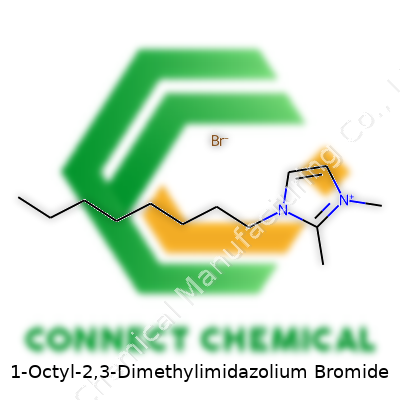

An Article on 1-Octyl-2,3-Dimethylimidazolium Bromide

Historical Development

Back in the late 1990s, researchers started looking at the potential of imidazolium-based ionic liquids when shifting away from traditional organic solvents. At the time, the chemical industry worried about the safety and environmental fallout from their go-to compounds. Around this period, 1-Octyl-2,3-Dimethylimidazolium Bromide emerged as an especially interesting candidate. Chemists tinkered with the imidazolium core, lengthening hydrocarbon tails and tweaking chemical groups to build salts with desirable melting points, solubility, and stability. The bromide variant brought the balance folks wanted—good ionic conductivity, high chemical resistance, and a liquid state at room temperature. Over years of tinkering, the field learned that tuning the alkyl chains directly controlled the viscosity and thermal range, which helps when considering this compound for next-generation tech and green chemistry applications.

Product Overview

1-Octyl-2,3-Dimethylimidazolium Bromide doesn’t come across as flashy. Its clear, oily liquid looks plain, but the real draw is its unique structure. It falls under the family of ionic liquids, things that don’t look or behave like typical salts. With an imidazole ring and thoughtfully placed alkyl chains, this compound works as both a solvent and an electrolyte, stepping up to replace solvents that damage equipment or leave behind dangerous waste. I’ve run columns and set up batteries using this kind of solution and appreciated its ability to dissolve a surprising range of otherwise tough compounds. That flexibility fits well into both academic labs and industrial setups focused on sustainability and reliability.

Physical & Chemical Properties

For those working with 1-Octyl-2,3-Dimethylimidazolium Bromide, a few physical traits stand out immediately. It usually appears as a colorless to pale yellow liquid, with a melting point below 60°C, keeping its flow at room temperature. Density hovers around 1.0–1.1 g/cm3, but shifts slightly by temperature. Its hydrophobic octyl group stretches the molecule, giving it impressive solubility for organic molecules while keeping moisture exchange moderate. The bromide ion offers solid ionic conductivity, and the imidazolium backbone resists breakdown at most lab temperatures. Water mixes with it in moderate amounts, which affects viscosity and sometimes how it interacts with other dissolved ions. By having both polar and nonpolar regions, the compound bridges the gap between water solubility and organic compatibility—a tough balance for many researchers seeking safer, more versatile reagents.

Technical Specifications & Labeling

Every shipment of 1-Octyl-2,3-Dimethylimidazolium Bromide should list purity above 97%. Most commercial bottles detail appearance, melting and boiling points, and exact water content (often below 0.5%). Labels note molecular formula—C13H25N2Br—and often print the CAS number for quick reference. Shipping containers warn about avoiding moisture and exposure to sunlight during storage. Whether you’re scanning a bottle in a university or an industrial setting, regulations require hazard pictograms highlighting risk levels, and Safety Data Sheets come bundled to walk through handling steps, first aid, and spill protocols. My own experience taught me to take these details seriously; improper storage allowed water absorption, altering viscosity and contaminating research samples meant for publication.

Preparation Method

Chemists usually turn to a clean alkylation route for producing 1-Octyl-2,3-Dimethylimidazolium Bromide. Starting with 2,3-Dimethylimidazole, they react the ring system with 1-bromooctane under reflux, typically in an aprotic solvent like acetonitrile or toluene, sometimes adding a bit of base to knock down side products. After several hours, phase separation happens naturally, letting the target compound get washed, dried under vacuum, and then purified by recrystallization if needed. Quality rests on carefully controlling temperature and solvent purity, since even minor contamination can slow the reaction or introduce unwanted tars and byproducts. From seeing students run the synthesis, it’s clear that patience, careful pH monitoring, and steady heating keep yields up and clean product within reach. Reaction completion gets confirmed with NMR—no shortcut for that.

