Commentary on 1-Octyl-3-Vinylimidazolium Hexafluorophosphate

Historical Development

People in science circles have always looked for new ionic liquids that do more than just replace organic solvents. After the late 1990s, chemists started moving away from simple alkylimidazoliums toward more creative designs. One of those ideas gave us 1-Octyl-3-Vinylimidazolium Hexafluorophosphate. The backbone of this ionic liquid owes a debt to early studies that added functional groups onto imidazolium rings for extra chemical handles. With this, researchers could tailor a molecule's viscosity, stability, or reactivity instead of working around the limitations of older salts. Over the last decade, more work poured into these vinyl-modified ionic liquids, unlocking pathways to better polymer composites, greener extraction, and useful catalysts. I remember reading early papers where the excitement came from simply getting these salts pure enough for real application. It’s hard to believe how far things have come since then.

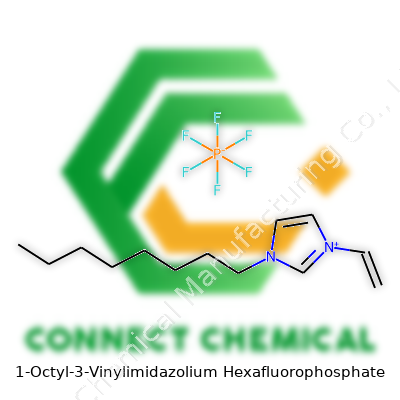

Product Overview

1-Octyl-3-Vinylimidazolium Hexafluorophosphate stands out because of the vinyl group it carries on its imidazolium ring and the bulky octyl side chain. These allow for uses far beyond classic solvents. Today, the compound finds space in electrochemistry, extraction, polymer modification, and advanced materials science. The chemical mediates reactions and offers a low volatility alternative in labs. Commercial suppliers have started listing it in their catalogs, showing its climb from specialty molecule to a growing niche market. Labs I’ve worked in have used it as a building block—almost like a chemical Lego—to assemble novel polymer chains for membranes or custom catalysts for challenging reactions.

Physical & Chemical Properties

This salt supports a liquid state at room temperature, and that helps when someone wants to blend it into reaction mixtures. The long octyl group shifts the melting point, and the vinyl group makes it more reactive than its basic cousins. Its moderate viscosity lets it act as a dissolving medium, but it resists mixing with water because of the hydrophobic alkyl chain. With the hexafluorophosphate anion lending stability, the molecule resists decomposition at higher temperatures, staying liquid past 100°C. Chemically, it stands up to strong bases and acids but reacts with nucleophiles at the vinyl end. That mixture of stability and selectivity makes it ideal for research and specialty chemical manufacturing.

Technical Specifications & Labeling

This ionic liquid usually ships as a clear to pale yellow viscous fluid or, less often, as a solid chunk if stored cold. Reputable suppliers quote purities above 97%, since contaminants mess with its conductivity or reactivity. The bottle comes labeled with hazard pictograms because the hexafluorophosphate ion, under certain conditions, generates toxic fluorine compounds. Labs need to store it tightly capped in cool, dry conditions. The CAS number, chemical structure, and date of manufacture are always on the label, so researchers can check for batch-to-batch consistency. Regulatory bodies in Europe and the US have started including it in safety datasets, a sign that its industrial use is growing.

Preparation Method

Synthetically, the route starts with 1-vinylimidazole. Alkylation with 1-bromooctane forms 1-octyl-3-vinylimidazolium bromide. Anion exchange with potassium hexafluorophosphate produces the final ionic liquid. Each step needs careful monitoring, since side products or incomplete reactions throw off purity and performance. I’ve watched several colleagues struggle with the last step—the hexafluorophosphate sometimes forms stubborn crystals that need filtration and repeated washing. High vacuum or rotary evaporation dries the product, then the liquid goes through column purification for the top grades.

