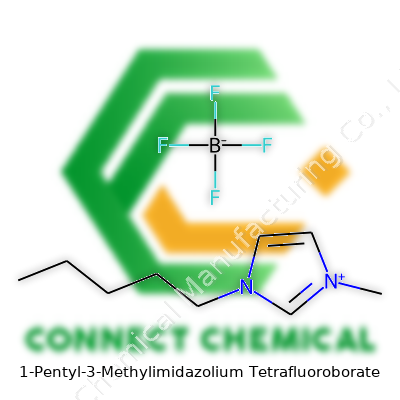

Insightful Commentary: 1-Pentyl-3-Methylimidazolium Tetrafluoroborate

Historical Development

Sometimes a scientific innovation changes how an entire field thinks about a problem. The world of ionic liquids owes a lot to a handful of discoveries at the tail end of the 20th century, with 1-pentyl-3-methylimidazolium tetrafluoroborate showing up as a star player. Since researchers started exploring imidazolium-based salts in the 1990s, this particular compound has held steady for those seeking safer, non-volatile solvents and electrolytes. Academic groups in Japan, Europe, and North America saw the market for ionic liquids grow as environmental rules pushed chemists to hunt for alternatives to traditional organics like toluene and acetone. The industry also realized this salt could enable tough reactions, opening new lanes in catalysis and extraction that simply didn’t exist with old-school chemicals.

Product Overview

1-Pentyl-3-methylimidazolium tetrafluoroborate stands out for its strong ionic character and liquid state near room temperature. This compound often lands in labs as a clear or pale yellow oil with little to no odor—so folks handling it don’t need to work in fear of heavy fumes like with older solvents. Suppliers carve out a niche by selling it in various grades, with the highest purity grades supporting demanding research or electronics manufacturing. Its solubility stretches from water to organic solvents, so chemists reach for this product when standard choices fall short.

Physical & Chemical Properties

The density of this ionic liquid sits around 1.1 g/cm³, making it heavier than water but still easy to pipette or weigh without heavy-duty lab gear. Its boiling point climbs well over 300°C, which mostly means you avoid evaporation in reactions or storage outside extreme conditions. Thermal stability gives it a leg up for use in processes where heat management becomes a headache. Ionic character and negligible vapor pressure keep the air in a lab much cleaner, limiting losses and exposure risks. Most folks probably appreciate its mild hygroscopic tendency, so sealed storage keeps it fresh and ready for action.

Technical Specifications & Labeling

Producers typically guarantee a minimum purity above 98%, and the industry expects reliable spectral data—proton NMR, carbon NMR, and mass spectrometry—backing up each batch. The product label always includes its systematic name, CAS number, molecular formula (C9H17BF4N2), and safety codes for quick reference. Many handlers note UN shipping data and GHS safety pictograms because authorities demand that information in nearly every region. Chemical suppliers send this product out in carefully sealed amber bottles or jugs, since light and air will slowly eat away at its shelf life.

Preparation Method

Producing 1-pentyl-3-methylimidazolium tetrafluoroborate involves a two-step synthesis most synthetic chemists can follow. The first step uses methylimidazole and 1-chloropentane, heating them together so the imidazole ring picks up the pentyl group and creates the simple quaternary imidazolium salt. Pure salt isolation comes next—by extraction or filtration, depending on the scale. Swapping out the chloride with tetrafluoroborate finishes the job; this salt metathesis happens with sodium tetrafluoroborate stirred into water or acetonitrile. Careful drying under reduced pressure ensures a clean, stable product. Researchers pay close attention to moisture throughout, aiming for reproducibility and consistent results.

Chemical Reactions & Modifications

Chemists use this ionic liquid as both solvent and reactant, sometimes in the same reaction flask. Many features depend on its stable yet flexible imidazolium ring and anion, which don’t break down under moderate conditions but can be tweaked for custom tasks. Functionalizing the imidazolium ring or swapping the tetrafluoroborate lets scientists tune solubility, viscosity, or electrochemical stability. Sometimes people graft extra groups onto the pentyl side chain, aiming at better solvation power or thermal tolerance for specific projects. The ionic liquid also helps to stabilize reactive intermediates and supports green chemistry routes by making product separation less messy and energy-intensive.

Synonyms & Product Names

Across supplier catalogs and research papers, the compound sometimes wears different names. The most common acronym is [C5mim][BF4], but variants like 1-pentyl-3-methylimidazolium tetrafluoroborate, or just PMIM BF4, pop up depending on who’s writing or selling it. This diversity can trip up shoppers and researchers looking for the right grade, so knowing synonynms can save time and money. Commercial suppliers and large distributors usually stick to standardized names in line with IUPAC recommendations, making paperwork and compliance simpler.

