1-Octyl-3-Methylimidazolium Acetate: Past, Present, and Future

Historical Development

Not all that long ago, chemists struggled to find green solvents capable of tackling real industrial problems. The discovery and ongoing study of room-temperature ionic liquids changed the game, with 1-Octyl-3-Methylimidazolium Acetate emerging as a strong candidate in both the lab and the plant. Before imidazolium-based salts came onto the scene in the late 20th century, traditional organic solvents like toluene or dichloromethane dominated, offering reliability but with real environmental baggage. Synthesizing ionic liquids such as [OMIM][OAc] (short for 1-Octyl-3-Methylimidazolium Acetate) meant researchers finally had materials that resisted evaporation, caught less fire, and mixed better with a wide range of chemicals. The journey carried through the early 2000s, fueled by the green chemistry wave, and carried into industry-led investigation for cellulose processing and biofuel extraction. The developmental story behind this chemical isn’t just one of laboratory curiosity but of industrial need pushing academic innovation.

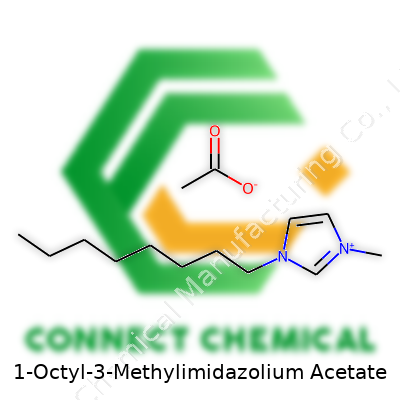

Product Overview

1-Octyl-3-Methylimidazolium Acetate looks like a pale, yellowish, viscous liquid under room conditions. It carries the imidazole ring at its core—a structure famed for both thermal stability and nuanced chemical behavior. With a positively charged imidazolium body anchored by a methyl group at the third position and an octyl group at the first, it partners with the acetate anion. This structure means it stands out among ionic liquids, bringing together hydrophobic character and the ability to solvate tough-to-dissolve substances like plant cellulose. Labs and factories order it for projects ranging from catalysis to fractionating biopolymers, thanks to its unique combination of structure and reactivity.

Physical & Chemical Properties

[OMIM][OAc] keeps a tidy liquid form at room temperature, with a melting point hovering around -20°C and a decomposition point well above 200°C—a far cry from the low flash points of conventional solvents. High thermal stability translates into less risk during storage and use, attracting engineers looking for a safer turn-key alternative. Its viscosity varies with water content and temperature, typically settling between 80–100 mPa·s at 25°C. The ionic character results in negligible vapor pressure, another strike in favor of improving lab and plant air quality. For anyone who’s lost time to solvent evaporation headaches, this counts for a lot. Its moderate polarity and strong hydrogen-bonding capacity grant it the power to dissolve cellulose and even some stubborn polymer blends—an ability almost unheard of among non-ionic solvents.

Technical Specifications & Labeling

Producers sell [OMIM][OAc] at high purity (usually >98%) but users still check certificates of analysis for water and halide levels. Attention falls on pH, color, and residue after evaporation. Labels specify CAS number 81934-76-9, formula C12H22N2O2, and the precise weight per batch. Laboratories rely on clear handling guidelines, storage temperature limits, and instructions for cleanup in case of a spill. Any reputable supplier includes hazard pictograms, warnings about eye or skin contact, and disposal guidance—an area where ionic liquids typically carry lower vapor risk but must still meet stringent workplace hazard controls. The push toward harmonized global standards has tightened up requirements, so shipping and storage labels look familiar worldwide, making transfer between research groups or production facilities smoother.

Preparation Method

Chemists start with 1-methylimidazole and 1-chlorooctane, running a quaternization reaction to give 1-octyl-3-methylimidazolium chloride. The intermediate is then treated with silver acetate, causing a straightforward metathesis that swaps chloride for acetate. Filtration removes insoluble silver chloride and, after washing and vacuum drying, the product emerges as the pure ionic liquid. Some industrial processes skip silver, choosing an ion-exchange route for larger-scale production, especially where cost and waste management matter. The acetate anion’s relatively low basicity makes purification easier, sidestepping issues with hydrolysis or unwanted side reactions.

