1-Pentyl-3-Methylimidazolium Acetate: A Down-to-Earth Look

Historical Development

The rise of ionic liquids like 1-Pentyl-3-Methylimidazolium Acetate started with increasing demands for safer, greener solvents. In the late twentieth century, scientists noticed the limitations of volatile organic solvents—evaporation, environmental harm, workplace hazards—and shifted attention to salts that melt below 100°C. Research exploded after recognizing these salts stayed liquid at room temperature and barely released vapors. Chemists, engineers, and industry folks chased after new formulas, hoping to build a cleaner chemistry toolbox. The story of this compound tracks with the broader journey for alternatives that relieve pressure from fossil-based chemicals, hasten efficient catalysis, and drive recycling. Looking back, it’s clear that the motivation behind its synthesis never came from theoretical curiosity; it grew from practical necessity.

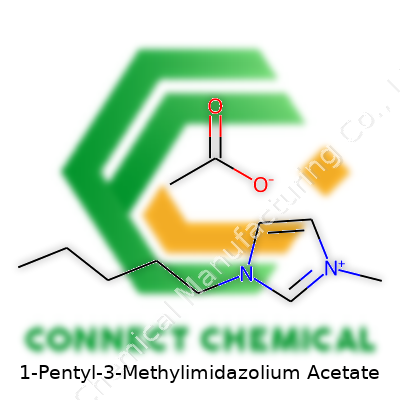

Product Overview

1-Pentyl-3-Methylimidazolium Acetate stands out in the world of designer solvents. It’s built around an imidazolium cation, stapled with a pentyl tail and a methyl group, matched with the simplest carboxylate anion—acetate. The personal experience of handling this material tells a lot: no sharp odor, low vapor, slightly oily feel, and a stubborn resistance to catching fire. These traits make it a favorite in labs and pilot plants where green chemistry matters, especially in applications like cellulose dissolution, enzymatic reactions, and extraction of fine chemicals. Companies selling this material describe it with a sense of pride, knowing their product slips seamlessly into the workflow of research teams aiming to cut down on hazardous waste.

Physical & Chemical Properties

Pouring a sample of 1-Pentyl-3-Methylimidazolium Acetate reveals a light, nearly colorless to pale-yellow liquid at room temperature. With a melting point comfortably below 25°C and a boiling point high enough to avoid worries during most chemical processes, it behaves nothing like traditional solvents. Its density tends to fall close to 1 g/mL, so handling feels familiar, but its high viscosity becomes obvious during mixing. Insoluble in nonpolar solvents but freely mixes with water and alcohols, making it a versatile tool. It holds up under heat and mild oxidizing conditions, but direct contact with strong acids or bases rapidly changes its character. Electrochemical stability stretches the range past what early ionic liquids could offer, opening doors in advanced battery and fuel cell research. The acetate anion sometimes shows mild basicity, affecting reaction mechanisms and selectivity. Under UV light, the solution may pick up a weak fluorescence. Every physicochemical property ties back to the balance between its organic cation and carboxylate anion, controlling everything from viscosity to solubility.

Technical Specifications & Labeling

Product datasheets carve out key specs—purity levels push past 98 percent, and trace metal content hits the low parts-per-million range. Moisture content stays below 0.2 percent with proper packaging, a key concern for research labs. The labeling speaks plainly: 1-pentyl-3-methylimidazolium acetate or [C5mim][OAc]. The label shows chemical formula C11H20N2O2, molecular weight 212.29 g/mol, and hazard pictograms as per GHS requirements. CAS registry and EC numbers line up for seamless procurement. Storage suggestions line up with first-hand lab practice: seal tightly, store in a cool, dry spot, and keep away from incompatible materials. If transport becomes necessary, shippers flag its chemical status, but don’t list it as hazardous under most transport regulations. Shelf life typically stretches over several years if handled right, but open containers call for desiccation and regular checks for water uptake.

Preparation Method

Synthesizing 1-Pentyl-3-Methylimidazolium Acetate takes some patience but follows a straightforward path. Start with methylimidazole—an off-white powder or liquid—then alkylate it with pentyl halide (usually pentyl bromide) under controlled temperature, yielding the quaternary imidazolium bromide. Lots of stirring and energetic reflux speeds things up. To swap out the halide for acetate, mix with sodium acetate in water or ethanol. The acetate trades places with bromide, leaving a neat two-phase system: organic phase contains the ionic liquid, aqueous phase holds sodium bromide. Extract, dry over anhydrous magnesium sulfate, filter, and use high vacuum to finish the job. Crude product goes through charcoal filtration and repeated washings for purity. This process, tested by many undergrad labs and commercial teams, produces a high-quality liquid ready for advanced use.

