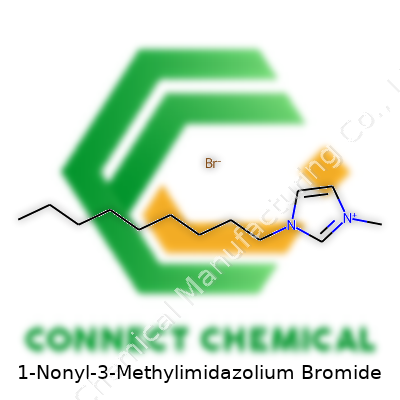

1-Nonyl-3-Methylimidazolium Bromide: A Deep Dive Into Its Story, Science, and Future

Historical Development

During the late twentieth century, academic labs started exploring room-temperature ionic liquids in search of better alternatives to volatile organic solvents. The breakthrough came when researchers discovered the practicality and surprising stability of imidazolium-based salts. Among these, 1-nonyl-3-methylimidazolium bromide, with its unique blend of a long nonyl chain and a methyl group, drew scientific interest. Unlike older salts, its structure provided greater flexibility in industrial processes. Over the past few decades, studies built a robust knowledge base on synthesis, purification, and complex ion interactions. Chemistry conferences and peer-reviewed journals became grounds for scientists to challenge assumptions, improve purity, and propose new uses. This ionic liquid evolved from a curious lab novelty to a reliable component in multiple advanced applications.

Product Overview

1-Nonyl-3-methylimidazolium bromide belongs to the family of ionic liquids characterized by their low-melting points and liquid state at ambient conditions. Researchers pursued this compound for its ability to dissolve a broad range of materials, especially in green chemistry and catalysis. Companies began to offer it in finely controlled purities for specialized research and pilot-scale industrial projects. Laboratories working with volatile organic compounds started swapping in this ionic liquid to lower fire risk and toxic emissions. The substance rarely shows up in everyday products, though it quietly plays a dependable role behind the scenes of innovation, sometimes supporting tough separations or acting as a reaction medium in organic synthesis.

Physical & Chemical Properties

A clear, viscous liquid at room temperature, 1-nonyl-3-methylimidazolium bromide combines the hydrophobicity of the nonyl group with the ionic integrity of the imidazolium and bromide moieties. Its melting point typically stays below 50°C, and the compound resists decomposition up to moderate temperatures. The bromide anion brings moderate solubility in polar solvents, while the long hydrocarbon chain tunes the liquid’s miscibility profile and viscosity. Absence of strong odor makes handling more pleasant than chlorinated solvents. Electrochemical stability allows use in systems where standard solvents decompose. Its density, refractive index, and surface tension values sit comfortably within the range of other imidazolium ionic liquids, but the nine-carbon alkyl chain boosts affinity for hydrophobic molecules. The material offers excellent conductivity, essential for use in electrochemical devices.

Technical Specifications & Labeling

Suppliers typically deliver 1-nonyl-3-methylimidazolium bromide as a high-purity sample verified by NMR and mass spectrometry. Documentation covers molecular formula (C13H25BrN2), molar mass, lot purity (often 98%+), and residual moisture. Packaging warns against exposure to open flames and excessive humidity, as both can affect product stability. Labels provide hazard pictograms where required, with safe handling advice in both printed and online forms. Regulatory numbers and barcodes track each lot from production to customer. Chemical hygiene and up-to-date material safety data sheets come standard, reflecting the industry’s move towards full transparency. Batch records include spectral data to guarantee identity.

Preparation Method

Labs generally prepare 1-nonyl-3-methylimidazolium bromide through a two-step method. The first step couples 1-nonylbromide with 1-methylimidazole in a solvent-free or minimal solvent approach under controlled temperature, allowing alkylation of the nitrogen atom on the imidazole ring. Purification follows via repeated washing and recrystallization, removing unreacted materials and salts. Advanced protocols opt for solvent recycling and energy-efficient temperature controls, reflecting industry trends toward sustainability. Researchers scaled this process from milligrams in Erlenmeyer flasks to kilograms in glass reactors as new markets emerged. Protocols often stress the importance of exclusion of water, since hydrolysis can compete with the desired reaction and impact purity.

