1-Propyl-3-Methylimidazolium Chloride: An In-Depth Look

Historical Development

Synthetic chemistry went through a revolution with the discovery and commercial scale of ionic liquids. 1-Propyl-3-methylimidazolium chloride, a member of the imidazolium-based ionic liquids, first appeared in reports as academic curiosity. In the 1990s, industry turned more serious about ionic liquids, searching for alternatives to volatile organic solvents. That’s when labs focused on imidazolium salts, especially ones with manageable melting points and strong thermal stability. Before the green chemistry movement picked up steam, chemists typically leaned on volatile and flammable solvents. Awareness spread, and ionic liquids like this one presented a picture of innovation—non-flammable, reusable, and customizable. As commercial production of specialty chemicals ramped up in the early 2000s, manufacturers and research labs selected these compounds for their stability and unique liquid state at low temperatures. Today, 1-propyl-3-methylimidazolium chloride (often shortened as [PMIM][Cl]) sits among popular options for academics and industry tackling modern chemical challenges.

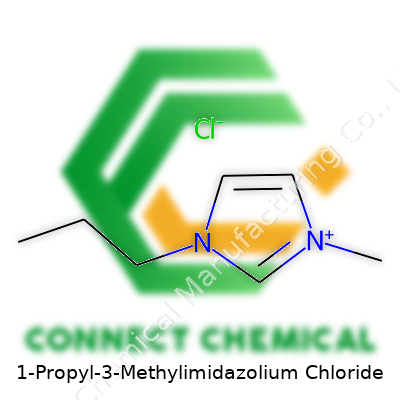

Product Overview

Look at 1-propyl-3-methylimidazolium chloride and you’ll see a salt, but not one that belongs on a kitchen shelf. The structure brings together a propyl group and a methyl group on an imidazolium ring, with chloride balancing the charge. This design produces a liquid at room temperature in many formulations, even when standard salts sit solid. In practice, this compound often appears as a colorless to pale yellow liquid or as a white crystalline powder depending on purity and storage. Suppliers bottle it for research or for use as a reaction medium, catalyst support, or extraction agent. Unlike most other solvents, it doesn’t vaporize easily or catch fire. Instead, it often stands in as a safer option for experiments where researchers want strong solvating power without high volatility.

Physical & Chemical Properties

This salt catches attention for its remarkable physical characteristics. At standard pressure, the melting point typically falls between 70°C and 85°C. It dissolves well in water, producing clear solutions, though its ability to mix with organic solvents like alcohols and acetone can depend on minor structural tweaks. Its stability stands up even against elevated temperatures, thanks to strong interactions between organic cation and chloride anion. A high ionic conductivity, low vapor pressure, and broad electrochemical window round out its property list. The density usually hovers near 1.1-1.2 g/cm³ at 25°C, and viscosity decreases steadily as temperature increases. These numbers might seem dry, but they change how labs approach separations, catalysis, and materials development. More than once, I’ve reached for a vial of [PMIM][Cl] instead of a traditional solvent simply because my reactions ran cleaner and recoveries shot up.

Technical Specifications & Labeling

Suppliers present this product with customizable specifications: purity above 98% most often, moisture content typically below 0.5%, and chloride content assured by titration and NMR. Labels usually list storage instructions—keep sealed, protect from air and excessive moisture, avoid heat above 90°C. Product packaging—from glass vials to bulk HDPE drums—includes hazard pictograms and GHS-compliant language. Catalogs spell out chemical formula (C7H13ClN2), molecular weight near 160.65 g/mol, and lot number for traceability. Trace metals stay minimized, with labs regularly demanding certificates of analysis showing Fe, Cu, and Zn below 10 ppm. Clarity in labeling helps avoid costly confusion; in a shared academic lab, I’ve seen the trouble a swapped bottle can cause when prepping sensitive experiments.

