1-Pentyl-3-Methylimidazolium Hexafluorophosphate: A Ground-Level Look

Historical Development

Back in the late 1990s, ionic liquids started making noise in chemical circles. Classic solvents caused plenty of headaches with their volatility and environmental impact. Chemists needed something safer, less flammable, and easier on the world. 1-Pentyl-3-Methylimidazolium Hexafluorophosphate, often called [C5mim][PF6], landed right in the middle of that search. Sometimes, breakthroughs follow a persistent itch — in this case, the urge for cleaner, more reliable alternatives. Laboratories that leaned into the ionic liquid movement quickly put this compound on their radar, impressed by its strong thermal stability and willingness to dissolve a wide range of compounds. Over time, patents piled up and research groups realized this salt could cut through the status quo in green chemistry.

Product Overview

Sold as a colorless or faintly yellowish liquid, 1-Pentyl-3-Methylimidazolium Hexafluorophosphate often carries the telltale chemical smell of its family. Its real charm doesn’t sit on the surface—it's hidden in the way it acts as a solvent for notoriously stubborn organics, metals, and even some polymers. Inventory sheets for lab supply companies show this ionic liquid getting bottled in HDPE or glass, capped tight against moisture and air. Once poured, it clings to glassware long after cleaning, a stubbornness that most synthetic chemists know well. Companies usually stamp batch numbers and manufacture dates on the label, with purity levels reaching as high as 99% for research-use grades.

Physical & Chemical Properties

[C5mim][PF6] displays the viscous, oily texture common to many imidazolium-based ionic liquids. The pentyl side chain helps drop the melting point below room temperature, keeping it liquid almost year-round, even in cold labs. Unlike typical solvents, it barely evaporates — vapor pressure clocks in at nearly zero. The hexafluorophosphate anion adds chemical resilience, standing up to most acids and bases, although strong nucleophiles can break it down. This compound doesn’t light up easily; flash points hover well above those of common organics, making it much safer in scale-up. High ionic conductivity sets it apart from most solvents, giving electrochemists a reliable starting point for new battery electrolytes and sensor tech.

Technical Specifications & Labeling

Most suppliers ship this liquid with specs covering water content (usually under 0.1%), heavy metal analysis, and NMR confirmation of structure. You’ll see SDS files flagging hydrolysis warnings, since hexafluorophosphate can release small amounts of hydrogen fluoride after prolonged contact with water. Standard labeling includes the full IUPAC name, unique CAS number 68434-98-6, hazard symbols, and instructions for closed-container storage at room temperature. Some producers certify their product meets ISO 9001 or similar quality management systems. Glass jars typically ship with PTFE-lined caps to prevent contamination from leaching.

Preparation Method

The usual route to 1-Pentyl-3-Methylimidazolium Hexafluorophosphate starts with 1-Methylimidazole. Chemists react it with 1-Bromopentane, using reflux and a gentle hand to keep water out of the process. This step rolls out 1-Pentyl-3-Methylimidazolium Bromide as an intermediate. Next comes metathesis—adding potassium hexafluorophosphate in water or acetonitrile, shaking things up until the bromide swaps for PF6-. After washing away salts and drying the organic layer, the liquid product appears dense and ready for further purification. I’ve run this in the lab with only a few hiccups, mainly from side reactions or excess moisture tripping up the PF6- transfer.

Chemical Reactions & Modifications

[C5mim][PF6] stands its ground through most reaction conditions, but some shortcuts can backfire. Strong bases can cause a breakdown of the PF6- group, leaking out fluoride. In electrochemical setups, folks have managed to tweak the alkyl chain, swapping pentyl for longer or branched versions to shift viscosity or hydrophobicity. Researchers keep pressing the imidazolium core, altering side chains for custom solubility and selectivity profiles. On the anion side, switching PF6- for less hydrolyzable members like bis(trifluoromethanesulfonyl)imide (NTf2-) can ease worries about HF byproducts.

Synonyms & Product Names

Across journals and catalogs, this compound answers to a handful of names. You might catch it as 1-n-Pentyl-3-Methylimidazolium Hexafluorophosphate, [C5mim][PF6], or just PMIM PF6. Some brands shorthand it to ‘Imidazolium Ionic Liquid 5’ in their lineups. The core identifiers remain the same: a five-carbon alkyl chain, a methyl on the imidazole ring, and one PF6- anion per cation.

