1-Sulfobutyl-3-Methylimidazolium Methanesulfonate: From Origins to Opportunities

Historical Development

Scientists in search of better ionic liquids turned their eyes to imidazolium-based compounds in the late 20th century. The field of green chemistry started to shift during this time, with researchers hoping to replace volatile organic solvents in industrial processes. As those new compounds emerged, 1-sulfobutyl-3-methylimidazolium methanesulfonate was one of the outcomes—a product born of chemical innovation where synthesis and ionic interactions could be tuned for particular applications. This move away from harmful solvents changed the trajectory of chemical processing and environmental stewardship, with imidazolium ionic liquids leading the way in everything from electrochemistry to organic synthesis.

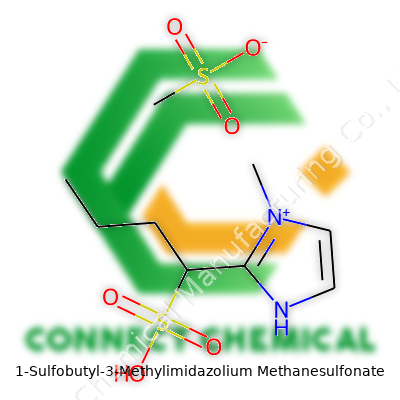

Product Overview

1-Sulfobutyl-3-methylimidazolium methanesulfonate lands in the category of room-temperature ionic liquids. It comes together from an imidazolium core and two well-chosen sulfonate substituents. The cation draws attention for its sulfonate group, which offers water solubility without giving up temperature stability. Its structure lets the product work both as a solvent and a process facilitator, which makes it fit into a range of research labs and industrial plants. Scientists use it for electrochemical studies, organic synthesis reactions, catalyst design, and as a supporting electrolyte in batteries and supercapacitors.

Physical & Chemical Properties

This ionic liquid presents as a colorless to pale yellow viscous fluid at room temperature. It does not evaporate like many classical solvents, mainly because its ions stick together in a liquid state without forming a solid when cooled. Density sits around 1.2 g/cm³, while the melting point hovers below room temperature. Strong ionic interactions push its boiling point much higher than you’d expect, easily outpacing traditional molecular solvents. The methanesulfonate anion pairs tightly with the cation, conferring hydrophilicity and high thermal endurance. Hydrogen bonding from the sulfonate groups supports solvating polar and ionic substances, a property particularly valued in advanced synthetic processes. Its electric conductivity stays high compared to conventional organic solvents, which suits electrochemical devices. Its low flammability and vapor pressure help drive industry interest in using it as a safer, greener alternative.

Technical Specifications & Labeling

Producers usually supply 1-sulfobutyl-3-methylimidazolium methanesulfonate in amber glass bottles to protect it from UV degradation. Purity levels above 98% show up on product labels, as demanding laboratory applications require high-grade material. Labels also mention the molecular formula C8H17N2O5S2, molecular weight near 300 g/mol, and its CAS number for clear identification. Product sheets highlight storage advice — sealed containers, kept at cool temperatures, with moisture excluded to prevent hydrolysis or slow decomposition. Analytical results such as NMR, IR, and elemental analysis back up reported purity, letting labs trust the product for sensitive syntheses.

Preparation Method

Chemists synthesize 1-sulfobutyl-3-methylimidazolium methanesulfonate in well-controlled conditions. The route usually starts by alkylating 1-methylimidazole with 1,4-butanesultone in the presence of a base, forming the 1-(4-sulfobutyl)-3-methylimidazolium intermediate. Neutralization with methanesulfonic acid produces the final ionic liquid. Strict temperature and pH controls matter for maximizing yield and purity. After the main reaction, purification involves repeated washing with organic solvents and water to strip out unreacted precursors and side products. Vacuum drying at mild heat removes residual solvents, giving a pure and ready-for-use ionic liquid. Advances in process control and continuous-flow reactors now let manufacturers produce this chemical on larger scales, supporting both research and high-volume industrial supply chains.

Chemical Reactions & Modifications

The imidazolium cation in this compound stays fairly stable, resisting degradation across a range of chemical environments. Yet, the sulfonate and methylimidazole groups allow further modification. Chemical engineers explore functionalizing the imidazolium ring to alter solubility, redox stability, or interaction with specific catalysts. Ion exchange swaps out different anions to tailor electrochemical or solubility properties. Blending with other ionic liquids or mixing into polymer matrices can enhance performance in targeted applications like electrolytes for batteries or as separation media. For certain organic transformations, using this chemical as both a solvent and a reactant changes yields and selectivity—often boosting rates or enabling transformations previously out of reach.

Synonyms & Product Names

It appears under other names in scientific and industrial catalogs. Some refer to it as SBMI methanesulfonate, or simply as [SBMIM][MeSO3]. These abbreviations help chemists distinguish among similar-sounding imidazolium products. Some catalogs use the term sulfoalkyl methylimidazolium methanesulfonate to describe its structure more generally, while others list it under custom blend or electrolyte product codes. Knowing synonyms helps buyers and researchers identify equivalent products across global suppliers, reducing confusion and duplication in experiments or procurement.