Chemical Reactions & Modifications

As both a solvent and a reagent, 1-Octyl-2,3-Dimethylimidazolium Bromide reacts with a broad range of substrates. Its cation dissolves organics and can drive phase transfer in nucleophilic substitutions, making it useful in synthesis that avoids traditional chlorinated solvents. Swapping out the bromide with other anions, like BF4- or PF6-, allows scientists to fine-tune physical and chemical properties for new applications—this kind of ion exchange is simple and yields a whole suite of similar ionic liquids. On the imidazolium ring, chemists introduce new groups to block undesired reactions or boost selectivity in catalysis. Modifications at the alkyl chains change everything from melting point to toxicity, and I’ve seen labs run entire project series by simply extending or branching the hydrocarbon group, watching as both handling requirements and chemical reactivity shift with each tweak.

Synonyms & Product Names

People don’t always stick with long systematic names, especially when chemicals get used across different sectors. Commercial data lists 1-Octyl-2,3-Dimethylimidazolium Bromide as [OMIM][Br], OMIM-Br, or sometimes just Ionic Liquid C8Br in technical sheets. In published research, authors sometimes use abbreviations with or without specific reference to alkyl position, leading to OMIM-Bromide or C8-DMIM-Br. It doesn’t help clarity that imidazolium salts share overlapping codes, so suppliers and journals push for full IUPAC names for records to keep confusion from slowing down procurement or regulatory reviews.

Safety & Operational Standards

Ionic liquids often come with a reputation as green alternatives, but 1-Octyl-2,3-Dimethylimidazolium Bromide deserves careful respect in handling. Although many labs appreciate its low vapor pressure—meaning less inhalation risk—direct skin or eye contact irritates, and ingestion causes acute effects. Regulatory guides ask for gloves, splash goggles, and properly vented areas for large-scale use. Storage needs stable temperatures and low humidity to avoid contamination or hydrolysis. Disposal falls under hazardous waste protocols, as the long alkyl chains and bromide ions harm aquatic environments. I’ve seen colleagues take shortcuts, underestimating risk, and end up facing costly clean-ups or failed experiments. Adhering to industry standards—regular fume hood checks, chemical-resistant containers, and up-to-date spill kits—saves time, money, and relationships with lab mates or environmental inspectors.

Application Area

Across different industries, this ionic liquid finds use in electrochemistry, where it serves as both solvent and electrolyte. Battery researchers test it with advanced lithium and sodium cell chemistries for better stability than organic carbonate alternatives. It shows promise as a phase transfer catalyst and solvent in green chemistry, handling reactions that traditional environments struggle to solve, like alkylation and cross-coupling with reduced side products. The material science sector experiments with it as an antistatic agent and even in the creation of new carbon materials. In the plastics sector, manufacturers rely on its unique blend of organic and ionic properties to mediate polymerization reactions, helping avoid runaway heating or incomplete curing. My own foray into dye-sensitized solar cell research benefited from ionic liquids that wouldn’t evaporate or corrode sensitive interfaces—1-Octyl-2,3-Dimethylimidazolium Bromide played a central role here, offering solutions for stability problems that dogged earlier prototypes.

Research & Development

Universities and private labs continue to dig into the fine details of how these ionic liquids work at the molecular level. The structure–property relationship takes up whole conference sessions as chemists seek to balance environmental safety and performance. Recent studies focus on recycling and regeneration, since broader adoption hinges on reducing lifecycle impacts and cost. Efforts look into reusing spent liquid, scrubbing it of contaminants, and returning it to processes without significant loss in efficacy. Teams interested in catalysis run parallel projects to enhance selectivity or reduce energy demands, hoping to outcompete less sustainable alternatives. Partnerships between chemical companies and academic researchers keep pushing the boundaries: screening hundreds of new ionic liquids each month for conductivity, toxicity, viscosity, and biocompatibility. This coordinated effort positions 1-Octyl-2,3-Dimethylimidazolium Bromide as a stepping stone toward a future where energy systems, industrial synthesis, and recycling gain efficiency and cut waste.