Safety & Operational Standards

Lab work with 1-Pentyl-3-Methylimidazolium Hexafluorophosphate brings its own set of rules. Splash goggles and nitrile gloves don’t just collect dust in drawers; they shield against accidental spills, which can sting on the skin and irritate mucous membranes. Open bottles in well-ventilated spaces, since even faint traces of HF should never build up indoors. Keep lots of water or neutralizing solution nearby in case things go sideways. I’ve personally seen cracked open bottles corroding steel benches after being left with a little water inside, a clear signal that careful storage pays off. Waste disposal hits hard, too, since PF6- compounds belong in hazardous waste, not down the drain.

Application Area

The main draw for [C5mim][PF6] shows up in modern synthesis. Its ability to dissolve both polar and nonpolar ingredients makes it a bridge in biocatalysis, organometallic reactions, and even pharmaceutical production. In electrosynthesis, batteries, and solar cells, it acts as both a solvent and an ionic conductor. Extraction chemists lean on it to pull tricky analytes from water and oils—something old-fashioned solvents struggle to do neatly. Its resilience against air and light means one bottle can handle dozens of projects, stretching research budgets and earning its keep on crowded shelves.

Research & Development

Labs now push 1-Pentyl-3-Methylimidazolium Hexafluorophosphate into new territory every year. Teams in Asia and Europe clock impressive publication counts, aiming it at CO2 capture, enzymatic reactions, and functional materials. Battery developers in the US and Germany continue chasing more stable, less toxic versions based on feedback from early failures with lithium-ion prototypes. Conferences echo with calls for safer, recyclable ionic liquids; [C5mim][PF6] usually ends up in the conversation, given its reliable performance and easy modification options.

Toxicity Research

Concerns over toxicity popped up quickly after wider adoption. Early reports found low acute toxicity on skin or ingestion, but later work outlined longer-term environmental risks. PF6- anion can slowly break down into fluoride-containing byproducts—in some cases, persistent in aquatic systems. Regulatory agencies now call for strict handling and disposal, with several studies rating environmental hazard as moderate to high. Cell cultures and animal testing turn up only minor acute harm, yet chronic impacts remain a question. Years back, teams in Scandinavia flagged possible build-up of these salts in local waters, leading to stricter waste management protocols in research-heavy cities. My own experience with persistent residue on glassware convinced me that these compounds don’t break down easily outside controlled burning or specialized chemical waste treatment.

Future Prospects

Researchers and industry leaders continue to chase more sustainable options. The reality is, nothing handles both organic and ionic duties quite like [C5mim][PF6]. Companies are developing new anions to lower persistent environmental threats, hiking energy efficiency in electrochemical applications, or cutting down toxicity. Scaling up production needs cleaner synthetic methods and more robust protocols for waste management. Schools and training centers now anchor safety briefings around ionic liquids. With sustainability targets driving change, I see a future where custom-tailored ionic liquids—including this one—play a central role in carbon capture, green synthesis, and beyond. In chemical research and manufacturing, demand remains steady for safe, high-performing solvents that balance innovation with responsibility.

Unpacking an Ionic Liquid That’s Shaping Lab Life

Meet 1-pentyl-3-methylimidazolium hexafluorophosphate, a tongue twister of a name with a real job in research and industry circles. Its structure tells us everything about its behavior—it’s not just a puzzle for chemists but a real tool that drives innovation in fields like catalysis, electrochemistry, and even green chemistry. You won’t glimpse this compound at the grocery store, but folks working with batteries, sensors, or next-gen extraction techniques probably have stories to tell about it.

Getting Down to the Structure: What’s Inside?

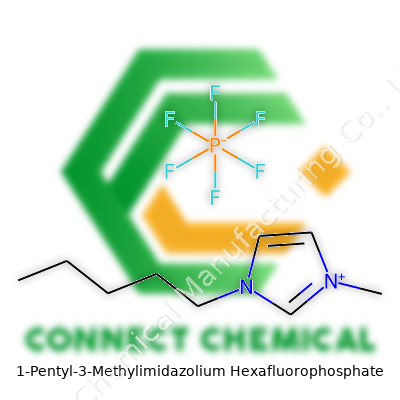

The name pulls double duty, spelling out each piece. On one side, there’s the cation: 1-pentyl-3-methylimidazolium. This starts with an imidazolium ring—a five-membered ring with two nitrogens. Stick a pentyl group on one nitrogen and a methyl group on the other. The pentyl group is a straight chain of five carbons, while methyl brings just one. These side chains tweak the solubility, viscosity, and stability of the compound, and their placement—locked right on the nitrogens—matters more than most assume. The imidazolium core brings plenty of stability, helping make this ionic liquid so useful.