Chemical Reactions & Modifications

The chemical architecture of 1-Octyl-3-Methylimidazolium Acetate supports a broad palette of reactions. It doesn’t just act as a solvent—researchers use it as a reaction medium, catalyst, and even a phase-transfer agent. Its robust structure tolerates many organometallic reactions and surprisingly harsh processing steps. Chemists attach functional groups to the imidazolium ring or tweak side chains to tune solubility and reactivity. Cation exchange can introduce different functional groups, while swapping the acetate for other anions tailors interactions with solutes or catalysts. Some labs modify the octyl or methyl chain, extending or truncating to find the best fit for a particular extraction or polymerization step. These modifications reflect a steady search for process improvements, whether for biopolymer dissolution, improved electrolyte behavior in batteries, or streamlined catalysis workflows.

Synonyms & Product Names

Beyond its main name, [OMIM][OAc] turns up in research and procurement catalogs as 1-octyl-3-methylimidazolium ethanoate, OMIM Acetate, or just C8MIM Acetate. Other variations include 1-methyl-3-octylimidazolium acetate and trade names offered by specialty chemical suppliers. These aliases help professionals locate the right product in crowded catalogs or international trade, though the CAS number provides the most reliable anchor for identification. Some industrial buyers lean on naming conventions set by the IUPAC or adapt to local regulatory language to cut paperwork confusion.

Safety & Operational Standards

Working with [OMIM][OAc] still calls for full respect for chemical protocol. Direct eye or skin contact brings the classic risks of local irritation, with long-term exposure studies urging gloves, goggles, and coats during use. Laboratories and production floors require spill kits and fume hoods—not because of runaway fumes but to avoid transfer or contamination in a busy environment. Waste must follow local hazardous disposal pathways, not just ordinary drain or landfill routes, even though its environmental persistence trails far behind that of legacy solvents. Anyone setting up a facility focuses on ventilation, labeling, and record-keeping, leaning toward built-in safety features rather than last-minute fixes after an incident. With global chemical control agencies watching closely, regular audits and team training keep everyone on the right side of both safety and the law.

Application Area

Few chemicals show up across as many sectors as [OMIM][OAc]. Its impact shines in biomass pretreatment, where it dissolves cellulose and hemicellulose directly from plant matter, simplifying the logistics of biofuel and bioplastic production. Pharmaceutical researchers pick it for green syntheses, while electrochemists explore its potential as a stable electrolyte in next-generation batteries and capacitors. The textile industry uses its strong polarity to pulse-dye fibers or separate biopolymer streams. Analytical labs deploy it in sample preparation, especially for stubborn, hydrophobic compounds. In recent years, scientists have started probing its usefulness in catalysis, both as a green alternative to organic solvents and as a medium that actually boosts reactivity for metal-catalyzed transformations. I’ve seen companies in composite manufacturing try it out for dissolving tricky polymers, replacing long-standing, oxidizing acid treatments with something tamer and less corrosive to equipment.

Research & Development

Research groups keep pushing boundaries on what [OMIM][OAc] can manage. The focus has shifted from basic solubility studies to unraveling exactly how it interacts on a molecular level with biopolymers and catalysts. Cellulose dissolution sits front and center, but the chemical’s story doesn’t end there—teams have probed its effect on enzymatic reactions, explored novel blends with other ionic liquids, and chased pathways for recycling and regeneration after use. Work on electrochemical devices continues, with researchers testing conductivity and durability under cycling stress. Universities and private labs track degradation products and screening for uses in carbon dioxide capture, always angling for higher performance and greener output. Collaboration between plant engineers and bench chemists often drives development, matching field needs with real molecular innovation.

Toxicity Research

Toxicologists still caution against calling [OMIM][OAc] completely harmless. Animal studies link high-dose exposure to acute irritation and organ stress, though the doses run much higher than most workplace encounters. Environmental screens track persistence in water, more so than in soil, but standard wastewater treatments tend to neutralize much of the hazardous effect. No one recommends direct discharge to environments, especially aquatic habitats, but with proper containment and disposal schemes, risks to handlers and broader ecosystems remain manageable. Ongoing studies look at not just acute toxicity but chronic, lower-dose exposure as well—especially since industrial-scale use produces recurring streams of ionic liquid waste. Monitoring programs and regulatory guidance from chemical safety boards draw on this expanding research base to hardwire best practices into factory and laboratory operations.

