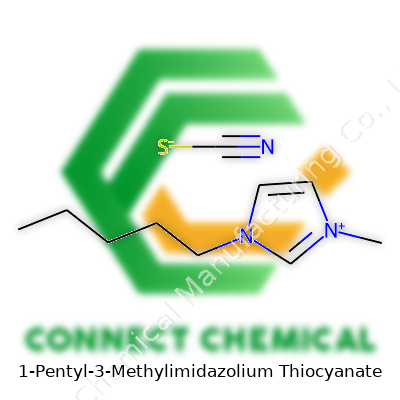

1-Pentyl-3-Methylimidazolium Thiocyanate: A Closer Look

Historical Development

Chemists started experimenting with ionic liquids in the late 20th century, searching for alternatives to volatile organic solvents. 1-Pentyl-3-methylimidazolium thiocyanate stands out among new-generation ionic liquids. Its discovery came on the heels of a greater curiosity for imidazolium-based compounds in the 1990s. Researchers concentrated efforts on structural modification, trying longer alkyl chains and mixing in different anions to tweak melting points, solubility, and environmental impact. Early labs sketched out basic methods to synthesize and purify these salts, paving the way for scalable production. Over time, the compound found acceptance in both chemical research and specific industrial settings thanks to its flexibility and unique characteristics.

Product Overview

1-Pentyl-3-methylimidazolium thiocyanate, often labeled as [C5mim][SCN], falls under the broad family of imidazolium ionic liquids, which trade in a conventional cation-anion pair. People choose it for its liquid state under room temperature and strong ability to dissolve a range of polar and nonpolar substances. Its pentyl side chain (five carbon atoms) not only bends the melting point but also steers solubility and viscosity in practical scenarios. Chemists use this liquid as a solvent for reactions that push the boundaries of green chemistry and sometimes as a carrier or medium for extraction processes.

Physical and Chemical Properties

At ambient temperatures, 1-pentyl-3-methylimidazolium thiocyanate presents as a clear to pale yellow liquid. It stays liquid below 30°C because of the flexible imidazolium ring and the length of its alkyl chain. Density tends to hover around 1.08 g/cm³ at 25°C, with a viscosity of roughly 80–200 cP, depending on purity and water content. It dissolves completely in water, alcohols, and some organic solvents, outperforming many traditional salts in this role. Thanks to the SCN⁻ anion, the compound shows moderate coordination with metals and can take part in a range of redox reactions. It also resists evaporation due to negligible vapor pressure and does not burst into flames easily below 200°C.

Technical Specifications and Labeling

Suppliers typically label this product with purity above 98%, indicating trace levels of water and halides. Batch certificates detail residual solvents, cationic and anionic purity, absence of heavy metals, and UV-visible spectra. Storage recommendations call for sealed glass or HDPE containers, kept dry and protected from direct sunlight. The MSDS flags the product as sensitive to acids and oxidizing agents but stable under usual handling conditions. Each shipment includes a tracking number, hazard codes (irritant, not acutely toxic), and emergency instructions written for trained staff.

Preparation Method

Synthesis starts from 1-methylimidazole and 1-bromopentane under controlled reflux. The two react in a polar aprotic solvent, forming 1-pentyl-3-methylimidazolium bromide in a few hours. Workers then isolate the salt by precipitation and remove solvents with vacuum techniques. For ion exchange, this intermediate is dissolved in water, and an aqueous solution of potassium thiocyanate gets added slowly. Stirring encourages SCN⁻ to swap in, producing potassium bromide as the byproduct. Filtration and solvent extraction steps purify the ionic liquid, which finishes with drying under reduced pressure to strip out water and traces of unreacted agents.

Chemical Reactions and Modifications

The compound tolerates a broad swath of reaction conditions—acidic, mild base, or even heated systems. The imidazolium ring stays put in most uses, but the pentyl group can undergo alkylation or oxidation if pushed hard enough. The thiocyanate ion, being ambidentate, coordinates through nitrogen or sulfur, opening doors for metal complex formation in solution. Chemists sometimes swap the SCN⁻ anion for other nucleophilic anions, tailoring properties without upending the cationic core. During catalysis, the ionic liquid can stabilize charged intermediates, especially in organic synthesis, electrocatalysis, and polymerization.

Synonyms and Product Names

Many labs refer to the salt by its systematic name, but short forms show up: [C5mim][SCN], PMIM-SCN, N-pentyl-N’-methylimidazolium thiocyanate, or even as 1-pentyl-3-methylimidazolium isothiocyanate in older literature. Some catalogs list it only by its CAS number or trade name, but the chemical formula and structure stay consistent across the board.