Chemists shorthand the formula as [C5mim][PF6]. The PF6 part isn’t just empty shorthand—it stands for hexafluorophosphate, an anion made up of one phosphorus atom surrounded by six fluorine atoms. This chunk brings non-coordinating behavior and impressive chemical stability, which keeps reactions clean and equipment safe, especially in environments where moisture might spell trouble. The large, symmetrical, and hydrophobic anion pairs with the cation to form a liquid that rarely evaporates and barely breaks down, even at higher temperatures.

Why the Structure Matters in the Real World

Peek behind the curtain, and you’ll see why labs hold onto bottles of this stuff like gold. The length of the pentyl chain isn’t random. Longer alkyl groups stretch out the cation, peeling apart the ions just enough to soften the melting point. That’s one reason this salt doesn’t stay solid under most lab conditions. Flexibility in its structure lets this liquid dissolve all sorts of organic and inorganic players that regular solvents just can’t handle. It feels odd to call a salt a “liquid,” but the truth is, the irregular shapes and differing sizes of the cation and anion don’t want to snap into a lattice like table salt; the structure loosens them up and keeps the mixture flowing like oil.

For me, there’s something almost rebellious about working with these ionic liquids compared to the old guard solvents. Volatile solvents have always packed the lab with fumes; these newer liquids back off, with nearly zero vapor pressure. Lighter environmental footprint just follows. On top of that, the hexafluorophosphate anion fends off water and air, so you don’t wind up with mystery compounds or ruined tests—a relief if precise, repeatable results matter.

Room to Grow and Improve

Nobody’s calling it perfect. The phosphorus-fluorine combo in the anion sometimes sparks handling and disposal worries, so researchers keep searching for greener alternatives. On the cation side, getting the perfect alkyl chain length often takes some fiddling. Still, the core ideas—combining a nitrogen-rich ring with the right anion—produce liquids that cut headaches out of tough syntheses and open up new ways to reuse valuable metals or run batteries hotter and longer.

I’ve watched the field expand, driven by chemists finding new recipes tweaks, each tuning the structure to fit a different challenge. The magic sits right there in the molecule—a blend of rigid rings, flexible chains, and tough anions that keep moving the science forward.

Emerging Role in Green Chemistry

The push for cleaner reactions opened up opportunities for ionic liquids that cut down on hazardous waste. I’ve seen many labs swap out volatile organic solvents for salts like 1-Pentyl-3-Methylimidazolium Hexafluorophosphate. Once, our group switched to this compound for a catalytic hydrogenation. What struck me most—the efficiency barely changed, but the lab air smelled cleaner, and nobody coughed from solvent fumes. This approach not only lessens air emissions but also makes chemical handling safer for graduate students. That matters, especially over years of exposure.

Use in Electrochemistry and Energy Storage

Energy sector researchers keep looking for ways to build longer-lasting, higher-capacity batteries and capacitors. A friend developing supercapacitors found that 1-Pentyl-3-Methylimidazolium Hexafluorophosphate offers good electrochemical stability and wide potential windows. Because this salt doesn’t catch fire and barely evaporates, workers can focus on performance without worrying about safety lapses. Real-world implications can already be seen. In studies at Tsinghua University and elsewhere, ionic liquid-based electrolytes have pushed device lifetimes up and cut accidental shutdowns caused by short-circuits.

Practical Extraction and Separation Applications

Industries handling dyes, metals, pesticides, and radioactive materials turn to ionic liquids for specific separations. From watching extraction chemists operate, efficiency and selectivity attract them to this compound. Extraction of precious metals like gold and palladium gets a boost with 1-Pentyl-3-Methylimidazolium Hexafluorophosphate, since it dissolves some stubborn species that water and simple alcohols cannot. I’ve even watched an environmental team pull toxic dyes out of river samples using this ionic liquid. Such work secures water quality—and prevents contaminants from ending up in food chains.

Role in Catalysis

Companies racing to streamline drug synthesis manufacturers started leaning into ionic liquids as “reaction media” for tough cases. Researchers at Merck used 1-Pentyl-3-Methylimidazolium Hexafluorophosphate to support transition metal catalysts, improving both yield and selectivity. One reason for that—its structure keeps catalysts active longer, so fewer raw materials get wasted. The resulting process often cuts energy use or shortens reaction times, meaning more medicine with less environmental toll.

Challenges and Possible Solutions

Some folks raise valid concerns about the environmental persistence of fluorinated ionic liquids. This isn’t baseless. 1-Pentyl-3-Methylimidazolium Hexafluorophosphate contains the PF6- anion, related to per- and polyfluoroalkyl substances (PFAS). These don’t break down fast in nature. Chemical policy watchdogs flagged possible buildup in water systems. In my view, if you want to get the benefits without new pollution, better recovery and recycling methods must become routine. One solution comes from companies developing collection systems so spent liquid can be distilled and reused, instead of tossed. Careful tracking and rules on disposal would close the loop further.

