1-Propyl-3-Methylimidazolium Acetate: A Practical Look

Historical Development

Scientists started looking for better solvents as environmental rules tightened and traditional chemicals kept showing their limits. Almost two decades ago, 1-Propyl-3-Methylimidazolium Acetate caught the attention of researchers searching for liquids that dissolve complex materials without causing headaches for workers or the planet. Few people outside labs had heard of ionic liquids then, but the buzz grew bigger as studies showed that this salt, liquid at room temperature, could tackle tasks that other chemicals just couldn’t touch. My own brush with the compound started in the late 2000s. Colleagues enjoyed how quickly it dissolved cellulose without needing heat or strong acid. That drew folks from biofuel, pharma, and clean chemistry to consider using it in their own labs. By now, this compound has found its way into research from China to Germany, each group hoping it solves a piece of their process puzzle.

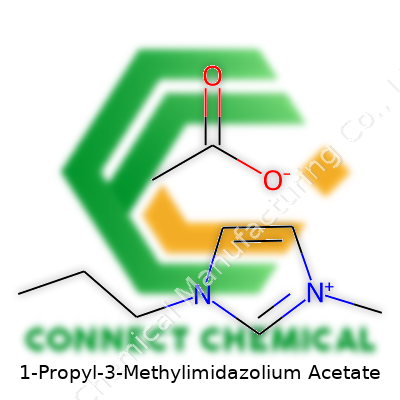

Product Overview

1-Propyl-3-Methylimidazolium Acetate usually looks pale yellow or clear and comes without a strong smell. The liquid serves as both a solvent and a reagent, making it a jack-of-all-trades for people who experiment with plant fibers, polymers, or metal ions. You’ll see bottles in labs labeled as “PMIM Ac,” “[C3MIM][OAc],” or just its formula laid out for those who know the shorthand. Production has grown, so larger suppliers now offer bigger, purer batches than the niche sources just a few years ago.

Physical & Chemical Properties

This ionic liquid stands out because it stays liquid at room temperature, doesn’t evaporate or catch fire easily, and manages to dissolve sticky or stubborn materials. It weighs about 198.24 g/mol and has a density close to 1.1–1.12 g/cm3 at 25°C. If you spill it, you’ll notice the high viscosity, almost like thick oil. 1-Propyl-3-Methylimidazolium Acetate handles temperatures above 100°C without boiling off, which matters if you want to extract plant matter or run industrial-scale separators. Solubility numbers show water loves to mix with it, but it also handles some organics better than others. Acetate as the anion brings basicity, letting it join in mild acid-base chemistry without wrecking delicate molecules.

Technical Specifications & Labeling

People who need results care a lot about what’s in the bottle. Most reputable suppliers now guarantee purity near 99%, with water content kept below 0.2%. Labels usually state CAS number 663440-35-5, molar mass, batch origin, and clear storage advice. Shelf life depends on the seal, but dry, dark places extend its usefulness for more than a year. Handling certifications, like ISO 9001, give buyers confidence that every batch matches what appears in published research. Folks who run food or drug trials demand added paperwork, pushing suppliers to standardize how they validate each step from source chemicals to sealed glass flask.

Preparation Method

The path to making 1-Propyl-3-Methylimidazolium Acetate usually starts with a simple quaternization: one part 1-methylimidazole reacts with a fair bit of 1-chloropropane to form 1-propyl-3-methylimidazolium chloride. Lab folks follow up with metathesis using sodium acetate. They solve both salts in water or acetonitrile, churn the mixture, let the unwanted sodium chloride drop out, and separate the valuable liquid. After washing and drying – often under vacuum with gentle heat – they weigh out a reliable batch for chemistry experiments. Each tweak, from solvent purity to mixing order, changes the final color, smell, and water content. Small labs manage a few grams, but smart process engineers now scale up to kilograms without leaving all the residue or trace metals of early batches.