Preparation Method

Manufacturers usually turn to a two-step synthesis. The first stage links N-methylimidazole and 1-chloropropane under controlled conditions—sometimes with mild heating. After stirring, extraction, and crystallization, the resulting salt undergoes purification cycles. Common methods include repeated washing with ethyl acetate, recrystallization, or drying under vacuum oven to strip away last traces of water. Stringent controls keep side-products low. Small-scale prep works in the glassware of a standard university lab, but bigger quantities need reactors that handle controlled temperatures and scrupulous air exclusion. More than once, I’ve learned the importance of patient washing steps: skip those, and leftover precursor haunts later analysis.

Chemical Reactions & Modifications

This ionic liquid acts as both a solvent and a reactant in cutting-edge applications. It dissolves a wide range of polar and non-polar molecules, easing reactions like acylations, alkylations, and metal-catalyzed couplings. On occasion, the imidazolium ring itself gets modified, with chemists swapping out alkyl side chains for properties like lower melting point or higher hydrophobicity. Chloride can participate in ion exchange, helping scientists tailor the anion to adjust solubility or reactivity—replacing with tetrafluoroborate, for instance, ramps up catalytic effectiveness in organic synthesis. Tinkering at this level drives advances in pharmaceuticals, nanomaterial fabrication, and electrochemical cells.

Synonyms & Product Names

Across papers and catalogs, you’ll spot names like 1-propyl-3-methylimidazolium chloride, [PMIM][Cl], or 1-methyl-3-propylimidazolium chloride. Some sources use common acronyms: PMIMCl or [C3mim]Cl. Each one refers to the same cation-anion pairing, and suppliers often highlight these synonyms to help customers track down the right product in a saturated market. Such consistency removes headaches for both bench scientists and logistics teams, keeping the focus on results rather than paperwork.

Safety & Operational Standards

Every lab using this compound follows strict safety norms. Gloves, goggles, and lab coats form the baseline. Ventilated spaces improve comfort during use—accidentally inhaling fine powder or mist isn’t a pleasant experience. Most risk lies in eye and skin contact, with mild irritation possible. Environmental persistence can raise concerns; wastewater from experiments gets collected and handled as hazardous waste, preventing ionic liquids from slipping into public water systems. Storage away from strong acids and oxidizers reduces risk of dangerous degradation. MSDS sheets guide these practices, and regular staff training means fewer accidents or exposures. Memories of rushed transfers remind me just how quickly a safe-seeming compound can spill and complicate a day.

Application Area

Researchers and industry veterans pick 1-propyl-3-methylimidazolium chloride for jobs that punish traditional solvents. It dissolves cellulose for biofuel processing, purifies metal ions in hydrometallurgy, and even stabilizes sensitive catalysts in organic synthesis. Battery developers incorporate it into electrolyte blends, seeking higher lifetime and improved safety. Extraction scientists make use of its selectivity for challenging extractions in environmental and food samples. In polymer science, it swells or cross-links specialty plastics. LAB-scale work brims with creativity—few solvents burnish their reputation for both flexibility and safety quite like PMIMCl.

Research & Development

The past decade delivered a flurry of new uses for imidazolium-based ionic liquids. Academic groups push boundaries, investigating novel catalysts or greener separations with 1-propyl-3-methylimidazolium chloride in pivotal roles. Electrochemical pioneers seek new battery and supercapacitor designs, driven by this compound’s stable electrochemical window and high ionic mobility. Combinatorial chemists shuffle side-chain variations to tweak melting points or lipophilicity. A constant theme shows up: finding better, safer tools for challenging chemical problems. Collaboration between universities and companies helps convert breakthroughs into real-world products, blurring the old line between research bench and factory floor.

Toxicity Research

Long-term effects of ionic liquids on health and the environment keep cropping up in conferences and hazard reviews. Acute toxicity of 1-propyl-3-methylimidazolium chloride remains low, with skin and respiratory irritation at high doses or direct exposure. Chronic outcomes still raise more questions than answers, and researchers rely on in vitro and small-animal testing to track bioaccumulation and breakdown. Wastewater management takes extra care to intercept ionic liquid spills, and strict local disposal rules often outpace federal regulations in this fast-evolving sector. Environmental scientists measure breakdown rates in soil and water, weighing up persistence, toxicity to aquatic organisms, and long-view sustainability. Safer-by-design principles guide many next-generation derivatives, targeting both low toxicity and quick degradation.