Safety and Operational Standards

People who handle 1-pentyl-3-methylimidazolium thiocyanate need a well-ventilated workspace and nitrile gloves at minimum. Spills irritate skin and mucous membranes on contact, and longer exposure without washing off brings out mild to moderate dermatitis. The compound resists ignition, but decomposition above 200°C releases compounds that irritate airways. Eye protection and a working fume hood either at bench or pilot scale cut risk even further. Disposal routes run through incineration or authorized chemical waste facilities, never poured down regular drains, since thiocyanate ions hurt aquatic life. Regular workplace monitoring and staff training on spill response make a difference in keeping operations smooth.

Application Area

Anyone exploring extraction, catalysis, or advanced materials has likely heard of pentyl-methylimidazolium thiocyanate. Lab teams reach for it during biphasic separations of heavy metals, picking this liquid because it dissolves both hydrophobic and hydrophilic substances. In organic synthesis, it outperforms volatile organic solvents, supporting alkylation, condensation, or redox reactions with lower waste generated. Electrochemical devices—such as supercapacitors and sensors—use this compound as an electrolyte, taking advantage of its broad electrochemical window and minimal volatility. Pharmaceutical labs report using it as a stabilizing media for sensitive drug molecules, and some environmental engineers depend on it to recover precious metals from ore and waste streams efficiently.

Research and Development

Research groups tweak alkyl chain lengths and swap anions, measuring the results on solid–liquid phase behavior, ionic conductivity, and thermal stability. Many papers highlight the effect these changes have on recyclability and toxicity, especially as industries push for greener processes. Some teams are now blending the liquid with biodegradable polymers or housing it in membranes for next-generation separations. Partnerships between universities and chemical makers have pushed pilot-scale syntheses forward, reducing costs and improving yield. Latest trends angle toward computational modeling, predicting new combinations before anyone mixes them in the lab.

Toxicity Research

Toxicologists track the impact of imidazolium ionic liquids, including the pentyl variant, on cells, aquatic species, and the environment. Lab studies report low acute toxicity for brief skin and eye contact, though ingestion and prolonged exposure show more pronounced effects on fish and invertebrates. Mammalian cell cultures sometimes reveal mild cytotoxicity at concentrations above 100 μM, causing researchers to suggest limits for industrial discharge and handling. Ongoing studies seek to link subtle structure changes—such as longer alkyl chains—with bioaccumulation or breakdown in soil and water. Regulations and eco-tox screens guide chemistry teams toward safer practices and smarter design.

Future Prospects

Industrial demand for safe, flexible solvents keeps growing as people leave behind old organics. With better toxicity profiles and adaptable chemistry, ionic liquids like 1-pentyl-3-methylimidazolium thiocyanate will see broader use in extraction, synthesis, and materials processing. Hybrid materials that use these liquids in nanotechnology, fuel cells, or high-performance polymers draw a lot of attention. As green chemistry and circular economy thinking spreads, scientists will keep moving toward sustainable synthesis and easy-to-breakdown chemistries. Ongoing collaboration between industry, academia, and regulators will shape production, labeling, and applications, letting innovation continue while protecting health and environment.

Peering into an Unfamiliar Compound

Ask most people about 1-Pentyl-3-Methylimidazolium Thiocyanate and eyes start to glaze over. Chemists, though, keep finding new tricks up their sleeves with ionic liquids like this one. These aren’t just scientific curiosities—they’re practical, and play roles in real research and industry.

Why Chemists Pay Attention

This particular chemical belongs to a group called ionic liquids. Imagine a salt, but it stays liquid at room temperature. That means no clouds of fumes, no splashy flammable solvents, no extra energy spent on heating or cooling. Now toss in thiocyanate as the counter-ion, and you have one that dissolves metals, organic molecules, and gases in ways plain water, or common solvents, can’t touch.

Scientists, including myself during a project on less hazardous metal extraction, keep turning to these liquids to stay away from harsh chemicals. 1-Pentyl-3-Methylimidazolium Thiocyanate is not some lab-only oddity. It steps into applications from greener chemistry to electroplating to pharmaceuticals. For instance, in separating rare earth metals—think about magnets, batteries, all the gadgets people carry—it can pluck out valuable elements from industrial waste a lot more gently than old-school acids.