Chemical Reactions & Modifications

The vinyl handle on the imidazolium ring opens up crosslinking, polymerization, and grafting reactions. Chemists use radical initiators to stitch the ionic liquid into new polymer networks, giving rise to membranes that separate gases or ions. It’s been tethered to silica surfaces or incorporated into block copolymers for enhanced ion transport. In organic syntheses, the cation can coordinate with transition metals, adding another layer of catalytic diversity. The anion stays out of most chemical arguments, but offers thermal and electrochemical stability—good if you need to run a reaction hot or apply a voltage. These reactivities moved the molecule from a mere solvent to a key reactant in materials science labs. I saw a group turn it into dense, sticky networks using UV irradiation, creating resins with totally new electrical properties.

Synonyms & Product Names

1-Octyl-3-Vinylimidazolium Hexafluorophosphate appears as [C8vim][PF6] or OVI-PF6 in journals and supplier lists. It sometimes shows up as 1-vinyl-3-octylimidazolium hexafluorophosphate, and some catalogs shorten it to Vinyl-octylimidazolium PF6. Although confusing at times, these names all point to the same molecule, provided the vinyl group sits at position 3 and the octyl at position 1 on the imidazolium ring. Keeping track of synonyms helps researchers match experimental results across countries and suppliers.

Safety & Operational Standards

Nobody wants an accident, but the expanding use of fluorinated ionic liquids demands strong protocols. PF6-based salts emit toxic gases under heat or strong acid. Handling means gloves, goggles, and working in ventilated hoods. Waste needs collection by trained personnel—hexafluorophosphates remain persistent in the environment. At my last job, we had to treat any spill as hazardous, rinsing tools and benches multiple times. Regulatory agencies set occupational exposure limits, especially in Europe. Labs and factories keep Safety Data Sheets on hand and conduct regular training for everyone using these chemicals. Safe storage—away from water and reactive agents—remains routine.

Application Area

This ionic liquid crops up in projects that need both ionic conductivity and chemical flexibility. One of its big uses: as a template in the manufacture of designer membranes for fuel cells. The vinyl group locks into polymers, creating a network that channels specific ions, adding to membrane durability. In catalysis, it boosts rates for alkylation and coupling reactions. Environmental engineers eye it for extractions that traditional solvents can't pull off, such as rare earth or precious metal recovery. I’ve seen analytical labs use it to make functionalized silica for solid-phase extraction. The list keeps growing because chemists continue to exploit that vinyl handle, whether for multi-functional coatings, next-gen batteries, or nanoparticle stabilization.

Research & Development

In academic circles, this compound attracts attention for its role in custom polymer synthesis and electrochemistry. Early projects studied how the vinyl group participates in radical-initiated chains, yielding gels and films with tuneable ion mobility. Groups in Asia and Europe lead the way on new uses, publishing monthly on hybrid materials and ionic liquid composites. Industrial labs probe it for corrosion inhibition in challenging environments, and teams are tweaking its structure for higher conductivity in solar cells and battery electrolytes. Conferences buzz with talk of longer alkyl chains, new anions, or ways to recover and recycle the fluid after use. Researchers also work on better methods for purification, since trace contaminants sink performance fast. My own graduate advisor tasked a postdoc with making an entire family of these salts, just to see how side chain length and vinyl reactivity impact membrane toughness.

Toxicity Research

Studies keep piling up about the environmental and biological impact of hexafluorophosphate-based ionic liquids. Some findings show low acute toxicity, but the persistence of the PF6 anion raises concerns for long-term exposure. Waste mustn’t wash down drains, since fluorinated species stay in ecosystems for years. Tests in freshwater crustaceans and algae suggest moderate toxicity at high concentrations. Most labs treat the compound like any persistent contaminant—careful containment, no landfill disposal, and rigorous cleanup. People with allergies or sensitivity to organic fluorine need extra care. New research models the breakdown products under sunlight and acidic or basic conditions, aiming to map the entire risk landscape. As regulations sharpen, so does interest in making safer or more biodegradable analogues.