Future Prospects

Interest in 1-propyl-3-methylimidazolium chloride stretches across green chemistry, energy storage, sustainable manufacturing, and analytical sciences. Companies scale up production in tandem with market demand for clean solvents, recyclable catalysts, and robust electrolyte blends. Cost stands out as a limiter, but new synthesis routes and recycling protocols slowly bring prices down. As environmental scrutiny sharpens, manufacturers highlight both reduced emissions during use and innovative treatments to reclaim and reuse spent material. In the next few years, the compound’s role in biorefining, carbon capture, and hybrid battery material design seems set to expand. The real secret to ongoing progress will focus on safer formulations, better recycling, and enduring partnerships between industry and research groups, making the future for imidazolium chlorides anything but dull.

Chemistry in Daily Life

1-Propyl-3-Methylimidazolium Chloride sounds like something tucked away in a research lab, but its uses could fill a surprising number of gaps in the way people approach chemistry and engineering today. As someone who pays attention to the way the building blocks of matter support industries, I find it interesting how simple ions can shape a whole field.

Bringing Greener Solutions to Industry

This compound belongs to a group called ionic liquids. Unlike typical solvents, these don’t evaporate the way water or acetone do, so they solve a real problem: harmful chemicals getting into the air. Many industries want less waste and lower emissions, so these features make 1-Propyl-3-Methylimidazolium Chloride an appealing option for large-scale processes. For example, during cellulose processing—think paper, biofuel, textile—this chemical helps dissolve wood pulp much more efficiently than many old-school solvents. Companies have moved away from harsh and caustic solutions, picking ionic liquids because they aren’t flammable and keep volatile organic compounds out of the workplace.

Changing the Game in Electrochemistry

I remember visiting an academic lab where the researchers swapped out old electrolyte formulations in batteries for newer ones containing ionic liquids. 1-Propyl-3-Methylimidazolium Chloride showed up as a safer, more reliable replacement in certain types of experimental batteries, especially where high temperature or long cycle life posed challenges. It doesn’t just carry ions inside a cell; it reduces the chance of fire, which matters in devices meant to sit around people’s homes or hospitals. There’s also a growing interest in using the compound in supercapacitors, as it helps boost the devices’ ability to store energy for short, heavy bursts of power.

Catalysis and Synthesis: Making Chemistry Smoother

In organic synthesis, speed and precision matter. This compound handles acids and bases well, so chemists use it during cross-coupling and other reactions that demand efficient mixing and a controlled environment. Organic reactions often stumble when solvents break down or interfere with the results, causing expensive delays or wasted materials. 1-Propyl-3-Methylimidazolium Chloride holds steady and supports diverse transformations, from pharmaceuticals to specialty plastics. Some of the greener drug synthesis processes in recent years rely on this approach, cutting out some of the worst residues and hazardous stepwise reactions.

Challenges, Responsibility, and Moving Forward

No chemical is perfect. Cost often runs high when shifting to new solvents, especially at an industrial scale, so companies run pilot projects before jumping in. Waste management comes up, because even ionic liquids can pose risks if dumped carelessly. Regulatory bodies in Europe and the United States keep a close watch, pushing for safe handling and disposal guidelines. More efforts need to go into recycling and recovering these materials after use. Researchers keep tweaking the formula, using computational chemistry and hands-on testing to lower toxicity and raise performance without losing the features that make these ionic liquids so useful.

Building on Trust—Why Careful Use Matters

Industries don’t just adopt new chemicals based on trends. They look for proof. Journals, regulatory filings, and real-world case studies help build trust around the use of 1-Propyl-3-Methylimidazolium Chloride. Companies that make and use it also train their workers, install sensors to track exposure, and invest in closed-loop systems. By combining good science with strong workplace habits, it’s possible to push chemistry in a cleaner and more practical direction.