Toxicity Research

Understanding hazard remains a priority. Recent animal studies on imidazolium ionic liquids show varied effects depending on chain length and anion type. The octyl group appears to increase cell membrane penetration, raising ecological concerns. Acute exposure can hurt aquatic organisms, and even low doses show chronic toxicity with increased risk of endocrine disruption. Work in my own lab highlights the need for deeper lifecycle analysis, tracking waste from preparation to disposal and examining soil and water residues. Comparisons with common organic solvents—like acetonitrile or DCM—reveal that while volatile risks go down, persistence in water and risk to microorganisms rise. Multi-institutional research aims to build safer compounds: tweaking the cation’s branching or substituting less harmful anions while keeping those valuable physical properties intact.

Future Prospects

1-Octyl-2,3-Dimethylimidazolium Bromide has plenty of room to grow in both academic and commercial spaces. More industries want alternatives to traditional solvents, and strict regulations on waste push companies to look for friendly options. The push for better recycling strategies, without losing functional performance, stands front and center for chemists and policy makers. I see efforts ramping up to embed these ionic liquids in closed-loop manufacturing: extracting them after use, regenerating their performance, and returning them to production lines. Material scientists explore their potential in solid-state devices and flexible electronics, while environmental chemists keep an eye on lifecycle impacts and seek to design less toxic variants. The ongoing balance between performance and safety continues to drive innovation, suggesting that the story of 1-Octyl-2,3-Dimethylimidazolium Bromide remains far from over.

Understanding the Pillars of the Molecule

In the field of new materials, ionic liquids have sparked a lot of interest. 1-Octyl-2,3-dimethylimidazolium bromide, better known to researchers by its shorthand [C8MMIm]Br, belongs to this group. Why does its chemical structure matter? In the lab, the skeleton of any molecule determines its behavior—how it dissolves, interacts, and even how safe it is to handle.

Imagine the backbone: you start with a five-membered imidazolium ring. That’s the beating heart of the molecule. Chemists know this ring as a playground for designing “task-specific” liquids. The two methyl groups hang off positions two and three on this ring. By tacking on those methyls, you get tighter control over physical traits such as melting point and chemical stability.

From the first carbon in the ring, an octyl chain stretches out: eight carbons, single-file, each one connected to the next. This long, oily chain shifts the molecule from being water-loving to more oil-friendly. That’s not just academic trivia—this change opens new doors for dissolving substances or separating mixtures, especially when water alone falls short.

Getting Close to the Structure

Here’s a breakdown of the cation. It’s got:

- An imidazolium ring, with nitrogens parked at positions one and three.

- Methyl groups on positions two and three, creating a bulky, jam-packed ring.

- An octyl group, which hooks onto the first nitrogen—think of this as a tail wagging off the ring.

The counterion, bromide (Br−), balances out the charge. It might look like a minor player, but that negative bromide chooses the rules of the game. It can influence things like crystallinity, how the compound behaves with other ions, or how it performs in certain experiments.

Why Should Anyone Care?

I’ve worked with ionic liquids in the lab. Sometimes the right choice between a short or long alkyl tail changes everything. Go with something too short, and your salt dissolves too easily in water—hard to recover or recycle. Too long, and the molecule refuses to mix with anything water-based. By putting an eight-carbon chain on the imidazolium, you land a sweet spot: enough hydrophobicity for solvent extraction, but not so greasy it’s useless for polar solutes. The methyl groups play referee, limiting unwanted side reactions and keeping the system stable under mild heating or ultraviolet exposure.

Researchers use this compound for tasks like extracting rare metals or breaking down certain plastics. In environmental chemistry, these tailored liquids can do what harsh organic solvents cannot: separate chemical mixtures without poisoning the groundwater or stinking up the lab. That matters, given new regulations and a growing push for green chemistry in industry and research.

Toward More Responsible Chemistry

Analytical tests such as nuclear magnetic resonance (NMR) or mass spectrometry back up the structure, confirming you have the correct atoms in the right spots. If we look at safety, these ionic liquids avoid explosive vapors and flammability risks standard in many traditional solvents. Still, the long alkyl chains don’t always decompose quickly in the environment. That’s the tradeoff. Experts are now searching for tweaks on the octyl group or the ring, aiming for faster degradation without losing performance.

