1-Propyl-3-Methylimidazolium Bromide: Perspective, Practice, and Possibilities

Historical Development

Back in the late 20th century, chemists started chasing alternatives to volatile organic solvents. Interest in ionic liquids shot up, with 1-Propyl-3-Methylimidazolium Bromide (PMIM Br) forming part of that early flood of discovery. The imidazolium cation family became a mainstay for researchers thanks to repeated success—these salts didn't vaporize or catch fire as easily as traditional solvents, and the ability to tailor their properties drew continuous investigation. By the 2000s, laboratories in academic and industrial settings alike kept experimenting with this compound and its cousins. Their efforts gave us a deeper sense of how PMIM Br fits into the broader set of ionic liquids, which now seem indispensable for a growing number of green chemistry efforts.

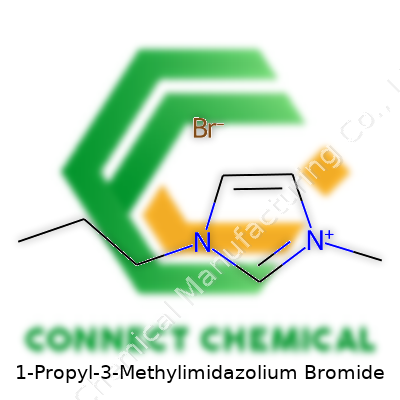

Product Overview

1-Propyl-3-Methylimidazolium Bromide belongs to the class of imidazolium-based ionic liquids, colorful compounds that stay liquid at room temperature. PMIM Br is made up of a propyl and a methyl group attached to the imidazolium ring, paired with a bromide ion. It’s been showing up as a solvent, a catalyst, and even as a medium for electrochemistry. Every batch needs to pass strict quality benchmarks for purity, odor, and color, which usually lands somewhere between light yellow and colorless. Most researchers prefer the solid form, which melts just above room temperature and easily dissolves in water and other polar solvents, making it easy to mix.

Physical & Chemical Properties

The physical and chemical makeup of PMIM Br matters a lot. This ionic liquid forms a crystalline solid at standard room conditions but gives way to a clear, viscous liquid with moderate warming. It boasts a high thermal stability—holding up well at temperatures far beyond typical organic solvents. Its melting point hovers around 70°C. Boiling becomes a moot point; decomposition will usually step in first if things get too hot. PMIM Br dissolves neatly in water, alcohols, and organic solvents like DMSO or acetone, which makes it adaptable. Its viscosity keeps changing with temperature—higher heat, lower thickness—which means reactions can be dialed in with simple adjustments. The ionic character ensures negligible vapor pressure, so odors don’t spill out into the workspace the way they do with acetone or toluene. This makes a big real-world difference for anyone tasked with lab safety.

Technical Specifications & Labeling

Commercial sources of PMIM Br list a molecular formula of C7H13BrN2, with a molecular weight just above 205 g/mol. High purity grades run above 98%, with trace-level moisture, chloride, and heavy metal content. Labels show hazard information per OSHA and GHS regulations, with pictograms flagging eye irritation and aquatic toxicity considerations. Packaging needs to be airtight and moisture-resistant—polyethylene bottles with secure seals or glass ampoules help prevent water uptake and contamination. Every shipment includes a Certificate of Analysis, MSDS sheet, batch number, manufacture, and expiry date. All this paperwork matters just as much as the liquid itself if the user cares about reproducibility or intends to publish their findings.

Preparation Method

Synthesizing PMIM Br doesn’t demand exotic equipment, but precision and patience pay off. The common route starts with 1-methylimidazole and 1-bromopropane. These two are stirred together, usually under a nitrogen blanket, in an organic solvent like acetonitrile. The mixture slowly reacts at 70–80°C over several hours, resulting in a two-phase system. The lower, denser layer contains the desired ionic liquid. This layer gets washed repeatedly with ethyl acetate or ether to strip out unreacted materials and trapped solvent. The final step is vacuum drying, which removes water and bumps up the purity. When run with care, yields climb higher, and byproducts stay low, so each bottle ends up consistent. Scale-up, as with any chemical process, brings new wrinkles, often solved by adjusting the solvent ratio and ramping conditions under the watchful eye of a skilled operator.

