1-Methylimidazole: A Comprehensive Commentary

Historical Development

Chemistry rolled into a new era in the late 1800s with the discovery of imidazoles, and among them, 1-methylimidazole carved out its niche soon after. Research in those days rarely received instant recognition, but early pharmaceutical chemists saw the value in nitrogen-rich rings. The push for synthetic dyes and the drive to craft better pharmaceuticals allowed 1-methylimidazole to catch on in both labs and industry. The early patents for its preparation reveal a collective eagerness to explore any route toward heterocyclic innovation, especially with German and British chemists diving into modification of basic imidazole. As modern organic chemistry matured, companies and research institutions alike poured time and resources into applications ranging from solvents in specialty synthesis to intermediates in the development of novel drugs, resins, and ionic liquids.

Product Overview

1-Methylimidazole stands out because of its simplicity and function. With a methyl group joined to the nitrogen atom of the imidazole ring, this molecule shows both basicity and nucleophilicity. Not only do chemists need it for reactions involving alkylation and acylation, but plant operators use it as a key building block in the synthesis of important materials, like epoxy curing agents and corrosion inhibitors. The electronics sector and pharmaceutical manufacturing pull vast quantities year after year—a testament to its steady demand. On a more technical note, this compound serves as a reference material and pH indicator, especially where traditional buffers can’t stand up to harsh conditions.

Physical & Chemical Properties

This clear, colorless liquid carries a distinct, pungent smell very reminiscent of amines or other nitrogen-containing rings. Boiling at about 198°C, it refuses to shy away from higher temperatures. With a melting point near -60°C and a density close to water at 1.03 g/cm³, 1-methylimidazole flows easily in most operating environments. The dielectric constant sets it apart in solvent applications where polarity matters. High solubility in water and organic solvents like alcohols, chloroform, and ether broadens its practical range, and that’s why industries rely on it for miscibility requirements others can’t meet. The molecule is chemically stable, surviving in air for extended periods as long as acidity or heavy oxidizers stay away.

Technical Specifications & Labeling

Industry-grade 1-methylimidazole comes with a purity north of 99%, driven by the strict needs of pharmaceutical and electronics customers. Detailed labels highlight the UN number, hazardous classifications, and batch-specific data like melting/boiling points and expiration dates. Handling instructions warn about its irritant properties, emphasizing eye and skin protection. Many manufacturers adopt color-coded drum systems for clear identification, and regulatory compliance in Europe, Asia, and the United States drives uniformity in specifications—especially for REACH and OSHA labeling. The need for traceability leads to rigorous batch certification, enabling end users to link every drop back to its origins.

Preparation Method

The most reliable method for synthesis involves methylation of imidazole under basic conditions. Chemists prefer to react imidazole with methyl iodide or methyl sulfate in aqueous or organic media, often using sodium hydroxide or potassium carbonate to neutralize the acidic byproducts. Solvent choice sometimes tips the scales in favor of efficiency, and some labs cut down on side reactions using high-purity imidazole and strictly anhydrous conditions. Industrial setups scale this up, with staged reactors, in-line purification, and continuous distillation ensuring steady output and fewer impurities. Afterward, distillation pulls out the product, while quality checks confirm structure, usually by NMR and GC-MS analysis.

Chemical Reactions & Modifications

1-Methylimidazole participates in a range of organic reactions. It’s a favored nucleophile in alkylation and acylation protocols, and it forms stable quaternary salts with alkyl halides. Some research teams use it to build advanced ligands for catalysis or modify its core under photochemical or oxidative conditions to craft fine-tuned derivatives. In polymer chemistry, it’s a hardener for epoxies, and battery researchers modify its structure to investigate ionic conduction in novel electrolytes. Its basic nature helps drive esterification, transesterification, and ester hydrolysis reactions in contexts where traditional amines struggle, and in chemical modifications, it accepts diverse substituents on the imidazole ring without losing its functional character.