Future Prospects

Looking ahead, [OMIM][OAc] sits at an interesting crossroads. Engineers and chemists expect growth in green construction materials and pharmaceuticals, with this ionic liquid helping break through the limits of conventional dissolution techniques. New synthesis strategies promise faster reactions with less waste, especially if recycling and regeneration infrastructure can scale up to match demand. Digital modeling and laboratory automation both speed up discovery cycles, so new modifications and derivatives will likely hit the market in the coming years. Energy storage and biorefinery fields stand out as settings where the need for robust, non-volatile solvents fits the capabilities of this chemical. As regulations steer industry away from hazardous volatile solvents, the reputation of [OMIM][OAc] and related compounds is likely to improve—provided safety profiles remain transparent and environmental concerns get met with real action, not just marketing. Broader integration into manufacturing hinges on cost controls, reliable reusability, and thorough public research into all life-cycle impacts.

A Real-World Take on an Unusual Chemical

The name 1-Octyl-3-methylimidazolium acetate doesn’t exactly roll off the tongue. This chemical tends to show up in specialized labs rather than in everyday life. Still, as someone who spent years working with biochemists and chemical engineers, I’m familiar with the questions people have whenever a chemical like this pops up: What’s it for, and why does it matter?

A Strong Solvent With a Gentle Touch

1-Octyl-3-methylimidazolium acetate belongs to a group called ionic liquids. Unlike water or acetone, which evaporate easily and can be flammable, ionic liquids barely evaporate and often avoid the dangers that come with traditional solvents. This chemical, in particular, excels at dissolving tough plant fibers. In my own stint with a cellulose research team, the stuff turned unimpressive wood pulp into a smooth solution that could be spun into eco-friendly fibers or films.

Outside the lab, where does all this matter? Picture a world still hooked on plastics. Those plastics clog landfills and oceans for centuries. 1-Octyl-3-methylimidazolium acetate steps in as a steppingstone for cleaner technologies. It breaks down cellulose, which is the backbone of plant walls, so people can create plant-based materials instead of relying on petroleum products. The textile industry, for example, uses cellulose dissolved by this compound to produce strong, washable fabrics without the harshness of old-school chemicals. It’s not hype — it’s supported by studies from research hubs in Europe and East Asia. Papers in journals like Green Chemistry highlight how it delivers less toxic waste and supports circular economies.

Helping the Biotech and Pharmaceutical Fields

Ionic liquids have also changed biochemistry labs. 1-Octyl-3-methylimidazolium acetate can stabilize enzymes and proteins, letting them keep their shape and activity longer than would ever be possible in water alone. I’ve watched biologists swap out typical buffers for this stuff, then run experiments that would have failed otherwise. It’s not magic—it’s a simple result of a solvent that creates a friendly space for fragile molecules that matter in drug production or diagnostic tools.

There’s a catch: ionic liquids often come with a hefty price tag. They’re also tricky to recycle at an industrial scale in a way that’s both cost-effective and truly green. If chemical recycling gets easier, the price falls, and the benefits are no longer limited to research labs and pilot projects. Some companies already work on closed loop systems for these solvents, and governments fund research in “green separation technologies.”

Moving Beyond the Lab Bench

People who care about greener chemistry should keep an eye on chemicals like this. 1-Octyl-3-methylimidazolium acetate helps in pulling valuable matter out of agricultural waste, turning what used to be rubbish into something worthwhile. In the pulp and paper sector, it could help reduce water pollution, simply by making the process less reliant on chlorine and other persistent chemicals.

Industry doesn’t always change quickly. Getting a lab-scale solvent into a pulp mill or fabric factory means tackling real hurdles: cost, regulation, and scaling up. Progress in material science often relies less on a single breakthrough and more on persistent improvement. 1-Octyl-3-methylimidazolium acetate represents this path—quietly nudging big industries toward cleaner options while researchers hunt for even better solutions.