Chemical Reactions & Modifications

The imidazolium ring in this salt stays reactive under various conditions, which invites chemical modifications and functionalization. Scientists have succeeded in anion exchange, swapping out bromide for other halides or more exotic anions to tune ionic conductivity, solubility, and compatibility with other solvents. Incorporation of functional groups on the nonyl chain provides a path to designer ionic liquids. The core structure takes part in ion-pairing reactions and can serve as a phase-transfer catalyst without decomposing. Literature reports stable performance under light acid or base exposure, yet careful control is vital to keep side reactions from introducing impurities—especially in pharmaceutical or battery applications.

Synonyms & Product Names

Depending on region or supplier, users find 1-nonyl-3-methylimidazolium bromide listed under names such as [C9mim]Br, N-Nony-1-methylimidazolium bromide, or nonylmethylimidazolium bromide. Catalog numbers, registry numbers like CAS, and proprietary branding names also crop up. Researchers recognize these alternate names thanks to the international nature of chemical science; however, accurate labeling matters, as a simple typo can lead to delays or experimental errors. Some companies use abbreviations such as [N9-MIM]Br, especially in technical datasheets or patents. Despite the variations, the core identity centers around the imidazolium-cored cation and the bromide counterion.

Safety & Operational Standards

Chemists approach this compound with the same precaution they use for other quaternary ammonium salts. Eye and skin protection along with ventilation remain standard during weighing, mixing, and heating. Toxicology studies point to moderate hazard to skin and eyes, along with sensitization when inhaled as dust. Direct ingestion or prolonged exposure carries risks, especially when compounded by heated vapors. Clean-up protocols favor absorbent materials and tightly labeled hazardous waste. Storage in sealed, labeled glassware, away from oxidizers or acids, avoids accidental reactions. The industry leans heavily on proper documentation, employee training, and scheduled audits. This culture of safety comes from lessons learned during the early years of organic synthesis work, before today’s mature regulatory environment took shape.

Application Area

Research teams put 1-nonyl-3-methylimidazolium bromide to work in extraction, catalysis, and materials science. As a solvent for metal ion extraction, it outperforms many traditional organic solvents by pairing high selectivity with minimal volatility. In biochemistry, it stabilizes enzymes in non-aqueous environments, boosting reaction yields or selectivity. Material scientists embed this ionic liquid in polymer membranes, aiming to create smarter sensors and more durable high-performance materials. Recent years saw breakthroughs in lithium battery development, where this salt’s ionic mobility opens doors for safer, more efficient solid electrolytes. In carbon capture experiments, researchers explore how structural tweaks to the nonyl chain influence CO2 solubility and selectivity. Lab techs and graduate students constantly test new applications, eager to push beyond the established frontiers.

Research & Development

University departments and industrial research arms invest in understanding structure-property relationships. Published papers often track how chain length, counterion, and ring substitutions combine to affect solubility, conductivity, or toxicity. Intellectual property races spur new synthetic routes, tailored derivatives, or improved recycling procedures. Companies look for sustainable processes that cut manufacturing costs while boosting yield. Journal editors demand rigorous standards for reporting purity, analytical data, and reproducibility. Collaboration across continents leads to information sharing that fuels ever-faster organic synthesis and greener chemistry outcomes. In my experience, hands-on troubleshooting in the lab—tackling stubborn emulsions or optimizing a column—teaches critical lessons that no review article can capture. Breakthroughs often begin with someone noticing a “non-standard” result during a routine reaction.