Safety & Operational Standards

Proper handling of this compound rests on clear understanding of its properties. Even though ionic liquids have much lower volatility than classic solvents, accidental skin contact, eye exposure, or spills can cause irritation or long-term effects. Safety data sheets warn against inhaling mist or dust, and recommend protective gloves, goggles, and lab coats when working with the product. Disposal must comply with chemical waste regulations, given persistence in the environment. Unintentional release down laboratory sinks or drains is discouraged, as ionic liquids aren’t neutralized quickly by standard waste treatment. Some international safety standards, such as REACH regulations in the EU, ask for detailed record-keeping, safe packaging, and tracking from manufacturer to end user.

Application Area

Research and commercial operations both chase after the special properties of 1-sulfobutyl-3-methylimidazolium methanesulfonate. In electrochemistry, it acts as a stable electrolyte that resists oxidation and reduction, even after repeated cycling in batteries or supercapacitors. Chemists value it as a solvent for tough organic reactions that underperform in water or hydrocarbons. Its thermal stability means it holds up in catalytic conversions run at high temperatures, such as alkylation or acylation processes. Engineers investigating carbon capture or selective separations find it especially effective in dissolving or extracting polar molecules. Some labs employ it to support enzyme reactions, boosting yields with less denaturing than in harsh solvents. Materials scientists even include it in polymer blends to design antistatic coatings or improve ion conduction in fuel cell membranes.

Research & Development

Discovery centers and academic labs still explore new uses for this ionic liquid. Published work examines how tuning the length of the sulfoalkyl group or swapping the anion alters conductivity, viscosity, or catalytic activity. A wave of papers looks at using these materials as media for ultra-fast, green chemical syntheses, helping shrink reaction times from days to hours or less. Scientists continue to test these liquids in new battery chemistries—lithium-air, sodium-ion, and flexible, wearable devices that demand stable and non-volatile electrolytes. Collaborations between academic groups and manufacturers work on scaling up the production without introducing impurities or losing performance. The thirst for greener and less hazardous processing keeps this research pipeline active, with regular new findings in journals like Green Chemistry and the Journal of Power Sources.

Toxicity Research

The push for safety doesn’t end at performance improvements. Teams scrutinize not just acute toxicity, but also long-term effects on living organisms and ecosystems. Testing on fish, invertebrates, or microbes reveals that, while less toxic than many legacy solvents, some ionic liquids can linger in water or soil, altering microbial balance or blocking breakdown of organic matter. Ongoing studies track bioaccumulation and how advanced waste treatment breaks down or contains these chemicals. Worker safety studies look for subtle impacts on skin, lungs, or chronic exposure scenarios. The field aspires toward finding or modifying ionic liquids so that they degrade more predictably outside a lab or factory, mirroring genuine green chemistry principles all the way from synthesis to disposal.

Future Prospects

The future of 1-sulfobutyl-3-methylimidazolium methanesulfonate lies at the crossroads of green tech and industrial pragmatism. Battery engineers want more stable, non-flammable electrolytes that last thousands of cycles; chemical manufacturers look for ways to make cleaner fuels or pharmaceuticals, pushing for solvents that don’t end up in the air or water. Environmental regulators expect every chemical to meet stricter limits on waste and emissions, adding pressure to pick low-toxicity, high-stability materials like this one. Academic groups continue to push boundaries by designing new derivatives or embedding these liquids in nano-structured matrices for sensors, actuators, or smart textile coatings. As sustainable chemistry grows in urgency and popularity, the practical versatility of this ionic liquid puts it in the mix for next-generation manufacturing, energy storage, and materials science.

Chemistry in Action: Beyond the Lab Bench

The world rarely gives attention to the chemicals working quietly behind modern industry. One compound, 1-sulfobutyl-3-methylimidazolium methanesulfonate, rarely enters headlines but quietly supports several key processes. My own time in research labs and the private sector brought me face-to-face with these ionic liquids, opening my eyes to their strengths in manufacturing, energy, and research.

Green Solvents for Cleaner Processes

The push for low-toxicity and reusable solvents drove many industries to experiment with ionic liquids. Traditional organic solvents, like toluene or benzene, sparked safety and environmental concerns, but 1-sulfobutyl-3-methylimidazolium methanesulfonate shifts that story. Many chemical engineers seek out this compound for synthesis and extraction because it resists evaporation and usually carries far less health risk than the standard stuff. You get a cleaner working environment and cut back on costly waste disposal. This shift lines up with stricter emission limits and pushes companies to drop volatile organics for safer, more stable alternatives.

Electrochemistry and Energy Storage

Developers and tinkers exploring next-generation batteries keep circling back to ionic liquids. Everyone wants batteries that last longer, hold bigger charges, and shrug off the heat. This particular compound got plenty of attention because it stands up under high voltage and doesn’t break down easily. Researchers plug it into lithium-ion and flow battery systems. Some projects I followed swapped out standard electrolytes for solutions based on this imidazolium salt, reporting stronger performance over more charging cycles. As consumer gadgets and green cars multiply, better electrolytes in batteries will ripple across everything from mobile phones to grid storage.