Chemical Reactions & Modifications

Chemistry with 1-Propyl-3-Methylimidazolium Acetate feels a bit different than working with standard organics. The acetate base allows for mild esterifications, alkylations, and sometimes helps run enzyme reactions that would die in regular solvents. You can swap out the acetate, installing other anions like chloride, tetrafluoroborate, or tosylate to chase particular results. Some creative teams even anchor the imidazolium cation to solid supports, recycling it for greener industrial lines. That kind of custom chemistry keeps popping up in patents from multinational firms looking to replace harsher solvents or run renewable material upgrades. My own hands-on with the acetate variant worked best for breaking apart cellulose into sugars—watching stubborn cotton dissolve within hours still feels a bit like magic.

Synonyms & Product Names

If you look through catalogs or academic papers, the language around this liquid can sound confusing. Synonyms include 1-Propyl-3-Methylimidazolium Acetate, PMIM Ac, [C3MIM][OAc], and the longer-form: 1-propyl-3-methyl-1H-imidazol-3-ium acetate. Some sellers simplify to PMIM Ace or tweak the spelling depending on the region. The CAS number 663440-35-5 gives the most reliable match no matter the supplier or country.

Safety & Operational Standards

Handling this ionic liquid doesn’t feel as risky as using classic volatile solvents, but the chemical isn’t completely harmless. Liquid exposure can irritate the skin and eyes, and its low vapor pressure doesn't mean you should skip lab ventilation. Spilled drops feel slippery and climb up inorganic surfaces, so it pays to work with gloves and splash goggles. Since this chemical breaks down under strong acid or base, storing it away from the extremes protects both reagent and worker. Disposal rules keep changing, but trained teams finish every project by incinerating leftover liquid, minimizing groundwater or soil contact. Smart labs keep clear instructions and clean-up supplies close, tracking every bottle for regulatory audits and worker health records.

Application Area

The appeal of 1-Propyl-3-Methylimidazolium Acetate comes from its flexibility. In life sciences, it unlocks cellulose—the main plant wall component—letting researchers turn wood, straw, or waste into sugars and then biofuels or biodegradable chemicals. In chemical engineering, its unique solvent mix runs reactions that stop dead in water or alcohol. Folks producing batteries and electronic devices add small amounts to tweak conductivity or help make new polymers. Textile and paper factories explore it for cleaner pulping, and recycling plants test it for separating metals from plastic in e-waste. Today, a growing number of undergraduate labs list it in course manuals, so the next generation picks up safer, smarter ways to handle tough industrial chemistry.

Research & Development

The steady expansion of published research shows how central this ionic liquid has become. In university and commercial labs, scientists experiment with its use to open up plant fibers and develop bio-based plastics. The acetate anion matters a lot—it softens and dissolves cellulose where acids or metal salts fail. Pharmaceutical scientists tinker with 1-Propyl-3-Methylimidazolium Acetate in enzyme recycling and separation of active molecules, aiming for products pure enough to pass regulatory hurdles. Teams in Europe and Asia follow each other's successes and failures, often sharing results openly online. Research collaborations include full-scale pilot projects, not just small flasks, so new discoveries move quickly from journal to prototype plant. In recent years, advances in computer modeling help guide molecular tweaks, saving time and chemicals as new derivatives hit the market.

Toxicity Research

Concerns about toxicity pushed this liquid through plenty of ecological and medical screens. Compared to classic chlorinated solvents, it scores much lower in evaporation rate, lessening air emissions around busy workspaces. Biological impacts haven’t vanished, though. Aquatic toxicity stands out—higher doses harm some small fish and bugs—so environmental chemists focus on containment and recycling systems. Long-term studies with rodents suggest low absorption through skin, but accidental swallowing or injections still show moderate toxicity. I once saw a misplaced sample burn a patch of grass in an outdoor waste area, leading our team to tighten up disposal rules and spill controls. Regular updates of safety data sheets and training help new lab workers avoid mistakes, knowing both personal and ecosystem risks.