Toxicity Research

Scientists approach toxicity studies with care, blending cell culture, aquatic assays, and animal model work to build a nuanced toxicity profile. Preliminary results show low acute toxicity but raise questions about long-term environmental fate, especially in aquatic systems. The hydrophobic chain may slow biodegradation, leading to possible bioaccumulation. Regulatory agencies watch new data closely, and many journals require clear hazard assessment in publication. Responsible labs treat waste according to hazardous material protocols, minimizing environmental release. Studies probe metabolic pathways using advanced analytical techniques; these efforts reveal which metabolites form under biological or environmental stress. Industry and academia align on the priority for safety, knowing that one overlooked risk could jeopardize both progress and public trust.

Future Prospects

As technology pivots towards greener manufacturing, ionic liquids like 1-nonyl-3-methylimidazolium bromide stake their claim as cornerstones of safer, more efficient processes. Engineers and chemists seek to harness its properties for next-generation batteries, industrial separations, and eco-friendly syntheses. Meanwhile, pressure mounts to design ever-safer variants—lower toxicity, tunable lifespan, faster breakdown in the environment. For those of us working in the lab, each new application brings a chance to contribute to cleaner industry, smaller environmental footprints, and smarter science. Global collaboration, robust data sharing, and responsible stewardship remain critical to pushing both safety and performance forward. Chemical innovation is not a solitary act, but the result of teams, experiments, and lessons collected across many years, all striving to create compounds like this that truly move science forward.

Breaking Down the Basics

1-Nonyl-3-Methylimidazolium Bromide isn’t a chemical that pops up in everyday conversation, but in the lab, it has quite the reputation. This compound falls into the group of ionic liquids, salt-like materials that melt below the boiling point of water. What makes ionic liquids interesting is how they handle tasks that would trip up traditional solvents. For chemists and engineers, this brings new avenues for cleaner technology and more efficient processes.

An Unconventional Solvent

I’ve watched green chemistry pick up momentum. The usual solvents—like acetone, methanol, or toluene—pose health and environmental questions we can’t afford to ignore. 1-Nonyl-3-Methylimidazolium Bromide, thanks to its structure, has stepped up as a potential replacement. This ionic liquid doesn’t evaporate into the air like volatile organic solvents, which means less harmful vapor indoors and fewer headaches for workers. It’s less flammable and often less prone to contamination from moisture in the air, giving labs cleaner, more controlled reactions.

Separation and Extraction

This compound shines in tasks such as extracting metals or organic compounds from mixtures. The oil industry still digs deep for answers, and ionic liquids offer safer ways to pull metals from ore, or even clean up petroleum spills, because they’re reusable and respond well to tweaks in temperature or pH. Scientists looking for sustainable extraction methods have found that this compound often captures trace metals or dyes better than its traditional rivals. That kind of selective grabbing power cuts down on waste and cost. Studies show some ionic liquids can help recover over 90% of a metal from electronic waste, which is not just good for the planet, but with e-waste piling up, also good for industry.

Catalyst and Reaction Medium

Chemical reactions can ride smoother with the right medium. 1-Nonyl-3-Methylimidazolium Bromide often acts as both solvent and catalyst, speeding up processes while supporting better yields. Synthetic chemists tell me they’ve managed tough reactions that stalled out with conventional methods, just by adding this compound. It lets labs cut down hazardous byproducts, which meets stricter regulations and keeps downstream treatment costs in check.

Challenges and Looking Ahead

The story isn’t all rosy. Making these ionic liquids costs more than mixing up standard solvents. Large-scale applications need solutions that fit both safety and economic needs. Long-term toxicity or environmental impact isn’t always fully mapped out, especially where regulations lag behind new molecular blends. One step that helps—manufacturers invest more in testing. Universities and research groups publish data fast, sharing breakthroughs and hiccups for everyone to learn from.