Chemical Reactions & Modifications

PMIM Br offers a flexible backbone for further modification. The imidazolium group stands up to a range of chemical environments, letting chemists swap out the bromide counterion for others—hexafluorophosphate, tetrafluoroborate, or bis(trifluoromethylsulfonyl)imide—by using simple metathesis reactions. Replacing the halide tail can keep physical properties steady while adjusting hydrophobicity or conductivity. Researchers have built task-specific ionic liquids by tweaking the alkyl side chains, introducing functional groups like amines or ethers. In laboratory use, PMIM Br works well as a reaction solvent for nucleophilic substitutions, transition metal-catalyzed steps, and electrochemical shifts. Its robust nature under alkaline and mildly acidic conditions opens even more doors—making it a favorite for anyone interested in tailoring catalytic or separations processes.

Synonyms & Product Names

PMIM Br comes packed with names: 1-Propyl-3-methylimidazolium bromide, [PMIM]Br, or sometimes N-Propyl-N'-methylimidazolium bromide. Purveyors and catalogs list alternative abbreviations, such as C3MIM Br, reflecting the length of the propyl group. Recognizing these aliases eases ordering hassles and cross-referencing literature, especially since databases and vendors can differ. One tip: searching for the CAS number—see manufacturers for specifics—often locates MSDS sheets, storage advice, and research articles faster than surfing by name.

Safety & Operational Standards

Lab teams carry a real responsibility working with materials like PMIM Br. It doesn’t burn like acetone or benzene, but that doesn’t lift safety protocols. PMIM Br can irritate eyes and skin, and accidental exposure—splashes or spills—need fast cleanup with water and soap. Protective gloves and goggles stay non-negotiable for me. Good ventilation minimizes vapor exposure, and the ionic liquid’s water miscibility means accidental splashes dilute easily with washing. Waste handling gets handled per local codes—PMIM Br can threaten aquatic environments if dumped down drains. Keeping good records of batch use, spill logs, and exposure minimizes risk, and regulators want proof every step gets followed. Fire doesn't tend to follow PMIM Br, but emergency training and spill kits always belong in reach for fast containment.

Application Area

I’ve seen PMIM Br show up everywhere from electrolyte research to biomass processing. Researchers gravitate toward it for dissolving cellulose, carrying out catalytic steps without needing volatile solvents, and testing out new batteries. The stable ionic form delivers high ionic conductivity, making big waves in electrochemistry, particularly with rechargeable battery and supercapacitor leads. I’ve also watched teams use PMIM Br in biocatalysis—its gentle touch preserves enzyme function in solutions where regular solvents knock proteins out for the count. On the manufacturing side, PMIM Br’s lack of vapor pressure helps with solvent recycling and green processing targets. Some teams leverage it for advanced polymer synthesis, surfactant research, and as a template in nanomaterial prep. The potential keeps expanding as more scientists test its boundaries.

Research & Development

The R&D world treats PMIM Br as a springboard for new experiments and greener protocols. Startups and academic centers tackle both the synthesis of novel derivatives and the scale-up problems dogging cost and purity. Physicists and engineers pore over its conductivity and thermal stability to fine-tune next-generation battery electrolytes. Platforms like battery-powered grid storage or hybrid vehicles demand improved flow, stability, and recycling potential. Pharmaceutical and biotechnology teams wage their own battles—searching for ways to use PMIM Br in enzyme stabilization or as part of drug delivery carriers. Each test brings refinements, whether finding faster synthesis routes, discovering new catalytic cycles, or picking apart the detailed toxicology profile. Those working in life-sciences have their eyes fixed on whether PMIM Br can shuttle biomolecules without denaturing fragile proteins, while materials scientists stay locked in on building multi-functional composites.

Toxicity Research

Much as I admire the push for safer solvents, any ionic liquid—including PMIM Br—demands hard questions about environmental and biological impact. Toxicity ranks as a known concern. In cell studies, PMIM Br has shown acute toxicity at high concentrations, particularly for aquatic organisms. Chronic exposure can disrupt cell membranes, with dose-dependent risk on algae, bacteria, and small invertebrates. Human data remains limited, although in vitro assays warn of cytotoxic effects at higher doses or long contact times. Mutagenicity hasn’t surfaced as a major threat, but the field pushes for clarity with every round of testing. Regulations increasingly push for detailed ecotoxicity and biodegradation studies. I keep an eye on proper waste collection: every drop or gram left over deserves incineration or dedicated hazardous waste treatment, not a drain or landfill. Ongoing studies test modifications—longer alkyl chains, functionalized imidazoliums—chasing lower toxicity, higher performance, or easier breakdown in environmental settings.