Synonyms & Product Names

Products labeled as N-Methylimidazole or 1-Methyl-1H-imidazole appear across global catalogs. Companies might call it 1-MeIm, NMI, or Methylimidazole, especially in electronic and pharmaceutical supply lists. Those working with import/export should watch for terms like Monomethylimidazole, showing up in older labeling systems. Regulatory filings often favor the IUPAC name, but trade names crop up in documentation about epoxy additives and specialty solvents.

Safety & Operational Standards

Workers in handling facilities learn quickly that 1-methylimidazole causes irritation to eyes, skin, and respiratory tracts. Industrial hygiene policies demand gloves, splash goggles, and fume hoods. Inhalation leads to coughing and sore throat, while skin absorption over time poses risk of dermatitis. Handling spills calls for activated carbon or absorbent pads and immediate disposal in chemical waste containers. Storage stays well away from acids and strong oxidizers in locked, ventilated cabinets. Safety Data Sheets detail first aid, disposal, and firefighting measures, and plant staff run regular drills to meet EPA and OSHA expectations. Transport regulations mandate hazardous labeling and tracked shipments to reduce health and environmental risks.

Application Area

The epoxy industry leans heavily on 1-methylimidazole as a curing agent, and electronics producers count on its ability to drive cross-linking at controlled rates. Layouts in coatings factories often place 1-methylimidazole close to resins and hardeners because plant workflow depends on immediate access. Pharmaceuticals pull it in as an intermediate for antifungal and antihistamine drugs. It pops up in crop protection research and dye synthesis labs as a critical N-heterocycle. Battery engineers use its derivatives to test high-conductivity electrolytes for next-generation storage. Even analytical chemists use it as a reference or calibrant in proton NMR—its single methyl group and well-understood chemical shifts leave little room for confusion.

Research & Development

Every year, scientific journals turn up a stack of papers on 1-methylimidazole and its cousins. Researchers develop task-specific ionic liquids for green chemistry, finding that tweaks on this molecule can lower toxicity or boost catalytic effects. Pharmaceutical labs chase new antimicrobials by building diverse derivatives, and polymer researchers look for additives that improve curing time or thermal resistance in new resins. Industrial R&D outfits invest in greener, safer syntheses, racing to limit waste and energy use by shifting away from old methylation agents to less hazardous alternatives. Detailed mechanism studies help predict outcomes in alkylation and cross-coupling, and academic labs often publish open-access protocols to speed collective progress.

Toxicity Research

Animal tests and epidemiological reviews show that 1-methylimidazole has moderate acute toxicity. Studies point out its local effects on exposed tissues, especially the skin and mucous membranes, while concerned occupational safety experts note that chronic inhalation or repeated exposure should trigger regular health surveillance. Some rodent studies observed liver and kidney stress with very high doses, although short-term exposure guidelines draw a clear line beneath which health impacts drop sharply. Regulatory agencies set permissible exposure limits and ventilation requirements to prevent worker complications, and ongoing research tracks any possible links to bioaccumulation or subtle long-term effects.

Future Prospects

1-Methylimidazole shows every sign of staying relevant as industries chase greener and more effective chemicals. The ongoing shift to sustainable solvents and energy-storage materials creates new markets for functionalized imidazoles. Research pushes towards ionic liquids and organocatalysts—areas where this molecule brings both flexibility and structural reliability. Large-scale manufacturers invest in closed-loop systems for recovery and reuse, reflecting the environmental regulations tightening around nitrogen-containing solvents. Academic collaborations inch forward on finding less toxic alternatives while holding on to 1-methylimidazole’s performance. As manufacturing processes demand higher throughput and lower emissions, this little ring structure remains crucial for chemical innovation worldwide.

What 1-Methylimidazole Brings to the Table

Chemistry never seemed like a big deal when I started out in science, but I learned quickly that some molecules show up everywhere, even if most people never hear their names. 1-Methylimidazole is one of those behind-the-scenes workers that makes a huge impact in labs and factories. It’s a colorless, water-miscible liquid with a mild odor and a structure similar to other imidazoles, putting it in the spotlight for chemists working on specialty products and large-scale manufacturing.

