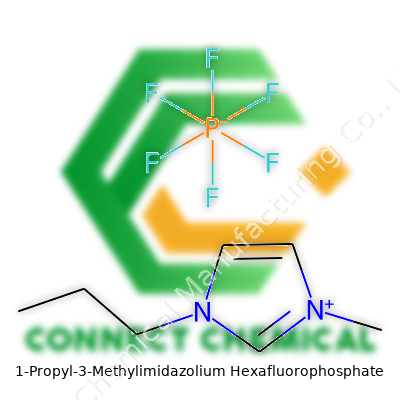

1-Propyl-3-Methylimidazolium Hexafluorophosphate: A Deep Dive

Historical Development

Scientists looking for safer, greener alternatives to volatile organic solvents found something interesting in the 1990s—ionic liquids. A group of researchers, noticing the need for non-flammable and thermally stable options, created 1-Propyl-3-methylimidazolium hexafluorophosphate, often known by its shorthand [PMIM][PF6]. The rise of this compound started in academic labs and soon reached a point where it appeared in chemical supply catalogues. Green chemistry was no longer a theory but a movement powered by results, and ionic liquids became a point of focus for chemists pushing boundaries. Seeing the rapid expansion in publications and patents around this class of materials highlighted both their promise and their practical importance for industrial processes attempting to modernize and get ahead of new safety regulations.

Product Overview

[PMIM][PF6] took off as an ionic liquid appreciated for its unique combination of properties. It's a colorless to pale yellow liquid at room temperature, with no smell that can alert you to its presence. Producers market this compound to labs and companies interested in sustainable solvent systems, extraction processes, catalysis, and advanced battery research. Orders often include detailed safety and technical documentation, reflecting the chemical’s origin as a thoroughly studied research tool. I first saw a bottle of it during a university project on green solvents, and was struck by how modern chemistry sometimes fits in such unassuming packages—a small bottle with a long resume.

Physical & Chemical Properties

This liquid stands out for several reasons. Its melting point sits well below room temperature, and it hardly evaporates—showing off a vapor pressure that’s so low, most lab balances can't even detect it leaving the bottle during an experiment. The density hovers around 1.35 g/cm³, making it heavier than water. Unlike typical solvents, [PMIM][PF6] doesn’t catch fire easily and neither does it promote corrosion in glassware, so working with it feels less like handling a hazard and more like working with a tool designed for the long haul. Its significant ionic strength allows it to dissolve a wide range of metal ions and organic molecules, so both organometallic chemists and extractive metallurgists find plenty of uses for it. One thing that grabbed my attention was its electrochemical stability—it takes a lot to break it down, and that quality expands its appeal into battery and capacitor technologies.

Technical Specifications & Labeling

Sourcing [PMIM][PF6] means looking closely at purity grades—some labs work with 97% grade, others demand 99.5% or higher, especially when they’re pushing for reproducible reaction outcomes. Bottles arrive with technical sheets describing composition, moisture content, and trace impurities. Labeling always emphasizes the PF6 anion’s potential to release hazardous byproducts under certain conditions, and producers package the compound in tightly sealed glass or HDPE containers to limit atmospheric exposure, moisture ingress, or accidental contact. Detailed batch records come standard, so anyone conducting regulated work or scale-up studies can trace every detail of their sample. An experienced chemist checks not just the main substance but also tests for hydrolysis products, which can pop up if the material has been stored badly or exposed to damp air.

Preparation Method

Synthesizing [PMIM][PF6] looks straightforward on paper but rewards patience and careful technique. The process starts by quaternizing 1-methylimidazole with 1-bromopropane to produce [PMIM][Br]. This intermediate then undergoes a metathesis reaction with potassium hexafluorophosphate (KPF6). Stirring the two together in water pushes the reaction toward the formation of [PMIM][PF6] and a byproduct of potassium bromide. Extracting the ionic liquid layer, washing away residual salts, and drying with vacuum yields a product ready for most research uses. At scale, operators keep a close eye on temperature, stirring rates, and washing steps, knowing that small changes can tip the product toward unwanted impurities or hydrolysis, which damages its value. In my experience, using freshly dried solvents at every step avoids many of these headaches—mistakes here can waste both time and expensive reagents.