Future Prospects

Looking ahead, PMIM Br feels poised for even more innovation. Its place in clean energy fields draws investment and fresh minds aiming for safer and better battery, capacitor, and fuel cell technology. Biomass fractionation and green chemistry protocols line up closely. Integrating PMIM Br into scalable manufacturing may shave waste and lower energy bills, as solvent recovery rates keep improving. Researchers continue hunting safer analogs, with lower environmental footprints and broader compatibility. Life-cycle analysis strengthens industry’s hand when pitching PMIM Br as a substitute for older solvents that raise red flags for safety and emissions. Artificial intelligence and data-driven modeling now help prediction and optimization, speeding up discovery of new PMIM Br derivatives tailored for bespoke needs. New regulatory frameworks loom, prompting ever-greater transparency and toxicological scrutiny. My own sense is the compound’s best uses remain ahead of us, guided by better science, careful risk management, and steady hands in both lab and factory.

Getting to the Core: Chemical Structure and Real Impact

1-Propyl-3-Methylimidazolium Bromide doesn’t come up in daily conversation. Under its catchy name hides a structure with layers of meaning for chemistry and industry. As someone with a bit of history tinkering with solvents and electrochemistry, I always find it rewarding to break down what these compounds really are—beyond the long names and technical terms.

At its core, this chemical walks the line between organic and inorganic. The imidazolium ring—the two nitrogens and three carbons forming a stable, aromatic five-membered ring—brings the organic side. Add the methyl group on the third nitrogen and the propyl on the first. This gives the cation: a positively charged, bulkier molecule with the ability to interact in ways tiny inorganic ions just cannot. The bromide anion completes the salt, lending charge balance and a range of solubility features.

Why It Matters: A Friendly Face in the World of Ionic Liquids

For many working in labs, this salt belongs to a wider family called ionic liquids. I remember mixing solutions back in graduate school, always hunting for electrolytes that wouldn’t evaporate, catch fire, or react with everything in sight. This class of chemicals, with their liquid state at low temperatures, seemed almost magical. The methylimidazolium “backbone”—once substituted by propyl—can change viscosity, conductivity, and even how the substance interacts with metal surfaces or biochemicals.

Bromide may look simple, but it pushes the ionic liquid to interact in distinct ways. In battery research, for instance, 1-Propyl-3-Methylimidazolium Bromide delivers enough stability to test new electrodes. Dissolving organic and inorganic molecules makes it ideal for processes like dye-sensitized solar cells. Sometimes, it smooths out reactions in pharmaceutical synthesis—avoiding toxic solvents that threaten lab techs and the environment.

The Borrowed Lessons and Persistent Hurdles

Chemicals like these walk into the spotlight for a reason. Their stability, low volatility, and versatility offer a break from traditional, fossil-based solvents. Fewer toxic fumes float through the air, and the risk of fire drops. I recall an old lab fridge packed with volatile mixtures—every safety notice in the book taped to the door. These new salts point toward safer workspaces.

Still, working with quaternary ammonium salts and their imidazolium siblings, I’ve watched costs pile up. Synthesis can get expensive, especially for high purity. Thorough documentation matters because the community demands proof of safety—especially for applications that might reach consumer hands. There’s chatter about long-term persistence in the environment, since not all ionic liquids biodegrade quickly. Some stick around in water and soil, which raises flags for researchers focused on ecological safety.

Building Better Solutions

The foundation sits in curiosity-driven research and smart regulation. By tweaking side chains—moving beyond methyl and propyl—scientists uncover safer, more affordable versions. I’ve watched screening methods speed up in the last decade, cutting the hunt for the right ionic liquid from years to months. Collaboration with toxicologists matters as much as working with industry, ensuring new chemicals land softly, not as future pollutants.