Resins and Hardeners: Essential for Industry

Walking through a factory floor, you’ll probably see big tanks of resins. These don’t turn into useful plastics or coatings by themselves. 1-Methylimidazole acts as a catalyst or curing agent in making epoxy resins harden. Think about airplanes, cars, wind turbines, or the computer in front of you – a lot of the tough and reliable parts in those products come from epoxies that set up thanks to this little molecule. It helps the resin set faster and better, which makes products safer and more durable.

Pharmaceuticals: A Useful Building Block

In a chemistry lab, 1-Methylimidazole helps build medicines. Drug makers use it as a starting material or as a stepping stone in creating more complicated molecules. It often shows up in the development of antifungal medicines, certain cancer drugs, and even experimental treatments. The imidazole ring is a favorite among chemists because it interacts in special ways with biological targets in the body. Over the years, researchers have proven that small tweaks to this ring structure, like adding the methyl group, can make drugs safer and more potent.

Solvent and Intermediate: Hands-On Chemistry

I’ve noticed that many chemical processes run more smoothly using 1-Methylimidazole as a solvent. Its ability to mix with water and other organic liquids makes it valuable for separating and refining chemicals in labs. It also serves as a base in a lot of reactions—especially useful in organic synthesis, where reactions need the right conditions to go to completion without making too many unwanted byproducts. Chemists rely on its consistency and performance for results they can trust, batch after batch.

Environmental and Health Concerns

Every chemical brings questions about safety. There’s no point in making stronger building materials if people get hurt in the process. Studies show that 1-Methylimidazole can irritate the skin and eyes with direct contact. There’s evidence it can be toxic if someone swallows a large amount or breathes its fumes over time. Factories and labs have shifted their practices to include airtight systems, gloves, and fume hoods. From my own work, regular checks of ventilation and spill procedures make the difference between a safe shift and a close call. Regulators look closely at emissions and waste, which reduces the risk of this compound ending up where it shouldn’t.

Meeting Today’s Challenges

Demand for stronger materials and better medicines keeps rising. Safer alternatives or improvements in recycling and disposal can cut the impact of 1-Methylimidazole. Researchers keep exploring ways to replace it in some uses with less hazardous compounds, or design processes where it gets recovered and reused instead of thrown away. Industry and labs both push for greener chemistry solutions, since cutting waste and exposure means healthier workers and less pollution. The conversations around 1-Methylimidazole remind me that every ingredient matters, not just for the product but for people and the planet.

Working With a Chemical That Bites Back

1-Methylimidazole often turns up in labs and factories where folks make pharmaceuticals, coatings, or specialty resins. Nothing in its clear liquid look warns of the mess it can cause if someone skips safety measures. I’ve watched both novice lab techs and seasoned chemists drop their guard around chemicals like this, thinking a quick pour or spill cleanup won’t matter. That’s where problems start.

Don’t Trust a Label or a Memory

The danger with 1-Methylimidazole comes from its skin and eye irritation risk, and the cough it provokes if someone smells too much. University chemical hygiene officers warn all the time that even brief contact can leave burns or trigger asthma-like symptoms. Last year in our workplace, sloppy glove use left someone with red, blistered fingers for days. The safety data sheets lay out these risks in plain text, so everyone working with this compound must read them, not just sign off on training.

Simple Actions Keep You Safe

Nobody needs fancy gear to stay safe—basic lab coats, chemical-resistant gloves, and goggles make a big difference. Splashing is more common than most think. I’ve wiped down counters after experiments and found little droplets with a strong, amine-like smell hours later. Good quality nitrile or butyl gloves last longer against this chemical than latex, which tends to degrade and fail quickly. Any cut or pinhole in gloves gives 1-Methylimidazole an open door. Changing gloves frequently has saved my skin plenty of times.

