An In-Depth Look at 1-Propyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide

Historical Development

Innovation often moves forward in jumps, not little steps. The birth of ionic liquids tells a story as vivid as any discovery. Chemists tried to break old bonds in the 1970s, hunting for alternative solvents that moved away from the brass-tacks rules of volatility and flammability. 1-Propyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide (abbreviated as [C3mim][NTf2]) appeared among the earliest ionic liquids to bring more than just a lab curiosity. Laboratories across Europe and Japan used it for electrochemistry and separation in the ’90s, ready to walk away from ether-laden headaches. Not every chemical knocks down doors, but this one let scientists work without fears about flames or clouds of evaporating solvent. Seeing chemists nod at the mention of [C3mim][NTf2] shows how much trust this compound has built.

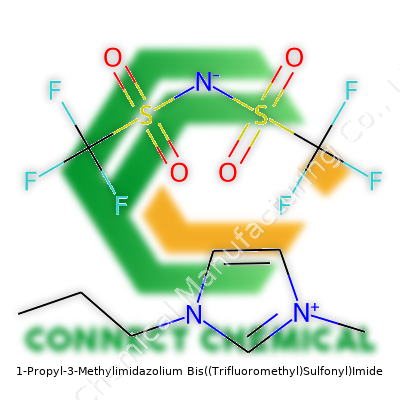

Product Overview

Every bottle marked with [C3mim][NTf2] promises a colorless or faintly yellow liquid, not much for the nose, but able to carry out complex work behind the scenes. Chemists value its stability under heat and exposure to air. Handling it, you notice the weight in your palm—not surprising, since its density stands well above water’s. The strength here comes from its imidazolium ring coupled with a highly delocalized anion, bis(trifluoromethyl)sulfonylimide. Research teams select it because, unlike classic volatile organics, it holds steady both under stress and over time. Several producers use product codes like H-IL-101 or C3MIM-TFSI, signaling a focus on purity and tailored technical specs, while keeping clarity on what truly lies inside.

Physical & Chemical Properties

No chemist expects a simple catalog of numbers to capture a compound’s soul. Still, data shapes decisions. [C3mim][NTf2] checks in with a melting point just below room temperature, usually between -10 and -20°C, and only starts to vaporize above 200°C. Its density sits around 1.43 g/cm³ near ambient conditions. Solubility sets it apart: whole groups of organics mix beautifully, while water gets only a grudging handshake—limited miscibility, serving as an edge in certain analyses. Viscosity depends on every degree of temperature, thick and syrupy at the bench but flowing smoothly once gently warmed. Stability under electrochemical conditions gives more flexibility for plating, separations, and even novel battery systems. The compound’s hydrophobic nature keeps moisture out, which speaks volumes when you need reliability in electronics or air-sensitive reactions.

Technical Specifications & Labeling

Certainty lifts the pressure from an experiment. Spec sheets from reliable suppliers list a purity threshold at or above 99%, with residual halides, water, and transition metals all tracked below 100ppm. Standard labeling balances hazard identification—those small diamond-shaped pictograms—with operational guidelines like required gloves and pipettes. In my own lab, I learned to respect the unique alias TFSI: its reputation comes not just from its chemical backbone but from how it’s tracked, categorized, and shipped. Suppliers include batch-specific certificates of analysis, barcoding every vial for full traceability, which makes audit trails less of a headache for safety managers. Regulatory numbers and custom labeling, including its CAS number 174899-83-3, are carefully matched to regional chemical safety norms across continents.

Preparation Method

Sparks in innovation often come from methods that save steps and sharpen results. [C3mim][NTf2] typically starts its journey by quaternizing 1-methylimidazole with 1-bromopropane, yielding 1-propyl-3-methylimidazolium bromide as a precursor. This salt then meets lithium bis(trifluoromethyl)sulfonylimide in a water or acetone mixture, where gentle stirring and lots of patience coax out the final ionic liquid. Washing with distilled water peels away the leftover lithium bromide and brine. Rotary evaporation, then vacuum drying, finish the process and drive off lingering volatiles. Good practice means checking for residual ions by NMR and mass spectrometry before calling the synthesis complete. Having prepped this liquid before, I saw real benefits in investing time into slow drying with molecular sieves, which cuts down on the headaches of water interference during precise measurements.

