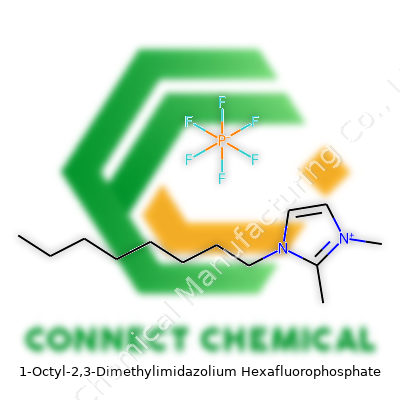

Breaking Down 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate

Historical Development

Chemistry has always chased versatility, and ionic liquids have been game-changers since researchers figured out how to keep salts in their liquid state at room temperature. Imidazolium-based ionic liquids popped up in the late 20th century, grabbing the spotlight for their powerful solvation and nonvolatile nature. Looking back at this field, the shift from simple salts to something like 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate stands out for pushing boundaries. Labs across Europe and Asia, inspired by environmental concerns and process efficiency, got familiar with this compound as early as the 2000s. Folks realized pretty quick that tweaking the alkyl chain and imidazolium ring made serious differences for melting point, hydrophobicity, and chemical compatibility. Its story mirrors the steady march from basic electrolytes to sophisticated, utility-packed compounds for the world’s toughest chemical challenges.

Product Overview

1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate often gets mentioned in technical circles as an advanced ionic liquid. With a long, flexible octyl chain attached to the imidazolium head and a PF6- counterion, this compound brings together a rare mix of low volatility and strong solvating power. Niche, yes, but professionals know why it matters. This ionic liquid finds its way into everything from electrochemistry labs to materials science plants. Across my own work, whenever the need arises for a medium that outperforms traditional solvents—especially in terms of stability and low environmental risk—1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate delivers with consistency.

Physical & Chemical Properties

Pick up a bottle of this ionic liquid and you’ll notice the oily texture, a faint but distinct color, and barely any odor. This stuff doesn’t evaporate under standard lab conditions, thanks to its ionic nature. Its melting point runs below room temperature under common atmospheric pressures and its density usually clocks in higher than water, meaning it settles in a two-phase system. Thermal stability stands out, making it a strong performer in high-temperature reactions and extractions. The hexafluorophosphate (PF6-) part adds to its chemical robustness but also means caution is key when moisture could be present, thanks to the risk of slow hydrolysis to release HF, a dangerous acid.

Technical Specifications & Labeling

Scalar labs and chemical suppliers usually label this compound clearly with its full systematic name, formula (C13H25N2PF6), and major safety warnings. Items like batch number, purity (often above 97%), and water content get listed too. Every experienced chemist knows to check, since even tiny changes in impurities or moisture can turn a promising synthesis into a mess. For transportation, packaging material stands up to the challenge to prevent any leaks or exposure, especially where regulatory standards for PF6-based salts grow stricter each year.

Preparation Method

Manufacturing starts with imidazole and alkyl halides, usually giving the parent imidazolium salt. For 1-Octyl-2,3-Dimethylimidazolium, chemists use specific alkyl halides to introduce the methyl and octyl groups in carefully sequenced reactions. Once the quaternization’s done, they swap the initial halide counterion with hexafluorophosphate using a salt metathesis process—commonly via reaction with potassium hexafluorophosphate under controlled, anhydrous conditions. Every step demands vigilance about moisture and purity, since impurities or water can limit the final performance and even pose safety challenges.

Chemical Reactions & Modifications

In the lab, this ionic liquid faces all sorts of reagents. Its imidazolium cations offer unique reaction environments—helpful for catalysis, phase transfer, and facilitating stubborn organic syntheses. Changing either the cation’s alkyl chains or even swapping the PF6- counterion gives a family of related ionic liquids, each tailored towards a special need. The octyl chain boosts hydrophobicity, extending the range of solvents or solutes it can handle. Some teams go a step further, modifying the ring or introducing functional groups to fine-tune solubility or catalytic behavior.

Synonyms & Product Names

Chemists stick with technical but clear names: 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate ranks as the go-to. Some catalogs prefer abbreviations like [ODMIM][PF6], while international suppliers might append their proprietary labels. It rarely hides behind more common names; anyone working with it knows exactly what they’re getting.

