1-Propyl-3-Methylimidazolium Methanesulfonate: A Down-to-Earth Look

Historical Development

Researchers started hunting for new green solvents back when stricter regulations and environmental worries about traditional organics like chloroform and toluene grew louder. The birth of ionic liquids came out of this search, and 1-Propyl-3-Methylimidazolium Methanesulfonate landed on the radar for its balance of low volatility, solid thermal stability, and easy synthetic routes. Lab benches in the early 2000s became testing grounds for families of imidazolium-based ionic liquids. Once scientists realized how the tail length shifted the properties, the propyl variant gained traction, especially in research labs that wanted both manageable viscosity and tuneable solvent power. Enterprises looking for less flammable and more recyclable alternatives have turned to this compound as industries phase out old-school solvents not just for safety, but also because lawmakers forced their hands.

Product Overview

1-Propyl-3-Methylimidazolium Methanesulfonate falls in the imidazolium ionic liquids family, sitting alongside its cousins with longer or shorter alkyl chains. It exists as a colorless to pale yellow liquid at room temperature, catching the attention of chemists who want a practical alternative to moisture-sensitive or air-sensitive salts. With its methanesulfonate anion, it brings both moderate hydrophilicity and chemical resilience to tough working environments. Its main draw lies in the way it blends ionic conductivity, low vapor pressure, and room temperature liquidity. For anyone dealing with electrochemical devices, biomass processing, or specialty catalysis, this product doesn’t come off as exotic anymore; it’s simply another tool worth reaching for.

Physical & Chemical Properties

This liquid resists evaporation, giving off almost no smell and showing practically zero vapor pressure under standard lab conditions. The density floats close to 1.15 g/cm³, and its viscosity at room temperature lands around 80–120 cP, falling into the workable range for pumping and mixing. It stands out for its ability to dissolve a surprising range of both organic and inorganic materials. The cation’s imidazolium core brings electrochemical stability, so it rarely breaks down or interferes in high-voltage or thermal work. The melting point drops well below room temperature, preventing the sort of crystallization headaches seen with older salts. Its electrical conductivity, around 7–13 mS/cm depending on purity and temperature, makes device fabrication and analytical setups possible without the fire hazards of classic solvents. Solubility in water and some polar organics provides flexibility for blending with more standard mixtures when process tweaks are necessary.

Technical Specifications & Labeling

Bottles ship with batch numbers, production dates, and minimum purity requirements, which often hit 99% or higher on the certificate of analysis. Every reputable supplier spells out water content, measured by Karl Fischer titration, plus levels of halide or elemental impurities. You’ll find clear identification by both the IUPAC name and common industry acronyms (like [PMIM][MeSO3]), plus storage and disposal guidance in the safety documentation. Labels highlight the importance of tightly sealed containers since excess water influences both viscosity and reactivity. For those handling kilograms instead of grams, drum packaging requires labeling with United Nations numbers in line with transport regulations.

Preparation Method

Making 1-Propyl-3-Methylimidazolium Methanesulfonate usually starts with a neutralization between 1-propyl-3-methylimidazolium hydroxide or chloride and methanesulfonic acid. Small-scale bench syntheses use a two-phase extraction: dropping the acid into the imidazolium salt, stirring, and removing the by-product (like water or chloride) by washing or rotary evaporation. Manufacturers scale up by controlling temperatures below 60°C to avoid side-reactions, then removing trace water through a gentle vacuum bake. Good operators hold purity by monitoring conductivity, color, and running NMR and HPLC checks before bottling.

Chemical Reactions & Modifications

On the bench, 1-Propyl-3-Methylimidazolium Methanesulfonate can serve as a reaction solvent for processes from SN2 substitutions to transition metal catalysis since it stays unreactive and doesn’t interfere with most reagents. Chemists sometimes swap its anion for others (like tosylate, triflate) via metathesis reactions for tailored applications. Some advanced projects tether functional molecules to the imidazolium ring for use as task-specific ionic liquids, dialing up selectivity or binding power. Attempts at recycling have shown that basic washing followed by ion-exchange brings most spent material back to close to original specs. In electrochemical setups, the liquid acts as a supporting electrolyte, shuttling ions without getting chewed up at electrodes.

