a cap, check the Safety Data Sheet. You see firsthand how one white powder might corrode skin while another barely scrapes a hazard score. Bleach and ammonia, safe alone, send people to the hospital when mixed. The SDS gives warnings, lists burn risks, outlines how fumes damage lungs, and whether gloves block skin absorption. Check those hazard pictograms—everything else flows from that spot.

No Substitutes for Good Gloves

There's a big difference between blue nitrile gloves and thick neoprene. I've had friends wear thin latex with acetone on the bench—fingers burning half an hour in. Choosing the wrong material punishes fast. Glove manufacturers post handy charts online, cross-matching compounds with glove types. Take five minutes to check; your skin will thank you.

Keep Fumes Moving Away

Many don’t realize how much vapors work their way up. A few seconds with an open bottle and you'll catch a throat tickle. Running experiments in a well-ventilated fume hood changes everything—the smell disappears, headaches stay at bay, and exposure plummets. Even simple compounds—acetone, toluene, ammonia—build up fast in a stuffy room. Fume hoods or proper fans cut that risk down to almost nothing. At home, keep windows wide and fans running when working with even seemingly mild chemicals.

Spill Response Isn’t Just for Big Accidents

It’s easy to laugh off tiny messes—until a drop etches a table, or vapor irritates lungs. In our lab, every benchtop carried a small kit: paper towels, baking soda, a bucket of sand. I’ve had classmates panic with a simple mercury thermometer break; trained staff calmly rolled out sticky tape and got rid of the problem. Pre-packed spill kits with neutralizers, absorbent granules, and sealed bags can save both time and nerves.

Communication Goes a Long Way

Working alone multiplies the risk. Peers can spot mistakes, offer a fresh read of the SDS, or catch someone cleaning up acid with bare hands. Even now, if I handle anything riskier than dish soap, I let somebody know or check in after. In labs, signs go up when work happens, and doors stay unlocked for quick evacuation.

The Value of Training and Ongoing Learning

Protocols don’t just sit in binders; they grow with each near-miss. From early school chemistry, teachers drilled PPE and cleanup routines. Industry courses add spill control, fire extinguisher use, and first-aid refreshers. Real learning happens when stories circulate: the graduate who soaked their sleeve in phenol, or the tech who forgot to tie hair and bent into a flame. These reminders hit home stronger than any warning sign.

Living Better by Thinking Ahead

Taking chemicals seriously means planning—knowing what might go wrong, double-checking procedures, and respecting limits. These steps aren’t red tape. They’re what send people home healthy and ready to learn from the next day’s work.

Why Proper Storage Matters

Handling chemicals like 1-(Methoxycarbonyl)Methyl-3-Methylimidazolium Hexafluorophosphate isn’t a task for someone looking to cut corners. Over the years working in small academic labs and larger industry settings, I’ve seen even seasoned professionals underestimating the risk that improper storage creates. This compound might look stable in a catalog, but you treat it wrong, and things can go sideways.

Physical and Chemical Properties

This particular compound belongs to the family of ionic liquids, which gives it some interesting characteristics. It doesn't evaporate fast, and it doesn’t break down easily at room temperature, but that’s not a free pass. Its hexafluorophosphate anion can react with water or moisture, splitting off dangerous chemicals like hydrofluoric acid — a risk that’s anything but theoretical. One mishap with humidity in the air, and there’s a very real danger for anyone close by, not to mention long-term damage to sensitive equipment.

Essentials of Storage

Anyone who’s handled fluorinated compounds learns to stay alert around water. For this ionic liquid, the top priority is a dry environment. I’ve seen teams store similar chemicals in standard glass bottles, only to regret it after seals degraded or caps let in moisture. You want tight-sealing containers, preferably made of materials tested for chemical resistance — high-density polyethylene or fluoropolymer bottles stand up best over time. Forgetting a desiccant in the storage cabinet is a rookie mistake that bites back quickly.

Heat spells trouble for stability. This compound holds up at room temperature, but heat—especially if it’s close to any source of ignition—can stir up a headache. Some ionic liquids break down unpredictably when hot, and nobody wants to track down the origin of a strange smell or reaction. Keeping things out of direct sunlight and away from lab ovens avoids surprises. Room temperature storage, out of the light, keeps your workspace safe and saves money on spoiled stock.