Chemical Reactions & Modifications

Tinkering with [C3mim][NTf2] reveals all kinds of pathways. Its makeup lets it act as a non-aqueous solvent for carbanion generation and oxidative coupling, with transition-metal complexes keeping their cool through the process. The imidazolium ring allows functionalization at either the propyl chain or the ring itself—sometimes for catalysis, occasionally for tuning solubility or viscosity to match new processes. Electroorganic chemists exploit its high ionic conductivity and arylation potential, making it a player in contemporary battery research. Mixing, blending, or modifying the anion changes its hydrophobicity and thermal endurance, expanding the liquid's reach without needing a full redesign. With each new modification, industries discover tweaks that make tough separations or tricky syntheses less laborious—and a little safer, too.

Synonyms & Product Names

One chemical, many labels, but always the same backbone. [C3mim][NTf2] pops up under aliases like 1-propyl-3-methylimidazolium TFSI, [C3mim][TFSI], and 1-propyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide. The “TFSI” and “NTf2” shorthands recognize regional branding. In technical catalogs or review papers, you can spot other variants depending on a company’s own product codes: H-IL-101, 3MPI-TFSIL, and so on. A chemist used to working with ionic liquids tends to trust the TFSI abbreviation, perhaps reflecting the broader push for cross-referencing in scientific supply networks. Every synonym rests on the same foundation of tested batch quality and full regulatory compliance.

Safety & Operational Standards

Every bottle deserves respect, no matter how benign its reputation. [C3mim][NTf2] rarely flashes in the pan but can still pose a skin and eye irritant risk. Inhalation of fine mists or direct contact with concentrated liquid needs to be avoided. My experience underscores the importance of tight lab discipline: nitrile gloves, eye shields, and proper fume hoods. Waste management guidelines focus on containing all ionic liquids in segregated containers, with scheduled pickups by certified chemical handlers. Spill response kits, absorbent pads, and quick access to decontamination showers round out safe practice. Storage demands airtight containers in low-humidity, well-ventilated rooms, far from incompatible acids or oxidants. Safety data sheets encourage thorough training, and regular personnel reviews keep everyone sharp on changes in global regulatory frameworks. Even after hundreds of uses, familiarity never replaces healthy caution.

Application Area

No trend in green chemistry has resonated quite like ionic liquids. [C3mim][NTf2] anchors itself in electrochemical devices, especially in advanced lithium-ion battery electrolytes, where its wide electrochemical window supports both stability and safety in next-gen cells. In separation science, its unique solubility profile boosts extraction efficiency, isolating precious metals, lanthanides, or rare organics from confusing mixtures. Pharmaceutical labs test it to stabilize enzymes, while catalysis operations rely on its ability to dissolve both polar and nonpolar reagents. Organic syntheses benefit from its low vapor pressure, allowing high-yield reactions under open air. Looking at its environmental performance, reduced volatility means air emissions drop, cutting both occupational risks and wider environmental impact. Newer uses in supercapacitors, fuel cells, thermal storage fluids, and carbon capture have started to emerge, thanks to its marriage of chemical resilience and functional flexibility.

Research & Development

Research into [C3mim][NTf2] runs hotter every year. Universities and private labs chase fresh applications, especially where common volatile organics hit a wall—think safer electrolyte formulations for grid-scale batteries, or robust supports for enzyme catalysis in drug manufacturing. In my own field, projects focus on integrating this ionic liquid as a stationary phase in advanced chromatography, where tuning selectivity becomes more art than science. Teams also build on its environmental data, probing biodegradation pathways, and working on faster, greener syntheses or recycling routes. High-throughput screening, artificial intelligence, and quantum chemistry modelling now converge to predict new modifications, so every tweak brings quantifiable results before bench testing even begins. Academic and industrial partnerships pour millions into this class of compounds, confident that incremental improvements have huge payout potential in both safety and sustainability.