Synonyms & Product Names

Depending on where you buy it or which catalog you browse, this ionic liquid goes by names like 1-Propyl-3-methylimidazolium methylsulfonate, [PMIM][MeSO3], or simply Propyl-MIM-MeSO3. Researchers sometimes abbreviate it in publications, but all variations point to the same compound. Some vendors sell it under trade names or in blends tweaked for particular industries.

Safety & Operational Standards

Anyone handling this liquid wears gloves and goggles, not because it burns on contact, but because skin dries out and irritation sneaks up with repeated exposure. Lab air rarely sees measurable vapor, so fume hoods come in handy more for reactions and less for storage. Regular practice involves storing tightly sealed bottles out of direct sunlight and away from reactive acids or bases. Industry guidelines suggest keeping water content as low as possible, since high humidity ages the liquid and may shift properties or create corrosion risks in sensitive devices. Labs and factories need good training to avoid bottling mistakes, and proper spill capture materials—nothing fancy, but layers of absorbents and a plan for neutral disposal. In larger settings, rinse water and waste get sent for chemical treatment in line with local rules, not dumped or poured down the drain.

Application Area

You spot 1-Propyl-3-Methylimidazolium Methanesulfonate in the test cells of next-generation batteries and supercapacitors, where its ionic conductivity boosts energy transfer. Chemists running biotransformations lean on it as both solvent and co-catalyst since it doesn’t denature enzymes the way some old-school solvents do. Processes that turn waste biomass into fuels or platform chemicals often use it to dissolve cellulose or lignin, skipping steps required by other solvent systems. In analytical chemistry, it acts as a supporting electrolyte or phase modifier, especially for liquid-liquid extractions or non-aqueous separations. Factory lines experimenting with greener coatings or lubricants sometimes choose this ionic liquid when a process can’t handle extreme pH or fire risk. Research on chemical recycling of plastics also uses it for depolymerization, as it cracks certain bonds without producing side products.

Research & Development

Academic labs and corporate R&D divisions keep tweaking the molecular structure, hunting for lower viscosity without sacrificing conductivity or chemical resistance. Teams around the world publish on mixtures with other ionic liquids, deep eutectic solvents, and unique salts to shave costs and improve process yields. Some focus on sustainable feedstocks, pushing for biobased versions of both the imidazole core and the methanesulfonate component. Research tracks performance in electrochemical sensors, aiming for robust systems that survive hundreds of cycles in wet or dirty environments. Fields like flow batteries and organic synthesis keep generating new data, proving out or disproving theoretical claims about solvent power or reaction selectivity. Every year, conferences showcase a wider range of uses from pharmaceutical manufacturing to biosample preparation.

Toxicity Research

Lab toxicity tests tell a mixed story. Acute contact or small spills don’t lead to severe hazard, but longer-term studies push for caution—skin absorption can cause irritation, and accidental ingestion or eye exposure inflames tissues. Environmental research flags persistence in water and soil, raising questions about long-term disposal and accumulation. No evidence links it to cancer, but fish and aquatic invertebrates show stress when exposed to higher concentrations. Regulatory bodies call for more work on biodegradability. Most industrial codes rank it below hazardous solvents like pyridine or dichloromethane, yet not as benign as acetates or glycols. Handling practices stress containment and cleanup, with many labs treating waste as hazardous to cover worst-case scenarios.

Future Prospects

Looking ahead, this ionic liquid seems ready for a broader role in clean technology, advanced energy storage, and more forgiving chemical processes. The mix of low volatility, thermal ruggedness, and solvent versatility makes it a favorite for startups designing new battery chemistries or aiming for zero-emission chemical recycling plants. Scientists keep searching for tweaks that improve biodegradability or drop production costs enough for wide-scale industry adoption. If the regulatory environment keeps aiming for less polluting, safer options, 1-Propyl-3-Methylimidazolium Methanesulfonate and its relatives could move from specialty lab staples to core workhorse chemicals in a cleaner industrial future.