Chemical Reactions & Modifications

[PMIM][PF6] resists reacting with most organic and inorganic chemicals, which brings peace of mind but also limits chances to customize its structure after synthesis. Still, its imidazolium ring can be fine-tuned by changing the alkyl substituents during synthesis, offering a family of similar ionic liquids where length and branching of the alkyl chains change everything from viscosity to solubility. The PF6 anion can swap out for other anions like BF4 or NTf2 during synthesis, each offering a different landscape for reactivity and solvation. Chemists exploring catalysis or electrochemistry sometimes tether functional side chains onto the imidazolium core for specific purposes, making use of the basic framework provided by [PMIM][PF6] as a platform for tailored ionic liquids. I remember a project focused on increasing CO2 solubility by swapping the anion, which completely flipped the behaviors without a need for completely new synthesis pathways.

Synonyms & Product Names

Researchers and commercial entities recognize this compound by several names: 1-propyl-3-methylimidazolium hexafluorophosphate, PMIM PF6, or sometimes the shorthand [PMIM][PF6]. Catalogues list it alongside compounds like BMIM PF6 (the butyl analogue), highlighting its place in a growing family of ionic liquids. Trade labels may display “Ionic liquid, PMIM PF6” or simply “Propylmethylimidazolium hexafluorophosphate,” but the chemical structure and trusted CAS numbers drive most bulk purchasing decisions. The changing names can throw off newcomers, so habit pushes many chemists to double-check catalog numbers or supplier synopses before placing an order. I learned that lesson the hard way once, confusing PMIM with BMIM, and had to repeat an expensive experiment for accuracy’s sake.

Safety & Operational Standards

Working with [PMIM][PF6] means following strict safety routines beyond just gloves and goggles. The PF6 anion, though stable in most uses, can break down in the presence of water or acids to release toxic hydrogen fluoride (HF) and other hazardous byproducts. Air and moisture exposure slowly shift the material toward hydrolysis, so storing under inert gases and in tightly sealed vessels preserves the sample. Disposal rules vary according to region, but professionals never pour this material down drains. Environmental regulators classify it as a specialty waste, best handled by licensed facilities capable of handling fluorinated byproducts. Labs adopt spill kits and emphasize quick cleanup, knowing that even small spills turn into big costs if contamination spreads. I’ve seen neighboring benches shut down because a drip wasn’t handled properly, driving home the need for focus every time the bottle comes out.

Application Area

Researchers in synthetic chemistry, catalysis, and material science value [PMIM][PF6] for its flexibility. It serves as a solvent for transition metal complex synthesis, offering high stability and unique solvation power that unlock reaction pathways difficult or impossible to achieve with common organic solvents. In electrochemistry, batteries improve their cycling stability and energy density when ionic liquids like [PMIM][PF6] replace flammable organic electrolytes. Engineers looking for more sustainable hydrocarbon separations use this compound to strip out aromatics or extract rare earth elements from ore leachates. Academic reports show enzyme catalysis running smoothly in [PMIM][PF6]-rich systems, predicting more efficient biocatalytic manufacturing down the road. As green chemistry regulations tighten, industrial users look to ionic liquids as drop-in alternatives or as enablers of entirely new clean-tech businesses.

Research & Development

Research continues at a brisk pace. Investigators study not just the fundamental properties but also find new combinations and process intensifications. Reports from leading chemistry institutes show [PMIM][PF6] supporting nanoparticle synthesis, protein folding studies, and development of carbon capture technology. Teams test its performance in recycling and recovery of precious metals, given the growing global pressure on electronic waste streams. Patent filings track new uses, optimization of recycling protocols, and ways to recover or regenerate spent ionic liquids with minimal environmental footprint. Based on published data, large-scale adoption rests on improving recyclability and ensuring supply chains avoid contamination that could compromise performance in high-value applications. My experience in collaborative R&D teams reveals one constant: curiosity blends with pragmatism—every innovation gets weighed against cost, safety profiles, and prospects for waste minimization.