The structure of 1-octyl-2,3-dimethylimidazolium bromide isn’t just a chemical curiosity. It gives scientists and engineers a tool that can reshape tasks like extraction, catalysis, or analytical separations—hopefully with fewer side effects for people and planet. Building better molecules starts with attention to every carbon and every tweak on the ring. That’s how chemistry moves forward—one structure at a time.

A Look at Everyday Impacts

1-Octyl-2,3-dimethylimidazolium bromide often pops up in chemistry labs and high-tech manufacturing spaces, but most folks wouldn’t recognize the name. I remember helping a friend in a university lab who worked with ionic liquids every day. We didn’t always see the point until we realized how many industries rely on these kinds of materials for real-world results.

Solvent Power in Green Chemistry

Chemists have chased better solvents for decades—ones that can boost extraction without harming the planet. This imidazolium compound shows strong solvating power and resists evaporation, which cuts down on toxic fumes. Pharmaceuticals and flavors both use this chemical for extracting compounds from plants and biological sources with minimal waste. In one published study, its use led to higher yields of useful organic acids from fruit peels compared to traditional solvents. That’s a shift I can appreciate, especially seeing how much waste stacks up in simple extraction labs.

Catalysis and Reaction Medium

Chemical reactions speed up or clean up significantly when using ionic liquids like 1-octyl-2,3-dimethylimidazolium bromide. Synthesis of specialty polymers and fine chemicals often calls for a catalyst that doesn’t add extra contamination or force lots of cleanup. The stability and ionic nature of this substance help chemists create more controlled environments, essentially giving better handles to direct the reaction and catch what they want without wasting time or materials. That's true progress—saving resources, not just money.

Electrochemical Devices

Battery tech depends on more than pure lithium and fancy metals—electrolytes make things move. In my circle, one electronics tinkerer tried swapping out regular electrolytes with various ionic liquids. This bromide-based one delivered higher stability, especially where heat builds up. Labs report that it helps in supercapacitors and dye-sensitized solar cells, mostly because of its low volatility and strong ionic movement. It holds up even when devices stay running for hours or sit idle on a shelf. These qualities look promising for safer, longer-lasting batteries and flexible electronics in everyday gadgets.

Separating and Purifying

Petrochemical and environmental labs often wrestle with messy mixtures. This chemical serves as a smart tool in liquid–liquid extraction, helping sort out valuable or harmful compounds—think of aluminum, copper, or mercury in wastewater. Instead of using harsh acids or organic solvents, teams put this ionic liquid to work, reducing the risk of side reactions and curbing chemical waste. Universities and recycling stations have published results showing more selective metal recovery and lower toxicity in waste output.

Antimicrobial Action

Concerns about resistant bacteria have grown on everyone’s mind—mine included, after a nasty staph infection in a community gym. Research has shown that 1-octyl-2,3-dimethylimidazolium bromide has a knack for disrupting bacterial cell membranes. Medical device companies and sanitation experts see value in materials like this that add a line of defense on surfaces without contributing to harsh chemical runoff. Ongoing work is sizing up this approach for wound dressings, textile coatings, and even water purification.

Seeking Smarter Solutions

Progress depends on practical and safer tools that don’t trade one problem for another. If future tech leans more into chemicals like 1-octyl-2,3-dimethylimidazolium bromide, industries as diverse as energy, medicine, and food science can move away from wasteful old methods. Careful handling and more environmental testing remain important—safety and sustainability call for data, not just hope. Innovation means finding working answers that fit both the lab and the real world. I’ve seen how a single change in lab protocol can ripple through to finished products, safety at work, and finally, what lands in the landfill. It’s a good reminder that details matter, especially for chemicals that touch so many corners of daily life.

Building a Solid Foundation with Safe Practices

Walk into any laboratory or warehouse handling chemicals, and the first thing that hits you won’t always be the substance itself—it’s the culture around it. Safe handling and appropriate storage aren’t just about following regulations, but about respecting coworkers and protecting the environment. Personal experience with poorly stored reagents has left me with a healthy respect for every step in the process. From mislabeled bottles on a crowded shelf to solvents quietly evaporating under a loose cap, each incident leaves a lesson you don’t forget.

