The Story of 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate: More Than Just a Chemical

How Did We Get Here? Historical Development

Stepping into the world of ionic liquids, the journey behind 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate offers more than a timeline of organic chemistry breakthroughs. Early versions of imidazolium-based ionic liquids caught the eyes of chemists back in the late 20th century. Researchers noticed how swapping methyl for bulkier groups on the imidazolium ring shaped melting points and solubility. Tetrafluoroborate, with its strong resistance to hydrolysis, made a natural partner. Laboratories across Europe and Asia kept tinkering with functionality on both the cation and anion—for durability, for cost, sometimes for no other reason than curiosity. By the end of the 90s, chemical suppliers started seeing requests for this compound on their order forms, marking its practical arrival and embedding it in research catalogs worldwide.

Product Overview

1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate stands out from both older, more viscous ionic liquids and single-use organic solvents. Its low volatility and wide electrochemical window offer a package deal chemists want—one that allows higher reaction temperatures and stabilities, and far fewer hazardous fumes. This compound doesn’t just drop into lab glassware; it shows up in pilot-scale projects that demand both consistent performance and recyclability. The chemistry community leans in for a closer look, hoping to pair green chemistry’s idealism with industry practicality.

Physical & Chemical Properties

1-Propyl-2,3-dimethylimidazolium tetrafluoroborate typically forms a colorless to pale yellow liquid at room temperature, fairly dense, with a sweet spot for fluidity—thick enough to handle without fear of splashing, thin enough to pipette smoothly. Its melting point hovers well below 50°C, meaning it remains liquid under most lab conditions. The compound dissolves nicely in polar organic solvents, but keeps water absorption lower compared to some ionic liquids—thanks to the hydrophobic push from the methyl and propyl substitutions. The tetrafluoroborate anion grants a strong resistance to hydrolysis and decent thermal stability, making this salt an appealing choice for applications that see temperature swings or exposure to trace water. The ionic conductivity, specific gravity, and viscosity all fall into a range trusted by electrochemical researchers and process engineers alike.

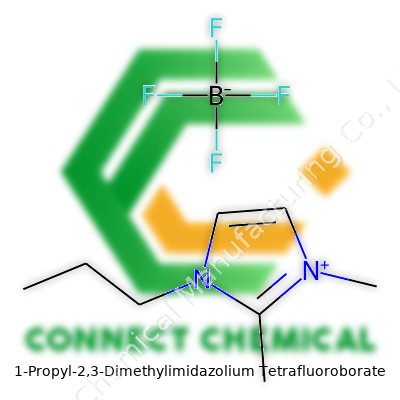

Technical Specifications & Labeling

Chemists expect clear labeling. Typical labels list the molecular formula as C9H17BF4N2, with a molecular weight in the vicinity of 256 grams per mole. The commonly accepted purity stretches above 98 percent, supported by NMR, GC-MS, and elemental analysis. Depending on the supplier, specific gravity at 25°C usually sits between 1.15 and 1.18. Containers range from amber glass to PTFE-lined bottles, helping guard against light and moisture. Storage guidance spells out cool, dry, and away from acids or bases, underscoring both the compound’s relative stability and its vulnerability if left on a humid shelf or next to strong reagents. Safety sheets give practical instructions and remind users that the absence of smell or color doesn’t mean the absence of hazard.

Preparation Method

The most reliable approach uses a two-step protocol. Step one: React 2,3-dimethylimidazole with 1-chloropropane under mildly basic conditions. After a good stir at elevated temperature, the cation forms as a chloride salt, which precipitates out and gets collected by filtration. Step two involves anion exchange: Dissolve this intermediate in water or acetonitrile and add sodium tetrafluoroborate. The target product drops out or remains in the organic layer, separating out from the sodium chloride byproduct. Final purification relies on repeated washing and vacuum drying, stripping away traces of water and leftover impurities. This recipe reflects both old-fashioned glassware work and modern, scalable upgrades—one of those processes that can move seamlessly from a round-bottom flask to a jacketed reactor.

Chemical Reactions & Modifications

This ionic liquid has proven a flexible building block for chemical innovation. The imidazolium core handles stable carbene formation, metal complexation, and hydrogen-bond-driven manipulations. Researchers value the methyl and propyl groups for tuning hydrophobicity and increasing steric bulk, protecting the cation from nucleophilic attack. Introducing tailor-fit functional groups—and swapping the anion for the likes of hexafluorophosphate or bis(trifluoromethanesulfonyl)imide—changes the liquid’s solubility and reactivity, giving researchers a shortcut to custom-made solvents for specific catalytic cycles, separations, or battery chemistries. Attempts to anchor catalysts or extract metals build on this core structure, showing how such compounds serve as adaptable platforms for new concepts in both academia and industry.