Toxicity Research

Environmental and biological safety demands careful evaluation. Although [PMIM][PF6] started as a green alternative, more recent studies show toxicity risks under certain circumstances. The imidazolium cation can inhibit microbial activity in wastewater, complicating claims of “benign by design.” The hexafluorophosphate anion brings acute concerns for persistence and fluorinated byproducts. Work with zebrafish and cell cultures revealed toxicity thresholds at low concentrations, and chronic exposure threatens aquatic life. Health agencies track workplace exposure routes and enforce limits where possible. As a chemist reading the latest reviews, I appreciate how regulatory agencies push manufacturers and users to invest in closed-loop systems, limiting emissions and protecting both workers and the environment. The real challenge sits in balancing unique performance with a tight leash on environmental risks, a familiar trade-off across modern chemical practice.

Future Prospects

Looking ahead, [PMIM][PF6] stands at the crossroads of advanced materials design and stricter sustainability expectations. Researchers are experimenting with biodegradable anion and cation variants, hoping to retain performance while unlocking better environmental compatibility. Industrial companies trial pilot procedures that recover and purify spent ionic liquids for reuse, directly cutting costs and potential liabilities. Regulations will likely push product labeling, handling, and disposal to even higher standards, so both researchers and businesses will prioritize transparency and traceability from synthesis to end-of-life. Improvements in green synthesis—using less hazardous reagents, generating less waste, and discovering compatible additives—could tip ionic liquids into wider industrial use, possibly reshaping how industries view solvents and specialty fluids. Every step forward will reflect science informed by hands-on experience, clear-eyed safety assessments, and a willingness to adapt as real-world impacts come into focus.

What This Chemical Offers in the World of Science and Industry

1-Propyl-3-Methylimidazolium Hexafluorophosphate, often abbreviated as [PMIM][PF6], stands out in the world of ionic liquids. For folks who dabble in chemical labs or those working in modern manufacturing, this mouthful of a name carries real weight. It isn’t one of those chemicals you find on grocery shelves, but its applications show up behind the scenes in ways that shape everyday life.

Battery Breakthroughs and Cleaner Power

Ionic liquids have a reputation for stability and low volatility compared to old-school organic solvents. [PMIM][PF6] lands in the spotlight as a safer choice for new generations of lithium-ion batteries and supercapacitors. Tinkering with energy storage, I’ve seen firsthand how flammable liquids can derail safety claims. In sharp contrast, this ionic liquid doesn’t catch fire so easily and resists thermal breakdown, which gives engineers more room to develop longer-lasting, safer batteries. You find this chemical inside electrolyte solutions where consistent performance matters, especially as carmakers and tech companies push for better electric vehicles and portable gadgets. Research published in journals like "Electrochimica Acta" shows that batteries using this compound as an electrolyte hold up better under stress and deliver improved charge-discharge cycles.

Cleaner Synthesis for Pharmaceuticals and Green Chemistry

Traditional solvents burden the environment with toxic residues, but [PMIM][PF6] works differently. It dissolves a wide range of compounds, which lets chemists run reactions more efficiently. In my years working with synthetic methods, this chemical allowed me to skip some of the usual steps in purification, saving both time and resources. Pharmaceutical manufacturers use it to carry out reactions that otherwise demand harsh or hazardous chemicals. According to studies in "Green Chemistry" journal, this shift reduces hazardous waste and exposure, which speaks volumes for both worker safety and planet health.

Electroplating and Corrosion Protection

One important arena for this compound shows up in surface finishing. Metal electroplating, common in factories, banks on precise control over deposit quality. Using this ionic liquid, I’ve seen operators lay down metal coatings with fewer defects and less unevenness, replacing harsher, less predictable alternatives. This means electronics gain longer life, and even jewelry keeps its shine with less tarnish. The Science Council of Japan highlights how ionic liquids contribute to eco-friendly plating by lowering the burden of volatile organic compounds released to the environment.

Supporting Safer, Smarter Lab Work

In academic research, [PMIM][PF6] cuts down on solvent fumes and unwanted side reactions. Anyone who’s spent long hours in the lab knows how quickly caustic or noxious vapors make work miserable. Since this ionic liquid shows negligible vapor pressure, it keeps the air cleaner. I’ve found it helps run reactions at room temperature, which not only reduces the energy bill but minimizes risk to staff. The American Chemical Society points out that using ionic liquids in teaching labs sets the standard for greener, safer education for future scientists.