Changing How We Approach Solvents

Green chemistry keeps picking up steam, and the shift isn’t just about ditching harmful chemicals. A big part of this movement is the arrival of ionic liquids like 1-propyl-3-methylimidazolium methanesulfonate. These salts melt at low temperatures and barely give off any vapors, so they help avoid the health and fire risks tied to regular solvents like acetone or chloroform. I’ve seen chemists swap out these common solvents for ionic liquids in the lab—not because the textbooks say so, but because the workplace smells cleaner and the headaches disappear.

One real-world use shows up in extraction processes. Plant oils, rare metals, and specialty chemicals come out of mixtures cleaner and quicker with this ionic liquid. It gets used in places where efficient separation is key, such as recovering precious metals from e-waste. The modern world runs on electronics, so the pileup of old smartphones and laptops only grows. By using safer solvents during recycling, workers face fewer hazards, and more metal returns from discarded devices. That process saves money and shifts us closer to a genuine circular economy.

Making Reactions Smoother and Greener

Ionic liquids give a boost to chemical reactions that normally gobble up lots of energy. Take organic synthesis in pharmaceutical labs: heat-sensitive drugs degrade quickly, and the labs often draw a ton of power. But this salt’s special structure and high polarity let reactions run cooler and sometimes without any extra water. That change slashes both energy bills and waste. The push for efficiency isn’t about being trendy—it’s what keeps young chemists interested and drives down costs for patients down the line.

Electrochemistry offers another field where this ionic liquid stands out. Batteries and fuel cells rely on electrolytes that can carry ions well. Typical liquid electrolytes are volatile and flammable, but 1-propyl-3-methylimidazolium methanesulfonate resists catching fire and keeps working even after dozens of charge cycles. Researchers in battery labs keep testing this material because safer energy storage matters. As electric cars and backup grids fill city streets and country homes, asking engineers to take fewer risks with explosions is a no-brainer.

Industrial Cleaning Meets Environmental Sense

Industries such as electronics manufacturing and pharmaceuticals struggle with cleaning residues from tiny circuit boards or sensitive equipment. Water alone barely shrugs off some contaminants, and strong acids damage delicate surfaces. This ionic liquid dissolves residues like flux and lingering chemicals without corroding metal or glass. People working on assembly lines find fewer health complaints and less downtime spent fixing ruined parts. Wastewater also comes out cleaner, skipping some of the usual headaches with local regulators.

Challenges and Smarter Steps Forward

No material comes without trade-offs. Some ionic liquids cost more to produce than older solvents, and disposal raises its own set of questions. Finding greener ways to make and recycle these salts must stay on the priority list. We need strong rules on the environmental impact and new options for reclaiming these salts after use. Industry should fund independent tests, and regulators ought to set smarter standards based on real toxicity data, not just promises from suppliers. That approach builds trust, helps avoid health risks, and keeps the door open for future breakthroughs.

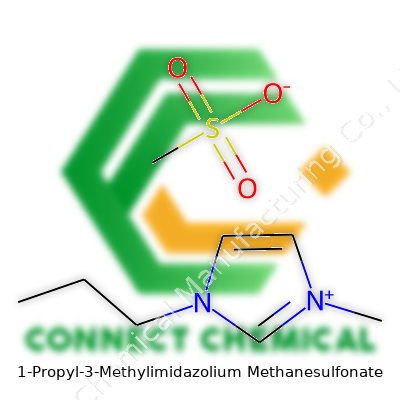

The Building Blocks: Chemical Structure

1-Propyl-3-methylimidazolium methanesulfonate forms through the combination of an organic cation, 1-propyl-3-methylimidazolium, and an inorganic anion, methanesulfonate. The cation features a five-membered imidazole ring. Two carbon atoms in this ring carry the propyl and methyl groups at positions 1 and 3. That shape isn’t only for show — the structural arrangement boosts the salt’s stability and gives it unique properties as an ionic liquid.