Synonyms & Product Names

Industry shorthand for this compound often appears as [PrMMIm][BF4] or 1-propyl-2,3-dimethylimidazolium tetrafluoroborate, depending on the lab or supplier. Some catalogs use the abbreviation PDMIMBF4 for faster inventory searches. Beyond the technical aliases, vendor trade names sometimes show up, but chemists keep coming back to the straightforward systematic names, especially in regulatory files, published papers, and grant proposals.

Safety & Operational Standards

Any new, seemingly benign laboratory chemical calls for respect, especially when it’s meant to replace volatile organic solvents. 1-Propyl-2,3-dimethylimidazolium tetrafluoroborate displays modest toxicity, but accidental contact—especially eye or prolonged skin exposure—brings risk. Safety protocols recommend working in ventilated hoods, avoiding unnecessary skin contact, and using protective eyewear and gloves. Spills clean up with absorbent material and soap, not harsh oxidizers or strong bases, as both imidazolium and tetrafluoroborate can break down in extreme conditions. Waste disposal should go through a licensed hazardous handler, preventing release into waste streams. Laboratories across Europe, Asia, and North America track exposures based on evolving regulatory standards. While no widespread incidents have occurred, the push to catalog and understand long-term risks keeps safety researchers busy.

Application Areas

Lab benches in fields as varied as organic synthesis, electrochemistry, and materials science see steady use of this ionic liquid. In synthetic organic chemistry, it sees bench tests as a reaction medium for alkylations or transition metal catalysis, often outperforming conventional solvents in yield or selectivity. Battery developers test it as a safer, non-volatile electrolyte in lithium-ion prototypes and supercapacitors, banking on its ionic conductivity. Engineers eye this compound for use in advanced sensors and energy storage materials, while environmental chemists examine its recyclability and potential to break stubborn contaminant chains. Each application puts performance and safety claims to the test.

Research & Development

The story of this compound keeps unfolding in research labs every day. Two decades ago, only a handful of groups dared swap in ionic liquids for legacy solvents in mammoth separation columns or large-volume electrochemical cells. Now, interest grows in integrating these liquids into continuous flow reactors, using them to stabilize unusual reaction intermediates, or harnessing them for selective extraction of rare earth elements. Cutting-edge work explores how minor tweaks to the cation or anion can knock years off process development times. National funding bodies keep adding calls for green, safe materials, putting further wind in the sails of researchers who want to adapt ionic liquids for industrial plant scale without trading away environmental safety.

Toxicity Research

Data so far points to low acute toxicity in laboratory animals, though longer-term environmental effects remain a work in progress. Researchers track persistence in soil and water and assess how much ends up in aquatic or terrestrial food webs. Some studies have found slight inhibition of microbial growth at high concentrations but little evidence of acute toxicity to fish or mammals. The compound rarely volatilizes, but improper disposal or chronic small leaks could add up in sensitive ecosystems, triggering regulatory red flags. Research groups across several countries advocate for bioassays that cover not just extreme exposure events, but slow, chronic background contamination as well.

Future Prospects

More companies lean into the benefits of low-volatility, efficient ionic liquids. The push for safer, cleaner alternatives to established organic solvents won’t let up, and 1-propyl-2,3-dimethylimidazolium tetrafluoroborate finds itself riding this wave. Scaling up from grams to tons, embedding in battery designs or renewable energy projects, and linking its future to circular chemistry initiatives give this compound an enduring relevance. Success will depend on responsibly managing toxicity, recycling, and supply chain security—but the relentless search for better, safer, and more sustainable chemical tools keeps opening new doors for this unique liquid.

Quiet Powerhouse in Electrochemistry

Working with 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate taught me about quiet innovation. This ionic liquid looks like another specialty chemical, but its impact lies in how it handles electricity. I first came across it while helping a startup design safer batteries for handheld devices. Its stability, especially at high voltages, meant we could push batteries farther without risking as much thermal runaway. Lithium-ion research has leaned heavily into these ionic liquids to create safer and longer-lasting batteries. Why? The salt structure brings high ionic conductivity and doesn’t evaporate easily, which means a battery runs cooler and handles more charge-discharge cycles before breaking down.

Green Chemistry is Personal

Some solvents make the news for all the wrong reasons: groundwater contamination, worker health issues, or expensive cleanups. This hits home for me, having watched an uncle develop respiratory problems after years working in industrial labs. 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate answers the call for less toxic alternatives in labs and factories. Researchers have used it instead of volatile organic solvents—especially in organic synthesis and separation processes. By swapping in this ionic liquid, chemists cut down on emissions and waste. Research published in Green Chemistry backs this up, showing these liquids excel at dissolving reactants that once needed tough or dangerous solvents.