Future Prospects

Ionic liquids like 1-Octyl-3-Vinylimidazolium Hexafluorophosphate continue to reshape parts of materials chemistry and green engineering. I expect more applications as people develop new vinyl-linked imidazolium salts, sidestepping older solvent constraints. With energy storage, electronic materials, and specialized separations always needing new tricks, this molecule’s adaptability stands ready. Sustainability remains a critical direction — future work might deliver alternative anions or cleavable vinyl groups for easier recycling. As regulation tightens on fluorinated chemicals, research will focus on low-toxicity, high-performance versions. I'd like to see life cycle analyses become mandatory in industry to track risks and benefits. If early patterns are any hint, cross-disciplinary teams will keep finding reasons to build with this compound, building up the next wave of cleaner chemistry tools.

Unlocking the Power of Ionic Liquids

1-Octyl-3-vinylimidazolium hexafluorophosphate stands out in a growing class of ionic liquids—salts that remain liquid at surprisingly low temperatures. These materials push chemists and engineers to rethink how to tackle some stubborn challenges in industry and research. My background in chemical research showed just how eagerly many labs chase new solvents and electrolytes. Every experiment needs consistency and safety, but it never makes sense to ignore progress for the sake of old habits.

Solvent Innovation in Green Chemistry

Ionic liquids like this one draw serious attention as alternatives to traditional volatile organic solvents. Many traditional solvents evaporate, spreading pollution and risk. 1-Octyl-3-vinylimidazolium hexafluorophosphate, on the other hand, hardly evaporates and doesn’t carry the flammability risk. Plenty of scientists have turned to it for processes like extraction and separation, which often produce hefty chemical waste streams. Using this ionic liquid minimizes hazardous emissions. The Environmental Protection Agency has even promoted less volatile solvents for a reason—worker health and clean air both see obvious improvement.

Pushing Battery and Electrochemical Tech

Everything from smartphones to electric vehicles needs a better battery. The chemistry behind these batteries depends on stable, conductive, and safe electrolytes. The hexafluorophosphate anion in this liquid helps resist decomposition at high voltages and wide temperature swings—a crucial quality in the batteries that power everyday life. Researchers have published strong data: using this ionic liquid directly improves ionic conductivity and lifespan, making batteries safer and less prone to catching fire.

Polymer Science and Advanced Materials

It’s always exciting when a new chemical doesn’t just replace an old one but opens unexpected doors. In polymer chemistry, this ionic liquid does more than act as a solvent; the vinylimidazolium cation allows scientists to build the chemical directly into the backbone of new polymers. That provides the backbone for membranes and gels used in next-generation fuel cells, sensors, and water purification. Having a solvent that doubles as a building block drives real efficiency in the lab and industry.

Turning Research into Real-World Solutions

No single chemical fixes today’s environmental and energy challenges, but some make the options a little better. In my own experience with electrochemistry setups, switching to ionic liquids took care of persistent leakage and corrosion problems in high-voltage conditions. Labs and factories that use these compounds cut back on hazardous waste disposal costs, a win for both budgets and communities.

For now, price and large-scale production keep 1-octyl-3-vinylimidazolium hexafluorophosphate from wider use. Solutions will likely come from advances in manufacturing, better recycling methods, and strong support from regulators who prioritize green alternatives. Chemists and engineers should keep sharing practical data—seeing a solvent handle harsh conditions or enable a new polymer in a real-world setting builds trust faster than any technical spec sheet.

Looking at the Substance

1-Octyl-3-vinylimidazolium hexafluorophosphate stands out as an ionic liquid with a strong track record in the lab. Its structure pairs a flexible imidazolium core, topped with a long octyl “tail,” and a vinyl group that lets chemists play with polymerization. Add in the hexafluorophosphate anion, and you get a material tailored to push common boundaries in electrochemistry, catalysis, and material science research. As someone who’s handled similar ionic liquids, I have seen firsthand the practical sides of using and storing such chemicals—small differences in molecular design can lead to big changes in how they behave over time or under stress.