Toxicity Research

While [C3mim][NTf2] carries a reputation for safety compared to older solvents, scrutiny remains sharp. Recent in vitro and ecotoxicological assessments reveal moderate toxicity to aquatic organisms, which means blanket use without oversight isn’t wise. Chronic exposure data in animals is sparse, so conservative exposure controls form best practice today. Many labs, including mine, enforce closed-system transfers, strict PPE, and disposal compliant with local regulations. Regulatory agencies keep a close watch, adjusting thresholds as new data comes out, which pressures producers to publish fresh studies annually. Laboratory safety officers increasingly demand bioaccumulation assessments—not solely acute risks—and want transparency on any degradation byproducts. A culture of care, built on real-world injury and exposure incidents, pushes this compound down safer and greener paths.

Future Prospects

Thinking ahead, [C3mim][NTf2] looks ready to push boundaries in sustainable chemistry. Next-gen energy storage, smart extractions, and green catalysis each rely on safer, long-lasting solvents—its strengths in low volatility and thermal stability fit those needs. Future work will likely tackle improved biodegradability, closing the loop from production to recovery to end-of-life. Greater adoption hinges on scalable, less wasteful syntheses, aiming for a cradle-to-cradle approach. Researchers are pursuing custom derivatives to fine-tune ion mobility and compatibility for electronics, wearable tech, and new sensors. As companies and labs tangle with the realities of tougher environmental rules and greener product mandates, [C3mim][NTf2] brings more than an alternative—it has proven it can shape entirely new ways of thinking about chemistry’s role in both the lab and the world beyond.

Beyond the Lab: An Everyday Look at Ionic Liquids

A few years back, I came across a bottle with a name long enough to make your eyes cross: 1-Propyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, or just “PMIM-TFSI.” Scientists lump it in with a group called ionic liquids. These are salts, but they don’t form the typical, crunchy crystals we know from table salt. This one acts more like a thick, oily fluid, even at room temperature.

Batteries Press for Better Chemistry

Tech companies constantly search for new materials that stretch battery lifetimes, especially for gadgets and electric vehicles. PMIM-TFSI doesn’t catch on fire easily, which makes it far safer than standard lithium-ion electrolytes. Researchers found that swapping standard solvents for ionic liquids like PMIM-TFSI shields batteries from overheating and extends how long they run. No need to worry if your phone heats up on the charger; researchers think this ionic liquid may help cool things down.

Greener Choices in Chemical Processing

Most industrial solvents and cleaners are notorious for spewing fumes, polluting water, and hurting workers. PMIM-TFSI skips a lot of those problems. It doesn’t evaporate much, so there’s less risk of breathing toxic vapors, and it refuses to mix with water, making it easier to recover and reuse in closed-loop processes. Green chemists turned to ionic liquids because they do the work of harsh chemicals while sparing the environment a nasty hit.

Extracting Value in Metals and Recycling

Modern mining faces a tough job coaxing precious metals from gritty ores or heaps of circuit boards. With PMIM-TFSI, metals like lithium, platinum, and rare earths can dissolve into the liquid, letting companies pull them out with less energy compared to old-school roasting or acid leaching. It’s not magic—just sharper chemistry. I’ve seen reports from researchers who swap out toxic cyanides in mining fluids for ionic liquids, pushing toward less dangerous workplaces and cleaner waste streams.

Pharmaceuticals Demand Purity—This Helps

Drug makers struggle to separate their products from byproducts right down to the last drop. PMIM-TFSI brings an advantage: it dissolves certain organic molecules easily while rejecting water. That means less contamination, smoother purifications, and fewer chemicals tainting the finished medicine. The U.S. Food & Drug Administration keeps a tight leash on purity, and every new tool for cleaner extractions matters.