Tough Jobs in Metal Processing

Metallurgists keep a close eye on what touches a metal surface. I once saw a massive recycling operation struggle to reprocess e-waste because their leaching solvents ate away at expensive reactor vessels. With 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate, recovery of precious metals gets a boost. This ionic liquid doesn’t corrode as aggressively and can dissolve metals with selective precision. Copper, silver, and gold recovery all improve in yield, conserving resources and dollar value from discarded electronics.

Cost and Access Still Stand in The Way

Every chemist wants to use the next best thing, but nobody likes getting hit with a giant invoice. This ionic liquid, like many in its class, costs much more than legacy solvents. That price tag limits its use outside research or high-stakes manufacturing. Then comes the challenge of recycling it after use. Recent work looks promising: catalysis specialists have started finding ways to recover and clean the liquid for reuse. In my experience, buy-in skyrockets once people see a solvent can be run through dozens of cycles without losing its edge.

Plenty of Room for Smarter Adoption

The safety record of chemicals rests on thousands of hours of careful use and observation. Regulatory bodies want to see long-term health data and scalable strategies for handling spills or accidental exposure. So while these ionic liquids look appealing, decision-makers wait for stronger real-world studies before greenlighting large-scale adoption. I believe the next decade brings tighter partnerships between researchers, regulators, and industry. Groups are already publishing life-cycle studies and pilot results in journals like ACS Sustainable Chemistry & Engineering.

Practical Steps Toward Safer, Cleaner Tools

After years working with hazardous process solvents, I appreciate every advance in safety and sustainability. 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate represents an alternative that brings known performance in batteries, greener reactions, and smarter metal recovery. The path to broad adoption runs through lower costs, clear handling guidelines, and a cycle of reuse instead of disposal. Meaningful change takes persistence, clear data, and a wider conversation between the folks who invent, use, and regulate industrial chemistry.

Chemicals in the Real World

Most folks outside the lab hear a name like 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate and imagine something exotic or maybe even unstable. It sounds like the kind of thing someone in a white coat tiptoes around. In reality, substances like this get used every day in research and industry. The worry always pops up: will the container on the shelf hold up over time or could something go wrong?

What Experience Teaches About Ionic Liquids

Some ionic liquids have a reputation for being finicky and sensitive to both air and water. After handling many related salts, I’ve learned that the stability of these chemicals usually ties back to their specific chemical bones and the conditions of the room where they get stored. Tetrafluoroborate as an anion sits in an interesting spot. In my time with BF4−-containing materials, a few things clearly matter:

- exposure to air and light,

- humidity around the bottle,

- the nature of the container,

- and the general cleanliness of the sample.

Most suppliers pack 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate in airtight vials. The ionic liquid itself isn’t inclined to combust or degrade on its own. Leaving it open on a bench, though, leads it to absorb water from the air—a notorious trait in the imidazolium family. Over weeks, you might notice it gets slightly slushy or even changes color if enough water creeps in. Tetrafluoroborate breaks down into toxic fluorine-containing substances under harsh acid or strong base, but this rarely happens in a dry, cool storeroom.

What the Literature Shows

Digging into recent journal papers and safety data sheets, chemists report the ionic liquid holds steady under dry, ambient conditions for months at a stretch. BF4− begins to hydrolyze if left wet over long periods, leading to boron trifluoride and other byproducts. Not ideal for anyone concerned about chemical integrity. Safety sheets from well-known suppliers, like Sigma-Aldrich, recommend storing it tightly capped, away from strong acids and bases. With these precautions, that liquid remains largely unchanged, with neither the imidazolium ring nor the BF4− anion showing much tendency to break down.

Why Stability Matters

Researchers and manufacturers stake a lot on the predictability of their chemicals. A compound that drifts from its original state means wasted money, unreliable results, and sometimes real safety risks. In my work, a batch gone off due to air leaks usually signals more testing, more delays, and mounting frustration. The cost adds up quickly, both in supply budgets and in hours lost.

For folks on the ground, setting some clear protocols helps prevent headaches: keep the bottles in a dry, room-temperature spot, cap them well, avoid scooping out material with damp tools. Decent glove handling goes a long way. Environmental monitoring—simple humidity sensors or desiccator cabinets—make a clear difference. If someone suspects a problem with their ionic liquid, a quick NMR or conductivity test shows whether things have started to slip.