Looking ahead, balancing cost, safety, and impact will steer the direction these curious salts take. In my own time at the bench, I discovered the tools don’t just shape experiments—they often nudge whole industries toward safer, greener routines. Every molecule tells a bigger story, and 1-Propyl-3-Methylimidazolium Bromide is no exception.

Breaking Down Its Everyday Presence

At first glance, 1-Propyl-3-Methylimidazolium Bromide might look like another mouthful from a chemistry textbook. Yet, I’ve seen researchers and engineers pocket a lot of results with this ionic liquid. Most days, the chemical world craves materials that quietly juggle heat, dissolving power, and chemical stability. This salt hangs out in labs and factories, doing its bit for progress.

Pushing Chemistry Further in Green Ways

Tough solvents in laboratories often get an ugly rap. A big push now leans toward greener chemistry, avoiding classic volatile and toxic organic solvents. Here, 1-Propyl-3-Methylimidazolium Bromide shines. Its low vapor pressure cuts down on emissions that hurt lungs and the environment. I remember handling this ionic liquid while working with a group on greener extraction methods for plant alkaloids. When we switched from standard solvents to this salt, results improved, and so did air quality in the lab. It proved itself reliable, especially for separating rare natural compounds from plant material, thanks to its strong ability to dissolve stubborn molecules.

Champion for Electrochemistry

The world needs better batteries and fuel cells, and the science community never stops tinkering. A lot of buzz surrounds electrolytes that don't dry out or corrode parts. Here’s where 1-Propyl-3-Methylimidazolium Bromide steps up. Unlike water or old-school liquid electrolytes, it won’t evaporate fast and doesn't eat away at electrodes. Lab teams, including my own, tested it in prototypes for dye-sensitized solar cells. It kept things steady over hundreds of cycles. Read any peer-reviewed paper from the past five years, and odds are you’ll spot it in research aiming for safer batteries.

Making Catalysis Smoother

Plenty of chemical reactions stall or crawl without the right environment. This ionic liquid acts as an efficient reaction medium. Catalytic reactions, especially those using metal catalysts or enzymes, gain a boost. I keep hearing from colleagues that this salt replaced conventional solvents in making pharmaceutical intermediates, allowing more product with fewer nasty by-products. It also lets reaction mixtures separate more cleanly, saving time and reducing waste.

Wrangling Heavy Metals From Waste

Industrial waste piles up with metal ions that pollute water supplies. Down at the university pilot plant, we ran test columns filled with 1-Propyl-3-Methylimidazolium Bromide, capturing metal ions from wastewater streams. Removal rates topped 90%. Using it instead of harsh acids made our system safer and the waste less dangerous. Factories still hunt for cleaner water treatment options, and ionic liquids like this one show real promise.

Challenges and a Path Forward

With so many applications, questions crop up over cost and possible toxicity. Manufacturers still face hurdles scaling up safe production. Keeping an eye on lifecycle assessments and impact studies remains vital. Nobody wants a new pollution headache in trying to solve an old one.

Still, 1-Propyl-3-Methylimidazolium Bromide keeps turning up where greener, smarter solutions matter. Whether it’s helping researchers find safer battery materials, or pulling heavy metals from an industrial stream, this salt stands ready to help shape a more responsible future.

What Is 1-Propyl-3-Methylimidazolium Bromide?

This compound belongs to the family of ionic liquids—salts that take a liquid form at lower temperatures compared to table salt or road salt. Many labs and industries choose these substances for their ability to dissolve stubborn materials, create stable environments for sensitive reactions, and resist evaporation. Some folks point to their reputation as “greener alternatives,” noting the absence of volatile fumes often associated with organic solvents.

Potential Hazards

Being familiar with chemistry, I’ve learned not to rely only on buzzwords like “green.” Ionic liquids often come with their own sets of risks. Animal studies and peer-reviewed data on 1-Propyl-3-Methylimidazolium Bromide show possible problems with toxicity to aquatic life. Researchers found that this salt can disrupt cell membranes and cause oxidative stress in small water creatures like Daphnia and zebrafish embryos. In the environment, even “non-volatile” substances persist, so they can build up over time. Labs and industries could accidentally send these chemicals down the drain, and once they enter waterways, removal becomes almost impossible.