Chemists boil this down to a clear formula: the cation is C7H13N2+ and the anion is CH3SO3-. Combining these two, the complete molecular formula becomes C8H16N2O3S.

The chemical structure ties directly to its role as a so-called “designer solvent.” Ionic liquids like this don’t evaporate easily and stay stable at high temperatures. Labs often sketch its structure as an imidazole ring with the methyl and propyl “tails,” paired with a sulfonate group featuring sulfur double-bonded to two oxygens and single-bonded to a methyl group and another oxygen.

Why the Structure Matters in Everyday Research

Ionic liquids have reshaped many areas of science, and 1-propyl-3-methylimidazolium methanesulfonate, by my own lab experience, carves out a special spot in green chemistry. It skips over the problems common with volatile organic solvents. If you’ve ever worked through messy solvent spills or noxious fumes, switching to a salt like this feels like opening a window in a stuffy room. One can measure and mix without worrying about breathing in chemical clouds or starting a fire with a stray spark.

This balance of organic and inorganic pieces brings real-world impact. For researchers cooking up new methods in catalysis or electrochemistry, the structure of both the cation and the anion influences solvent behavior. The large size slows evaporation. Charge separation improves solubility for tough-to-dissolve molecules. The methanesulfonate side stays chemically gentle, so it won’t attack sensitive catalysts or rare reagents. Chemists also appreciate its ability to help separate products from wastes during recovery, making recycling easier for labs that keep an eye on environmental impact.

Challenges and Steps Forward

Finding alternatives to traditional solvents means wrestling with a few issues unique to ionic liquids. Not every reaction plays nice with them. Sometimes, leftover impurities—especially water and halides—change results, and cleaning them out can steal hours from the workday. Manufacturing costs are another headache. The process to make these pure and in bulk remains expensive compared to mass-market organic solvents.

Researchers are working to iron out these wrinkles. Streamlining purification, designing new production pathways, and recycling ionic liquids after each use stand at the front of ongoing efforts. Better education around handling and storage also cuts down on waste and expense. Publications now highlight new “greener” pathways in both industry and academia. There’s more collaboration, from teaching labs to commercial factories, aiming to build large-scale production that won’t drain resources or leave behind harmful residues.

1-Propyl-3-methylimidazolium methanesulfonate stands as one clear example of how understanding and designing chemical structure can address health, safety, and environmental challenges—never only for theory, but for the real people using these compounds every day.

Looking Beyond the Label

Anyone who’s spent time in a lab knows the routine: suit up, scan the label, follow the sheet. These habits have good reason, especially with chemicals like 1-Propyl-3-Methylimidazolium Methanesulfonate. This ionic liquid appears mild, but even mild-mannered substances reveal new sides if treated carelessly. In daily work, one lesson stands out: respect for every bottle, no matter what the hazard rating says.

Why Storage Conditions Really Matter

Some folks view chemical storage like simple pantry organization, but chemistry laughs at laziness. For this compound, air and moisture spark trouble. It’s hygroscopic—draws in moisture quickly—and water inside shifts its chemistry. You risk product breakdown and funky results in research or manufacturing. Use a tightly sealed, chemical-resistant bottle, with a screw cap that actually fits. Glass works well, but high-quality plastics like HDPE hold up against leaks, too.

Light can affect ionic liquids over time. Store the bottle in a dark area, away from windows or lab heat sources. Many labs reserve a clearly labeled shelf or cabinet just for these liquids—so no one grabs the wrong bottle by accident. From experience, confusion leads to time-wasting spill drills, and nobody forgets the day acetone got poured into the waste jug meant for ionic liquids.