Moving Toward Safer Practice

Over the years, I’ve seen practices improve as more labs move to desiccator storage and better tracking of solvents and sensitive reagents. Training newcomers on the quirks of substances like this, especially how they interact with air and water, also pays off. This leads to less waste and a safer workspace. For a compound like 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate, consistency in storage keeps both researchers and managers on the right side of safe, productive, and cost-effective science.

Why Even Simple Mistakes Can Hurt

Many people believe small exposure won't really cause trouble. Recent injuries from common industrial cleaners, garden pesticides, and even simple solvents show this isn’t true. In my own early years at a recycling plant, I watched a new coworker skip gloves and goggles; his hands burned, his eyes stung, and management hustled him to the emergency room. That lesson stuck with everyone on the floor: shortcuts catch up fast, and recovery can take weeks.

Reading the Label Isn’t Optional

Legal warnings on packaging aren’t decoration. Labels share exactly what will burn skin, damage lungs, or linger in the air after you open a bottle. Shelf talk at big-box stores cannot replace those details. Before anything else, grab the safety data sheet if you can. I saw a young mechanic ignore the note about a paint stripper’s fumes, and his dizziness forced him to miss work. Nobody wants to sit in the break room with a splitting headache, all for skipping a few lines of text.

Gear Up—Don’t Guess

Gloves, goggles, and masks look awkward and feel clumsy, but burns and infections linger far longer. I bought nitrile gloves after latex left raw skin from handling a degreaser. One co-worker wore safety glasses so habitually that he never suffered eye splashes, unlike more than one person who trusted luck. Good boots and long sleeves also meant spilled chemicals never reached the skin. Ventilation fans or even an open window helped cut the sharpness of airborne fumes. No one at our workshop ever mocked these habits: we respected scars more than complaints about bulky gear.

Storage Isn’t Just “Put It on the Shelf”

I kept a story in mind from a neighbor whose son left fertilizer sacks in the sun; a backyard shed reeked, and plants wilted nearby. Chemical products break down, catch fire, or leak into soil if stashed in the wrong place. Lockable cabinets, dry shelves, and real separation from food or animal areas prevent nightmare calls to poison control or worse. In my home, garage chemicals stay in sealed bins, away from anything the kids touch or where pets sleep.

Be Ready if Something Goes Wrong

Accidents jump out of the blue. Routine drills might sound overdone, but just knowing where the emergency shower, clean water, or first aid kit hides means nobody panics. At our factory, regular training on spill cleanup cut incidents by half. Calling for help early and having the right number at hand makes all the difference during a spill or a splash. Calling a supervisor or local poison center fast beat guessing what home remedies might help.

Practical Solutions Save Health

The best safety steps don’t require fancy tech—just personal awareness and the effort to read, wear, and store things right. If employers invest even a bit in training and gear, the whole team stays on the job, unhurt, and able to earn for another day. Grocery stores, hardware shops and even online sellers could do more to explain those risks and solutions, but responsibility starts at home and work benches. Each unburned hand or clear lung proves these habits work.

Purity Expectations in the World of Ionic Liquids

Anyone who works with specialty chemicals has probably spent time comparing purity grades. 1-Propyl-2,3-dimethylimidazolium tetrafluoroborate, a common ionic liquid, pops up in plenty of research papers. Most places that sell this compound offer it at high purity—usually 97% to 99%. That number might sound impressive at first glance, but anyone who’s measured reaction yields knows that last percent sometimes matters most.

Lab work doesn’t play by “close enough” rules. Even something as small as 1% impurity can become a big problem, turning up as unwanted signals in NMR spectra or slowing down a catalyst more than you’d expect. Anyone who’s had to debug wonky data after a late-night synthesis run learns fast: it pays to ask the supplier for a real certificate of analysis. The bottle may say 99%, but only a full readout will show what’s hiding in the other one percent.

Why Purity Impacts More Than Just Results

There’s a funny mismatch in academic circles between “reproducibility crisis” talk and how casually some labs treat reagent purity. Ionic liquids like this one are doubly tricky thanks to their strong ability to attract water, dust, or even old solvent vapors if left uncapped. The typical purity grade is not just about known chemical contaminants; tiny traces of water, hydrolyzed borate, or old solvents can have outsized effects on solubility and conductivity. Trust me, anyone mixing up electrochemical experiments sees it fast—just a drop or two of water turns a stable voltage window into a noisy mess.

For industry, the difference between 97% and 99% can spell hours of downtime. Engineers working in battery or pharmaceutical pilot plants find out the hard way that different lots from the same supplier don’t always perform the same. More than once, I’ve seen production batches blamed on “equipment drift” only to uncover a change in chemical source.