Challenges to Widespread Adoption

PMIM-TFSI costs more than many standard chemicals. Scaling it for big industry means solving problems of waste, sourcing, and making sure it doesn’t break down into nastier parts. Some ionic liquids have raised alarms about lingering for too long in the soil or water. Lessons from other chemicals show ignoring long-term impacts never pays off. Regulators call for new toxicity data, while companies look for ways to recycle and recover every drop they use.

Finding the Right Fit

PMIM-TFSI’s future brightens as its price drops and as environmental laws get stricter. Labs and companies keep tweaking its formula to work in electronics, metals processing, energy storage, and drug manufacturing. The next big leap could come from greener production methods or smarter closed-loop systems that treat waste as a resource. As with any powerful tool, it’s always about finding balance between innovation and responsibility.

Respecting Chemical Dangers in the Workplace

Coming face to face with hazardous chemicals changes the way you look at everyday tasks. A bottle with a name too long to pronounce, the smell of something sharp in the air—the risk isn’t theory. It’s one spill, one careless move away. Experience on a lab floor taught me that accidents usually begin with small shortcuts. Once, a tiny splash on a glove reminded me how quickly things go south.

Protective gear stands as the first line of defense. Gloves, goggles, a well-fitted lab coat—they’re not decorations. I once saw a colleague shrug off wearing eye protection, only to end up blinking furiously after a vapor puffed up unexpectedly. Emergency eyewash had to do the job that a pair of goggles could have done better.

Good Ventilation Is Key

Proper ventilation outranks almost everything else. Fumes don’t wait for an invitation to fill a room. Always keep chemicals in hoods or spaces where fresh air moves contaminants out. An open window isn’t enough. Strong extraction fans, tested yearly, keep invisible hazards from piling up.

Know the Chemical and Its Limits

Chemicals love to surprise the unprepared. A clear liquid might attack the skin, a powder might seem innocent until it rises as a dust. Checking the Material Safety Data Sheet (MSDS) taught me that knowing the right firefighting method could mean the difference between a contained incident and a spreading blaze. Some react with water, some need special agents. Carelessness, in this context, never pays.

Storage Matters More than You Think

Stacking chemicals on any old shelf isn’t safe. Labels must face forward, caps should twist tight, and incompatible substances—like acids near bases—need a firewall between them. Years in the lab showed me what happens when someone leaves a reactive bottle near a heat vent; warped caps, fumes, and panic. Storage, done right, sets the whole team at ease.

Plan for Spills and Unexpected Events

Spills don’t follow a schedule. Absorbent pads, neutralizers, and good old-fashioned communication create real preparedness. A team too slow to react, or too embarrassed to speak up, makes small accidents snowball. Practice spill drills, keep emergency numbers on hand, and always review what went wrong after an incident.

Education and Vigilance: The Best Safeguards

The best equipment means nothing if people can’t use it. Training should happen before someone picks up a bottle. Learning to spot signs of exposure, symptoms like headaches or skin rash, saves time and health. OSHA reports link most chemical injuries to people skipping steps in training or ignoring posted warnings. A culture of vigilance—where people look out for one another and speak up—keeps everyone safer.

Building Good Habits Beyond the Lab

Workplace safety around chemicals doesn’t end with the clock-out. Many safety skills carry over to cleaning at home, gardening, or fixing up an old car. Understanding warning labels, following directions, and storing chemicals safely helps prevent fires, poisonings, and hospital visits outside work.

Respect for chemicals isn’t just about following rules. It’s about making sure everyone on your team goes home healthy each day. A little extra care goes further than any single piece of equipment.

Unlocking What’s Inside a Product

People often ask about the chemical formula and structure of a product. Some might see this as just academic curiosity, but the truth runs deeper. Every time you read a product label or handle a compound in a lab, you’re dealing with a world built from atoms locked in specific patterns. That pattern—its formula and structure—answers the real question: What is this thing, what can it do, and what risks does it carry?

Why These Details Aren’t Trivial

A simple example drives it home. Table salt is known everywhere, dug from mines or boiled from seawater. Chemically, it’s NaCl—sodium and chloride linked in a neat one-to-one ratio. The structure tells us something more: lattice-like arrangements, explaining why it dissolves so well and why it crunches under your teeth. Ask about potassium cyanide, and the answer will scare you. Its formula, KCN, hides a lethal side, with a carbon and nitrogen triple bond. One slip—accidental ingestion or inhalation—can be fatal, because the body mistakes it for something familiar and ends up disabling cells at the molecular level.