Future Prospects

The push for greener solvents and circular economies points straight at ionic liquids like 1-Propyl-3-Methylimidazolium Acetate. Industry executives, not just university researchers, now budget for pilot trials that cut out problematic volatile organics or boost raw material conversion. Ongoing projects target scale-up for plastics recycling, low-waste pulp and papermaking, and next-generation battery electrolytes. It’s likely that future versions will feature functional side chains or new ion pairs to further lower toxicity, speed up reactions, or simplify recovery. Tightening legal limits on waste means that closed-loop processing—recovering the liquid for reuse each cycle—shifts from luxury to necessity. As data piles up from real-world applications, expect regulatory agencies to clarify rules, giving both risk-averse industry and environmental advocates concrete numbers to work from. With every new trial and minor mishap, the field advances, leaning on open data, clever modifications, and relentless curiosity for cleaner chemistry solutions.

What Makes This Ionic Liquid Stand Out

Working in the chemical research field shows you pretty quickly that not all solvents are created equal. Some, like 1-propyl-3-methylimidazolium acetate (PMIM Ac), have built a reputation for being more than just background chemicals. With a structure rooted in the imidazolium family and paired up with the acetate anion, PMIM Ac finds its way into several real-world labs and companies. This isn’t by accident—its ability to dissolve complex biopolymers is no small feat, and that’s one reason it keeps attracting both scientists and businesses.

Pulp and Paper Moves Beyond Trees

Anyone who’s had to break down wood for bio-based products knows how tricky lignocellulose can be. Traditional solvents fall short, leaving lots of potential on the table. PMIM Ac brings unique qualities to the game, dissolving cellulose and even certain hemicelluloses more effectively. I’ve watched research teams switch to this solvent so they could get higher yields of cellulose nanofibers. In fact, studies out of Europe show a clear reduction in processing steps, less waste, and less time on the clock compared to older methods. This means a company looking to make environmentally friendly packaging or textiles gets better mileage out of its raw material.

Green Chemistry Isn’t Just a Buzzword

For a long stretch, people working on biofuel projects or bioplastics found themselves stuck between wanting clean processes and getting reliable results. PMIM Ac lands on a lot of shortlists for those projects. Unlike some harsh solvents, it can handle dissolving or modifying biopolymers under milder conditions, leading to less energy use. Academic literature points to safer lab and industrial environments, thanks to its much lower volatility. It’s not flawless—manufacturing and end-of-life issues need better solutions in the future—but the shift away from toxic chemicals has been noticeable in startups and established plants alike. Screenings by the American Chemical Society mark it as a safer bet in many scenarios, especially over older, fossil-fuel-based solvents.

Catalysis and Extraction: Efficiency over Tradition

PMIM Ac shows up in extraction columns and reactors across several industries. Anyone running process optimization for natural product extraction sees faster throughput and higher product purity. In drug discovery, the role of PMIM Ac as a reaction medium has delivered better selectivity and yields for some enzyme-catalyzed reactions. This liquid simplifies workups and recycling of valuable enzymes, which cuts down costs over time. Looking at the numbers, pilot projects in pharmaceutical and food production have actually slashed their use of organic solvents after making the switch. That’s not just better for worker health—it also means lower hazardous waste disposal bills at the end of the year.

Potential Solutions for Remaining Hurdles

Nothing’s perfect, and PMIM Ac isn’t an exception. Sourcing raw materials for its synthesis still links back to petrochemicals in some cases, so there’s work ahead for manufacturers to make its production greener. Recycling processes for ionic liquids also need improvement; right now, not every facility can afford the equipment needed to recover and reuse this solvent. Investing in new purification and recovery technologies would help extend the lifespan of PMIM Ac, making sure it stays on the right side of sustainability efforts. Policies and grants supporting this research could make next-generation solvents accessible for a wider range of companies, perhaps pushing the industry even further away from dangerous chemical mainstays.

Purity Isn’t Just a Number—It’s a Standard

Anyone working with 1-propyl-3-methylimidazolium acetate knows that purity isn’t just academic. There’s a promise behind every batch. Researchers count on high and consistent purity, often upwards of 99%, to keep experiments reliable. A slight variation in quality can throw off months of hard work or mislead a whole project. The expectation is always that the product actually reflects the specs on its label, not something close or “good enough for most uses.”