Ventilation makes its own difference. Even though evaporation isn’t the main problem with this chemical, using it in a well-ventilated space adds a layer of safety. In my own workspace, I keep chemicals like this in a ventilated storage cabinet. It prevents pressure buildup and keeps fumes (from accidental exposure or slow degradation) from lingering where people work.

Labeling and Documentation

Clear labels cut through confusion fast. After seeing one too many close calls from mixed-up chemical bottles, I always mark the bottle with the chemical name, concentration, purchase date, and hazard symbols. Good records, from suppliers’ safety data sheets to lab logs, keep everyone on the same page. Periodic inventory checks help catch any broken seals or expired material, which is way better than learning too late that a bottle leaked.

Staying Prepared for Problems

Mistakes happen even with a solid storage plan. Every lab tech should know where to find personal protective gear, from nitrile gloves to splash-proof eyewear. Spills don’t wait until you’ve checked the manual, so spill cleanup kits ought to be handy and chemical-specific. Emergency procedures—suggested by safety officers and based on real experience, not just paperwork—save pain and expense.

Building a Culture of Safety

Working around ionic liquids and fluorinated chemicals hasn’t ever felt routine to me. It takes a team mentality and respect for the material to keep accidents rare. You tell new researchers and old hands the same story: It’s never too much to double-check storage, never too careful to document, never too cautious to train for the unexpected. If more science teams worked with that mindset, there would be fewer stories of costly mistakes and hospital runs.

Making an Informed Choice Isn’t Just for Chemists

Ask anyone who’s tried to order a specialized product—lab chemicals, supplements, industrial materials—and you’ll hear the same story. The questions hit right away: “Do you have it in a higher grade? Can I get it in a smaller bottle?” A lot of folks outside of research or manufacturing might roll their eyes at the fuss, but the difference isn’t academic. Getting the right grade or size has shaped the way jobs get done, far beyond the white coat world.

Quality Isn’t Just a Luxury

A friend of mine runs a small craft brewery, so even outside the science field, purity dictates success. She needs sodium bicarbonate to balance pH in her brews, but the stuff she orders from a chemical supplier can’t have the same impurities as what you find in a grocery baking aisle. Even a trace contaminant means a ruined batch—thousands lost, angry customers. That’s the gritty reality behind those boring-sounding labels like “analytical grade” or “food grade.” The gradations cut losses, boost safety and help honest businesses stay afloat.

Waste and Cost Add Up Fast

Package sizes shape more than inventory space. People use chemical products by the gram, the liter, or the bulk pallet. A high school science teacher probably doesn’t want to wrestle with a 50-kilo drum; a copper mine might break the bank buying single-use bottles. In my old university lab, we wasted a fortune pouring out corrosives no one finished in time. Industry numbers back this up. A 2022 survey by the American Chemical Society showed roughly a quarter of researchers picked suppliers based on their flexibility in packaging. Having a range of options means products don’t sit unused, expire, or drive up disposal costs.

Safer Workplaces Through Customization

It’s easy to gloss over, but let’s take lab safety. Risk climbs the more hands have to transfer, measure, or portion out a material. Cutting down repackaging steps drops accident rates, and it protects employees from spills or dangerous fumes. Product recalls and contamination scares often come down to the wrong bulk size or a grade swap on paperwork. Safety data sheets lose value if they don’t match what arrives in the box. Suppliers who give clear, varied choices back up the health of entire workplaces from food labs to electronics clean rooms.

Fixing the Gaps

The next step seems obvious—companies have to keep listening to the people who actually use these products. Gathering feedback on which packages move fastest, checking how often people ask for a higher or lower grade, and using clear labeling go a long way. Building more transparency into sourcing lets buyers see country of origin and compliance (think ISO certifications, FDA status), which builds real trust. Some smaller suppliers are even allowing buyers to “build” custom kits or subscription boxes, slashing time spent hunting around for the right mix.

Learning from Broader Trends

Even as regulations tighten, the success stories usually hinge on a supplier’s ability to meet changing needs. The food and beverage world, for example, moved fast to create more package sizes and purities during COVID-19 supply chain breakdowns. Hospitals that switched suppliers based only on price found themselves with inferior grades or excess materials, costing more in the long run. Open conversations between end-users and suppliers—not just sales scripts—drive innovation in these basic but vital offerings.