Handling the Drawbacks and Next Steps

No chemical comes without hiccups. [PMIM][PF6] can get pricey and some breakdown products, especially under high heat, raise eyebrows about environmental impact. That’s a call for better recycling programs and stricter monitoring. To boost access and sustainability, companies experiment with more affordable production methods and recovery systems. Ongoing partnerships between academia and industry help drive safer, cost-effective uses, so cleaner tech and greener chemistry become standard practice.

If you’ve spent time in a lab, you know the drill — a new reagent arrives, the label screams “keep dry, protect from light,” and then the game of chemical chess begins. Stability isn’t just about avoiding an explosion; it’s about reliability, cost, and research safety. I’ve seen projects run into the ground over unstable compounds that morphed into something else after a few days on the shelf. So the focus here isn’t just chemistry, but also the stakes for anyone handling these substances.

Chemical Stability: Why It Counts

Chemicals lose their punch when exposed to the wrong environment. Some compounds, like certain peroxides, love to decompose at room temperature, giving off dangerous byproducts. Others, like some antioxidants, cling to integrity unless oxygen or light sneaks in. Stability means a chemical keeps the same structure and reactivity under ordinary handling conditions.

Picture a bottle of sodium azide sitting next to the radiator. If you forget its tendency to explode when heated or mixed with metals, that’s hardly a minor mistake. Stability isn’t just a theoretical concern; it shapes shelf lives, budgets, and even lab safety protocols. Organizations like OSHA and the EPA have published endless documentation cautioning against sloppy storage, after real disasters showed what can go wrong.

Storage Requirements: Not Just a Suggestion

If you’ve ever witnessed a sticky, gummed-up bottle labeled “anhydrous,” you’ve watched water vapor win the battle. Water-sensitive compounds like lithium aluminum hydride demand dry boxes and special containers. Light-sensitive dyes need amber bottles and low-light environments. Failing to follow these rules turns expensive chemicals into useless slush — or even a hazard.

Temperature changes spell trouble. Nitrates stored in hot rooms may undergo slow decomposition, risking the release of toxic gases. Or think of how even common pharmaceuticals can break down into toxic or inactive products if left above the recommended temperature range. Everyone likes to complain about the cost of lab-grade refrigerators, but after scrapping a ruined batch of one-of-a-kind synthetic intermediates, the investment seems minuscule.

Practical Guidelines and Smarter Solutions

Rules for chemical storage weren’t pulled out of thin air. They come from hard-earned experience. Clear labeling and up-to-date inventories help people avoid mistakes. Locking incompatible chemicals away from each other — acids and bases, oxidizers and organics — matters for both efficiency and safety. Anyone who’s had to evacuate a lab knows how fast a forgotten incompatibility can turn stressful.

Periodic checks keep surprises to a minimum. It’s tempting to toss a bottle on a shelf and forget about it, but regular inspections pick up signs of instability, like color changes or pressure build-up. Automated environmental monitoring, once considered a luxury, now saves labs from errors by sending alerts about temperature or humidity spikes before things spiral out of control.

Better packaging helps, too. Vacuum-sealed ampoules and nitrogen-flushed containers add years to some chemicals’ shelf lives. Researchers now use blockchain-based inventory systems to track expiration dates, shipment histories, and environmental conditions from supplier to storage. This isn’t just tech hype — it offers a real answer to the age-old frustration of spoilage and waste.

Why All This Still Matters

Long-term, careful chemical management ensures research results mean something. Projects don’t stall out as often, budgets stretch further, and labs operate more safely. My own experience taught me that a little effort in double-sealing or labeling on day one can save weeks of reruns and costly restocking. In science, getting the basics right makes every complex result possible.

Understanding the Chemical

1-Propyl-3-Methylimidazolium Hexafluorophosphate grabs attention for its use in chemistry labs and industry, especially in research on ionic liquids. The word “hexafluorophosphate” springs warning bells for a reason. Chemicals like this offer neat properties—low flammability, low vapor pressure, strong solvating power—making them popular for electrochemistry, catalysis, and advanced synthesis. Their exotic-sounding nature doesn’t cancel out basic safety risks.