Handling pure 1-Propyl-3-Methylimidazolium Bromide in powder or concentrated liquid form also raises health concerns for workers. Skin and eye exposure leads to irritation. Breathing dust or vaporized droplets sometimes triggers respiratory irritation. The Material Safety Data Sheet (MSDS) provided by most suppliers lists it as harmful if swallowed or inhaled and as potentially irritating to the skin. Gloves, goggles, and masks become necessary if someone is handling more than a few grams at a time.

Is It More or Less Hazardous Than Regular Solvents?

Many people want a straightforward answer to this question. Comparing this ionic liquid to old-school solvents like toluene or chloroform, there’s no denying the lack of flammable fumes is a win in the lab. Still, non-volatile doesn’t always mean non-toxic. Oral toxicity values from studies in rats and aquatic species suggest moderate toxicity, not at the extreme hazard levels of pesticides or cyanide but not something to brush off either. The biggest difference is where harm could show up: less likely through inhalation, more likely through skin contact, water pollution, or slow leaching into soil and groundwater.

What Can Users Do To Lower Risk?

Anyone working with 1-Propyl-3-Methylimidazolium Bromide needs solid protective gear and must follow proper disposal guidelines. Pouring leftovers down drains doesn’t stop problems—it only makes them invisible until they crop up somewhere downstream. Engineers and lab managers bear the responsibility of building better waste collection systems, ensuring storage containers stay sealed, and providing training based on real risks, not just manufacturer’s suggested procedures.

Companies should also read recent scientific reviews, not just data from five or ten years ago. Newer ecotoxicity findings sometimes reveal unexpected risks as these salts see broader use outside the lab, such as in battery manufacturing or water treatment. Regulations require MSDS documents and labeling, but a culture of safety goes beyond paperwork. Spills must be cleaned with care, not ignored, and everyone involved should understand the difference between “low volatility” and “safe for people and the planet.”

Room for Safer Alternatives

As makers and users of chemicals keep searching for safer, more effective options, ionic liquids like 1-Propyl-3-Methylimidazolium Bromide will stick around for special situations where nothing else works as well. Using them wisely, respecting their hazards, and adopting regular updates to protocols keep science and industry moving forward without risking our lives or the health of our water and land.

Understanding What You’re Handling

1-Propyl-3-Methylimidazolium Bromide belongs to the family of ionic liquids. Many chemists use it as a solvent or catalyst in labs and sometimes in industrial processes. The substance looks innocent—just another white solid or sometimes a clear liquid, depending on temperature. The risk sneaks in if storage habits slip. Even experienced lab workers occasionally misjudge safe storage practices with these salts because they don’t smell or smoke like some more dangerous chemicals.

Moisture and Air Sensitivity Matter

This compound pulls in water out of the atmosphere, so humidity always poses a problem. I’ve seen bottles clump up quickly in open air, ruining their usefulness in any precise synthesis. To sidestep this, keep bottles tightly sealed at all times. Screw the cap tight after each use, and always use the original packaging whenever possible. If the facility allows, storing open bottles inside a desiccator with fresh drying agent works well. No need for over-engineering: simple silica gel can protect the contents for months. Some labs invest in gloveboxes, but for most people, regular sealing and checking for clumping works just fine.

Temperature Control Avoids Breakdowns

Most ionic liquids hold up at room temperature, but fluctuations don’t help. Direct sunlight and hot spots above 30°C speed up unwanted reactions or just degrade the appearance and purity. I once watched a student leave a bottle next to a window and by afternoon, part of it liquefied—the product stopped working in their reaction the next week. A sturdy shelf away from direct heat or cold keeps the risk low. For anyone running a stockroom or academic lab, a labeled chemical storage cabinet away from busy work areas works every time.

Chemical Compatibility Makes All the Difference

Bromide-based imidazoliums behave pretty well near most chemicals, but strong acids, bases, and oxidizing agents spell trouble. Spills or evaporating liquids can trigger nasty surprises. Store 1-Propyl-3-Methylimidazolium Bromide in its own bin, away from acids like hydrochloric acid and oxidizers like sodium percarbonate. Don’t stack unrelated bottles together; dedicate a shelf space or bin so it doesn’t encounter leftovers or leaks from incompatible chemicals.