The push for greener chemistry rests on knowledge, honesty, and teamwork. If industries adopt ionic liquids like 1-Nonyl-3-Methylimidazolium Bromide for the right jobs, and not just for marketing gloss, we get a real chance to clean up technology, from pharmaceuticals to mining, without turning back the clock on convenience or quality. That balance takes effort, but history says we get better results once we recognize the stakes and roll up our sleeves together.

Understanding the Risks of Improper Storage

Store 1-Nonyl-3-Methylimidazolium Bromide like it matters, because it does. This isn’t just a random powder tossed on a shelf. Chemicals with complex organic structures can change their identity if the storage doesn’t line up with best practices. Leaving this ionic liquid in sunlight or in a humid room equals leaving a puddle of honey in your garage—eventually, things won’t look or work the same.

Getting the Temperature Right

Heat brings its own trouble in a lab. If the storage room gets too warm, the risk for decomposition gets real. Most manufacturers and reference guides peg room temperature (about 20–25°C) as safe for stability, but cooler is usually better, if you can swing it. Stick this chemical in a dry, temperature-controlled cabinet. Avoiding extremes protects against chemical breakdown. If you have access to a refrigerator meant for chemicals—not the staff fridge used for sodas and sandwiches—that’s even better.

Keep It Dry—Moisture Leads to Problems

Moisture does a number on ionic liquids. With this compound, water vapor acts like an unwelcome guest, bringing changes to both the consistency and chemical behavior. When I used to run experiments with similar compounds, any careless moment that left a flask uncapped meant running the risk of contamination. Use desiccators or sealed containers lined with desiccant packs. If those aren’t handy, pick an airtight plastic or glass bottle and keep it closed unless in use. Lab stories pile up fast about ruined batches just from letting a reagent "breathe" on a humid day. Don’t join that club.

Light Protection: Shades Down for Safety

Leaving light-sensitive chemicals exposed won’t hurt immediately, but slow damage creeps up. My lab used amber glass bottles, and once, we tested identical compounds stored in clear and amber containers. The clear-bottle sample lost its punch fast, while the amber one stuck around. Excessive exposure to light means increased risk for both chemical breakdown and hazard formation. Store 1-Nonyl-3-Methylimidazolium Bromide away from direct sunlight, and use colored glass if possible.

Safe Labelling and User Practices

Labels sound boring, but watch someone mix up two similar chemicals on a deadline and you’ll see why clear labels matter. Chemical name, lot number, and date of arrival go on every bottle, every time. Supply chain glitches can mean waiting weeks for a new batch. Save yourself the headache down the line—not just for you, but for anyone who uses the same bench.

Supporting Reliable Research & Handling

Quality data depends on chemical integrity. As a researcher, I’ve chased lost hours back to overlooked storage basics. Common sense steps—dry place, temperature control, and labeled, airtight containers—prevent disaster. Having clear, accessible Material Safety Data Sheets (MSDS) nearby takes care of those stepping into the lab for the first time. Familiarize newcomers with storage signs and routines.

Finding Simple Solutions for Daily Lab Life

Nobody wants to spend grant money twice on the same chemical. Rotating stock, checking integrity, and ditching questionable containers saves trouble. Companies and schools can prevent headaches by keeping a central log and running quick weekly storage checks. Tag expiring containers, and create a "quarantine" spot for anything suspect. Less waste, less risk, and more useful research depend on what we do long before the experiment begins. Simple fixes go a long way in keeping chemicals like 1-Nonyl-3-Methylimidazolium Bromide working for you, not against you.

Understanding 1-Nonyl-3-Methylimidazolium Bromide

1-Nonyl-3-methylimidazolium bromide falls into the category of ionic liquids. Scientists have explored these chemicals for roles like solvents, catalysts, and a bunch of tasks in modern labs. Just because it isn’t a familiar name for most people, doesn’t mean it escapes safety concerns. Many chemicals with long alkyl chains paired with imidazolium are good at dissolving things and stubbornly refuse to evaporate. That makes them easy to handle in a chemistry setting but trickier when it comes to the environment or personal health.