Real-World Impact: Why Quality Isn’t Optional

In the lab, impurities can masquerade as new results or ruin sensitive reactions. I’ve seen colleagues chase their own tails, not suspecting that trace contaminants have shifted reactivity in unexpected ways. Manufacturers rely on ionic liquids like this one for processes in cellulose dissolution, catalysis, and green chemistry applications. A subpar product leads to unpredictable performance, waste of resources, and sometimes major financial losses. Quality assurance isn’t a luxury—it’s what keeps research and industry moving.

Testing and Documentation: What to Watch for

Every reputable supplier offers a certificate of analysis with their chemicals. This isn’t just a courtesy; it’s proof. The document should show not only an overall purity percentage but also name any specific contaminants and their concentrations. Nuclear Magnetic Resonance (NMR), Karl Fischer for water content, and techniques like HPLC or ion chromatography usually back up these claims. A figure like “≥99% purity” means most unwanted byproducts sit below detectable or standardized levels.

Someone new to buying 1-propyl-3-methylimidazolium acetate might assume all suppliers play by the same rules, but I’ve learned to check for full test data. Some providers only measure water or chloride content, ignoring organic impurities that can wreak as much havoc in a reaction. Demanding full results keeps vendors accountable and saves a lot of headaches.

What Can Go Wrong with Impurities?

Even tiny amounts of residual starting materials or byproducts matter. In catalysis, impurities can poison catalysts or alter selectivity. In material science, they may change texture, color, or solubility. Impurities sometimes increase corrosiveness or toxicity, putting both process and people at risk. I’ve seen small shortcuts in purification lead to much bigger problems later in the production chain.

A common headache is water content. Even fractions of a percent can mess with hydrophilic or hydrophobic reactions and skew thermal properties. Moisture-sensitive work suffers most. Likewise, leftover halides or unreacted starting products can lead to dangerous side reactions, especially when working at scale.

How Buyers and Users Can Look Out for Themselves

Everyone wants a hassle-free experience and reliable results. The real command here sits with the buyer. Ask for documentation before placing an order. Review not just the headline number for purity, but ask how that number was measured. Verify the methods match your intended use. If a supplier can’t provide detailed spectra or batch analysis, consider it a red flag.

Building a relationship with suppliers who value transparency pays for itself. Over the years, sticking to vendors who share complete test records has saved me from wasted time, ruined reactions, and outright failed projects. Knowledge in chemistry is cumulative, and the wrong data from impure materials can seep into the literature, setting back everyone’s work.

Raising the Bar Across the Industry

Chemicals like 1-propyl-3-methylimidazolium acetate drive innovation in sustainable science, energy, and materials. Their impact depends on trust—trust that every bottle delivers what it promises. Holding suppliers to high standards, checking documentation, and sharing best practices strengthen the whole field. That’s the difference purity makes every day in the lab.

Why Storage Matters with Chemical Compounds

Spending years in research labs shows how much unexpected trouble crops up from poor chemical storage. 1-Propyl-3-Methylimidazolium Acetate isn’t some everyday kitchen cleaner. Used in advanced manufacturing settings, in biological extraction work, and as a solvent for cellulose and other tough materials, this ionic liquid demands respect beyond simple shelf space. Not only do leaks or spills put an entire operation at risk, but overlooked storage issues turn a pricey chemical into a future safety report.

How 1-Propyl-3-Methylimidazolium Acetate Reacts to Its Environment

This compound tends to absorb moisture from the air, which means leaving it exposed costs both purity and money. From my experience, you save yourself repeat orders and lab headaches by using airtight containers. Polypropylene and glass work well, but those with screw caps that seal tight prevent unwanted surprises.

Temperature control matters too. Letting it sit in hot storage pushes it closer to degradation, changes concentration, and may start breaking down the chemistry that labs pay good money to preserve. Cooler settings—around 20 degrees Celsius—have proven most reliable in keeping it stable. I’ve seen labs stash it in refrigerators, labelled clearly to avoid cross-contamination with organic reagents or perishable materials. If you find yourself in a busy shared environment, double-check labels and double-bag containers against drips.