Supplier Choices and the Cost of Going Pure

Buyers paying attention know that getting the best quality from reputable names ends up saving money in the long run. At the high end, specialized suppliers charge a premium for extra purification steps and detailed certificate reports for every lot. These vendors tend to invest in rigorous HPLC, Karl Fischer, and NMR checks. It’s not just technical hand-waving—these certificates back up real performance down the line. Students and small labs tempted to buy a budget option from a lesser-known supplier sometimes end up repeating experiments, costing weeks and eating up precious grant money.

I remember trying to replicate a colleague’s work—just to realize the cheaper “99%” sample I’d grabbed on a student budget had massive hidden water content. That taught me more about research quality than any seminar. The stakes can be even higher if you’re in a regulated field: documentation trails, audits, and safety checks all hinge on knowing what’s in your bottle, not guessing.

Raising the Bar for Quality and Consistency

Peer-reviewed work increasingly encourages detailed reporting on batch numbers, exact purities, and even the supplier’s name. These details help others repeat work instead of wasting time troubleshooting. Researchers who join networks or forums share real-world supplier reviews, making it easier to separate marketing from reality. Pressure from both academia and industry nudges manufacturers to sharpen up their practices. Everyone benefits—the science moves faster, the failures go down, and chemical waste takes a dip. Better practices start with curiosity: ask hard questions, demand documentation, and keep an eye out for those hidden decimals on the purity label.

Recognizing Potential Hazards

Anyone dealing with 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate learns quickly this isn’t your ordinary workplace chemical. Ionic liquids like this one come with advantages like low volatility and strong thermal stability, which makes them attractive for certain research and industrial uses. Still, handling them with care stays essential, especially since the tetrafluoroborate ion brings risk of hazardous by-products—think hydrofluoric acid—if exposed to water or high heat. Missteps in storage or disposal can invite health issues, equipment damage, or unexpected environmental fallout.

How Safe Storage Maintains Integrity and Safety

My time working in chemical labs taught me that keeping any specialty reagent in the right place stops accidents before they start. Direct sunlight, dampness, or wild temperature swings all speed up unwanted reactions. So, this material goes best in a tightly sealed glass or high-grade plastic container, away from any water source. Any nearby acids or bases create trouble and shouldn’t share a shelf with it. Temperature-wise, a cool, consistently ventilated chemical storeroom works better than a utility janitor’s closet. Never rely on casual labeling—a permanent, legible label protects the people who come after you.

I recall an incident where someone left a container with a cracked cap in a common area. One small spill, and the tangy smell gave away the presence of unstable ions leaking out. No one wants to clean up a mess that bites back. Following institutional guidelines isn’t about bureaucracy; it keeps that kind of day from happening.

Understanding Environmental Impact

Disposing of specialty ionic liquids raises tougher questions than tossing out a lab wipe or rinsing a beaker. Blind dumping can lead to ground contamination or hazardous water runoff. Many ionic liquids, especially those with fluorinated counterions, slow to break down in soil and water. You can’t just pour this stuff down the drain and pretend it disappears. Inefficient breakdown may lead to accumulation of toxic by-products—something European Chemicals Agency hazard assessments highlight when reviewing safe handling data.

Disposal Practices that Protect People and Planet

An industrial supplier once walked me through their disposal handshake: collect all ionic-liquid waste in labeled, tightly sealed containers, and hand it over to a certified hazardous waste processor. No shortcuts, no private cabinets full of “for later.” Anyone who thinks incineration at the office works underestimates the dangers; only certified facilities with gas scrubbing handle it correctly, since burning boron-fluorinated ions can spit out hydrofluoric acid or other nasties.

Even if you only have a small amount left, double-bag the contents with absorbent material, label it accurately, and notify the hazardous waste coordinator on site. Never mix with other unknown chemicals; cross-reactions make for unpredictable results in the barrel. Gloves, splash-proof goggles, and a chemical fume hood give some personal defense during the transfer.

Building Safer Habits for Future Use

Many chemical safety mishaps don’t stem from malice. They creep in from hurrying or copying someone else’s shortcut. Staying ready with spill kits, secondary containment trays, and detailed chemical logs helps everyone avoid the rookie mistakes that linger longer than anyone expects. If a lab runs through many ionic liquids each month, a written protocol, annual training updates, and an emergency plan transform chaos into quiet confidence.

The cutting-edge science around ionic liquids means more of us will encounter them. Treating 1-Propyl-2,3-Dimethylimidazolium Tetrafluoroborate like the specialty chemical it is, not just another bottle on the shelf, preserves health, equipment investments, and the environment for the long haul.