Risk is About More Than the MSDS Sheet

Many hazards don’t always jump out at you from a quick scan of safety data sheets. Industrial and academic labs trust ionic liquids to do tricky jobs, but that trust depends on understanding a few key facts. Hexafluorophosphate compounds, for example, can break down into highly toxic hydrogen fluoride (HF) if they come in contact with water. HF burns right through skin and bone, acting as both a contact poison and a gas. That stuff demands respect. My own lab keeps extra PPE just for handling anything with PF6- groups. Nitrile gloves, splash goggles, and lab coats are only a start.

A common myth paints ionic liquids as “green” because of their low vapor pressure, supposedly giving off fewer fumes. But low volatility doesn’t equal safe breathing air. A bench spill won’t evaporate into a fine mist, but the chemical persists on surfaces. A careless moment can leave invisible residue behind for the next person. I’ve seen cases where ignoring a glove change led to rashes, headaches, and more. The “newness” can fool folks into thinking these chemicals are as safe as salt water. That mistake can mean hospital visits or worse.

Health Risks: Don’t Underestimate the Threat

Most imidazolium ionic liquids have toxicity levels that don’t show up until after regular exposure. Some have shown possible links to genetic mutations, skin and eye irritation, and effects on aquatic life. For workers, direct skin or eye contact brings short-term pain and, in heavy spills, chemical burns. If PF6- breaks down, HF release can lead to immediate danger. I’ve met researchers who tossed out gloves after every handling session, and their caution feels right to me.

There’s no surprise that European agencies label many hexafluorophosphates—especially those containing imidazolium—with warnings for skin and eye hazards, aquatic toxicity, and sometimes suspected longer-term health impacts. That’s not academic worry; that’s the result of real-world exposure data.

Better Lab Practice Makes a Difference

Training matters more than any warning label. Every time a new student enters my lab, I walk them through the hazards and response plans. Fume hoods, carefully sealed waste containers, and double-gloving are not options. After every use, thorough clean-up and surface checks keep hidden traces from becoming a surprise. Simple steps—fresh gloves, eye wash readiness, no lone work with reactive compounds—help prevent small mistakes from turning into medical emergencies.

As more companies and schools jump into ionic liquid research and use, sharing those real lessons makes a difference. It’s less about “hazardous” or “not hazardous” and more about knowing risk and matching respect to the job. Tools and materials serve us best when we don’t take them for granted.

Purity as More than a Number

Ask any chemist or quality control manager about purity, and you’ll get stories—sometimes headaches—about chasing numbers on a certificate. Purity specification isn’t just a fancy detail tucked into a technical contract. It serves as the line in the sand for what’s acceptable in medicine, food, or electronics manufacturing. Having worked in labs and seen more than a few production hiccups, I know how easily a tiny impurity can throw off months of work. A spec keeps things honest and shows what to expect each time a batch rolls out.

Where the Numbers Come From

Usually, purity specification shows up on a document—from a supplier, internal QC lab, or outside agency. It will read something like “minimum 99.5% pure by weight.” Sometimes, it’ll drill into tests for heavy metals, water, or other contaminants. These aren’t numbers picked out of thin air. The requirements come from research, safety studies, and long, hard lessons in the field. Take pharmaceuticals—one strange contaminant and a whole shipment ends up getting destroyed. I’ve seen production lines grind to a halt until everyone figures out which upstream ingredient failed to meet its mark.

Making Purity More Than a Promise

Declaring a purity specification is only the start. Anyone who’s ever worked in compliance knows real headaches start with verification, not with spreadsheets. So, how do labs actually prove a product meets spec? The answer starts with validated test methods and the right equipment. High-performance liquid chromatography (HPLC), gas chromatography, mass spectrometry, titration—these are not just for show but form the backbone of daily testing, producing facts that manufacturers and customers trust.