Safety & Operational Standards

Handling means business. This compound doesn’t explode or burn easily, but take its hexafluorophosphate seriously: contact with water or high heat may break down PF6- and generate hydrogen fluoride. Eye and skin protection, gloves, and a trusty fume hood rank as standard. Teams keep disposal plans strict, sending used ionic liquid and any suspect mixtures to properly equipped waste treatment plants. Even in research settings, the risks drive continuous review of internal lab standards, national transportation laws, and environmental impact guidelines.

Application Area

Every time I’ve seen this compound in use, it stepped into projects where other solvents failed. In electrochemistry, it allows development of batteries and capacitors that run smoother and longer. In organic synthesis and catalysis, its stability opens up routes for reactions involving fine chemicals and pharmaceuticals. Researchers love it for dissolving both polar and nonpolar materials, and material scientists sometimes rely on it for crafting ionic liquid-based membranes or specialty coatings.

Research & Development

Labs and industry partners experiment constantly, testing new uses and modifications. The drive comes from unmet needs in energy storage, sustainable synthesis, or greener processing. Detailed studies track not only yields and efficiencies but how these ionic liquids interact with new catalyst systems or nanomaterials. Every year, more universities bring these materials into graduate research, and conferences fill with data on structure-property relationships. The hope is always clear: take what 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate offers already and stretch it further into clean energy, smart materials, and safer processing.

Toxicity Research

Most ionic liquids once earned a reputation for being “green,” but more recent work takes a hard look at toxicity. Studies show that, while low volatility reduces workplace exposure by inhalation, compounds involving PF6- need careful scrutiny. Chronic and aquatic toxicity tests reveal some cause for caution if these chemicals escape controlled settings. Breakdown products can sometimes act as environmental hazards. Regulators, especially in the EU and North America, track research on biodegradability and bioaccumulation, urging both chemists and industry leaders to design new versions with even lower risk.

Future Prospects

There’s growing pressure to deliver safer, more efficient chemical tools, and 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate sits at an interesting crossroads. Researchers keep improving its structure, seeking lower toxicity and better environmental compatibility. Green chemistry groups work to swap out riskier components while keeping the unique combination of stability and solvating strength. For industries, especially those looking to meet aggressive environmental targets or improve energy devices, this and related ionic liquids open doors. More sustainable versions with different counterions or biodegradable features show promise. Regulatory momentum and deeper safety data push all players toward choosing compounds with proven benefits and minimized hazards, and that sparks continuous innovation in this space.

Chemistry in Action

Down in research labs and bright industrial spaces, people search for better solvents. 1-Octyl-2,3-dimethylimidazolium hexafluorophosphate pulls its weight here. You’ll find it among the class of substances called ionic liquids. These compounds catch the interest of chemists because they do not evaporate like water or regular solvents. As someone who has watched the surge of interest in greener, less volatile chemicals, I notice that this material blends innovation with genuine utility.

Real-World Uses Take Shape

In my own work in applied chemistry, solvents often dictate results. This ionic liquid works as a medium for chemical reactions that struggle in water or thumping, old-school organic solvents. Because it stands up to heat and doesn’t fly off into the air, it finds a place with tricky chemicals and metals. If you care about recycling metals from waste or building cleaner batteries, a solvent like this gives an edge. It opens doors to cleaner extraction of valuable metals, such as gold and platinum, without the smoke-and-mirrors of harsh acids and smelly reagents.

People running fuel cell studies dabble with it because traditional electrolytes break down too quickly under real-world strain. The stability of this ionic liquid lets scientists crank up voltage and heat without the mess. I’ve heard stories of researchers shaving weeks off their testing time because this one chemical stood up to repeated cycles.

Safer, Smarter Labs and Factories

Safety makes a strong case. Too many chemical plants have paid for old-fashioned ways with injuries and lawsuits. Old solvents climb into the air; their fumes linger, and any slip can burn or choke. This newer approach skips much of that. Less vapor means less danger for noses and lungs, and the fire department doesn’t rush out at the drop of a flask.

I’ve seen industrial sites where spills mean a scrubbing and a sigh instead of an evacuation. As more companies search for chemistries that check both the “works well” and “keeps people safe” boxes, this kind of ionic liquid answers both calls.