Stability in the Lab and in Storage

The imidazolium cation is not just another ring—it’s responsible for a substantial chunk of the liquid’s stability. Researchers have measured the stability of similar salts and found them robust below 100°C, holding up under dry conditions and when not exposed to harsh reactants. The hexafluorophosphate counterion plays its own role: it adds chemical toughness, resisting breakdown from moisture and oxygen. Despite this, hexafluorophosphate is not invincible. In the real world, trace moisture can sneak into even tightly sealed flasks. Once that happens, slow hydrolysis can release PF5 and HF, both of which are corrosive and can degrade the ionic liquid, bite by bite.

I remember one routine where a colleague left a container open for just a lunch break. Within days, we noticed cloudiness and a harsh odor; lab analysis tracked it to PF6- breaking down. This demonstrated that even chemically “stable” compounds depend on care and awareness, not just design.

Thermal Handling—What Goes Wrong

Heat reveals the limits of chemical stability. Studies show 1-Octyl-3-vinylimidazolium hexafluorophosphate survives temperatures up to 150°C before signs of decomposition show up. Above this range, the vinyl group kicks off side reactions, forming cross-linked products or breaking down. What surprised me during scale-up work was that even modest overheating—think late afternoons with failing ventilation—could accelerate color changes and form new, unwanted products. These side products clog reactors or interfere with application performance in batteries and sensors. Academic publications, including some from 2022, point to the same thing: stability depends as much on tight environmental controls as on molecular toughness.

Looking Beyond the Bench

Long-term storage challenges can get overlooked until problems show up. Shelf life depends on both the vessel material and storage climate. Fluorinated plastics or amber glass seem to do the job best, but constant humidity or big temperature swings cut stability by months. A Stanford materials group tracked ionic liquids for a year and found those kept in dry, dark spaces lost less than 0.3% of their activity, while samples left near sunlight and humidity altered by over 4% in the same time.

Real Solutions—Small Changes, Big Impact

Lab workers often treat chemicals as “set and forget,” but I’ve learned that smart storage and frequent checks go a long way. Rotating stock, sealing containers tightly, and using desiccants keep moisture out. For labs running at scale, automated monitoring of temperature and humidity provides an early warning. Labeling containers with opening dates helps prioritize older stocks before younger, more stable batches. Periodic NMR or conductivity checks can confirm that nothing unexpected is happening inside the bottle. Long-term, research teams push toward less hydrolysis-prone anions, though that approach trades one set of challenges for another. Until then, practical steps and a sharp eye protect the material and the applications depending on it.

Final Thoughts

Stability is never just a theoretical point. Chemical design sets the stage, but daily habits and honest attention make the biggest difference. In my experience, the best labs aren’t just those with the newest chemicals, but those where everyone looks out for molecule and colleague alike.

Why Storage Matters

I have spent years in chemical research labs, and one reality keeps coming back—chemical safety works best when storage practices match the properties of the substance. 1-Octyl-3-Vinylimidazolium Hexafluorophosphate is an ionic liquid, so the habits that suit ordinary solvents or acids don’t always apply here.

This compound doesn’t behave like water or ethanol. It offers high thermal and chemical stability, but that doesn’t mean it’s fine to ignore storage conditions. Mishandling any ionic liquid, especially those containing hexafluorophosphate, invites some unwelcome risks. Chemical degradation, unexpected reactions, and moisture contamination have all burned even the most careful chemists before.

Environmental Factors Matter

Humidity messes with ionic liquids more than most folks expect. Although 1-Octyl-3-Vinylimidazolium Hexafluorophosphate resists hydrolysis better than some ionic liquids, prolonged exposure to moisture lets the hexafluorophosphate anion break down, potentially releasing toxic compounds like hydrogen fluoride. So any lab storing this chemical keeps it in tightly sealed containers, usually made from glass or inert plastic. I remember using polytetrafluoroethylene (PTFE)-lined caps, because regular caps might not provide a true barrier against water vapor or reactivity over time.