What Makes This Compound Useful

Lab work with ionic liquids can feel like stepping out of the past. With traditional solvents, you deal with toxicity, flammability, and disposal headaches. These new liquids, 1-Pentyl-3-Methylimidazolium Thiocyanate included, give cleaner reactions and are usually easier to recycle. When I first worked with them, it meant spending less time running from splashy hazards in the fume hood and more time actually looking at results. Thiocyanate-based salts bring in another feature—they can bind with a huge range of metals.

Take catalysis, for example. Technicians use this compound to keep catalysts stable and working at high efficiency. I’ve seen PhD students wince at the cost of silver salts or the mess left by hydrocarbon solvents. Using an ionic liquid, the waste goes down, and the yield stays up.

Potential Trouble and a Way Forward

Switching to new chemicals always comes with questions. Ionic liquids were once hailed as “green solvents.” Turns out, some are not as harmless as first hoped. 1-Pentyl-3-Methylimidazolium Thiocyanate exists in a world that’s learning from that mistake. Scientists keep looking at toxicity to aquatic life, biodegradability, and how these salts behave if spilled.

The honest approach here doesn’t mean ditching new chemistry, but using it smartly. We rely on data from journals, actual lab work, and field studies. Companies and universities share reports on how long these liquids last, how to recover and clean them, and what happens after use. The Environmental Protection Agency and European Chemicals Agency build guidelines from real evidence, not just promises.

Searching for Progress, Not Just Products

At its heart, 1-Pentyl-3-Methylimidazolium Thiocyanate stands as a tool for changing how we extract, process, and synthesize. By listening to both environmental experts and industrial chemists, we make sure new technology doesn't throw up old problems. My own experience—watching labs reduce dangerous waste, and switching out the stink of volatile solvents for much safer alternatives—makes it clear this isn’t just chemistry for chemistry’s sake. It shapes the phones, batteries, and clean technologies that keep us moving forward.

Getting the Basics Right

Safely storing chemicals like 1-Pentyl-3-Methylimidazolium Thiocyanate isn’t just a box-checking exercise. The choices made here affect safety, research quality, and sustainability. In my time working with both common and specialized chemicals, poor storage has cost researchers valuable time, money, and sometimes personal safety. Mishandling exotic materials leads to headaches no one wishes to experience: pressure build-up in bottles, sensitive odors in the lab, and mysterious changes in results over time.

Moisture Changes Everything

This compound, like many ionic liquids, reacts to big swings in temperature or humidity. Without proper care, moisture sneaks through seals and starts to break the chemical down. Hydrolysis creeps in slowly and sometimes goes unnoticed until results spiral out of control. So the advice from seasoned chemists: always use tightly sealed containers. Desiccators or inert gas blanketing make a huge difference in longevity. It’s a habit that saves labs from ruined samples and avoids the scramble for replacements.

Temperature Swings: Enemy Number Two

Room temperature feels like a wide target, but the air in most labs fluctuates more than people like to admit. Heating and cooling cycles upset sensitive materials over time. Official guidelines settle around 15-25°C as the sweet spot for this compound. Extreme heat can spark decomposition. Cold introduces crystallization or unwanted precipitation. Streamlining things with a storage log and a reliable thermometer keeps guesswork out of the equation. Even experienced researchers benefit from not trusting building thermostats too much.

Light Does More Harm Than You Think

Ambient lab light doesn’t seem like a culprit until chemical color fades or contaminants start to show up. Clear containers might look practical, but UV can start reactions slowly, especially for compounds with thiocyanate groups. Opaque bottles or at least dark cabinets cut down on those risks. Safe storage here keeps purity intact, and purity always serves better data. Regularly rotating inventory also makes sure old samples don’t languish in sunlight at the back of a shelf.

Segregation: More Than a Guideline

Too many labs learn about incompatible storage only after a near-miss. Keeping 1-Pentyl-3-Methylimidazolium Thiocyanate away from powerful acids, oxidizers, and bases saves everyone from surprises. Thiocyanate ions react vigorously if given the wrong partner. Color-coded labeling beats handwritten post-its anytime, so standardized systems help both new and seasoned folks react fast in emergencies.

Safer for People, Kinder to Results

The care taken in storage makes working life safer and smoother for everyone, from students to seasoned chemists. Proper containers with clear labeling and chemical compatibility checks ward off last-minute scrambles and exposures. In my own routine, carving out storage time pays back every month in reliable results and fewer disposal headaches. It also lets labs run more sustainably by cutting down waste from spoiled materials.

Long-Term Planning

Clear guidelines and dedicated storage zones shape responsible chemical management. Building these habits now keeps research budgets in line, reduces waste, and protects staff. Following these grounded lessons from direct experience often speaks louder than policy statements—and keeps labs safer, more productive, and confident in their results.