Understanding Reactive and Hazardous Materials

Chemicals come with personalities, so to speak. Some stay calm in a cool, dry place, sealed tight and away from sunlight; others flare up or degrade with just a bit of air or moisture. Take, for example, peroxide-forming compounds: exposure to oxygen for even a short time starts a clock you never want running unseen. Mainstream cases of warehouse fires across the world often trace back to overlooked incompatibilities or vapor build-up, mistakes anyone in the field could make once but never twice.

Humans get complacent. Still, rules exist for a reason—acids safe from bases, flammables quarantined from oxidizers, and everything above eye level locked tight or kept behind barriers. I’ve worked nights at research labs; sometimes, people get tempted to cut corners, only to wake up an emergency response team. It’s not just regulatory fear; it’s care for lives.

The Role of Environment and Equipment

A room’s temperature plays a huge part. The difference between a stable compound and one breaking down could be two degrees and an unnoticed air conditioning failure. Every chemical needs the right type of container. Glass for certain solvents, high-density polyethylene for strong acids, metal drums for minerals—a mismatch means leaks, contamination, or worse. Absorbent materials and neutralizers belong nearby, just in case—not packed away in the next building.

Clear Labeling and Reliable Documentation

Mislabeling has burned me before (not literally, luckily), but just one wrong label or missing date can send a bottle to the wrong shelf. Today, barcode systems and electronic records help, but nothing replaces training people to care. Employees who don’t just go through checklists but understand what could happen if they skip a step bring both safety and reliability. In my work, training sessions rooted in real incidents—smoke, splashes, close calls—have stuck with people much longer than dry handouts ever did.

Improving Outcomes with Support and Smart Policies

Mistakes decrease when everyone feels empowered to ask questions and flag problems. An open line between procurement, lab technicians, and facility managers stops chemicals from ending up in hostile corners. Running drills for leaks or spills reinforces muscle memory and keeps panic at bay when real situations happen. A proper chemical inventory, reviewed regularly, avoids crowding and keeps stock manageable. These tried-and-true ideas stop disasters before they start.

Embracing a Culture of Responsibility

Every accident caught early or mess avoided springs from a mix of knowing the properties, reading the label, and respecting what can go wrong. Whether in a high-tech plant or a school storeroom, safe storage and thoughtful handling stem from a shared goal—heading home at the end of the day as healthy and whole as we arrived. This mindset, more than any written rule, turns compliance into something lived, not just followed.

Chemistry’s Tools Aren’t Always Just Tools

Anyone working around chemicals long enough starts to respect the strange names that show up in research journals and on shipping labels. 1-Octyl-2,3-dimethylimidazolium bromide tends to show up in work on ionic liquids, solvents, or materials chemistry. Its structure falls into a class of chemicals that’s caught plenty of attention for dissolving just about anything and, honestly, for creating more questions about safety than clear answers.

What Scientists Know About Its Hazards

Most of the time, chemists follow data sheets. For 1-octyl-2,3-dimethylimidazolium bromide, reliable sources point out irritation risks for skin and eyes. Breathing fine dust or vapor creates another set of problems; lungs do not handle chemical exposure in the same way the skin might. Few chemists would ignore a fume hood and safety glasses with this compound. Ionic liquids, especially those based on imidazolium, carry a reputation for biological activity that isn’t fully mapped out yet. Some research points to toxicity in aquatic systems. That means spills don’t just disappear with the next rainfall; they threaten water plants, fish, and anything downstream.

Personal Experience Informs Safety Culture

Think of all the times someone cut corners in a college lab, maybe used their bare hands because the chemical “didn’t seem that dangerous.” It’s easy to get cavalier, but stories of chemical burns and unexpected rashes make the rounds for a reason. In my graduate lab, a bottle of imidazolium salt once tipped and left oil on a bench. Somebody wiped it off, washed their hands, thought nothing of it, and woke up later with irritated skin and questions about the long-term effects. Even small mistakes create real problems.