Trust Matters—Every Batch, Every Day

Suppose a company claims their vitamin C is “99.9% pure.” Next step is testing, and often, results travel with each lot as a certificate of analysis. In the best labs I’ve worked with, skilled techs run these checks day in and day out. Every discrepancy turns into a deeper investigation. Regulatory agencies, such as the FDA or the European Medicines Agency, check these records. Bad data, incomplete logs, or missed checks can mean delays, recalls, or even legal trouble.

Why Verification Fails—and How to Fix It

Problems sneak in. Old test protocols, poorly calibrated machines, or employee turnover can weaken the chain of trust. In my own experience, I’ve seen how team members cut corners under pressure. That’s why real oversight includes routine audits, proficiency testing, and clear handover procedures. Technology helps, but culture matters more—making sure no one fudges numbers when deadlines loom. Traceable records, frequent retraining, and unannounced cross-checks act as the brakes when speed threatens accuracy.

Better Solutions for Everyone

Want to fix verification problems? The answer isn’t only better machines or stricter paperwork. Leaders must invest in training so that everyone knows what good data looks like. Bringing in outside auditors, rotating test staff, and updating protocols each year stop small errors from growing into disasters. When labs, suppliers, and buyers keep talking—and keep records open—mistakes don’t get buried. The cost of getting it wrong often dwarfs the time spent double-checking each step.

Why Care About Disposal?

People who work in labs treat many materials as routine, and it's easy to underestimate the risks that come with highly specialized chemicals. Take 1-propyl-3-methylimidazolium hexafluorophosphate, for example—a favorite among researchers experimenting with ionic liquids and electrochemistry. Its usefulness in dissolving difficult compounds, or as an electrolyte, cannot be denied. Yet, one look at the chemical name tells you it’s not something to just pour down a drain.

Disposal of chemicals with a heavy fluorine component and imidazolium structures demands careful attention. These compounds don’t break down like food waste or general lab solutions. Instead, they can linger, affecting both the wastewater system and the environment. I’ve seen lab teams receive stern warnings after the wrong chemicals turned up in municipal wastewater. No one wants those fines, or worse, cause environmental harm.

Environmental and Health Risks

The hexafluorophosphate part matters most here. Once exposed to moisture or strong acids, it can break into hydrofluoric acid and other toxic byproducts. Lab safety handbooks highlight hydrofluoric acid because just a small amount on your skin can wreck tissue and bones. Municipal treatment plants can’t always catch these chemical fragments, so they slip into rivers and fields, putting animals and people at risk.

Some ionic liquids seem stable, but their real legacy comes later. They don’t just disappear. They build up in organisms and soil, which researchers have started finding in ecotoxicological studies. There’s real harm in assuming that anything labelled “green solvent” is safe in large quantities. The research community already faced problems with per- and polyfluoroalkyl substances (PFAS), which came from a similar mindset decades ago.

Lab Culture and Legal Landscape

Labs handle more regulations now than ever. Local, state, and federal laws shape what you do after finishing a synthesis run or an electrochemical test. Waste manifests, labeling requirements, and hazardous waste pickups aren’t just bureaucracy—they grew from disasters and accidents when chemicals were treated like regular trash.

Many universities and companies hold annual waste handling sessions. I learned more from watching a fire marshal visit our stockroom than any official training video. He’d point out how quickly things can escalate with the wrong waste management. Stories about shared buildings having to shut down after drainage lines corroded or unexpected reactions in waste storage stuck with me.

Responsible Disposal—What Works

Getting rid of 1-propyl-3-methylimidazolium hexafluorophosphate used in experiments should always run through a certified hazardous waste service. Make sure every container is clearly labeled and don’t mix unknowns, since reactive combinations multiply risk. Most professional chemical waste streams separate halogenated from non-halogenated organics, since mixing can trigger unpredictable reactions or complicate recycling.

Empty vials and contaminated gloves belong in special containers provided for hazardous waste, not the regular trash. Try to minimize leftover amounts in the first place by careful planning. I’ve noticed habitual planning keeps the hazardous waste drum from filling up too quickly, which helps everyone in the long run.

Keeping up with published best practices and updates from chemical regulators helps avoid surprises. The scientific community benefits every time a researcher takes five extra minutes to dispose of chemicals the right way. Respect for the chemical means respect for your team, your institution, and your neighborhood.