Real-World Stakes

People who work with chemicals, whether it’s in agriculture, industry, or a school lab, operate with formulas and structures because it’s the only honest way to assess risk and opportunity. Take acetaminophen—found in many medicine cabinets as painkiller Tylenol. Its formula, C8H9NO2, tells a chemist about its reactive sites. The actual structure, with its aromatic ring and amide group, reveals how the body breaks it down. Too much, and the liver struggles to process it, leading to damage. That’s not theory, but lived experience for too many.

Trust and Transparency

Full disclosure brings safety and trust. Food additives like ascorbic acid (vitamin C, C6H8O6) or citric acid (C6H8O7) show up on ingredient lists. The formulas open doors to research and regulation, letting anyone check for allergens, contaminants, or unnecessary fillers. The structure sometimes hints at how additives interact with the rest of the product, such as preservatives keeping bread mold-free, or colorants staying bright under supermarket lights. Without the chemical makeup plainly listed, manufacturers could slip in banned or harmful compounds unnoticed.

Supporting Innovation and Problem-Solving

No one bottles up new medicines, plastics, or fertilizers without tracing each atom. When problems come up—say, a drug causing side effects or a cleaning product corroding pipes—scientists turn back to the formula and structure, hunting for which bond or group is the culprit. During the pandemic, formulas and molecular diagrams of vaccines and antivirals spread online. Experts worldwide inspected and debated them, refining dosages and delivery, speeding discovery while building public confidence through transparency.

Moving Toward Safer Choices

Anyone reading a label deserves access not just to fancy names, but to the truth packed into real chemical details. Regulators and researchers learn what to ban, parents keep children safe, and industries build better products—not because of marketing, but because the foundation laid by chemical formulas and structures can’t be faked. They invite scrutiny and improvement, helping everyone choose wisely.

What Physical Properties Say About a Material

Touch any object, and you’ll run smack into its physical properties. They’re the things you can see, feel, measure, or test without changing what it’s made of. Take a metal spoon, for example. It feels cool, it’s shiny, and won’t shatter if you drop it, all due to its density, hardness, and luster. These aren’t just scientific labels; they affect real world choices. Consider how copper’s super flexibility and high conductivity made it the backbone for household wiring. Or how clear, slick glass looks gorgeous as a window, but one strong impact can turn it into shattered bits. That reveals brittleness, and means we need to double down on safety for skylights or windshields.

Kids playing with clay and water get a taste of solubility and malleability before they ever hear those words in school. Solubility is why you can stir sugar into your coffee until it vanishes, and malleability explains why jewelers can flatten gold into paper-thin leaf. Some stones can withstand scratches, and get chosen for jewelry. Some plastics bend and hold their shape, making them perfect for toys or containers. This stuff matters. Weak materials give out in buildings or gadgets; strong ones mean fewer repairs and less waste.

Chemical Properties Reveal the Heart

Looking deeper, chemical properties show how something reacts when it meets other stuff: oxygen, acids, even plain water. Take iron left in a damp shed. A layer of reddish rust tells you it reacts with air and moisture. Rust means tools might fall apart or machines break down. Sticking strong on the kitchen front, table salt dissolves in water, but doesn’t catch fire or explode if you sprinkle it on food. Vinegar’s sharp tang and ability to dissolve mineral buildup points to acidity—a property that matters both in salad dressings and cleaning hacks.

It comes down to chemical stability and reactivity. A roll of magnesium ribbon looks harmless, but light it on fire, and you’re staring at a flash brighter than a camera. The same reactivity that makes magnesium dangerous in fireworks makes it life-saving in emergency flares. Some chemicals, like gold, almost never react with anything, so buried treasure can wait centuries underground without losing its shine. If you have something that breaks down or reacts too easily, you’re asking for trouble—be it spoiled food, corroded pipes, or faded paint.