Understanding the Building Blocks

1-Propyl-3-methylimidazolium chloride brings together an imidazolium-based cation with a chloride anion. In the formula, you see it written as C7H15ClN2. This molecular assembly stands out in the world of ionic liquids, moving away from volatile organic solvents many labs used in the past. The compound itself features a five-membered imidazole ring, which holds two nitrogen atoms. On this ring, a propyl chain attaches to the first nitrogen, and a methyl group connects to the third. Pairing with a chloride ion, the compound forms a salt that melts at a much lower temperature than the old salts chemists worked with a couple of decades ago.

Structure in Perspective

Zoom in on the imidazolium core: you get aromatic stability from the ring, which changes how the electrons move and interact. The propyl group, a three-carbon chain, hangs off the ring, nudging the liquid’s solubility and melting point. I remember my first time working with imidazolium salts in a teaching lab. The deep, syrupy consistency made handling simple, even for beginners. Unlike the crystals I grew up seeing in chemistry sets, this salt poured like thick oil—no clouds of fumes, no sharp smells.

Synthetic chemists and materials scientists, especially those looking to green up their processes, have gravitated toward this structure. By swapping out the propyl group for something bigger or bulkier, the melting point and solubility take a turn, and so do the risk factors and environmental impacts.

Why the Structure Matters in Practice

The presence of two nitrogen atoms in the ring gives the molecule a positive charge after forming a bond with extra groups. This charge gets balanced out by the single chloride ion, which turns the whole unit into a stable salt. Chloride anions, easy to source and simple in their chemistry, improve the cost-effectiveness and accessibility for most laboratories and plants.

When running extractions, reactions, or even battery experiments, 1-propyl-3-methylimidazolium chloride brings high solubility and stays liquid at room temperature. Chemists don’t reach for masks and gloves to ward off noxious fumes with it; the risk profile sits far below classic solvents like chloroform or benzene. That means better working conditions, a nod to both experience and evidence about solvent exposure. The viscosity lets you control reaction speed just by changing temperatures slightly, which I’ve seen used in scaling up pilot processes where every degree and every minute of reaction time cost real money and materials.

Barriers and Solutions

Most ionic liquids, including this one, take a while to break down naturally. Waste management can stack up as a challenge. Studies point to some ecotoxicological effects, especially if salts build up in water supplies. Chemists now design alternative cations and explore biodegradable versions, nudged by environmental policies and a growing sense of responsibility among researchers and industry leaders. Some facilities install closed recycling systems that collect, wash, and reuse the salts. These solutions take cues from both research literature and field experience; as more people trade stories in journals and conferences, green chemistry becomes less a trend and more a routine part of the process.

The Value of Knowing the Structure

Recognizing the structure of 1-propyl-3-methylimidazolium chloride helps anyone from students to full-time chemical engineers predict behaviors—from solubility to toxicity—before even setting up a reaction. Practical know-how grows out of seeing these structures in action, watching how they interact not just on paper, but in real-world projects where efficiency, safety, and sustainability intersect.

Some chemicals make lab work smoother, but often bring a bit of risk with them. 1-Propyl-3-methylimidazolium chloride pops up in synthetic chemistry labs, frequently as an ionic liquid. Many research groups appreciate its low volatility and the fact that it dissolves a wide range of compounds. As nice as these properties are, safety should sit at the very front of every discussion about it.

Health and Exposure Risks

Working with any chemical means considering more than just its role in an experiment. Data on 1-propyl-3-methylimidazolium chloride points to moderate toxicity. A direct spill on bare skin doesn't necessarily result in instant burns, but irritation, redness, and dryness do show up after exposure. Inhalation or swallowing raises more severe concerns, largely due to the compound's potential to upset the gastrointestinal tract and respiratory system. Good evidence still remains scarce, largely because many ionic liquids haven't been as widely studied as other chemicals. Gaps like this push for extra careful handling every time.

Certain animal studies, such as those reviewed by regulatory agencies, suggest that imidazolium-based ionic liquids can disrupt cell membranes or hamper enzyme activity. Until scientists know the ins and outs of these risks, nobody should let their guard down during handling.