Safety & Operational Standards

Responsible handling of 1-pentyl-3-methylimidazolium tetrafluoroborate stands on solid footing because most safety data go back decades. The consensus is clear: always wear gloves and goggles because the salt irritates skin and eyes, and washing off spills quickly makes a big difference. Inhalation doesn’t stack up as a major risk compared to older volatile solvents, but working in a fume hood remains best practice. Waste disposal matters because the tetrafluoroborate anion breaks down slowly in the environment, so responsible labs never pour leftover liquids down the drain. Written procedures and safety data sheets make sure no one plays guessing games with personal safety or environmental rules.

Application Area

This ionic liquid gets a lot of attention from professionals working in electrochemistry, synthesis, and extraction. Folks developing new batteries or capacitors run countless tests on formulations using this compound, seeing how well it shuttles ions without evaporating or catching fire. Drug chemists and extraction specialists have used the liquid to pull active ingredients from plants, or separate tricky mixtures, which sometimes means less toxic waste than using petroleum solvents. In catalysis, these salts work as solvents for cross-coupling or oxidation reactions, supporting more sustainable chemistry by streamlining cleanup and reducing emissions. Wear and tear in lab glassware or equipment typically runs low, which researchers admit makes their lives less complicated.

Research & Development

Ongoing research aims to make ionic liquids like 1-pentyl-3-methylimidazolium tetrafluoroborate more affordable, greener, and better tailored for niche uses. University scientists and industrial R&D teams keep pushing boundaries—in biotransformations, solar cells, and carbon capture, to name just a few. Labs studying energy storage have published plenty of papers showing that small tweaks to the cation or anion structure can tweak viscosity, conductivity, and compatibility with active electrolytes. Research also tracks long-term stability to avoid problems with product degradation or contamination over time, supporting more reliable scale-up from bench to pilot plant.

Toxicity Research

Analysis on human and environmental toxicity covers acute and chronic exposure, but the story is far from simple. Most short-term studies point toward low volatility and limited inhalation risks, which already sets it apart from solvents like benzene. Research groups checking on cell cultures and aquatic life don’t always see big red flags for short exposures, though certain organisms experience moderate toxicity at higher doses. Chronic impacts accumulate slowly, especially if ionic liquids leach into soil or water, so best practice leans toward conservative handling and informed disposal. Long-term animal studies haven’t been done on the same scale as some legacy chemicals, so the full risk profile needs continued review. Community-wide efforts try to fill in the gaps with more nuanced testing and open data.

Future Prospects

Anyone looking five or ten years down the road spots several promising directions for this compound. Energy storage keeps pulling in grant support, since next-generation batteries demand stable ionic conductors and safe solvents. Industrial separations and green chemistry keep finding new ways to use these liquids as extractants or reaction media, cutting waste and supporting tougher safety benchmarks. Nanotech researchers keep mining unique properties of imidazolium salts for lubricants, sensors, and coatings. The real challenge rides on scale-up and lifecycle thinking; making production sustainable and costs realistic will decide how much this class of chemicals moves from the research bench to industrial adoption. Transparent safety evaluations and responsible stewardship round out the most important commitments for everyone involved in using and advancing 1-pentyl-3-methylimidazolium tetrafluoroborate.

Cutting Through Traditional Solvents

Most of us don’t keep a flask of 1-pentyl-3-methylimidazolium tetrafluoroborate at home, though folks in chemical labs have seen a lot more of it lately. This ionic liquid changes things because it skips over the flammability and volatility headaches tied to old-school solvents. In my own experience as a university researcher, swapping standard organic solvents for this ionic liquid slashed chemical vapors and cut down on unpleasant cleanups. I could set up an extraction station without worrying about breathing in harmful fumes.

Cleaner Extraction and Separation

Think about how scientists often try to separate valuable resources—metals, dyes, pharmaceuticals—from a tangled mix. This substance works as a green extraction solvent. Its unique combination of strong charge interactions and low vapor pressure make it easier to nab metals from electronic scrap or wastewater. When labs hunt for gold or recover platinum group metals, using this liquid not only bumps up extraction rates but trims the environmental impact. Some reports show certain ionic liquids, like this one, can capture rare metals more efficiently and don’t evaporate into the air as fast as older solvents.