Hazards and Toxicity Profiles

Looking at toxicity, information from peer-reviewed literature, including studies referenced in ChemSpider and PubChem, gives us a few important pointers. Many imidazolium-based ionic liquids have a reputation for moderate to high toxicity when compared to more basic salts. Toxicity often scales with the length of the alkyl chain—the longer the carbon tail, the bigger the concern about harm to aquatic life and cells. 1-Nonyl-3-methylimidazolium bromide has a nine-carbon chain, sitting in that zone where researchers start worrying about environmental persistence and biological toxicity.

Lab tests have shown that similar compounds disturb cell membranes and can damage aquatic ecosystems. A real-world example comes from studies observing Daphnia magna, a tiny water flea used worldwide to track water health. These organisms often show stress or die-off after exposure to imidazolium compounds, especially as the tails get longer.

Human Exposure and Handling

If you work with this compound, it’s easy to underestimate the risks because ionic liquids don’t smell much or evaporate quickly. Skin and eye contact poses legitimate concerns. Most materials safety data sheets (MSDS) for this class of chemicals recommend gloves, goggles, and careful handling in a chemical fume hood. No one wants to deal with skin irritation or worse, and absorption isn't out of the question.

Why Scrutiny Matters

Many companies tout ionic liquids as “green solvents.” The reality looks different once a substance sticks around in water or soil and interacts with living creatures. Safety claims sometimes fall apart under careful scrutiny, especially if the focus sticks to flammability and volatility without looking at biological effects. In my own work with sand filters and frog tadpoles, we learned that compounds can have hidden consequences, showing up in changed growth rates or skewed behaviors, long after the initial spill.

Finding Better Ground

Researchers need to dig deeper into the long-term impact of these chemicals. Waste management and effluent controls should keep up with new compounds. Substituting shorter-chain imidazolium salts or using entirely different classes of solvents can help. Practicing green chemistry starts with knowing the true impact of what lands on the workbench, under the hood, or in the drain. It’s not just about what works in the lab—people need to weigh what happens to the world outside.

Moving Toward Safer Chemistry

Keep safety routines tight. Demand robust toxicity data from suppliers. Push for transparency and updated safety sheets, even if the compound wears a “green” reputation. Every chemist, teacher, or student touching these liquids should learn from the growing pile of evidence and support policies that ask tough questions about long-term safety. Small steps—like double-gloving, using containment, and choosing less persistent chemicals—help bridge the gap between lab science and real-world responsibility.

Getting to Know the Details

Diving into the world of ionic liquids, 1-Nonyl-3-Methylimidazolium Bromide stands out with its own story. Chemists and engineers tackle its chemical formula, C13H25BrN2, and molecular weight, 301.25 g/mol, because these numbers say so much about how a compound will behave in the real world. I’ve handled plenty of tables filled with similar formulas, but every compound carves out its own place in research and industry.

More than Just Numbers

It’s easy to glance at a formula and move on. That’s a mistake. The presence of a nine-carbon nonyl chain and a methyl group attached to the imidazolium ring shapes how this compound interacts with solvents, metals, and organic molecules. For researchers looking for new ways to drive reactions or build new electrochemical devices, that structural difference shifts outcomes.

Experience teaches you the value of these details. In the lab, a shift in one chain length or an extra atom can change the way a substance dissolves—sometimes making the difference between a failed trial and a clean product. Toxicity and environmental impact often ride on these very same atoms and bonds.

Why Ionic Liquids Get Attention

The world wants cleaner solutions for chemistry. Ionic liquids, like this one, step up because they cut down on the use of volatile organic solvents. They don’t evaporate easily, which slashes pollution. But scientists and engineers still need to track toxicity, water solubility, and overall persistence. Those traits show up in the structure described above.

Researchers have shown that imidazolium-based ionic liquids offer promise in batteries and electroplating because of their unique stability and ion conductivity. That’s not just theory—I’ve seen companies dig deep into pilot projects after reviewing these basic chemical facts. Safe handling, actual waste management, and environmental impact all link back to the kinds of atoms in the compound.