Chemical Reactions & Modifications

Chemists love tweaking 1-Pentyl-3-Methylimidazolium Acetate because changing the structure means adjusting the function. The acetate group invites esterification, serving as an acetyl group source for organic transformations. Under basic or acidic stress, the imidazolium ring resists ring-opening, holding up better than many aromatic-based solvents. Adding short-chain alcohols or strong nucleophiles sometimes leads to minor side products, but sharp eyes and careful conditions hold that in check. Researchers use this liquid in organometallic catalysis, electrosynthesis, and even as a co-solvent with enzymes because the cation rarely breaks down. It’s not just a solvent; it can take part in the reaction. Some teams graft the liquid onto polymer backbones or use it to make stable nanoparticles, making it a chameleon in nanoscience and process engineering.

Synonyms & Product Names

Suppliers and publications often swap names: 1-pentyl-3-methylimidazolium acetate, [C5mim][Ac], and C11H20N2O2. Some catalogs shorten it to PMIM Acetate or use the label 1-Pentyl-3-Methylimidazolium ethanoate. Labs sometimes refer to its ionic liquid shorthand, like [C5mim][OAc], to cut down confusion during group meetings or in project logs. Trade catalogs group it under imidazolium-based ionic liquids or list it with cellulose solvents. Remembering these variations keeps orders accurate and prevents costly mix-ups in purchasing.

Safety & Operational Standards

Handling comes with some real world lessons. Spills feel oily and slippery, but they clean up with soap and water since it dissolves readily. Still, gloves and eye protection always come out when dealing with this ionic liquid. Direct skin or eye contact brings discomfort (usually redness or brief irritation), though nothing dramatic under normal use. Working with it in well-ventilated spaces, away from oxidizers, prevents buildup of unwanted vapors and risky byproducts. Dispose of containers just like other quaternary ammonium salts, aiming for high-temperature incineration or specialist chemical waste processing to keep groundwater safe. Most manufacturers run regular hazard audits and offer solid MSDS paperwork. Safety standards fall in line with GHS, and teams new to this class of chemicals usually pick up handling habits quickly after a few sessions.

Application Area

My experience in biopolymer research showcases how 1-Pentyl-3-Methylimidazolium Acetate hits the sweet spot for dissolving cellulose and chitin, unlocking routes to new bioplastics. Its low volatility and low flammability ease concerns in continuous processing settings. Pharmaceutical firms test it for controlled API crystallization, taking advantage of its unusual solvation traits. Specialty chemical firms put it to work in high-efficiency extraction of rare earth metals, not just because of its unique selectivity, but also the simplicity in recycling the solvent between cycles. In enzyme catalysis, it keeps biocatalysts active far longer than standard aqueous or alcohol solutions. Labs building designer nanoparticles find the ionic strength and low toxicity enable direct synthesis routes, cutting months off pilot runs. Researchers at large see this compound as a game changer, especially where traditional organics pose a safety or waste problem.

Research & Development

Innovation with 1-Pentyl-3-Methylimidazolium Acetate keeps picking up speed as new labs enter the field. Teams explore modifications that widen the scope—swapping out acetate for propionate or butyrate, tweaking alkyl chain length, or using it in new flow chemistry setups. Collaboration spans from chemical engineering giants to small start-ups driving greener process scale-ups. Computational chemists model its solvation properties to predict new uses, and academic groups design new polymers incorporating the ionic liquid as a physical crosslinker. The journal pipeline overflows with papers demonstrating improved yields, better selectivity, and greener process footprints. In my circles, partnerships with biotech firms show real gains from combining ionic liquid use with enzyme cascades, not just tinkering for publication but aiming for actual market products. That synergy keeps the intellectual energy high and the real-world impact tangible.