Keeping People Safe

Accidents don’t begin with explosions or clouds of smoke—they creep up from complacency. Standard lab gloves and safety goggles make sense, but always check if your gloves withstand organic ions. Some labs print out a compatibility chart and stick it on the cabinet. I’ve seen nitrile gloves hold up under short exposures, but after repeated contact, tiny tears show up. Change gloves as soon as they feel off.

Inhalation might not seem like a big concern at first glance. Still, work with the stuff in a ventilated area, preferably a chemical fume hood. Room fans don’t cut it if something tips over and splashes. Closed-toe shoes and a lab coat offer basic coverage, and spill kits need to sit within arm’s reach. Seen the difference between a prepared team and one hunting for paper towels? The prepared team finishes before lunch.

Labeling and Awareness

Labels in plain English, with clear hazard symbols and expiration dates, help everyone. Too many storage incidents trace back to faded marker or a lost secondary label. An annual check clears out anything expired or questionably sealed. If something smells off, don’t ignore that hunch—call over a supervisor and keep colleagues informed. Labs thrive on communication.

Responding as a Team

Nobody handles chemicals alone. Training makes a difference—newcomers do better after seeing real-life demonstrations, not just PowerPoints. Regular drills let everyone practice stopping spills and cleaning up. Practice builds confidence so no one freezes if liquid hits the bench. Most of the time, safe practices keep incidents from happening in the first place.

Final Thoughts Based on Experience

Every year brings fresh reminders about the value of storing and handling chemicals with care. One person’s shortcut becomes everyone’s hazard. Staying vigilant with every step—cap, label, gloves, storage spot—saves people from grief down the road. Out of all the things learned in the lab, the habits for safe handling matter more than any reaction yield or clean spectrum. This approach deserves attention, every single day.

Understanding Solubility from the Lab Bench

Questions about solubility pop up every time I talk shop with chemists or students. Somewhere along the line, someone always asks, “How well does 1-Propyl-3-Methylimidazolium Methanesulfonate mix with water?” On a practical level, water is the ultimate test. This ionic liquid, part of the imidazolium family, brings a reputation for dissolving smoothly in water. That comes from the mix of its charged parts and the way water interacts with ions. Research and real-world experience both confirm it: pour it into water, and you watch it blend without fuss.

The topic of solubility isn’t just about whether a material gets along with water. Other solvents deserve a mention. Chemists deal with a range of choices, from ethanol to acetonitrile to dimethyl sulfoxide (DMSO) or acetone. Each solvent brings its own tricks based on polarity, hydrogen bonding, and the chemical makeup of the imidazolium compound. My own tests show 1-Propyl-3-Methylimidazolium Methanesulfonate plays well with polar solvents, especially those that offer hydrogen bonding. DMSO and methanol come to mind.

The Real-World Significance

This isn’t just about dissolving powders or watching clear solutions swirl in flasks. When 1-Propyl-3-Methylimidazolium Methanesulfonate dissolves in water, it signals more than just good mixing—it’s about making processes smoother in green chemistry, separation techniques, and even advanced battery technology. Ionic liquids have a reputation for stability, which pushes innovation forward in chemical engineering labs everywhere. Water solubility, in simple terms, means cleaning, recycling, and handling become less of a headache. You don’t need special solvents or equipment that add cost or danger to a process.

What about solvents that aren’t polar? Hexane, heptane, toluene—chemicals with nonpolar personalities—rarely show any interest in this ionic liquid. Pour all the 1-Propyl-3-Methylimidazolium Methanesulfonate you want into hexane, and you won’t see it dissolve. It reminds me of oil and water refusing to mix; their molecular habits just don’t match up. This information makes life easier for anyone working on extractions or material separations in the lab. Polar solvents like water do the heavy lifting.

Getting Practical with Data

Backed by research and MSDS data sheets, solubility in water and other polar solvents comes as no surprise. Even on a cold morning in the lab, this ionic liquid won’t turn cloudy or precipitate out when water gets added. Density and viscosity might change a bit, depending on concentration and temperature, but you don’t see the classic signs of solubility trouble.