Learning From the Everyday

It doesn’t take a science degree to see why these details matter. Houses built from wood stay cozy, but termites and moisture can eat through the walls if you don’t treat the timber. The stuff inside your fridge hinges on plastics and foams chosen for the right mix of strength and safety. Pharma companies obsess over purity and stability so drugs don’t spoil on the shelf. I’ve seen car engines fail in the winter not because of poor design, but because someone forgot antifreeze, and water’s high freezing point did the rest. Every industry, from food to electronics, relies on picking the right materials—ones that can survive the real challenges of heat, pressure, time, or even gravity’s relentless force.

Aim for Smarter Choices

Better choices start with understanding. Smart building codes and safety standards grow out of years spent testing and watching which combinations work—and which ones fail. We can look at each product or process and ask: does this fit the job, stand up to real-life wear, and keep people safe? Getting materials right keeps families safe, businesses running, and prevents costly disasters. If more folks pay attention to these physical and chemical basics, maybe our world runs a little smoother, and our stuff lasts a little longer.

Keeping Chemical Safety Real

Every chemist who’s spent time in a lab has watched substances spill, degrade, or mix in dangerous ways. These lessons stick. The storage and disposal of ionic liquids like 1-Propyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide isn’t some theoretical exercise. This compound features strong chemical stability, but it’s not a simple bottle you can shove in a cupboard and forget about.

Storage: Beyond a Label on the Shelf

1-Propyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide (PMIM-TFSI) draws interest for its low volatility and high thermal stability. It’s easy to assume those traits offer a free pass on storage. I’ve seen what happens if folks take shortcuts: residue on gloves, sticky benchtops, or persistent vapors in poorly ventilated rooms.

A cool, dry storeroom delivers real benefits. Allowing the bottle to stay sealed tight saves material and sidesteps exposure. Facts matter: direct contact with moisture degrades the substance, and humidity rarely respects open containers. Choose materials like glass or high-density plastics for containers — the kind that show no reaction after years of use. Avoid stacking next to strong oxidizers or other reactive chemicals; cross-contamination takes seconds but cleanup can take half a day.

Fireproof cabinets never get enough respect, but seeing the aftermath of a storage-room accident once makes the case. Although PMIM-TFSI does not catch fire easily, nobody should tempt fate by keeping it close to ignition sources. Every responsible lab signs off on an organized safety data sheet log, so everyone knows where each substance sits and what to do in an emergency.

Disposal: More Than a Quick Trip to the Sink

You learn to respect disposal rules after a few scares with chemical waste. Pouring PMIM-TFSI down the drain sounds fast — and it’s the fastest way to lose good standing with the local authorities. Environmental persistence from its fluorinated sulfonyl groups raises a red flag; nobody wants compounds building up in soil or waterways.

Most university and industry labs rely on contract hazardous waste pick-up, sending non-volatile ionic liquids off in sealed, labeled containers. Mark every bottle clearly — the chemical name, date, and amount matter when those waste drums head out the door. Throwing old solvents or ionic liquids in regular trash makes the whole supply chain unsafe. Local rules sometimes change, but the core principle stays: contact a certified chemical disposal service. They’ll handle incineration or high-temperature treatment to break down stubborn bonds, rather than letting toxic material into the regular waste loop.

Personal protective equipment helps in these tasks, too; gloves, goggles, and lab coats prevent splashes or skin contact, which can cause irritation or worse. Ventilated hoods take some of the stress out of working with unfamiliar or stubborn substances.

Setting Better Practices for the Future

I’ve found that the safest labs aren’t the ones with brand-new equipment, but ones with a team that believes in double-checking chemical storage and following disposal rules. Training new hires on the risks of improper disposal and routine audits for chemical stocks keep problems from building up. Companies should look out for greener alternatives and support research into safer, more degradable versions of ionic liquids. Collaboration with regulatory bodies makes it possible for everyone to handle, store, and retire these cutting-edge materials responsibly — for health, for safety, for the wider world.