What Kind of Chemical Are We Dealing With?

1-Pentyl-3-Methylimidazolium thiocyanate belongs to the family of ionic liquids. Developers in labs use it for its ability to dissolve compounds regular solvents can’t touch. The compound sits right in the crosshairs of green chemistry—researchers look for alternatives to traditional, more volatile organic solvents. With that said, the “green” label often gets thrown on ionic liquids before we know the full picture.

Where the Hazards Start

Ionic liquids like this one turn heads for their low flammability and negligible vapor pressure. That doesn’t always line up with safety. 1-Pentyl-3-Methylimidazolium thiocyanate owes part of its properties to the thiocyanate ion. Here’s where personal experience counts: thiocyanate in different forms can irritate the skin and eyes. Touching or inhaling dust from similar compounds left me with red skin and nagging discomfort more than once in college labs.

Thiocyanate itself turns toxic in the right concentration. It can disrupt the thyroid when exposure runs high. Animal studies link high doses to changes in nervous system function and mild kidney problems. Ionic liquids often move through wastewater systems, since they don’t evaporate. This sticky nature leads to another worry—persistent chemicals build up in water and soil, and researchers haven’t mapped out what happens over years. The imidazolium component, while stable, has shown traces of toxicity in aquatic organisms.

Digging Up the Data

Direct toxicity data for 1-Pentyl-3-Methylimidazolium thiocyanate lags behind other chemicals. The European Chemicals Agency lists related imidazolium-based ionic liquids as hazardous to aquatic life. Research points to moderate cytotoxicity in cell cultures. I read one study from 2018 where researchers measured cell death rates at different concentrations and saw negative effects increase after just a day. The compound didn’t set off alarms at trace levels, but as concentrations increased, cells started dying. That rings familiar—most ionic liquids slip under the radar at small doses, but build-up changes the story.

Real-World Impact

Labs might treat 1-Pentyl-3-Methylimidazolium thiocyanate with kid gloves, but industrial users risk spills or accidents. Cleanup efforts get complicated since these liquids love to stick around and don’t break down fast. Wastewater treatment plants haven’t caught up with ionic liquid removal, so some portion leaks into surface water. Given the toxicity toward aquatic invertebrates, it could quietly reshape river ecosystems. There’s also a risk to workers in factories that don’t use adequate gloves and ventilation—short-term exposure could mean skin or eye irritation. Long-term, repeated exposure remains an open question. Regulations lag behind, in part because newer chemicals outpace traditional toxicology.

Possible Solutions

Engineers and chemists can lower the risk several ways. Closed systems keep chemicals away from hands and the air, limiting exposure. Installing proper filters on waste streams reduces what slips into the environment. Clear safety sheets and real-world testing fill in knowledge gaps—manufacturers need to pressure test these liquids beyond the lab. Workers deserve gloves, goggles, and air purifiers if handling this daily. From experience, double-checking glove thickness and swapping out anything with visible wear kept my own irritation at bay. Companies can also support research into breakdown reactions. Biodegradable versions or substances that deactivate quickly after use cut the long-term worry about contamination.

It pays to stay honest about what “green” means—no single chemical checks every box. Knowing the tradeoffs means the industry avoids trading one problem for another.

The Essentials: Formula and Weight

For anyone who cares about chemistry’s practical side, knowing the formula and weight of a compound shapes everything from safety sheets to synthesis choices. For 1-Pentyl-3-Methylimidazolium Thiocyanate, the chemical formula comes out as C10H17N3S. People break it down this way: The 1-pentyl-3-methylimidazolium cation offers C9H17N2, and the thiocyanate anion adds SCN. Together, these make C10H17N3S. The molecular weight lands at about 211.33 g/mol. Numbers matter in labs, especially when you’re measuring out materials or calculating risk, and this one’s no different.

Why This Compound Matters

Ionic liquids like this catch interest because they don’t evaporate easily and often work well as solvents. That matters if you're after green chemistry – less vapor means less mess for both air quality and workers’ lungs. Scientists use this stuff to dissolve tough compounds, even some biomolecules that water or alcohol leave behind. The imidazolium family has this way of pairing up with a host of anions, tuning properties for all sorts of tasks, from extractions to material science.

Throughout my own research, ionic liquids looked strange at first compared to more familiar solvents. Over time, the low volatility and sharp selectivity convinced me they earn a spot on the chemist’s shelf. People in pharmaceuticals and biochemistry look here to minimize contamination and keep processes efficient. Having the correct structure on paper avoids guessing games — it keeps projects on track, budgets sane, and regulations satisfied.