Toxicity Research

Initial concerns about the safety of ionic liquids often arise due to their limited biodegradability and persistence in some environments. Bench-top trials and standardized aquatic toxicity assays, running over several years, show that 1-Pentyl-3-Methylimidazolium Acetate lands in the middle ground: it demonstrates lower acute toxicity than imidazolium salts with longer alkyl chains but still outpaces traditional solvents in many safety tests. Chronic impact on microorganisms and soil fauna gets close scrutiny, spurring development of new assessment models and rapid degradation pathways. Research teams publish works testing it in zebrafish, algae, and even controlled mammalian cell lines to ensure future safety. Direct handling with personal protective equipment prevents workplace incidents, but accidental environmental release is a growing discussion in regulatory circles. Progress on next-generation ionic liquids focuses on cutting their environmental footprint, and many labs already pursue greener synthesis pathways that use renewable feedstocks, less hazardous reagents, and simpler purification schemes.

Future Prospects

The horizon for 1-Pentyl-3-Methylimidazolium Acetate stretches far, anchored by moves toward renewable resources and green manufacturing. Demand in biomass processing, specialty chemical synthesis, and energy storage will likely climb, fueled by solid evidence of operational gains and real reduction in waste streams. New startups, eager to translate academic findings, bring in automation and digital quality controls, raising standards and consistency in supply. Environmental standards ratchet up each year, pushing for further reductions in toxicity and breakthroughs in biodegradability. Ongoing advances in polymer science and nanotechnology promise even tighter integration of this ionic liquid, bridging performance gaps in advanced composites and smart materials. From my view, the compound stands at a crossroads where industrial efficiency and environmental responsibility can finally move together. It’s a tool not just for chemists chasing new reactions, but for entire industries rethinking their impact on the planet, bringing needed optimism in the race for cleaner, safer, and more sustainable chemistry.

How I Saw This Chemical Change the Game

Most people have never heard of 1-pentyl-3-methylimidazolium acetate. In a regular conversation, the name alone twists tongues. But deep in research labs and behind the doors of innovative companies, I've watched as this so-called ionic liquid shakes up old ways of doing things. Years spent working with green chemistry and bioprocessing mean I've seen hype chemicals come and go, but this one keeps sparking talk among folks who care about making science cleaner and more efficient.

Getting to the Heart of Its Value

This isn’t a common household ingredient, but people in materials science or biotechnology labs know it well. In short, it's a room-temperature ionic liquid. That means it stays as a salt melted into liquid form at fairly low temperatures. This special structure gives it unique powers as a solvent. In my experience with research projects on cellulose processing, I've found this chemical dissolves cellulose much faster than water or traditional solvents. Wood pulp, cotton fibers, even old newspaper scraps—tough materials that hardly react with most liquids—break down in hours. That opens up new ways to make biofuels and biodegradable plastics.

Traditional cellulose dissolution often calls for harsh chemicals like concentrated acids or bases, leaving behind toxic waste. When I worked with undergraduate teams, we tried replacing these with ionic liquids, and the lab waste was safer to handle. For large companies focused on renewable energy, this means not just a smaller environmental punch but also an easier time staying on the right side of environmental rules. Even now, more scientific papers are pointing to lower toxicity and higher recyclability as real advantages.

Digging Deeper into Its Uses

Beyond cellulose, this ionic liquid plays a role in separating and purifying tough-to-crack mixtures. Pharmaceutical labs need new solvents to cut down on hazardous byproducts. In my work supporting green manufacturing, I’ve seen how people run into a wall with traditional organic solvents—flammability, volatility, trouble reusing them. By using 1-pentyl-3-methylimidazolium acetate, process engineers can reuse the solvent over many reaction cycles. That drops costs and saves companies from constantly buying and disposing of dangerous chemicals.

This chemical doesn’t stop at the lab stage, either. Polymer engineers experiment with it to both dissolve and reshape plastics, giving a second life to waste. With electronic devices putting pressure on earth’s metal resources, folks in recycling test this solvent for pulling rare metals from e-waste. From my own projects, the fact that it doesn’t evaporate at room temperature means fewer fumes—healthier for both researchers and factory line workers.

What’s Holding Back Wider Adoption?

Costs stay higher than old-school solvents. Scale-up needs specialized tanks and piping, so not every facility can jump right in. Still, technology marches on. Whenever I’ve spoken with chemical suppliers or startup founders, many see demand growing as regulations tighten on hazardous materials. Universities and industry startups want something sustainable that actually works, not just a green label for advertising. That gives real motivation to improve production and recycling, and I expect to see prices drop and adoption rise.