Challenges Don’t Disappear

Costs sit near the top of the worry list. These ionic liquids take effort to make. You pay for those extra steps with a steeper price tag. Not every application justifies that kind of investment, so the miracle solvent still hasn’t taken over every lab bench.

There’s also the fact that not every ionic liquid, including this one, has a long history of environmental study. We know it shrugs off heat and sticks together, but the jury is still out on what happens if a drum leaks into soil or water. That matters to anyone who cares about long-term impact.

Looking Forward

As science digs deeper into sustainable technology, I expect more work on scaling up production and monitoring environmental effects. Chemical engineers watch these substances because they promise real change, without just shuffling risks from the air to the ground. If manufacturers and researchers keep raising questions, steering careful studies, they’ll find better answers about risk and reward.

It’s not the cement or steel or gasoline that built the last century. But for niche jobs in metal recovery, advanced batteries, and clean chemistry, this ionic liquid is already carving out a future.

Digging Into Chemical Connections

Whenever someone rattles off the name 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate, thoughts might drift to the world of chemistry classrooms and complicated whiteboard formulas. But real impact starts further up: this is an ionic liquid, a group transforming lab science into actual practice. The name might taste like alphabet soup, but it translates to a powerful tool built for tasks that go beyond routine solvents or salts.

What Lies Inside the Structure

The backbone breaks into two big pieces, each one shaping purpose and performance. One part, the cation, springs from imidazolium—a five-membered ring often known for its stability and resilience. Swap in two methyl groups at the 2 and 3 spot, and bolt on a long octyl chain at the 1 spot. Picture it like upgrading a sedan for off-roading: adding a long alkyl tail to that compact imidazolium ring turns it into something that easily dissolves stubborn organic compounds. The other part, the anion, comes from hexafluorophosphate—a cluster of phosphorus covered in six fluorine atoms. This combo makes the whole structure more resistant to water, and less likely to break down in tough conditions.

The Importance in Real-World Applications

I learned long ago in the lab that solvents can become a bottleneck in getting cleaner chemical reactions. Water and familiar organic liquids don’t always fit the job. Ionic liquids like this one work at room temperature, cut down vapor pressure, and support reactions that would normally stall or create a mess of byproducts.

Imagine sitting in a research group, stuck on how to recycle aluminum more efficiently. The answer didn’t come from a fancy catalyst, but from picking a liquid that held the right ions, stayed stable, and didn’t ruin equipment. This specific compound allows for electrodeposition and other advanced processing that regular solvents just can’t handle. In my view, these structures aren’t just chemical curiosities—they help shift entire industries toward safer, more sustainable routes.

Safety and Environmental Concerns

No chemistry story skips health and nature. Hexafluorophosphate brings stability, but also some risk. If it meets strong acids or high temperatures, dangerous products like hydrogen fluoride can show up. Used without thinking, these substances can outlast natural systems and trickle into water supplies. The path forward depends on robust protocols—think improved safety in handling, and closed-loop processes that keep waste in check. Europe’s REACH legislation, for example, forces suppliers and users to pull together data on hazards and document safer usage patterns.

Opportunities for Future Research

Instead of sticking to one formula, labs now swap methyl or octyl groups for others, always on the hunt for better dissolving power, or lower toxicity. Tweaking these branches means turning a single structure into a library of customized liquids, each built with a job in mind. For chemical engineers and material scientists, this offers a rare kind of flexibility. Developing tools for greener chemistry demands more options, and structures like 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate open new doors—if handled with knowledge and respect for both people and the planet.

Getting Real About Storing Unfamiliar Chemicals

Stepping into a chemical storeroom, I remember seeing rows of brown bottles and clear vials with long, cryptic names. Over time, dealing with specialty salts like 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate taught me that proper storage isn't just about following a rulebook—it's about protecting yourself, your colleagues, and the quality of your materials. This particular ionic liquid draws chemists in with unique properties, but mishandling—heat, moisture, sunlight—turns a helpful tool into a headache.