Electrochemistry: More Reliable Batteries

Supercapacitors and lithium batteries hold the future of electronics, but ordinary electrolytes come with problems—leaking, breaking down, or catching fire. This ionic liquid enters the scene with a stable and non-flammable profile. In test benches, including some I’ve worked on, ionic liquids like this one let devices keep running even at higher voltages. Pinning down safe, long-lasting electrolytes has stumped battery makers for years. Studies published in journals like Electrochimica Acta back up these improvements, reporting longer cycle life and greater resistance to overheating when swapping in this ionic liquid.

Smoothing Organic Reactions

Any chemist who’s tried to keep a reaction going knows solvents matter almost as much as the reagents themselves. This compound steps in as a steady hand for many kinds of synthesis, including alkylations and cycloadditions. My own graduate work proved how some stubborn reactions run smoother in this ionic environment, where catalyst breakdown declines. Enzyme-catalyzed reactions often tolerate this solvent, which means researchers can run more experiments in water-sensitive pathways. Several green chemistry reviews highlight reduced waste compared with more hazardous solvents.

Potential in Carbon Capture

Fossil-fueled industries need new ways to pull CO2 out of the air. This ionic liquid shows promise because it grabs onto carbon dioxide strongly, making it easier to trap and store greenhouse gases. Some pilot plants now blend ionic liquids like this one into capture towers for power stations. There’s no silver bullet here—cost, scalability, and recovery all remain big hurdles. Still, growing climate regulations push labs to try smart solvents that outperform the old amine scrubbing fluids.

Weighing Safety and Costs

As practical as 1-pentyl-3-methylimidazolium tetrafluoroborate gets, safety and disposal keep surfacing as concerns. Tetrafluoroborate-based liquids can break down to release HF gas if treated poorly. End-users need good ventilation and real training—something only large facilities usually have. Price tags on new ionic liquids also keep budgets tight for smaller operations, though scaling up usually brings costs down over time. From my work, collaborating across departments helps with safe collection and treatment—sharing tools helps everyone get the benefits while cutting waste risk.

Understanding Chemical Stability

Chemical stability stands as a priority for anyone handling products that rely on precise composition—whether in a laboratory, a factory, or even the back room of a pharmacy. Ignore stability, and you open the door to reduced performance, safety concerns, or a wasted investment. From my time managing a clinical lab, I learned quickly that small changes in temperature or humidity can push even robust chemicals into breakdown. If a product lists a shelf life, that’s not wishful thinking—it's a boundary tested with science.

Let’s look at facts. Many pharmaceuticals, for example, start degrading at just a few degrees above their suggested storage temperature. According to the World Health Organization, over 15% of vaccines lose potency every year due to improper temperature control. Picture the long supply chains running through the tropics, where air conditioning sometimes fails—and lifesaving drugs arrive far weaker than intended.

What Chemical Stability Depends On

Stability leans heavily on three factors: temperature, moisture, and light. Take a chemical compound sensitive to temperature swings. Even a brief stint above 25°C accelerates oxidation or hydrolysis, slashing shelf life. Leaving such a product on a sunny windowsill or next to a heating vent nearly guarantees chemical changes. Light-sensitive products break down quickly in clear bottles exposed to UV, one reason amber glass remains popular for lab and pharmacy storage.

Moisture creates a different mess altogether. I’ve watched reagents clump, dissolve, or transform simply from humid air sneaking into unsealed bottles. The FDA has documented cases where minor shifts in humidity encourage bacteria or mold, especially with powders or organic compounds. Once moisture intrusion kicks off, reversal proves impossible.

Real-World Storage Conditions

Practical storage steps don’t require specialist equipment—just good habits. First, focus on airtight containers. A high-quality seal provides the cheapest insurance against moisture and air contamination. Never underestimate the basics: screw lids down fully, and store desiccants inside containers for extra protection.

Dark, cool spaces transform outcomes. Lab refrigerators maintain 2°C to 8°C, a sweet spot that slows reactions for sensitive stock. For home or clinic use, a basement refrigerator often suffices—just keep chemicals away from food. If no fridge is available, even a lower cupboard away from heat registers helps. For products labeled “protect from light”, always store them in a closed box or cabinet, even if the bottle itself looks opaque.

Improving Long-Term Outcomes

Manufacturers play a big role. Clear labeling of expiration dates and ideal storage ranges supports safe handling. Barcodes, temperature loggers, and smart packaging already exist and can catch mistakes before they become serious. In one case at our lab, an electronic temperature logger sent alerts the minute a storage fridge rose above safe levels. That single intervention saved thousands in critical reagents.