Smart Labeling Pays Off

People ignore the importance of legible labels until something goes wrong. Clear names, dates, and concentrations on every bottle protect not only the chemical but the entire workspace. University policies sometimes require hazard icons or QR codes for inventory tracking. One time, I found a bottle with handwriting so faded we couldn’t confirm the lot number, and the entire batch ended up being discarded. Spare pens and sturdy tape prevent these headaches before they start.

Personal Protective Equipment and Spills

Even though it’s not as toxic as some chemicals, direct contact or inhaling the dust can irritate skin and lungs. Always handle with gloves and safety glasses. If accidents happen, have sodium carbonate or a similar neutralizing agent nearby, along with plenty of paper towels or absorbent pads for cleanup. A quick response keeps contamination from spreading, and prevents long-term damage to work surfaces.

Responsible Waste Disposal

Disposal can’t be an afterthought. Used or degraded 1-Propyl-3-Methylimidazolium Bromide must head to chemical waste containers, not the trash or sink. Every institution sets its own procedures, but sticking to hazardous waste protocols protects water supplies and prevents future problems during inspections.

Why Purity Makes or Breaks a Purchase

Chemists and engineers count on the high purity of 1-Propyl-3-Methylimidazolium Bromide (PMIM Br) for their projects. R&D teams in labs, pharmaceuticals, and chemical processing facilities aim for precision in every reaction. If a bottle contains contaminants, results shift off course. The grade most sought-after reaches at least 98% purity, with some suppliers offering options at 99% or even higher. Reliable vendors back up these numbers with COAs, as experienced researchers know that “almost pure” never really means pure enough—residues complicate recovery, and unwanted ions wreck yields in sensitive electrochemistry, catalysis, and even green solvents research.

I’ve stood at the bench, scanning batch labels, sometimes double-checking with simple melting point or NMR tests. My own results threw curveballs when I accepted “high purity” without confirmation. If a supplier cannot provide an analysis certificate, pause and press for proof. Quality isn’t just a marketing word in this business; downstream applications—ion transport in batteries, separation membranes, analytical standards—demand that the product matches what’s advertised.

Packaging Sizes: From Lab to Pilot Plant

Packaging for chemicals like 1-Propyl-3-Methylimidazolium Bromide depends on the buyer’s scale. Academic groups often buy tiny glass vials with as little as 5 grams inside, perfect for running a dozen experiments without overcommitting budgets. Companies or scale-up outfits shift gears, opting for 100 grams, half a kilo, or full kilogram bottles in sturdy HDPE or amber glass, depending on light or moisture sensitivity.

Bulk buyers may deal directly with chemical manufacturers; I’ve seen requests for 5 or even 25 kilogram containers. Drums and carboys work for such quantities, especially when processes run continuously and downtime costs money. Not every project warrants that scale—I remember pitching new ionic liquid processes, starting from 10 grams before jumping to 2 kilograms, balancing cost against the risks of suddenly changing supply lots.

Smaller packs cater to research labs testing several ionic liquids side by side. I favored 25-gram jars for new electrode coatings, since shelf-life drops as soon as the seal breaks and cap moisture seeps in. Small-volume packaging allows safer handling and easier storage, reduces the risk of contamination, and cuts waste, especially when the project scope shifts unexpectedly. Large-volume containers prove their worth for manufacturing or upscaled prototyping; purchasing managers watch prices by kilo and manage logistics for receiving, tracking, and disposal.

Purity and Sizing: Pitfalls and Fixes

Errors in purity or packaging can grind a research timeline to a halt. Impure batches bring mismatched results, and oversize orders waste money and shelf space when projects pivot or grant money dries up. To avoid these headaches, buyers should vet suppliers thoroughly, ask for batch-specific COAs (not generic ones), and check compatibility of packaging materials with their process. Seasoned teams might even designate a “quarantine shelf” for each new lot, running checks before it touches their core workflow.

A collaborative relationship with a reputable supplier remains the best insurance. Direct feedback about previous orders, prompt replacement of questionable batches, and shared understanding of exact needs help both sides. There’s no substitute for strong records—track every batch received, log observed differences, and build your own picture of supply chain reliability. Careful selection—plus a little vigilance—turns what looks like a routine purchase into a nod to quality and safety.