Experience Explains Function

Holding a bottle of 1-octyl-3-methylimidazolium acetate in a gloved hand, you notice right away it doesn’t feel like most lab solvents. It’s more viscous, doesn’t grab your nose with harsh fumes, and leaves no static cling. This chemical belongs to a group called ionic liquids, a set of compounds gaining ground in research and industry for their odd mix of fluid and salt-like behaviors. In my time spent working with these liquids, I’ve seen firsthand how their quirks open doors in the lab that regular solvents can’t.

Physical Traits Stand Out

The first thing anyone notices is the texture. This stuff flows slowly, almost syrupy compared to everyday solvents like acetone or methanol. At room temperature, it stays as a clear or pale yellow liquid, thanks to a melting point sitting comfortably below freezing. The compound’s long octyl tail gives it an oily nature, making it slick and flexible in formulation work. Compared to water or alcohols, it evaporates at an almost glacial pace—practically stubborn when asked to leave a surface.

Ionic liquids like this boast thermal stability. 1-octyl-3-methylimidazolium acetate keeps its cool and doesn’t break down until temperatures hit around 200°C. Its structure means it won’t burn off or degrade the way lighter, everyday molecules do. You can push it hard in heat-driven reactions without laying waste to your solvent supply.

Chemical Temperament Worth Respecting

Looking at chemical behavior, the story gets more interesting. This acetate salt dissolves a wild variety of substances—cellulose, dyes, some metals, even sturdy polymers. On the bench, breaking down tough plant tissue or chitin isn’t a challenge with this ionic liquid, unlike water or alcohols, which barely touch biodegradation. That opens up biorefinery routes, making recycling natural fibers much more sensible.

The imidazolium core resists most chemical attacks. Exposure to air and moderate acids barely fazes it. Still, strong bases might break down the ring if you keep the mix too hot or too basic for too long. Most researchers learn quickly to mind the compatibility with highly alkaline solutions. In my own work, keeping containers tightly capped prevents any absorption of water, because this liquid loves to draw in moisture—a magnet for atmospheric humidity. That affinity helps with dissolving biomaterials but means you can’t store it carelessly.

Why Properties Like This Matter

Why care so much about these idiosyncrasies? The unique blend of organic and salt-like character puts 1-octyl-3-methylimidazolium acetate on lab shelves for reasons beyond ordinary solvents. For dissolving cellulose or extracting metals, nothing else cuts as cleanly. That comes at a price—these liquids cost much more than ethanol or acetone, so people often look for recycling protocols or containment strategies to minimize waste.

The slow evaporation, high boiling point, and ability to tackle tough molecules bring up both opportunities and headaches. Green chemistry folks like the low vapor pressure, giving it an edge in safer workplace environments. On the flip side, accidents become hard to clean up. Nothing beats keeping good training and spill kits nearby.

If the demand for recycling natural materials continues its upward march, you’ll see more attention to these properties. Green-minded researchers look for ways to reclaim or regenerate the liquid after use, cutting down on environmental impact and long-term supply costs.

What is 1-Octyl-3-Methylimidazolium Acetate?

1-Octyl-3-methylimidazolium acetate, or OMIM Ac, belongs to the group of chemicals called ionic liquids. In labs and in industry, people use it to dissolve cellulose, break down biomass, and sometimes run chemical reactions that stubbornly refuse to happen in water or standard solvents. Like many ionic liquids, this compound caught attention for its ability to replace more toxic, flammable organic solvents. It sounds promising, but every chemical has a flip side.

Hazards People Might Ignore

Compared to old-school volatile organic solvents, OMIM Ac doesn’t evaporate fast and won’t burn like acetone or gasoline. That leads some to assume it’s basically safe. But staying power can be a double-edged sword. If OMIM Ac spills, it lingers on skin or surfaces, sneaking past gloves that work fine for other lab chemicals. I once saw someone wipe a splash off a lab bench with bare hands, not realizing this stuff clings and creeps into the skin. Later, their hands felt sore and irritated—a lesson in not judging a substance by its appearance.