Clear Steps Forward

Companies should invest in pilot projects to build firsthand know-how. Scientists and engineers need better training for safe handling and effective purification. Partnerships between research labs and waste management groups can find new ways to recycle this solvent after its work is done. If government grants or policy incentives help level the playing field, I believe real progress will come sooner. I've seen over and over that good science combines environmental sense with practical improvements—this chemical gives both a fighting chance.

What the Name Reveals

Names in chemistry carry a lot of weight. Take 1-Pentyl-3-Methylimidazolium Acetate. The name itself breaks down almost like a recipe, and knowing how to read it helps you picture what’s going on at the atomic level. There’s a “pentyl” group, a “methylimidazolium” core, and the whole thing partners with an acetate ion. I remember seeing chemicals with big names and feeling lost. Things started clicking once I learned to interpret names as maps.

Breaking Down the Structure

Let’s start with the core: imidazolium. This is a five-membered ring with two nitrogen atoms. The ring is aromatic and flat, like a disc, and the nitrogens sit apart from each other by one carbon. In 1-pentyl-3-methylimidazolium, a methyl group attaches to the nitrogen at position three, while a pentyl chain—a straight five-carbon string—dangles from the nitrogen at position one.

That core—bulky, positively charged (thanks to the double nitrogen)—carries a lot of the properties that make ionic liquids stand out. The positive charge isn’t just a technicality. It shapes how the molecule interacts with others, including the acetate anion that completes the salt.

Looking at Acetate

Acetate doesn’t get as much attention in the chemical name, but it’s equally important. You have a two-carbon fragment, with one of them carrying a double-bonded oxygen and a single-bonded oxygen with a negative charge. This negative charge pairs tightly with the positive imidazolium, giving the overall molecule its salt property.

Why does this matter? Acetate isn’t as aggressive as some other anions. It’s kind of gentle, especially compared to fluorinated cousins that can cause headaches and environmental worries.

From Structure to Usefulness

What does this mean for actual use? Salts like 1-pentyl-3-methylimidazolium acetate belong to a group called ionic liquids. They don’t behave like table salt or sugar in water. Instead, they’re often liquid at room temperature. That means they dissolve things other solvents leave untouched. Lab workers use them for cellulose, which usually laughs off most solvents.

A few years ago, I helped pull apart plant matter using ionic liquids—cellulose would usually clump together, clog filters, and make a mess. Using this particular class of chemicals, we could break cellulose into a smooth solution and filter it easily. It felt like we’d unlocked a set of chemical handcuffs.

Risks and Responsible Use

There’s another side here. Not every ionic liquid is safe. We all know famous stories about “green” solvents turning up as problems later on. One thing that makes imidazolium-based salts appealing is that their properties shift a lot based on the choice of side chain or anion. Acetate doesn’t build up in ecosystems the way others can. That eases some safety concerns but doesn’t eliminate the need for care.

What to Look for in the Future

Researchers keep tinkering with the core and the side chains. Trying to blend safety, performance, and affordability isn’t just a balancing act—it’s a moving target. As the field grows, it’s worth asking tough questions about end-of-life disposal, breakdown in the environment, and full-life-cycle analysis. Personal experience with failed green chemistry projects tells me this isn’t optional. A few modifications at the molecular level can mean the difference between a breakthrough and a costly misstep.

It’s not just about knowing the structure. It’s about understanding the ripple effects from lab bench to industrial scale, and thinking two steps ahead of where that molecule might end up.

Why Storage Matters For This Chemical

Keeping chemicals safe goes beyond a checklist. In every lab I’ve worked in—whether academic or industrial—the way we store ionic liquids like 1-Pentyl-3-Methylimidazolium Acetate changes everything. It’s more than protecting equipment or ticking compliance boxes. It’s about safety, shelf life, and real-world outcomes. This compound, often valued for tasks like cellulose processing or research into green solvents, can make or break an experiment when not handled right.

Shutting Out Moisture and Air

I learned the hard way that ionic liquids practically invite water over for a party. Leave a bottle uncapped for an afternoon, and you’ll find the substance has soaked up moisture. This not only changes its performance, it can run up costs. Keeping this chemical dry isn’t just good housekeeping; it determines if the next experiment works. Some researchers store their stock in tightly sealed containers—borosilicate glass vials with screw tops, for example. Silica gel packs help keep moisture at bay. I’ve seen seasoned lab techs add extra parafilm just for peace of mind.