Why Ventilation Beats Bravery

A fume hood isn’t just there for the really toxic stuff. One whiff of 1-Methylimidazole in a closed room reminds you how caustic these vapors get. Without good airflow, even small spills can cause problems for everyone nearby. I’ve cleared labs because a half teaspoon went down a bench and someone decided to clean up without checking the vent. Trusting the smell as a signal doesn’t cut it—by the time you smell trouble, the damage might be started.

Attention Pays Off

Small habits matter most. Keeping bottles capped tight after each use, using proper pipettes instead of pouring, and always labeling containers keep accidents down. One time, we avoided a costly mishap because a sharp-eyed intern noticed a graduation flask labeled with a faded marker—nobody knew it held leftover 1-Methylimidazole until we uncapped it and caught a noseful of ammonia-like vapor.

Getting Ready Before Things Go Wrong

Even if folks never expect a spill or splash, planning for it takes just minutes. Every workspace should keep an emergency eye wash and safety shower open and working—an ounce of practice using those before trouble hits saves minutes during a real crisis. We run drills twice a year. Testing the response lets newcomers and old hands find the fastest paths and reduces confusion.

Learning From Simple Fixes

People sometimes believe only expensive equipment or big programs protect from chemicals. Over the years, I’ve seen more injuries prevented by common sense and attention to detail. Double-check gear before sessions, replace gear without waiting for visible cracks, and read reports of past incidents so old mistakes don’t come back. None of these steps need a big budget or high-tech systems—just daily buy-in from everyone working nearby.

Safe Habits Make the Difference

Safety around 1-Methylimidazole lines up with the same lessons handed down from every good mentor I’ve learned under: read up, suit up, slow down, and clean up. That culture, more than any single rule, keeps both new learners and experienced technicians healthy.

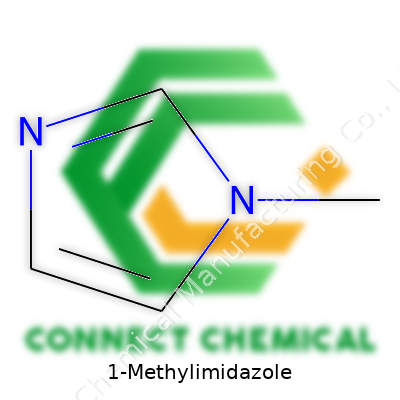

The Nuts and Bolts of 1-Methylimidazole

Organic chemistry has its share of complicated names, but 1-methylimidazole stands out for its usefulness rather than just its syllables. The real charm of 1-methylimidazole sits in its structure. It's built around the imidazole ring—a five-membered ring made of three carbon atoms and two nitrogen atoms. One of those nitrogen atoms sits next to the methyl group, which is a single carbon with three hydrogens attached. That methyl group bonds directly to the first position on the ring, and that’s how the “1-methyl” most folks see in its name shows up in its chemical formula. So, what is the formula? C4H6N2.

I remember seeing this molecule for the first time in a lab as a grad student—watching its faint, pleasant odor come off a tiny beaker. It looked so unassuming. The ring structure allowed for delicate balance—stable enough to sit on the shelf, reactive enough to jump into plenty of chemical reactions as needed. Chemists like me would draw that ring around a hexagonal shape, throwing in a double bond and sticking an extra methyl group where others might put a plain hydrogen. It’s simple enough to sketch in an organic chemistry exam, but the difference that little methyl group makes can show up everywhere chemistry gets applied in real life.

What Makes Its Structure Useful?

The imidazole backbone shows up in everything from medicines to industrial processing. That small methyl group packs a punch when it comes to tweaking chemical behavior. It boosts the molecule’s ability to dissolve in various organic solvents and increases its stability—making it useful as a catalyst and in solvents that need to stay reactive under heat or pressure. 1-methylimidazole steps up in the manufacture of pharmaceuticals, corrosion inhibitors, and as a key intermediate for specialty chemicals. That’s not a list from a textbook—it’s what I’ve seen firsthand in research groups and, later, in industrial spaces where quality and reliability mean the difference between a successful batch and thousands of lost dollars.