Light, Air, and Other Threats

Light exposure slowly degrades some ionic liquids, and 1-Propyl-3-Methylimidazolium Acetate offers no exception. Amber bottles or storage in a dark cabinet helps extend shelf life. Even with robust compounds, cutting out direct light keeps colors, viscosity, and composition healthy longer. Oxygen also causes headaches by sparking unwanted reactions. Restoring the container’s lid right after pouring limits how much humid or oxygen-rich air gets in. Keeping records of every opening and pouring means no more guessing what went wrong after the fact.

Spill Control and Chemical Compatibility

From spilled acids to sticky ionic residues, chemical storage turns dangerous if incompatible materials end up neighbors. Separating strong oxidizers, acids, or anything flammable from 1-Propyl-3-Methylimidazolium Acetate prevents chain reactions that catch even seasoned chemists off guard. Every year, disaster stories stem from sloppy shelving or ignoring material safety data sheets. Storing this compound on its own dedicated shelf or cabinet, with clear dividers, keeps the air clean and the workspace safe. I once watched a minor mix-up result in a full lab shutdown for an afternoon and ruined weeks of data. Nobody wants a repeat of that hassle.

Simple Labels, Regular Checks

Clear, typed labels—date received, opened, and the responsible person—save the day during audits or safety checks. Adding hazard statements reminds everyone what’s inside, especially in emergencies. Scheduling monthly visual inspections keeps any leaks, crusty lids, or changing liquid colors from going unnoticed. By treating it as routine housework, labs sidestep big problems and keep their insurance companies happy too.

Training: The Solution Often Overlooked

Most storage failures trace back to people, not gear. A half-hour refresher on storing chemicals makes more difference than the fanciest cabinet if folks don’t understand what’s at stake. Walking each team member through the process, showing them what a good label looks like, and telling stories about near-misses makes safety stick. No one wants their name in the accident report. With the right training and a few simple steps, storing 1-Propyl-3-Methylimidazolium Acetate becomes one less thing to worry about in a long lab day.

Looking at What Researchers Say

1-Propyl-3-methylimidazolium acetate has turned into a workhorse for chemists. This ionic liquid dissolves cellulose, helps in extracting useful plant compounds, and even pops up in battery technologies. People sometimes call these liquids “green solvents,” thinking they are less harsh than old-school chemicals. It’s tempting to assume something with a scientific-sounding name and a “bio-based” reputation would be safe. I’ve learned through my years in a lab that reputation only goes so far—real safety counts on real facts.

Digging Into Safety Data

People working with this substance notice the odd smell and sometimes complain of eye or skin irritation after spills. Several peer-reviewed studies show that 1-propyl-3-methylimidazolium acetate can irritate the skin, eyes, and lungs if splashed or inhaled. One journal article from 2016, published in Chemosphere, compared a handful of ionic liquids and found that their toxicity sits somewhere near that of basic soaps or cleaning agents. The real problem comes with large exposures, as higher doses harm aquatic life more seriously and start to cause cell death in laboratory animals.

Beyond the Lab Table

Safety data sheets always make clear: keep this stuff away from kids, pets, food, and drink. The acetate part may sound familiar, but this chemical isn’t something you’d want in the kitchen or garden. My experience handling similar compounds taught me to suit up with gloves and goggles and work with good ventilation. Poison control records don’t show major public incidents with this specific ionic liquid, but the data pool is still shallow compared to well-known risks like ammonia or bleach.

Looking at the Bigger Picture

The environmental angle needs more attention. Disposal by pouring down the sink is a big no. One German study from 2018 reported that it doesn’t break down fast in soil or water, so wildlife could end up exposed for months. That matters, especially when more industries are experimenting with ionic liquids. Even small leaks can build up after years of use, and most wastewater treatment doesn’t filter out compounds like this. So, companies using it have started storing waste separately or sending it to specialized chemical processors.