Everyday Lab Precautions

Standard PPE works fine for this sort of material. Nitrile gloves, splash-proof goggles, and a sturdy lab coat go a long way to block direct contact. Users should watch out for tiny droplets or dust, especially if they’re working with powders or pouring from bottles. Even though this compound doesn't waft through the air like a solvent, mistakes can easily scatter small particles. I learned to double up on glove layers if I knew messy work might come up—a few seconds of prevention can save from hours of dealing with a rash.

Ventilation matters too. Fume hoods play a big role, even for chemicals with a low vapor pressure. Nobody wants to breathe in fine suspended droplets that may stick around the bench area. Rushed work in open spaces only invites trouble, so planning ahead and using the right workspaces pays off. Washing hands thoroughly after every session (not just after accidental spills) soon becomes a habit worth building.

Storage and Spill Management

Containers should always stay tightly sealed, away from direct sunlight and moisture. Ionic liquids sometimes pull water from the air, which changes concentrations in solutions. Labeling with clear warnings helps everyone in the lab stay alert. I’ve seen substitutes poured into glass bottles without any label, which always sets up confusion down the line—clear tags save equipment and people alike.

For spills, loose absorbents and paper towels work fine. Smaller messes wipe up quickly, but always put on new gloves before handling contaminated waste. A chemical-resistant waste container beats a regular trash can every time for these sorts of jobs. One time, a forgotten paper towel caused a whole afternoon’s worth of cleanup—better safe now than scrubbing later.

Training and Awareness

Lab safety meetings might feel repetitive, but the risks around unfamiliar chemicals ask for a culture of shared awareness. Rushing through experimental steps or ignoring small spills never turns out well. If you’re unsure about the safety profile of a substance, reach out for the latest SDS (Safety Data Sheet) and review it before starting. One quick review of the document reveals not just toxicity info, but also reactivity and disposal guidelines.

As researchers keep developing new applications, understanding risks will deepen, but until then, experience and vigilance should always steer the way chemicals like 1-propyl-3-methylimidazolium chloride enter the lab workflow.

The Value of Careful Chemical Storage

Anyone working in a lab or chemical plant eventually notices that small mishaps often trace back to overlooked storage procedures. These “odd” bottles—especially ionic liquids like 1-Propyl-3-Methylimidazolium Chloride—deserve special attention, not because they’re explosive, but because they can degrade, develop impurities, or even leak into the environment. Accidents don’t always look like Hollywood fireballs; sometimes they’re sticky residue or corroded shelving. Over the years, nothing teaches about proper storage quite like scraping up a leaky mess or seeing a ruined lot due to poor labeling.

Moisture: The Persistent Threat

1-Propyl-3-Methylimidazolium Chloride reacts with water in the air. This trait makes it different from salts like table salt, which laughs off humidity. Once water sneaks in, purity takes a hit and performance drops. Many researchers keep these ionic liquids in tightly sealed glass or plastic bottles—anything moisture can’t slip through. Some folks go further, using desiccators with silica gel or a vacuum oven, especially if the stakes (or price tags) run high. The simplest dry cabinet, if checked often, works better than the most high-tech setup that sits unlabeled or unnoticed.

Temperature and Its Role

Heat speeds up every reaction, not only the ones you want. Over time, if 1-Propyl-3-Methylimidazolium Chloride faces higher or fluctuating temperatures, it can break down, yellow, or let impurities creep in. Regular room temperature, out of direct sunlight, fits the bill for most labs. In hotter environments, I’ve seen colleagues store this ionic liquid at lower temps—between 2°C and 8°C—which is just a regular fridge. Put a clear label on the bottle to prevent the next shift from mixing it up with someone’s lunch.

Container Choices and Compatibility

Chemists tend to prefer amber glass for storage, since it blocks out light and don’t react with the chloride. For long-term storage, I never trust a random screw cap or mystery plastic. Anything metal makes trouble—ionic liquids initiate corrosion faster than many expect. Before trusting a container, check its material safety data sheet and do a spot check. If you’ve ever watched a plastic cap crack or a metal lid corrode onto the bottle, you know why it’s not a one-time chore.