Plenty of research has supported this. In the mid-2000s, several studies published in chemistry journals broke down how 1-methylimidazole plays a role in making ionic liquids, which are prized in green chemistry for being less volatile and supporting cleaner reactions. Chemists have leaned on its structure to change the landscape for environmentally friendly catalysts. My own experience lines up with these findings: whenever we needed a solvent that could out-perform traditional choices, or a catalyst that wouldn’t break down half-way through a reaction, the methylated imidazoles were at the top of the shopping list. That flexibility gives chemical engineers more control and opens possibilities for new products.

Facing Challenges: Safety and Environmental Questions

No molecule comes without baggage. 1-methylimidazole is relatively safe compared to more reactive analogs, but like any compound used in industrial synthesis, it demands careful handling. People in labs expect proper ventilation, gloves, and policies to deal with chemical waste. The Environmental Protection Agency in the US lists it with clear guidelines for disposal. From personal experience, I’ve had bottles catch a little crust if left open—and that teaches a chemist quickly about care, containment, and labeling. Mistakes with chemicals like these may not always be catastrophic, but careless practices can still cause health problems, messy spills, or fire hazards in bigger plants.

Safer alternatives are a common thread in modern chemistry. Sustainable practices now shape how companies pick and use these chemicals. Green chemistry looks at ways to recover, recycle, or even redesign compounds like 1-methylimidazole. I've seen labs team up with engineering groups to tighten safety protocols and try out closed-loop systems that recycle imidazoles. These aren’t dreams; they’re day-to-day procedures for a growing number of research facilities and startups chasing cleaner chemical technology.

Why This Structure Still Matters

The C4H6N2 formula for 1-methylimidazole keeps showing up because it works, both as a building block and a problem-solver. Perfect safety won’t ever be reached in a laboratory, but constant vigilance can keep risks low and help new generations of chemists keep using such molecules responsibly. With continued investment in safety and sustainability, the humble methylimidazole will stick around—quietly helping to shape the products and medicines relied upon every day.

Understanding What 1-Methylimidazole Brings to the Table

1-Methylimidazole plays a role in everything from pharmaceuticals to epoxy curing agents. It’s no stranger to the research bench or industrial shelves. But the chemical’s benefits mean little if you cut corners on handling. Anyone who’s worked in a lab or stocked a storeroom has felt the sting of a leaky container or lived through the anxious moment of reading a material safety sheet for the first time. 1-Methylimidazole’s slightly fishy odor reminds me of just how quickly a safe space can become uncomfortable if you ignore good practices.

Hazards Are More Than Words in a Manual

Peer into the data, and this compound irritates skin, eyes, and throats. Breathing in the vapors, even for a short while, spices up your session with headaches or worse. In my experience, the folks who keep storage rooms cool, dry, and well-marked don’t do it for fun. They do it because it only takes one careless act to ruin a week's worth of work and health. If it spills, surfaces turn slick, and you’re one step closer to a chemical burn or an emergency visit.

Best Practices Aren’t Optional

I remember being a chemistry undergrad and seeing the mess that erupted when someone stored sensitive chemicals in the wrong cabinet. 1-Methylimidazole is no exception. A tightly sealed glass bottle, with a sturdy, chemical-resistant cap, set on a low shelf in a dedicated cabinet, keeps things predictable. Humidity encourages hydrolysis and corrosion, so I always make sure to avoid bathrooms, kitchens, or anywhere moisture collects.

Heat turns trouble into disaster. You leave the bottle out in the sun, and pressure inside starts rising, which could send the cap flying. Temperature control isn’t about perfection; it’s about avoiding surprises. Below 25°C works for most labs, though cooler is even better if nobody’s handling it for a while.

Why Isolation Matters

Cross-contamination doesn’t make headlines, but it wrecks both experiments and inventories. Acids, oxidizers, and bases—the regular troublemakers—should live far from this compound. Time spent reviewing the latest storage chart is never wasted. Segregation rules keep forgotten chemicals from taking part in unplanned reactions that sometimes play out dramatically.