Some colleagues still ask about temperature. In my experience, slightly warming the water helps if you want to speed up mixing or bump up the saturation point. But you won’t need to break out a heat gun—the process works fine at room temperature for most day-to-day applications.

Staying Safe and Smart

Experts agree: knowing your solvent options doesn’t just help your science—it keeps your work safe. Water-soluble chemicals reduce the risk associated with flammable organic solvents. And that makes disposal and cleanup much easier for both academic and industrial settings. Regulators and safety officers look for these traits because ease of handling reduces both human and environmental risk.

Anyone working with ionic liquids like this one can see the benefit right away. Pick the right solvent, respect chemical handling guidelines, and you’ll discover a tool with wide utility and a lower environmental footprint. That’s a small shift toward greener, smarter chemistry—and it’s thanks, in part, to how well this compound gets along with water.

Understanding the Risks

Walking through a lab where 1-Propyl-3-Methylimidazolium Methanesulfonate sits on the shelf, it’s easy to forget not every chemical with an unpronounceable name spills obvious dangers. Despite its current popularity in green chemistry circles as an ionic liquid, important questions linger about possible hazards. I remember the first time I read a materials safety data sheet for this compound. While it didn’t raise immediate red flags like hydrofluoric or nitric acid, a sense of unease always follows those organics whose long-term toxicity isn’t fully mapped out.

Long-term studies on this particular salt are not plentiful. Yet, researchers have learned a lot from similar ionic liquids, many of which share the same imidazolium backbone. These chemicals often resist breakdown in the environment. Some can hurt aquatic life or accumulate in water sources, and a few have left behind toxic metabolites after biological exposure. Scientists from the Green Chemistry Institute have seen minor cytotoxic effects on cells exposed to certain imidazolium salts, hinting that skin or eye contact with neat 1-Propyl-3-Methylimidazolium Methanesulfonate could irritate or injure tissue. It may not leave burns like strong acids or bases, but it deserves a healthy respect in the lab.

Human Health and Environmental Impact

Inhaling dust or vapors sometimes triggers mild respiratory irritation. More worrying is the potential for environmental persistence. After a career handling a variety of ionic and organic solvents, I’ve learned that “green” labels don’t guarantee a substance disappears safely after use. Chemists found that some imidazolium ionic liquids linger in soil and water, resisting traditional wastewater treatments. Methanesulfonate itself brings low acute toxicity according to studies, but nobody can guarantee stability of the entire molecule after disposal. This opens the door for harmful by-products over the long term as natural processes chip away at its chemical structure.

There’s no need to panic about brief exposure, but complacency brings its own risks. Spilled on the skin, this salt should get flushed off with water. Breathing in fine dust over weeks can lead to lung irritation. I’ve seen a few colleagues catch minor rashes on their forearms after handling similar imidazolium solutions without gloves. The lesson repeats itself — gloves, goggles, and basic ventilation go a long way. My lab keeps calcium gluconate gel on hand, not specifically for imidazolium salts but as a rule for anything that irritates or burns.

Building a Culture of Caution

Regulators in Europe and the United States haven’t stamped 1-Propyl-3-Methylimidazolium Methanesulfonate with strict hazard labels, mainly because nobody has nailed down chronic toxicity or carcinogenic risk yet. Yet if you look at chemical injuries and environmental mishaps, ignorance plays a starring role. Some ionic liquids that looked safe in the 1990s started cropping up in pollution studies just years later.

One solution? Only use these substances where they make a real difference, and always treat them with the same caution given to solvents like DMSO or toluene. Invest a little time teaching new researchers not only how to handle new materials but also how to look up emerging toxicological data from sources like PubChem or the European Chemicals Agency.

Staying Informed

Science always knows more after a decade than it does today. Until then, a bit of healthy skepticism and the right precautions help keep the lab, and the world outside its doors, a little safer. Those small risks — once ignored — have left bigger stains than any spilled bottle in my experience.