The chemical can do a lot of good, and its risks shouldn’t write it off. Responsible research shifts and honest reporting will steer this ionic liquid to safer applications across the board.

Understanding What You’re Working With

1-Pentyl-3-Methylimidazolium Hexafluorophosphate, a type of ionic liquid, shows up in labs for its unique properties. Its low volatility grabs a chemist’s attention, and researchers appreciate solvents like this during green chemistry experiments. Still, the name alone hints at complexity, and as with any unfamiliar substance, common sense and chemistry knowledge keep you out of trouble.

Evaluating Health and Environmental Risks

Not every ionic liquid deserves a hazard label, but this compound deserves respect. Studies have pointed out that hexafluorophosphate-containing salts, when they break down, may yield hazardous byproducts like hydrofluoric acid. Breathing in dust or vapors from this kind of material can irritate your eyes, nose, or throat, and swallowing it isn’t an adventure anyone walks away from feeling lucky. In my time working with similar compounds, even experienced folks never let their guard down—complacency leads to spills and exposures.

Other researchers have raised flags about the long-term impact of these chemicals in water and soil. Some ionic liquids stick around longer than solvents we know better, giving local wildlife a headache. Green chemistry communities want less toxic residues, and moving to a compound like this needs a fair assessment of its footprint beyond the test tube.

Personal Safety Precautions in the Lab

Gloves aren’t just for show. For 1-pentyl-3-methylimidazolium hexafluorophosphate, nitrile gloves block out skin contact much better than latex. I’ve seen friends reach for latex, only to discover their gloves degraded halfway through a procedure. Lab coats, goggles, and if you're heating or spraying, a face shield too. Fume hoods matter—a bottle crack or splatter puts vapor in the air, and you want that going up and away, not into your lungs.

Storing and Disposing Properly

Store this material in a cool, dry place, tight containers sealed with reliable lids. Water sneaking in can trigger hydrolysis, putting out toxic fumes or wrecking your stock. A dedicated flame-resistant cabinet makes sense, especially if you’re already storing other chemicals with fire risks. Segregate incompatible substances—mixing can trigger reactions nobody wants to deal with.

Disposal deserves its own plan. Do not pour any ionic liquid into a drain or trash bin. University or corporate labs collect hazardous waste separately, then send it out for incineration or advanced chemical processing. If you’re at home or a smaller facility, connect with a local hazardous waste program before starting work with this kind of compound. Responsible disposal keeps neighbors and downstream ecosystems safe.

Solutions for Safer Lab Work

Better safety comes down to clear training and up-to-date material safety data sheets right at your fingertips. Before touching any bottle, read the latest research. A few teams I’ve worked with swapped potentially damaging ionic liquids for less persistent ones, reducing both lab risks and downstream effects. Engineers now even design reaction setups with spill containment in mind. Simple things like routine equipment checks and scheduled safety drills make a big difference. Good habits, not just regulations, change outcomes.

Understanding the Risks

Handling chemicals like 1-Pentyl-3-Methylimidazolium Hexafluorophosphate pulls up a unique set of challenges. This substance falls under the family of ionic liquids, which usually means low volatility, but the story doesn’t stop there. An accident happens fast if you let care slip just because vapor pressure is reduced. Real-world experience in the lab reminds every chemist: overlook the little things—humidity, temperature, light—and trouble catches up quick.

This compound features a hexafluorophosphate anion, which can break down into toxic byproducts under the wrong storage conditions. Hydrogen fluoride forms if the compound comes into contact with moisture, and that’s not a risk to take lightly. Inhalation or skin exposure to hydrogen fluoride brings serious health hazards, including chemical burns and systemic toxicity.

Keeping Moisture Out

Always keep the bottle tightly sealed with a proper cap. Relying on parafilm or makeshift covers opens the door to water vapor slipping in. Store it in a desiccator if possible, or at least with plenty of drying agents, such as silica gel. From hands-on lab work, it’s clear that ambient humidity sneaks into containers left open just a couple of minutes. The change isn’t visible, but the chemistry shifts and safety declines.

Anhydrous storage is the best line of defense. Each molecule of water that slips in kicks off degradation that never reverses. I’ve seen a whole batch lost to condensation overnight because someone left the lid loose.