Labeling and Inventory

Proper chemical management isn’t all about the storage itself. I’ve been in enough labs to say that failing to label and date containers quickly leads to confusion, waste, and safety risks. A clear label including chemical name, date received, and responsible person makes recalls quick and prevents duplication. Modern tracking tools help, but a well-kept notebook works for small teams.

Efficient Solutions to Reduce Storage Risks

One of the low-cost fixes: start with smaller containers. This trick cuts down on repeated exposure to air, moisture, and cross-contamination. Rotate stocks and set up schedules for checking current supplies. Not every lab can afford fancy storage units, but consistent housekeeping trumps expensive gear. Open communication and accountability—real conversations about what gets stored, where, and by whom—make the tightest seal on safety and quality.

Conclusion

Good storage habits often stand as the main line of defense against lab mishaps. Simple steps—airtight containers, dry environments, stable temperatures, and decent labeling—go a long way. Despite the urge to rush, taking care in practice protects both research and people.

Why Purity Matters for 1-Propyl-3-Methylimidazolium Chloride

A chemist will always check purity before laying a substance on the bench. For 1-Propyl-3-Methylimidazolium Chloride, it usually lands above 98%. This level matters because an unexpected impurity can throw off an entire experiment. Imagine preparing a reaction, expecting the kind of reproducibility you read about in literature, only for side products or sluggish yields to interfere. For electrochemistry and catalysis, even half a percent of an unlisted contaminant can create noise on the voltammetry trace or harm the catalyst’s life span.

Most academic labs don’t settle for anything below 98%. In industrial work, trace metals or water content can be even more problematic. Moisture sensitivity in ionic liquids isn’t just a buzzword. Leave the bottle open for a few hours over a humid weekend, and the whole solution can shift its properties. I always check for suppliers using Karl Fischer titration and ICP-MS to back up their claims. Data matters more than a fancy label.

Real-World Packaging Practice

Order a bottle from a reliable vendor, and you tend to see 5g, 25g, and 100g packages as the most common choices. In small-scale synthesis, 5g gives enough material to run a few reactions and troubleshoot any solubility problems. If teams need to coat electrodes or prep bulk solutions, 25g handles the job for a few trials without risking leftover degradation. Large manufacturers, running ionic liquid electrolytes or using the material in continuous flow setups, often buy bulk packs over 500g or even a kilogram.

Anyone who’s handled chloride salts knows air and moisture can creep in easily, so vacuum-sealed bottles or nitrogen-flushed containers are best. Fancier vendors have switched to amber glass for light-sensitive materials, and I’ve seen triple-sealed Teflon as an option for more expensive lots. One careless storage decision can double the cost for new stock, and graduate students learn that lesson quickly.

Pitfalls and Solutions in Use and Supply

Not all vendors play by the same rules. Some still ship in simple plastic bottles without proper seals, raising the risk of hydrolysis or caking. Sourcing from suppliers with ISO or GMP certifications helps keep the default standard high. Also, for those ordering from overseas, pay special attention to customs paperwork. Labels should match MSDS data, and declarations about water, chloride content, and residual organics can smooth any regulatory checks.

One real headache? Finding clear documentation for each batch. Request a Certificate of Analysis for every order. It should show NMR, ICP, and water content data, not just a printed guess at purity. Solving this gap in documentation comes down to asking questions before purchasing, and research groups are getting better at networking with vendors to nail down specifics.

For labs where the budget patchwork barely covers all consumables, consider pooling orders with nearby groups or negotiating with distributors. Bigger orders often qualify for discounts. Sometimes, even local resellers will accommodate smaller custom sizes for repeat buyers, opening up more flexibility for unique projects.

Looking Forward

Purity levels above 98% have become expected, not optional. Packaging keeps evolving in response to practical demands: smaller bottles for quick studies, bulk options for industry, and specialty containers for high-precision work. Staying vigilant—verifying certificates, asking about water content, and storing smart—prevents waste and frustration. For me and many others, it’s not just about following protocol. It’s about making sure that months of work don’t hinge on an avoidable chemical misstep.