Direct sunlight heats storage areas fast, and heat speeds up chemical changes no one wants. Cool, dark cabinets or dedicated refrigerators away from food keep degradation in check. My old supervisor always insisted we put any new batch on the lowest shelf in a desiccator, behind a silica gel pack. That trick ended countless headaches with clumpy or compromised materials.

Separating from Incompatibles

Even though this ionic liquid sounds stable, it does react with strong bases and acids, especially if any leak or spill happens. A shelf full of aggressive cleaning agents or oxidizers increases the chances for messy reactions. In my experience, anchoring the chemical in its own labeled, secondary container—nested inside a spill tray—safeguards everything else nearby. Accidents don’t announce themselves, so separation keeps cleanup easier and safer.

Labeling and Documentation

One lesson that stuck with me: unmarked containers turn small issues into big mysteries. For ionic liquids like this, labeling goes beyond just the chemical name. A readable label lists the date received and the name of the responsible researcher. Stability depends on the vendor’s original purity, so holding onto the supplier’s data sheet and batch number helps trace any mystery decomposition or performance issue later.

Disposal and Training

Disposing of compounds with hexafluorophosphate usually involves professional waste handlers, since municipal drains won’t neutralize the toxic byproducts. Anyone handling or storing such chemical stocks needs more than written procedures—a hands-on run-through with an experienced chemist stands out as the safest way to learn how to minimize mishaps.

Sharing Lessons Learned

Smart storage involves simple habits. Sealed, moisture-proof containers, rigorous labeling, temperature control, chemical segregation, and a keen awareness of how this chemical changes over time—these steps form a solid line of defense. Labs and storage rooms can avoid expensive incidents by treating every bottle as a teaching tool. Chemical safety is about collective memory: every mishap prevented means more time spent on good science rather than damage control.

Not All Chemicals Are Created Equal

People often want to draw tidy lines between what is toxic and what isn’t. It rarely works out that way in real life—especially with new compounds like 1-Octyl-3-Vinylimidazolium Hexafluorophosphate. This chemical, part of the ionic liquid family, turns up in green chemistry labs and some specialty research settings. Its ionic nature lets it dissolve a lot of stuff and, at first glance, it seems to promise fewer emissions and less waste than volatile organic solvents.

Peeling Back the Layers of Hazard

Even with all the hope around ionic liquids, real risks often hide behind long, complicated chemical names. Hexafluorophosphate anions, for example, bring safety questions all their own. Most chemists who’ve spent time in a research lab know that hexafluorophosphates break down under certain conditions and may release hydrogen fluoride (HF). That’s no minor issue—HF has a bad reputation for etching glass and, more seriously, for causing deeply penetrating burns and systemic toxicity in people. The imidazolium ring structure, on its own, doesn’t spell instant danger, but substituents such as octyl and vinyl groups can nudge a chemical’s behavior in unpredictable directions.

Digging into peer-reviewed studies and reliable Material Safety Data Sheets, it becomes clear: this compound hasn’t undergone nearly as much toxicological testing as established industrial solvents. Some ionic liquids have been flagged for their possible effects on aquatic life, mostly due to the persistence of their cation-anion pairs and their habit of bioaccumulation. I’ve seen concerns raised in journals like “Green Chemistry” and “Chemical Reviews,” going back over a decade. These worries don’t always make it to the front page, but ask anyone handling these liquids regularly—they almost never get the “handle with wild abandon” treatment from safety officers.

Lab Habits That Matter

People in the lab sometimes get a false sense of security around modern materials, assuming “innovative” means “safe.” No chemical deserves that kind of optimism. Most institutions treating 1-Octyl-3-Vinylimidazolium Hexafluorophosphate like something new and harmless soon learn otherwise if spills or accidents happen. This compound doesn’t ignite easily or evaporate quickly, but low volatility isn’t the same thing as low risk. Gloves, splash goggles, and a fume hood still make sense every time it’s weighed, poured, or mixed. Anyone ignoring those safeguards risks skin contact or inhalation they’d regret.