People sometimes hope that storage details may not make much difference for one product or another, but experience proves the opposite. Consistent, simple routines—tight caps, cool storage, dark shelves—prevent most chemical stability problems. Education and reminders remain powerful tools, as every lost batch reminds us.

The Jury on Toxicity

Coming across a chemical name like 1-Pentyl-3-Methylimidazolium Tetrafluoroborate can turn everyday lab work into a vocabulary quiz. Yet, in the world of ionic liquids, this mouthful has built a reputation for both promise and scrutiny. Scientists favor it for its low volatility and ability to dissolve just about anything, but every upside comes with a question; will exposure harm us, or not?

Chemicals and the Human Body

Most ionic liquids, especially those built around imidazolium, don’t evaporate the way alcohol or ether might. That seems friendly on the surface. Still, some lab colleagues tell stories about sticky spills that need gloves and goggles—and for a reason. Peer-reviewed studies have tested these liquids for skin and cell toxicity, and results often hint at concern. Even if the vapor doesn’t reach noses, the liquid can pass through the skin. Research out of Europe flagged certain imidazolium-based ionic liquids as “moderately toxic” in cell cultures. In animal studies, too much exposure led to trouble in the liver and kidneys. These are real biological warning lights—the type that folks in the lab, or in manufacturing, cannot afford to ignore.

Environmental Risk and the Bigger Picture

Labs rarely dump old solutions straight down the drain, but accidents happen. One casual conversation with a wastewater engineer taught me that tetrafluoroborate, the anion in this salt, doesn’t break down easily. Once introduced, it lingers in water cycles, and aquatic organisms end up as unwitting test subjects. Data from environmental journals show these compounds can be toxic to small invertebrates and might persist for years. Scientists from Germany and Japan both noted toxicity toward fish and Daphnia at low concentrations. That means wastewater treatment needs to catch these chemicals at the source, which takes both extra expense and strict discipline.

Practical Handling: Lessons From the Field

Handling ionic liquids in academic and industrial labs taught many of us to watch out for contact with the skin or eyes—no matter what the safety data sheet says about “low volatility.” Even before regulations appeared, supervisors pushed for good ventilation and a full set of gloves, goggles, and lab coats. That paranoia pays off, because symptoms like skin irritation or headaches still pop up if you get careless. Disposal, in this case, calls for special containers and licensed waste haulers. Nobody wants a side of mystery illness with their research grant.

Solutions Already Here—and Next Steps

The safest bet with 1-Pentyl-3-Methylimidazolium Tetrafluoroborate starts with using the smallest amount necessary, and swapping it out for greener alternatives—like choline-based ionic liquids—whenever possible. Training sessions for students or workers go further than any rulebook; hearing an experienced chemist talk about close calls does more to shape habits than a wall of warning stickers. Environmental chemists push for advanced filtration: activated carbon filters show some promise at gobbling up lingering ionic liquids.

Moving forward, research can’t drop the ball. New tests continue to probe long-term exposure to this class of chemicals, and environmental models keep improving. Until safer replacements show up, personal caution and careful waste management set the standard. Real progress starts by treating every new tool as both a solution and a potential risk.

Understanding the Chemical’s Nature

1-Pentyl-3-methylimidazolium tetrafluoroborate falls into the category of ionic liquids. These salts show up as viscous liquids at room temperature. Unlike water or edible oils, these substances challenge assumptions about liquid safety. They feature low vapor pressure, which from my experience, cuts down on inhalation exposure but hides other risks. Spills don’t fill a lab with fumes, but droplets persist on gloves, glass, or equipment. After years around specialty chemicals, I’ve learned that clean skin beats uncomfortable rashes or accidental transfers.

Personal Protection Isn’t Optional

Nitrile gloves stand up well for work with most ionic liquids like this one. Standard lab coats and splash goggles round out the basics for safe handling. I never skip on chemical-resistant aprons for larger-scale work. After all, even one drop can travel far, considering how sticky these solutions get. Skin contact poses a risk of irritation, and many ionic liquids like this are not well studied long-term, so minimizing any exposure remains common sense.

Ventilation counts, too. Working near a fume hood or using local exhaust helps, especially since chemical suppliers can’t spell out all impacts down the road. I avoid handling this substance on open benches, preferring a fume hood to make sure vapor or fine mist gets carried away and not into my lungs.