Challenges and Looking Ahead

Novelty shouldn't replace caution. Many ionic liquids raised hopes, then gave disappointment when large-scale tests revealed unexpected toxicity to aquatic life. I'm reminded of a case from a few years ago: a closely related imidazolium compound showed strong antimicrobial properties, which raised hopes for pharma, but tests revealed persistence in water sources. These outcomes press home the need for not only understanding the chemical formula, but keeping sight of what those formulas do outside the lab.

One solution: push early for biodegradability and full life-cycle impacts before moving a new ionic liquid from lab to factory. Testing in diverse ecosystems rather than single-lab settings helps avoid surprises. Some groups have started tweaking the nonyl chain or adding biodegradable side groups, aiming for compounds that break down instead of sticking around.

Behind every set of chemical numbers, you'll find a long chain of consequences, both for chemistry and for the larger world. So every time a new compound enters the spotlight, those details—like the molecular weight of 301.25 g/mol and a formula that spells out every corner of its structure—ought to get real attention.

Why Handling Matters

Many of today’s labs use chemicals like 1-Nonyl-3-Methylimidazolium Bromide as part of research into solvents and materials. The risk in working with these ionic liquids lies less with their volatility and more with their tendency to linger. Getting careless with containment, storage, or disposal exposes workers to unnecessary risk, and can bring real trouble down the line if the substance escapes the lab—nobody wants that on their watch.

Workplace Safety Steps

Personal experience has taught me that treating any unfamiliar chemical with respect makes for fewer headaches. Good lab routines keep accidents from snowballing. Workers should suit up in gloves made for chemical resistance, wear goggles with side protection, and work in a well-ventilated space every time they open a new bottle. While data show this compound isn’t a dramatic inhalation risk, some ionic liquids can irritate skin and mucous membranes, so you can’t take shortcuts. I always keep the original container sealed tight, away from sunlight and moisture, and label it so others know exactly what they’re dealing with. One slip, or a misread label, and the clean-up gets messier than it needs to be.

Spills sometimes happen. The easiest cleanup uses absorbent materials like vermiculite or sand, which I then sweep up and put in a sealed waste container. Plenty of people want to grab paper towels and water—a bad idea. Water might spread the mess or encourage reactions you can't predict without digging through the safety datasheet.

Environmental Responsibility

Some folks don’t think twice before pouring things down the lab drain. That habit risks a lot more than a slap on the wrist. Ionic liquids such as this one aren’t simple organic solvents; wastewater facilities might not break them down fast enough, so they build up in rivers or even drinking water. Regulatory bodies like the EPA have flagged persistent chemicals as a priority concern for decades—safer waterways depend on good habits upstream. No one wants to drink trace chemicals, so every lab shares a bit of the load in keeping contaminants out of municipal systems.

Practical Disposal Strategies

Disposal isn't just tossing a container in the trash. The right solution follows local hazardous waste regulations. I learned early on to keep a specific waste drum for ionic liquids, clearly labeled and separated from acids, bases, and solvents. Combining streams without checking compatibility courts disaster. Once full, the waste drum goes to a licensed hazardous waste processor. Their equipment and expertise mean fewer risks to workers and the public.

Communication with local authorities makes compliance smoother. I always double-check the rules for my county. They often provide drop-off days or recommend certified contractors for transportation. In some places, extra fees go with specialized waste, but no shortcut makes up for clean water and safe communities.

Moving Forward

I’ve seen labs do a lot more training over the past decade, since researchers started relying on ionic liquids for greener chemistry. Investing time in regular safety refreshers builds stronger habits. The more comfortable workers get with routine procedures, the less likely something nasty sneaks through a crack in attention. Labs thrive when everyone on the team takes shared ownership of safety—not just for themselves, but for the entire community.