Disposal raises another headache. Unlike good old acetone or ethanol, there’s no neighborhood facility ready to mop up ionic liquids. Hazardous waste teams gripe about the long-term fate of hexafluorophosphate-based compounds in the environment. Online lab forums have no shortage of cautionary tales and cleanup horror stories from people who learned after the fact just how stubbornly persistent these chemicals can be.

Better Practices and Smarter Choices

Smart research has always separated breakthroughs from disasters. Plenty of industrial safety failures started with a shrug about “unknown” hazards. If a chemical’s record leaves too many blanks, it’s smarter to treat it with the respect you’d give its nastier cousins. Substitute with better-understood solvents when possible. Keep exposure to a minimum, and don’t take shortcuts on labeling or waste disposal. I always tell new students: if you can’t quickly explain what makes a compound safe or risky, you owe it more caution—not less.

No shortcut ever fixed a gap in data. Until health, safety, and persistence data for 1-Octyl-3-Vinylimidazolium Hexafluorophosphate fill out, best practice means treating it as hazardous—not “possibly safe.” Experience reminds us that serious problems don’t announce themselves; chemicals deserve respect before, not after, something goes wrong.

The Makeup of a Modern Ionic Liquid

Chemistry shapes much of what I see and use every day, far past the lab. Some names come packed with meaning, and 1-Octyl-3-Vinylimidazolium Hexafluorophosphate is a prime example. This name hints at its structure and also hints at the type of work chemists expect from it. The molecular formula stands as C15H27F6N2P. Tallying up the atomic weights, this compound weighs about 394.35 g/mol. While that might look like just a number, it tells a lot about the component atoms and how they come together to create unique properties linked to ionic liquids.

Molecular Structure: Why It Stands Out

This compound fits into the family of ionic liquids, a class known for low volatility and ability to dissolve a wide range of substances. My own work with solvents showed me how traditional choices like acetone or ethanol can pose health or environmental risks because of their volatility. The structure behind 1-Octyl-3-Vinylimidazolium Hexafluorophosphate gives it benefits like low vapor pressure and strong thermal stability. The octyl chain draws out hydrophobic interactions, the vinyl group adds reactivity, and the hexafluorophosphate brings excellent ionic conductivity and resistance to water solubility. These features are especially helpful in electrochemistry and advanced materials development.

The Role in Research and Real Life

In the lab, measuring and knowing the molecular weight of your ingredients cuts down on error. Every reaction I ever tried needed the right ratios, and that number—394.35 g/mol—anchors those ratios. Outside my own experiment days, this number matters to industrial chemists, who need to prepare liquids for energy storage, batteries, or catalysis. The formula C15H27F6N2P also serves as a shorthand for finding safety data or matching ingredients for future projects.

Why Should Anyone Care?

Put simply, materials like this are part of safer and more efficient manufacturing. Ionic liquids might replace hazardous solvents in sectors ranging from electronics to pharmaceuticals. With growing pressure to cut down on pollution, these options look attractive. That means more scientists and engineers lean into learning these numbers by heart. The formula and weight aren’t trivia for chemistry textbooks; they help make real changes—greener designs, longer-lasting batteries, and safer workplaces.

Pushing for Safer, Smarter Use

Stepping beyond the numbers, broadening the use of these advanced solvents requires careful consideration. Workers need clear information on hazards and long-term effects as these chemicals move from small-scale testing to factory floors. I’d urge producers to publish transparent, peer-reviewed safety data and invest in comprehensive training. Making sure disposal methods leave no trace in our waterways should always sit front and center. Info about the compound’s makeup—like that formula and weight—sets the foundation for these safety talks.

Choosing the Right Path Forward

In my years keeping up with chemical trends, the power of understanding the numbers behind molecules keeps coming up. C15H27F6N2P and its 394.35 g/mol weight will drive smart decisions for labs and companies looking to do better. No matter how fancy the application, a strong grip on the science behind these materials helps everyone: workers, consumers, and communities on the downstream side of industry. Putting facts and safety up front builds trust and leads to better outcomes across the board.