Ventilation Is a Basic Need

Nobody likes a room that smells like solvents. Strong air circulation snatches away tiny leaks before anyone inhales them. Anyone who has watched a fume hood turn cloudy with vapor knows the difference fresh air makes. Don’t cut costs by skipping proper exhaust. If you don’t have a specialty chemical storage area, even a well-ventilated closet with clear signage beats a cluttered shelf by the coffee machine.

Labeling and Inventory—The Simple Steps That Save You

Clear labeling can mean the difference between a routine transfer and a full-on cleanup. Sharpies fade, so invest in chemical-resistant labels. Put date of purchase, concentration, and filler’s initials on each container. Regular audits weed out outdated batches. In a shared lab, everyone benefits from knowing what’s inside each bottle—accountability lowers mistakes, makes emergencies less likely, and helps newcomers get their footing.

Solutions: A Dose of Respect and Routine

The fix isn’t high-tech or expensive—just deliberate. Keep containers closed when not in use. Wipe up every drip. Make eye contact with safety data before touching anything unfamiliar. Good habits take a little more time at first, but over months and years, they free you from worry about what’s quietly brewing behind a cabinet door.

Up-Close with a Common Chemical

Step into a lab or a chemical plant and you may spot a well-used bottle with a label: 1-methylimidazole. In my early years working with fine chemicals, 1-methylimidazole stood out for its sharp smell and its use as a basic building block in various industrial processes—things from pharmaceuticals to specialty coatings. Many chemists rely on it for its basicity and ability to help create better drugs or plastics. Still, the everyday person probably never thinks about it.

Hazards and Health Warnings

The first concern: 1-methylimidazole can cause problems if treated casually. The chemical is a strong irritant. If it gets onto skin, it stings. Eyes? They burn, tear up, and redden fast. Inhaling it brings headaches, sore throat, and even nausea if exposure lasts long enough. Now, most of my lab work demanded gloves, eye shields, and fume hoods—those rules weren’t optional. I’ve known people rushed to the eyewash after a careless splash. It’s not the worst substance out there, but it’s far from harmless.

Official sources give extra reasons to stay careful. The European Chemicals Agency (ECHA) calls it “harmful if swallowed” and “causes skin and eye irritation.” The American Conference of Governmental Industrial Hygienists suggests exposure limits, noting potential effects with high concentrations. Animal studies point to nervous system symptoms from large doses. The evidence isn’t crystal clear about cancer risks, but scientists haven’t totally ruled them out either.

Impact Beyond the Lab

Factories using 1-methylimidazole face environmental questions, too. Spills or improper disposal can harm aquatic life. Water contamination is a worry since the substance dissolves easily. As someone who’s watched clean-ups after tank leaks, I’ve learned spill-prevention plans matter. Some workers see chemicals as a necessary evil, but lax attitudes invite trouble—inside and outside the plant fence.

Building a Safer Workplace

The answer isn’t fear, but practical respect. Proper storage keeps bottles upright and leak-free. Fume hoods pull dangerous vapors away from faces. Regular training helps workers spot symptoms before they turn serious. Labels should be clear. Spills need fast responses, using absorbent pads and waste bins specified for hazmat.

Safety at home and in local neighborhoods matters, too. Cities often require disclosure of hazardous materials, and companies publish safety data sheets for transparency. The conversation doesn’t stop at the factory door. People deserve to know what’s going on with any chemical transported through town back roads.

Protecting Workers and Communities

Simple steps build trust—high-visibility safety plans, quick reporting of spills, honest answers to community questions. If you’re in charge of chemical stockrooms, double-check those seals. If you live nearby, stay informed and speak up through city meetings. 1-methylimidazole has clear hazards, but careful handling, routine safety checks, and ongoing, honest dialogue keep both workers and neighbors much safer. The right practices don’t just prevent injury—they prove respect for the people sharing those spaces.