Trusted Sources and Chemical Safety

Companies and researchers rely on data from the likes of PubChem, Sigma-Aldrich, or ChemSpider. Peer-reviewed literature also cements these numbers:

- PubChem lists the formula as C10H17N3S with CAS number 857308-98-6.

- The molecular weight lands right at 211.33 g/mol, matching what’s found in MSDS sheets.

Missing or confusing numbers can spell trouble — one decimal point off can wreck a dosing calculation or create toxic byproducts. As someone who’s handled both bench-top experiments and industrial-scale systems, I saw firsthand that precise information sets the foundation for reliable results.

Navigating Potential Risks

Imidazolium salts pose hazards if mishandled. Combustion products include sulfur oxides and cyanides. Some ionic liquids show toxicity in aquatic environments, so chemical waste streams need careful handling. Workers need proper gloves and fume hoods. I’ve heard stories about students exposing themselves by skipping standard protection, assuming ionic liquids play nice due to low vapor pressure. That sort of miscalculation leads to headaches, both literal and metaphorical.

Advancing Solutions in Chemistry

Solid data on formulas and weights empowers people to create safer procedures, better product routes, and greener manufacturing steps. Companies continue testing alternative ionic liquids that break down harmlessly after use. Accurate chemical data lets them swap one ingredient for another without risking safety or effectiveness.

Educators need to drill these details into new chemists so every lab, whether academic or industrial, works from a shared factual base. Open-access databases like PubChem support this learning, sparing a lot of frustration and waste. With reliable chemical identities in hand, science keeps pushing forward—one measured beaker at a time.

Understanding the Risks

1-Pentyl-3-Methylimidazolium Thiocyanate sits in the group of ionic liquids that have made a mark in labs and industry. This stuff doesn’t give off much vapor, so it slips under the radar for anyone just sniffing around for danger. That said, its chemical roots still raise flags. 1-Pentyl-3-Methylimidazolium groups carry the weight of organic solvent risks—skin absorption, eye irritation, and all sorts of trouble down the road for anyone ignoring their goggles or gloves.

Everyday Protection Counts

Working safely with chemicals isn’t rocket science, but sloppy handling still sends people to the emergency room. Before touching a single beaker, I grab my gloves, goggles, and apron. Even a small splash can burn, and if you forget that, it won’t let you ignore it for long. A fume hood does more than push air around—any spills or reactions that let out fumes or tiny bits get swept away fast. I’ve learned that soap and water can only go so far if a liquid like this soaks in; chemical-resistant gloves (nitrile or butyl) provide a solid line of defense.

Spill Response Done Right

Spills get overlooked until one happens on your watch. Small spills can be wiped up, but only after dropping absorbent pads and making sure no one else tracks it around. For larger messes, toss on extra protection and bring out the chemical spill kit. The key is making sure the substance can’t escape into the drain or onto the floor.

Disposal Isn’t Just Throwing It Out

Disposing of 1-Pentyl-3-Methylimidazolium Thiocyanate shouldn’t feel like tossing an empty soda can. It counts as hazardous waste—no shortcuts. Dumping it down the sink only sends chemicals into water systems. Commercial waste handlers know the drill: collect it in tight, tough containers, label it properly, and let experts process it by chemical treatment or incineration under controlled settings. That stops it from working back into soil and waterways, and that’s not just a rule; the EPA and OSHA can hit with fines that sting as much as any chemical burn.

Practical Steps in the Lab and Beyond

Training makes the biggest difference. Fresh faces often skip the safety sheets or tune out safety talks. I keep things simple—short refreshers, clear instructions, and drills every season. For storage, I always keep this compound away from oxidizers and acids in a cool, dry spot. Double-sealed containers keep leaks from spreading, and clear labeling stops mistakes before they happen. Emergency eye-wash stations and showers nearby might gather dust, but when accidents hit, they become the first stop.

Building a Culture, Not Just a Checklist

A workplace that values safety doesn’t hide manuals in cabinets. I push for open conversations about near-misses and improvements. Posting emergency numbers and spill response guidelines everywhere beats out hoping someone remembers their training under stress. Sharing tips, learning from others’ mistakes, and keeping lines open with waste contractors keep everyone honest.

Room for Improvement

Science keeps changing, and safer alternatives keep popping up. Green chemistry aims to squeeze out toxic choices, and chemists who stay on top of safer solvent research help turn good intentions into everyday practice. Paving the way for bulk return or recycling programs removes guesswork. Until those options replace older routines, strict attention and a little extra time always beat regret.