Acute toxicity data for OMIM Ac still fall short of complete. Its cousin, 1-butyl-3-methylimidazolium acetate, gets flagged for skin and eye irritation, and OMIM Ac likely behaves the same way. Extended exposure brings up bigger concerns. Studies show certain ionic liquids disrupt cell membranes and may harm aquatic life. Workers handling the stuff day in and day out shouldn’t rely on the gentler label “green solvent.” Chronic low-dose exposure often gets overlooked until skin rashes, eye redness, or headaches turn up. The health effects aren’t always loud, but they build up enough to cause real trouble over time.

How Real Labs Handle OMIM Ac

Lab safety books always mention goggles, gloves, and working under the fume hood. From personal experience, nitrile gloves need replacement after accidental splashes. Standard latex fails quickly. Once, during a pilot-scale experiment, a stubborn ring formed around my glove line—a sign that the liquid seeped through fine cracks. Washing up seemed enough, but itching started soon after. Lesson learned: double-glove and keep OMIM Ac off clothes. Cleanup needs soap and plenty of water. In an open room, slight vinegar-like fumes creep up, especially if the bottle sits uncapped. Nobody wants a cough that won’t quit after a day of working with this stuff.

Old containers shouldn’t get tossed in regular trash. Disposal needs chemical waste labels and collection, since OMIM Ac’s environmental footprints stick longer than usual solvents. Fish and small invertebrates don’t filter it out well, so accidental dumping hits waterways hard.

Improving Safety

Shifting to OMIM Ac doesn’t erase all hazards—just swaps sudden flames for more sneaky health risks. Labs that use it regularly need proper gloves, eye protection, and fume hoods, not just open windows. New users benefit from hands-on safety training, not just reading MSDS sheets. Sharing real-life close calls and incidents goes further than repeating generic warnings.

Some university groups now screen ionic liquids for safety and environmental impact before using them at scale. Future versions may add chemical tags to speed up breakdown after use, shrinking their environmental footprint. Until then, treating OMIM Ac with the same respect people showed for traditional solvents keeps people and the world a little safer. A good rule: if you wouldn’t splash acetone or bleach on your hands, don’t risk it with ionic liquids either—even if they seem harmless at first glance.

Understanding the Chemical’s Nature

1-Octyl-3-Methylimidazolium Acetate falls into the class of ionic liquids—those curious compounds that stay liquid at lower temperatures and have been earning attention for dissolving cellulose, coaxing reactions in synthesis, and serving as alternative solvents in labs. The substance comes with both promise and caution. It can attract and hold onto water from the air, and that single property shapes a lot of storage practices scientists and technicians have to adopt.

Storage Choices for Health and Longevity

It doesn’t work to leave this chemical sitting out on a crowded benchtop. Exposure to humid air pulls in moisture, causing the substance to change in a way that could throw off precise work. Resealable glass containers with airtight lids step in as the workhorses for safe storage. I learned early at the bench to stash chemicals like this in a cool, well-ventilated corner—think storerooms with a temperature below 25°C—out of direct sunlight and away from sources of heat. That slows degradation and avoids pressure buildup or unwanted reactions.

Labels matter—every bottle needs a name, concentration, and date of receipt. When supervisors walk through the lab, they check for this clarity because guessing what’s in an unmarked flask means risking unintended mixing, which in the best of times ruins research and, in the worst, causes real harm. Most protocols recommend keeping ionic liquids away from acids, bases, and oxidizers. These chemicals can spark surprising reactions, so keeping them physically distant cuts down accident risks.

Keeping Safety Straightforward

Handling instructions aren’t optional. I remember my first mishap with a similar liquid: gloves with tiny holes gave me a rash that lingered for days. Thick nitrile gloves, splash-proof goggles, and long sleeves became my uniform after that. Anyone reaching for this acetate has to check their safety gear, work with it in a well-drafted fume hood, and avoid breathing in fumes or letting it touch skin. Eyes and skin soak up chemicals faster than many expect, which can mean trouble without solid barriers.

When Disposal Looms

Disposal trips up even veteran lab workers. Pouring unused 1-Octyl-3-Methylimidazolium Acetate down a drain or into regular trash isn’t just risky—it often runs afoul of regulations. Ionic liquids can hang around in waterways, throwing off ecosystems far longer than more familiar lab solvents like ethanol. Waste bottles labeled for organic liquid waste collect leftover material. Facilities with incinerators rated for chemical waste see these bottles off. Any spill or broken container calls for absorbent pads, not paper towels, and a trip to hazardous waste bins.