Cool, Dark, and Out of the Sun

Sunlight and heat work like silent wreckers on chemical stability. Direct exposure can break down sensitive compounds and kick off reactions you didn’t sign up for. My preference, shaped by plenty of trial and error, is a temperature-controlled chemical fridge—not the one used for biological samples. These refrigerators lock the temperature at 4°C to 8°C, and you don’t get accidental freezing. In one project, our group left the chemical on a sunny shelf for only a month. The difference in color and viscosity shocked us. Never worth the risk.

Choosing The Right Label and Segregation

Mislabeled or loose chemicals turn simple mistakes into real emergencies. Each time a bottle gets used, it helps to write fresh date information and the initials of the handler. Segregation comes next—keeping 1-Pentyl-3-Methylimidazolium Acetate away from acids and bases, oxidizers, and anything incompatible. Too many folks in busy labs stack bottles together to save space. I’ve seen a minor leak from a neighboring oxidizer ruin an expensive batch of this chemical, all because of cramped storage.

Handling Spills and Waste

Even with great storage, spills can happen. Every lab should have a spill kit within arm’s reach. Absorbent pads, goggles, and gloves should be standard. Once, a container developed a crack unnoticed for weeks; the result was a sticky mess that took a team hours to clean up. Fast cleanup kept the damage minimal, but some nearby supplies had to be thrown out. Disposal isn’t just pouring down the drain—hazardous waste collection, with proper paperwork, keeps you on the right side of regulations.

Solutions For Long-Term Stability

Sometimes buying in bulk seems cheaper but introduces fresh headaches. If the chemical’s not used rapidly, contamination and degradation start to creep in. Buying smaller aliquots has saved me more money long term. Modern packaging—like amber glass to cut light, and vacuum-sealed pouches—adds another line of defense.

No one welcomes surprises in chemistry. Storing 1-Pentyl-3-Methylimidazolium Acetate with real attention keeps experiments productive, people safe, and the bottom line healthy.

Why People Ask About Its Safety

The name 1-Pentyl-3-Methylimidazolium Acetate sounds technical, but this chemical pops up more than most realize, especially wherever new ways of dissolving tough-to-handle materials are making waves. Teachers and lab technicians have asked me whether this ionic liquid is as safe as some chemistry companies claim. You may see it featured in research on greener solvents or cellulose processing. It's always smart to question the risks before working with something new, especially with a long chemical name.

What We Know About the Chemistry

This compound is an ionic liquid, which means it stays liquid at lower temperatures than most salts. Its structure allows it to dissolve whole chunks of plant matter with surprising speed. Scientists like it for this reason, since traditional solvents either struggle or give off some nasty fumes. But the push for “greener” solutions shouldn’t fool anyone into thinking that every new solvent is safer for humans or nature.

Hazard Data and Gaps

There’s no shortage of caution needed with 1-Pentyl-3-Methylimidazolium Acetate. Lab tests show low volatility, so fumes aren’t the biggest concern. People can’t count on low vapor pressure to make a substance safe, though. Direct contact with skin or eyes still brings irritation. Animal studies, mainly with similar ionic liquids, have found cell damage and organ effects at higher doses. There’s little long-term research on its buildup in the human body, but a few papers raise red flags about the persistence of these materials in soil and water.

Spill some on a bench or gloves, and it doesn’t just evaporate. These liquids can linger, making cleanup harder than with alcohol or acetone. Because of their unique nature, standard protective equipment still matters. I’ve seen people underestimate these risks, thinking the word “biodegradable” on a chemical data sheet equals low hazard. The reality: There’s not enough comprehensive data on chronic toxicity, reproductive hazards, or breakdown products once this substance hits drains or the wider environment.

Weighing the Evidence

The science world likes new tools, but safety must come first. For 1-Pentyl-3-Methylimidazolium Acetate, positive lab results don’t erase the uncertainty about what exposure means for live animals or people. The European Chemicals Agency lists limited acute data, and the U.S. Environmental Protection Agency treats most ionic liquids with caution and strict waste disposal requirements. The compound hasn’t shown a wild tendency to explode or catch fire, which helps storage concerns—but its reactivity with strong acids or bases still creates hazardous byproducts.