Why Respecting Storage Instructions Matters

I once watched a fellow researcher put a similar ionic liquid too close to an open window. The sun’s heat warped the label, and a sticky residue ran down the side by week's end. Air and water vapor found their way inside, and the compound started to break down. This chemical, like other imidazolium salts, wants little to do with humidity or direct sunlight. When hexafluorophosphate anions pick up moisture, they break apart, sometimes releasing hydrofluoric acid—a health hazard and a costly waste.

Actionable Ways to Store 1-Octyl-2,3-Dimethylimidazolium Hexafluorophosphate

Safe storage starts with a tight seal. Most labs use screw cap bottles made of glass or certain polymers. Out of habit, I always check that the cap closes with a soft snap before leaving anything on the shelf. Silica gel packets tucked beside the bottle add another layer of defense, sucking up stray moisture. Any sign of sweating inside the container means trouble.

Temperature comes next. Shelves out of the sun and away from heat vents serve well. Extreme cold can hurt too—freezers may cause phase changes that make these liquids less stable. So room temperature, kept steady and below 25°C, creates a sweet spot. My old supervisor always moved all moisture-sensitive reagents to a dry cabinet, and I've followed that ever since.

Some colleagues keep their sleeping chemicals in nitrogen-filled dry boxes. That level of caution makes sense in big labs with lots of specialty materials. Most smaller spaces do fine just focusing on dryness and darkness. Keeping the original manufacturer label legible, along with hazard symbols, helps everyone know what’s inside at a glance.

Handling Spills and Runoff Risks

No matter how careful you are, lids get knocked and accidents happen. Spilling ionic liquids rarely sends clouds of vapor, but contact with skin or eyes can burn and irritate. A spill kit with gloves and a chemical-absorbing pad sits close to my bench. After a clean-up, all waste goes straight to proper chemical disposal, not into the drain.

Supporting Lab Safety for the Long Haul

Storing chemicals right means keeping everyone in the lab safe and saving money on replacement supplies. I always show new lab mates how to manage sensitive ionic liquids. Open dialogue keeps everybody aware of risks. For bigger operations, regular refresher training rooted in real experience—not just reading out-of-date manuals—builds stronger habits than rules ever could.

I trust proper storage techniques not because the material safety data sheet says so, but because I’ve seen what happens if you skip steps. Reliable, careful practice extends the life of your chemicals and keeps you out of trouble. If management is listening, investing in quality storage containers and training pays off. It doesn’t take long for good habits to show their worth—in safety, savings, and peace of mind.

Understanding What We're Dealing With

1-Octyl-2,3-dimethylimidazolium hexafluorophosphate doesn’t have a name you’d throw around at a backyard barbecue. It falls into the family of ionic liquids, a category that’s gotten plenty of attention in recent years for things like green chemistry, battery development, and industrial extraction processes. On paper, ionic liquids often get pitched as "safer alternatives" to traditional organic solvents. That idea gets a lot of play in research circles. The problem: not every ionic liquid gets stamped "harmless" just because of the label.

Hazards Lurking in the Details

Let’s cut straight to it—hexafluorophosphate, the anion part of this compound, rings some alarm bells for people who care about workplace safety and toxicology. This group, PF6-, breaks down and gives off hydrofluoric acid (HF) in the presence of water or under acidic conditions. Anyone with experience in chemistry knows you don’t want hydrofluoric acid anywhere near your skin or lungs. Even small amounts can cause deep burns and systemic toxicity. During my own lab days, we never worked with anything containing PF6- unless wearing proper gloves, face shields, and—sometimes—working under a fume hood that roared like a freight train. Anyone who’s come home to find a hole in their favorite pair of jeans after an accidental spill probably paid a little more attention in the next safety seminar.

There’s another angle that gets less press: the long-chain alkyl group attached to the imidazolium ring. Octyl groups, like the one in this compound, don’t degrade easily in the environment. Researchers see some of these ionic liquids sticking around in soil and water, piling up in the food chain. Some journal articles, like one from 2010 in Chemosphere, point out that certain imidazolium-based ionic liquids show toxic effects in aquatic organisms, causing problems at surprisingly low concentrations. I find it hard to dismiss those findings, especially since the short-term benefits in a lab can sometimes blind us to longer-term environmental costs.