Local and national rules back these practices up. Chemical waste management teams run regular pick-ups at universities and larger companies. Smaller outfits work through certified disposal vendors. It helps to keep the Safety Data Sheet close. Instructions sometimes shift with new environmental data, so checking the latest recommendations can prevent trouble with auditors or environmental officers.

Building Safer Habits

Routine wins out in safety matters. I stick to a personal checklist—labeling, gear, double-seal storage, and careful disposal—because skipping a step has consequences that rarely show up until later. Training new staff or students takes patience, but the effort pays off every time a chemical gets handled or thrown away without a hitch.

Looking at the growing use of ionic liquids, habits built today affect lab safety for years. Storing and disposing of 1-Octyl-3-Methylimidazolium Acetate responsibly doesn’t demand miracles—just knowledge, diligence, and a healthy respect for the impact of chemicals beyond the lab bench.

Understanding What You’re Buying

People working with specialty chemicals like 1-Octyl-3-Methylimidazolium Acetate often look up where they can buy it and how pure it really is. This compound, an ionic liquid, finds use in research, pharmaceuticals, cellulose processing, and sometimes even in green chemistry. Project budgets and experimental outcomes both depend on the source and the substance’s quality. A small shift in grade can make or break a whole experiment.

Looking at Different Suppliers

Chemical supply giants such as Sigma-Aldrich, TCI, Alfa Aesar, and IoLiTec keep 1-Octyl-3-Methylimidazolium Acetate readily available in their catalogs. People who work in laboratories—or order for one—usually start with these names because each has a long track record and plenty of published data for reference. Most of the time, you’ll find purity grades labeled as >95%, >98%, or “analytical” and “laboratory” grade. This purity is important, especially in experiments where any impurity could throw the results off.

Common Pitfalls and Red Flags

Browsing smaller chemical vendors can tempt you with lower costs, but the problem is transparency. Some sellers either skip the Certificate of Analysis or refuse to show independent test data. People sometimes take a chance on bulk marketplaces such as Alibaba or eBay, but this can go wrong in a hurry, especially if your research demands batch documentation, safety records, or regulatory compliance. There’s value in sticking with trusted suppliers who offer up the manufacturing data and safety sheets right from the start.

Purity and Grade: Read the Fine Print

Purity often underpins trust in any chemical you order. In my years handling solvents and custom chemicals, almost every problem we hit tied back to either an overlooked impurity or a misread spec. Analytical-grade material serves academic research, where the results go public. Technical grade costs less and suits industrial use or pilot trials. Anyone looking for ultra-high purity—say, for crucial catalysis research—should scan supplier specs for detailed chromatograms or NMR results, not just a blanket percentage.

Staying Safe and Legal

Institutions usually want a reliable chain of custody and solid records to support their own compliance. Buying from reputable sources protects your lab from mishandled, mislabeled, or contaminated material. Some chemicals might attract regulatory attention, especially in larger volumes or if shipped across borders; sticking with known brands and distributors avoids snags at customs or in approvals. Most leading vendors provide GHS-compliant safety data, detailed hazard codes, and instructions for safe storage—all part of a responsible lab setup.

Supporting Smarter Choices

People in research roles manage tough trade-offs between cost and certainty. Having worked on grant-funded projects and start-up budgets, I see the draw of cheaper options… but recall costly lessons where a single mystery impurity ruined weeks of work. Talking directly with a sales rep or technical specialist at a trusted supplier sheds light on any fine print, like batch variations or upcoming recall issues. Peer-reviewed publications often cite the exact vendor and batch—they do this because the details matter, especially when repeating or scaling up a process.

Wrapping Up Purchasing Decisions

Nobody wants to derail their research over a bottle’s sticker, or lose time chasing paperwork after delivery. Doing a little extra homework on your supplier, digging into certificates, and asking for the right grade pays off every time. A careful buy supports honest results and keeps your project on track, whether you’re running a simple synthesis or pushing the boundaries in renewable materials.