How to Lower Risks and Move Forward

To work with 1-Pentyl-3-Methylimidazolium Acetate safely, gloves and goggles should be standard. Spill kits that focus on absorbent materials—not just water flushes—are better, since this chemical needs a careful approach to waste. Researchers and industries looking to use ionic liquids should keep clear logs of where and how much they use, then monitor for contamination. Open sharing of negative results about health impacts helps everyone, not just lab workers.

Safer alternatives might not hit the same performance levels right away, but chasing only efficiency risks exposing people and ecosystems to new hazards. Responsible adoption of new solvents should include both regular checks on old safety measures and curiosity for updated toxicology data. It’s not just about replacing old chemicals, but about changing how we think about long-term safety—because what’s new isn’t always harmless.

Green Chemistry: Pushing Away From Toxic Solvents

Stepping into most chemistry labs, you spot bottles of strong-smelling, flammable liquids. Solvents like toluene, methanol, and chloroform show up everywhere. Years in research taught me how rough those chemicals get, not only for researchers, but for the environment when waste leaves the lab. 1-Pentyl-3-Methylimidazolium Acetate offers an answer. This ionic liquid works as a powerful solvent, yet doesn’t release noxious fumes and doesn’t catch fire easily. The European Chemicals Agency flags these safety traits as critical, especially when companies aim for “green” manufacturing. Using this acetate-based ionic liquid, researchers swap out older, more harmful liquids with one that treats the team—and the planet—a little better.

Plant Material Breakdown for Biofuels

Building a future with less fossil fuel means breaking down woody plants into sugars usable by microbes. Lignocellulosic biomass wastes, like straw or sawdust, make an abundant source for bioethanol, yet their tangled structure resists many traditional solvents. What impresses many in energy research is how effectively 1-Pentyl-3-Methylimidazolium Acetate dissolves cellulose and breaks apart lignin. Out in the field, scientists use this tool to “pretreat” crop leftovers, speeding up the process, recovering more sugars, and promising a better yield. This isn’t just lab talk—pilot plants have already reached new efficiency records using ionic liquids like this in their workflow.

Separation Techniques: Pulling What Matters Out of a Mix

Every engineer gets challenged to separate one part of a mix from another, whether cleaning up water, pulling out metals, or refining pharmaceutical ingredients. Traditional solvents often fail here, especially with polar compounds or metal ions. The acetate component in this ionic liquid latches strongly onto certain metal ions. This makes 1-Pentyl-3-Methylimidazolium Acetate a favorite for extracting rare earths, cleaning up industrial wastewater, or recycling battery materials. A team working on lithium battery recycling explained to me how this liquid zeroed in on lithium ions, speeding up recovery while minimizing secondary pollution. Its selectivity can save money and reduce energy use across industries.

Smart Materials and Nanotechnology

Ionic liquids aren’t just solvents—they help design new materials. In one nanotech workshop, researchers mixed 1-Pentyl-3-Methylimidazolium Acetate with metal salts, producing finely shaped nanoparticles for catalysts and sensors. These nanoparticles, grown in the liquid instead of in water or alcohol, came out more uniform and less likely to clump. For industries building better batteries or solar panels, such control over material properties sets apart ionic liquids as next-generation manufacturing aids.

Room for Improvement and Responsible Use

No tool is perfect. Cost still slows widespread adoption—making ionic liquids, especially with custom alkyl chains, gets pricey. Plus, we always need to check for any toxicity issues in the environment. I’ve seen more journals focus on how these liquids break down and what happens if they slip into groundwater. A few promising projects recover and recycle the liquid after each use, cutting total cost and possible harm. New research also tweaks the structure, seeking ionic liquids with even lower toxicity and better biodegradability.

Moving the Needle in Industrial Practice

Beyond experiments, industry partners look for real-world wins. Early adopters—biofuel producers, metals processors, and clean-tech startups—show that ionic liquids like this acetate version solve sticky problems that slow down cleaner, safer, and more efficient manufacturing. As more big firms invest in sustainable chemistry, demand for smarter solvents will keep rising. If researchers keep refining these molecules and companies stay committed to safety, ionic liquids stand to make their mark on everything from energy to electronics.