Temperature Matters

Keeping things cool stretches the shelf life and reduces risk. Manufacturers typically recommend temperatures below 25°C, and there’s a reason for that. Higher temperatures speed up chemical breakdown. Even a few days at 30°C can degrade sensitive ionic liquids. Experience shows that placing containers near heat sources, like equipment or sunlight streaming through a window, leads to surprise decomposition. Cool, dry shelves away from radiators do the job well. For long-term storage, consider refrigeration but shield the compound from frost and repeated freeze-thaw cycles.

Avoiding Light and Air

Ionic liquids like this one don’t need regular sunlight. Light exposure drives photo-induced reactions that slowly affect purity. Amber glass or aluminum foil block light and cost almost nothing. Even in rooms with covered windows, stray UV finds its way in and breaks down sensitive chemicals. In my early research days, I once ignored the advice and stored a clear bottle near a window. Within a month, the contents showed color changes, and I lost valuable material—and time.

Oxygen sometimes sits lower on everyone’s worry list, but it reacts with some imidazolium salts. Inert gas blanketing pays off, especially for long-term work. If you have access to a glovebox or nitrogen atmosphere, use it—at least for transferring and sealing.

Solutions for Safer Handling

Label everything clearly with dates and hazards. Don’t store incompatible chemicals close together—acids or strong oxidizers near this salt increase the danger and raise cleanup costs if anything leaks. Keep spill kits ready and check stock often for unexpected color changes or crystal growth, clear signs of trouble. New staff often learn by watching, so it pays off to walk through actual storage setups, not just lecture on theory.

These habits aren’t just about meeting rules—they actually keep people safe and research budgets intact. Following them means not losing years of work to a preventable accident or unexpected degradation.

Pushing the Limits on Purity

Purity decides whether a chemical can handle complex work or if complications creep in. Researchers and professionals demand high standards, especially with ionic liquids like 1-pentyl-3-methylimidazolium hexafluorophosphate (often abbreviated as [PMIM][PF6]). Most suppliers advertise this product in purity levels starting from 97% and going as high as 99.5%. Purity matters, as impurities—halides, water, or unknown organics—often drag down performance. Low purity means cloudier results, unreliable repeatability, and sometimes unexpected hazards during development.

Industry and academic labs push for at least 98% certified by NMR or HPLC. Many critical processes benefit from 99% and above—think catalysis, separation technologies, or electrochemical research. Any contamination affects reaction profiles, distorts electrochemical windows, and even destabilizes the cation-anion lattice. I’ve personally seen researchers lose weeks troubleshooting because they tried to cut corners with cheaper, lower-grade material. It never pays off; impurities rear their head at the worst moment, from fouling equipment to wrecking sensitive measurements.

Packaging Sizes: Not One-size-fits-All

Lab-scale projects usually stick with modest bottle sizes. Glass vials containing 10 grams or smaller do the trick for method development or synthesis trials. Moving up, 25 g, 50 g or 100 g bottles serve those running repeated tests or pilot programs. Once companies scale up, kilogram units come into play, but small packages keep the liquid fresh and prevent cross-contamination. I’ve handled ionic liquids that seemed fine at purchase, but exposure to air or old stock led to hydrolysis, turning the product cloudy or corrosive. A smart choice often means dividing bulk lots into smaller, sealed amber glass bottles or HDPE containers, depending on volume.

For regulated work, especially in pharmaceutical or electronics industries, manufacturers seal and purge containers with dry argon or nitrogen, providing certificates of analysis and batch traceability. These details matter, since accidental water uptake—common with hygroscopic salts—alters conductivity, viscosity, and stability. High-quality sources often double-wrap the main container, then place it inside secondary, impact-resistant packaging. It protects both product integrity and end users who handle hazardous chemistries every day.

Advice for Buyers and Labs

Before placing an order, labs and sourcing teams ask for batch-specific COAs and check shelf life. It’s tempting to chase deals from auction sites, but mishandled stock winds up being costlier with wasted time and failed reactions. Since [PMIM][PF6] also poses environmental and handling risks, confidence in the supply chain reduces liability and protects lab personnel.

Manufacturers respond to these concerns with clear labeling, tamper-evidence, and strong technical support on storage or application troubleshooting. Experienced labs rotate stock to keep supply fresh, log lot changes, and sample test each new delivery. Simple practices, like using air-tight syringes to draw samples or quickly capping vials, save money and improve outcomes.

A Path Forward

Wider awareness about storage, purity, and packaging of advanced chemicals like 1-pentyl-3-methylimidazolium hexafluorophosphate could cut costs and avoid errors across research and industry. Informed buying decisions, and a good relationship with reputable suppliers, deliver consistent results and let innovators focus more on breakthroughs instead of backtracking due to a poor reagent.