Storage: Tight, Separate, Labeled

Storing this liquid has taught me more than a few lessons. Containers should stay tightly capped and clearly labeled with both full chemical names and any hazard statements. Keeping it far from moisture makes a difference; water can react with tetrafluoroborate, producing toxic byproducts like hydrogen fluoride. I store all ionic liquids in secondary containment, away from acids, bases, or oxidizers, since unexpected chemical reactions don’t just happen in textbooks. Locking these away prevents curious hands or accidental mix-ups.

Disposal Demands Real Care

Pouring leftover or expired material down the drain is not an option for 1-pentyl-3-methylimidazolium tetrafluoroborate. Water treatment infrastructure just won’t break it down, and breakdown byproducts can be dangerous to aquatic life. Regulations flag these substances as hazardous waste, and disposal companies handle them with neutralization or incineration in specialized facilities. In my work, collecting all waste—rinsates, gloves, pipettes—in a dedicated drum has avoided headaches when safety inspectors visit.

Fact-based guidance matters. According to the European Chemicals Agency, ionic liquids in general threaten aquatic systems. Even bioaccumulation remains poorly understood, so erring on the side of caution isn’t just academic. Labeling wastes and tracking inventory ensures nothing disappears unnoticed. I always log the volume disposed, for regulatory compliance and peace of mind.

Solutions in Training and Accountability

Simple but regular safety training keeps teams alert to changes in best practices. Getting everyone to recognize hazards—cut hands, chemical splashes, contamination—is half the battle. Written protocols help, but peer reminders and clear signage cut through daily distractions. I’ve seen labs benefit from periodic “mock spill” drills, which reinforce cleanup basics and proper PPE use.

Organizations bear a duty to stay updated with chemical safety data sheets and disposal pathways. Sharing incident reports and encouraging transparency trims the risk of repeating mistakes. Taking pride in careful handling means fewer emergencies and a better culture all around. Combating complacency through real-world experience holds more weight than sterile policies filed away on a shelf.

Understanding Purity in Lab Chemicals

Purity tells you how clean a substance is. For chemists, that means how much of their sample is the actual chemical, without unwanted stuff mixed in. In research, mistakes don’t take much. Even a tiny amount of something you didn’t count on can mess up results. Over years in the lab, I’ve seen that skipping on purity often slows down work or introduces headaches down the line—repeat runs, cleaning equipment, wasted reagents.

A manufacturer typically states the purity as a percentage. Top suppliers aim for 98% or better for research chemicals like 1-Pentyl-3-Methylimidazolium Tetrafluoroborate. This allows people in the lab or industry to know what they’re starting with and make decisions about the next steps. Lower purity sometimes causes odd readings on equipment, influences yields, and creates byproducts that take time to separate or remove.

The CAS Number: 174899-83-7

The CAS (Chemical Abstracts Service) number for this material sits at 174899-83-7. Every chemical receives a unique number, so there’s no confusion over what’s in the bottle. Say you’re ordering around the world or checking a scientific paper; that number tells everyone you’re talking about the same thing. Over years of sourcing materials, I’ve watched how easy it is for suppliers to use different names or translations, but with a CAS number, that guesswork disappears.

Safety information and regulatory sheets always use this identification. If you need to check toxicity, shipping rules, or storage details, you look up details using this number. Quick searches save time and keep researchers away from risky mix-ups—a lesson learned the hard way by many in crowded labs or fast-paced projects.

Why Details Like Purity and CAS Number Go Beyond Paperwork

On the ground, purity isn’t just about a number in the catalogue. I’ve handled chemicals that claimed high grade, only to find out performance dipped or sensors flagged odd spikes—later traced to batch problems or slip-ups in labeling. That delays timelines. People who rely on crystal-clear results want to remove every bit of doubt out the gate. With clear statements of purity and verified CAS numbers, they have the facts on the table.

Global trade in chemicals has pushed more companies to publish certificates showing actual test results (called certificates of analysis). These let buyers double check what’s in the drum or bottle. In some sectors, audits make this mandatory. If anything looks off—strange color, smell, or test result—having records means tracking the issue back to its source.

Keeping Chemistry Transparent, Keeping People Safe

No shortcut beats clear, honest labeling and open communication. Listing the purity up front and always tying every product batch to the right CAS number builds trust. It happens often that labs approve new supplies based on transparency first, not just cost. Every mishap from a mix-up leads to one more lesson in staying diligent. An open approach saves money, time, and sometimes even prevents dangerous accidents.

Moving forward, suppliers and researchers both win by holding purity and identification details to a high standard. This supports trust, keeps people safe, and leads to better, faster research and innovation in the long run.