Toxicity: More Than a Passing Concern

Toxicity comes in different flavors—acute, chronic, environmental. Acute toxicity data for this specific ionic liquid remain pretty scarce. There just aren’t enough independent studies yet to give a clear picture of how much harm comes from skin exposure, inhalation, or accidental ingestion. Still, the track record of structurally similar compounds tells us to stay cautious. For example, imidazolium salts with shorter chains and different counterions already pop up on regulatory hot lists in places like the European Union’s REACH database, flagged for their potential harm.

Practical Solutions

If your work involves this stuff, regular risk assessments should keep safety front and center. Proper labeling, storage in airtight containers, and strict handling protocols help cut down on nasty surprises. Labs and factories using hexafluorophosphate-based ionic liquids need spill kits and emergency guidelines in place. Switching to ionic liquids with less problematic counterions—something like tetrafluoroborate instead of hexafluorophosphate—cuts down the hydrofluoric acid risk. That’s not a magic bullet, but it’s a start. On a broader level, scientists and engineers should keep pushing for greener chemistries, making sure that new materials don’t trade one hazard for another down the line.

A Closer Look at the Stuff

Talk to anyone who's spent time in a chemistry lab and they'll have at least one wild story about ionic liquids. 1-Octyl-2,3-dimethylimidazolium hexafluorophosphate falls under that umbrella. The long, tongue-twisting name hints at an interesting structure: an imidazolium head with some bulky tails, paired up with a PF6- anion. Strange as it sounds, these details steer almost everything about this chemical — how it acts, how it looks, even what it smells like (usually not much, but sometimes faintly sweet).

What It Looks and Feels Like

This ionic liquid throws expectations about “liquid” out the window. Unlike water or oil, it’s got heft — you pick up a vial and notice the weight. Viscosity catches you off guard; it pours much slower than gasoline, often more like syrup than anything else. Color swings pale yellow or is fully clear. One overlooked trait: it often refuses to evaporate. Place a small drop on a glass slide and it can stubbornly stick around for weeks.

Thanks to its long octyl chain, this compound stays liquid over a surprisingly broad range of temperatures. Freezers don’t bother it, and heating won’t drive it away until temperatures get extreme (well above the boiling point of water). That makes storage and transport less of a headache than with many organic solvents. I've seen open vials sitting on a bench for weeks, changing little, while acetone or ethanol would’ve been gone in hours.

Digging Into Chemical Behavior

The defining feature here: negligible vapor pressure. This quality means it's rarely found floating through the air as a vapor, limiting fire risk and making spills less of a worry for air quality. That’s much safer than standard volatile solvents, which evaporate quickly and can fill a room with hazardous fumes. Hexafluorophosphate gives the molecule chemical toughness — it stays stable in air, doesn’t react with water under most conditions, and shrugs off mild acids and bases.

Electrochemically, this liquid has a wide "window," or safe zone, which allows it to carry current without breaking down easily. That proves useful for applications like batteries, electroplating, and even as a stabilizing medium in tricky chemical reactions. Chemists have used this property to push the limits on energy storage and to coax materials into forming in ways they couldn’t with traditional solvents. The ionic character also means it dissolves some materials other liquids can’t touch, especially metals and polar molecules.

Where Challenges Show Up

Handling is mostly straightforward, but contamination can sneak up on people. Any trace of water, whether from sweaty hands or a humid room, will affect its performance. Watching a student ruin an experiment by using a pipette with a single droplet of leftover water taught me hard lessons about laboratory discipline.

Cost pops up as another concern. Synthesizing a pure, high-grade product is neither cheap nor fast, limiting its use outside research and select industries. Disposal takes forethought, too. That hexafluorophosphate anion can break down under the wrong conditions, releasing toxic byproducts into water or soil.

How to Move Forward

Safety demands real attention. Gloves and goggles go on before the vial comes out of storage. Storage containers need clear labels because confusion between similar ionic liquids can lead to ruined experiments or worse. Researchers are testing greener anions as substitutes for PF6- to cut back on environmental headaches. Others focus on recycling methods—filtering out impurities and reusing the same batch, a process that slashes waste and saves money.

Getting familiar with 1-Octyl-2,3-dimethylimidazolium hexafluorophosphate teaches more than chemistry—it drives home respect for detail, preparation, and responsibility, values that chemistry and the world outside the lab both demand.