Practical Steps for Staying Safe

I’ve talked with several safety officers who encourage users in factories and research labs to respect these compounds as they would respect strong cleaners or mild pesticides. Store it in labeled, tightly closed bottles. Always keep some spill kit on hand, and never eat or drink nearby. If something does go wrong, rinsing thoroughly and seeking medical advice right away makes a difference. Share instructions—don’t just count on the next shift to know the rules.

Reducing Hazards Going Forward

Companies and universities can help by posting safety sheets in plain language, giving training, and checking on waste management. Governments, too, must continue pushing for new research and clear labeling, since the full health impact may not be known for years. Until more evidence appears, the smartest move means working with extra care and never treating the words “green chemical” as a free pass.

An Unconventional Tool: Ionic Liquids in Drug Development

Pharmaceutical labs constantly search for safer, greener, and more efficient ways to make medicines. One compound starting to catch some attention is 1-propyl-3-methylimidazolium acetate. This ionic liquid doesn’t follow the old rules scientists are used to with classic solvents. Born from a mix of imidazole, propyl, methyl, and an acetate group, it doesn’t evaporate quickly or combust easily. I remember the first time I encountered ionic liquids—the lab suddenly didn’t smell as much, and waste disposal felt less nerve-wracking.

Why Chemists Are Taking Notice

Green chemistry matters, not just for PR, but for safer workplaces and the environment around us. Organic solvents often carry health and safety risks nobody can ignore, so finding a replacement holds real value. 1-propyl-3-methylimidazolium acetate stands out because it dissolves both polar and non-polar chemicals, helping push reactions that sometimes stall or overheat with water or alcohol-based solvents.

Using this compound, researchers have managed to run coupling reactions, enzyme-catalyzed steps, and even difficult separations under milder temperatures. Imagine creating a complex drug precursor in a liquid that doesn’t evaporate or poison the air with fumes. Pfizer and Merck have already tested ionic liquids in process development, reporting fewer side-products and better yields. These improved conditions might save companies millions in raw material costs and toxic waste removal.

Health and Purity Always Come First

No scientist wants to swap old risks for new ones, especially in medicine. Studies show very low volatility for 1-propyl-3-methylimidazolium acetate, meaning less inhalation risk. It also ticks the box for thermal stability, letting chemists run reactions for hours without fear of breakdown. The actual impact on pharmaceutical impurities still needs serious checking, but new purification steps using activated carbon or liquid-liquid extraction can help clean up any residual solvents before a pill hits the pharmacy shelf.

Toxicity and recycling represent the next set of hurdles. No one wants residues in crucial medicines. Research from the University of Bologna put these ionic liquids through yeast and bacterial assays to test for harm. At typical process concentrations, toxicity stayed much lower than regular aromatic solvents. Many companies are also reusing ionic liquids after distillation, cutting down not just on pollution, but on the cost of supplies.

Bringing Innovation to the Factory Floor

Rolling out a new solvent across a manufacturing line feels risky. People with decades of experience using older solvents naturally feel hesitant. Bringing green chemistry into routine drug manufacturing takes training and tough questions about long-term exposure, cleaning equipment, and tracking possible contamination. Yet the potential for cleaner reactions and improved yields asks for an honest look.

I’ve watched technicians embrace better protective gear and adopt new waste-handling rules whenever the benefits become clearer. If scientists combine careful monitoring with robust engineering controls, there’s a good path forward for 1-propyl-3-methylimidazolium acetate in pharmaceutical synthesis. The next step goes beyond academic papers—putting newer solvents to the test at real scale, sharing results, and helping regulators set safe standards.

Building Trust Through Evidence and Shared Experience

Trust comes from real-world results, not marketing slides. Open case studies, transparent safety data, and feedback from factory workers will move the needle. If this ionic liquid continues to show lower hazards and delivers higher performance, it could redefine how we think about pharmaceutical synthesis. Success here reflects a willingness to learn, question, and adapt—all things that have driven real breakthroughs in medicine.