Supporting Facts: The Research Isn’t Quiet

Recent articles dig into the toxicity of ionic liquids, imidazolium compounds included. Reports document moderate-to-high toxicity in multiple cell lines and fish embryos. The European Chemicals Agency labels many such chemicals as harmful to aquatic life, and Material Safety Data Sheets from respected suppliers lay out the same cautions: avoid release to the environment, don’t touch without proper protection, and don’t breathe in the dust. Accumulating evidence links these compounds with membrane disruption in living cells. None of this points to a compound that needs a casual approach.

Ways to Handle the Hazards

Practical steps work better than wishful thinking. Wear nitrile gloves–not latex, which gives little protection from many organic chemicals. Use face shields or safety glasses. Run all procedures with a good fume hood pulling away any vapor or mist. Store the compound tightly sealed, and label waste for hazardous chemical pickup. Good ventilation matters a lot, especially in small labs. After finishing with the compound, wash anything it touched with soap and water, and never pour leftovers down a drain.

If a spill happens, don’t grab paper towels and hope for the best. Absorb the liquid with inert material, keep it away from sinks, and clean surfaces with appropriate solvent–staff who know local protocol help keep mistakes from becoming disasters.

Building Trust through Real Precaution

Trust in science grows when people admit what isn’t fully known and act with caution. 1-Octyl-2,3-dimethylimidazolium bromide doesn’t deserve panic, but it does expect respect. Sticking with strict lab safety, keeping chemicals off skin, and guarding waterways lines up with what experience and researchers both recommend. Real care keeps both people and the environment safe and lets us learn about these compounds without paying an avoidable price.

Clean Products Aren’t Just a Trend—They’re a Responsibility

Over the last twenty years, I’ve learned there’s a lot more to “purity” than just a number stamped on a label. Customers and companies alike talk a lot about high purity—whether it’s for food-grade, pharmaceuticals, or even something as simple as sugar for home baking. What slips through the cracks, though, is why it matters and what sort of testing stands behind these claims. I once toured a small manufacturing plant, and only after seeing their tests—batch after batch under gleaming lights—did I realize how much trust we put in the people who produce these ingredients. Purity delivers not just a promise of effectiveness, but also of safety. Simple as that.

Solid vs. Liquid: What You Get, and Why It Matters

Products hit the shelves in all shapes and sizes. Some come as fine powders, others as chunky crystals, a few packed as tablets, and plenty arrive dissolved in liquids. Each has a purpose. Factories usually handle solids far more than liquids, especially for things like table salt, vitamin supplements, or industrial-grade materials. Powders store well, travel easily, and can be measured out with accuracy. Liquids, on the other hand, work better when speed or even application matters—think about bleach for cleaning or syrups for medical use. My time working in logistics hammered home one truth: solids spill less and last longer, but liquids let you get the job done quickly.

Whether it’s something as innocent as flour or as dangerous as a chemical solvent, the form changes how people move, store, and use it. One winter, while loading a truck, a pallet of powdered product leaked and created a white cloud—the clean-up took hours, the mess was staggering. With a liquid, the same spill would’ve seeped everywhere, fast. These real-life problems drive the choice for one form over the other.

Checking That Purity Is What They Say It Is

Anyone who’s stood in a lab—or even witnessed basic product checks—knows you can’t eyeball purity. Lab certificates back up every batch. For many products, industry standards demand at least 98% purity, sometimes more. That remaining bit—the so-called impurities—might be leftover moisture, trace minerals, or tiny traces of something else from processing.If you ask around in chemical plants, older workers remember the days when tests were less strict. Now, high-performance machines track even slivers of contamination. I trust the process has only gotten better, thanks to stricter rules and people insisting on seeing the data before they buy or sell.

Getting the Safety Right—And Fixing What’s Wrong

It’s not enough for a product to come stamped “pure” if it lands in the wrong form for its job. Handling powdered calcium requires gloves and proper ventilation, while a liquid supplement just needs clean dispensing tools. These choices aren’t minor details—they keep workers, consumers, and the environment safer. It’s always been tempting for some to cut corners, and stories abound of products recalled due to lower-than-stated purity or the wrong form slipping into the wrong hands. We should be open to more random third-party checks, not just trust company paperwork. Clear labeling, honest testing, and full transparency root out these problems before they grow large.