Catalysis and Reaction Mediums

Some reactions barely get off the ground in water or common solvents but spark up quickly in certain ionic liquids. In the pharmaceutical labs I worked in, we sometimes hit stumbling blocks with competing side reactions or poor yields. Formulating with compounds like 1-sulfobutyl-3-methylimidazolium methanesulfonate often unlocked stubborn pathways or boosted overall selectivity. That means more product in less time, with fewer headaches caused by separating unwanted leftovers. Since it doesn’t react with most organics, chemists can experiment widely, speeding up drug discovery and specialty material synthesis.

Separation and Purification

Pulling out valuable metals, rare earths, or high-purity chemicals tends to chew through energy and generate intimidating amounts of waste. Industries exploring eco-friendlier methods started using this ionic liquid for extraction and separation processes. Its structure lets operators strip out specific ions or contaminants without the complicated dance of many traditional extraction agents. Mining operations, for example, can target rare earth recovery without the pollution and high costs tied to older solvent methods. I saw colleagues in water treatment test similar strategies for removing toxic metals like lead or mercury.

Supporting Solutions That Stick

The market wants green chemicals that don’t compromise on performance. Regulatory bodies demand less waste and lower risk. As companies step up sustainability goals, making full use of 1-sulfobutyl-3-methylimidazolium methanesulfonate lets labs and factories meet tightened standards without slowing down innovation. Investing in research, sharing real-world case studies, and setting up robust guidelines all build a foundation for scaling up these successes. In my own work, reaching out to people across industry lines and supporting hands-on trials proved more useful than endless technical seminars. Spreading practical know-how helps these solutions stick—and drive real change.

Understanding Purity in Everyday Products

Asking about the purity specification of a product means digging into what the material truly contains. This question crops up all the time—everything from vitamins to industrial chemicals. With so many choices on the market, people want to know whether they’re paying for top-grade material or something bulked up with extra fillers. I remember years ago, buying supplements at a discount store and later realizing the active ingredient barely made up half the tablet. The rest? Unlisted agents I couldn’t even pronounce.

Why Purity Impacts Safety and Results

Purity doesn’t just hint at overall quality. It hits right at the safety and performance of what you’re buying. Take pharmaceutical products as an example. The United States Pharmacopeia (USP) often calls for specific purity standards. Any deviation can weaken the effectiveness or introduce dangerous contaminants. Last year, we all saw headlines about tainted hand sanitizers loaded with methanol. That’s no rare misfortune. Low-purity solvents in labs can throw off entire research studies—even small changes can tip the scales between a clear result and an unreliable mess.

What Sets High Purity Apart?

Purity specification often lists the percentage or type of impurities allowed, usually set by organizations like the USP or European Pharmacopoeia. For fine chemicals, 99% purity or higher isn’t rare. Even so, it’s important to check what fills up that last percentage. Are they harmless trace materials, or something that could mess with performance or health? In electronics, for example, a tiny bit of copper in silicon can ruin a whole batch of microchips. Food producers look out for pesticide residue, and the standards for organic crops run much tighter than for conventionally grown produce. Consistency builds trust, year after year.

The Need for Verification and Transparency

As buyers, knowing about certificates of analysis (COA) and standardized test methods helps. I’ve found that products without COA documents tend to be less reliable, no matter what the label claims. Labs use tools like gas chromatography or mass spectrometry to double-check purity. If a company seems reluctant to share this paperwork, that signals a red flag. A good manufacturer maintains records and gladly discloses the data anyone can verify. Trust builds slowly through real facts, not pretty packaging.

Building Confidence Moving Forward

Solving problems with purity calls for more than trust. Governments and industry groups play their part by setting strict rules and enforcing consequences for cheating. Customers can support brands willing to publish third-party lab results. Most importantly, people should feel empowered to demand clarity. Every time someone asks, “What’s the purity specification on this?” it nudges companies to keep raising the bar. At the end of the day, transparency ensures safer use, reliable effects, and fewer ugly surprises for everyone.

Common-Sense Chemistry and Real Safety

If you’ve ever handled chemicals in a research lab or an industrial setting, you get real quick that storage has little room for shortcuts. For 1-Sulfobutyl-3-methylimidazolium methanesulfonate—a mouthful, sure, but an ionic liquid with unique roles in catalysis, electrochemistry, and more—the way you store this compound doesn’t just affect shelf life. Mishandling can threaten both your work and your workplace.

Temperature Matters

Fridges in shared labs get cluttered, but some chemicals deserve prime real estate. This ionic liquid stays more stable at lower temperatures—“room temperature” can mean anything, but aiming for around 20°C limits decomposition. Heat speeds up chemical change, and I’ve watched enough supplies turn bad from being left next to heat-generating equipment or direct sunlight. Cool, dry, and out of sunlight wins every time.

Why Dry Storage Isn’t Optional

Moisture turns many laboratory chemicals into headaches, and 1-Sulfobutyl-3-methylimidazolium methanesulfonate absorbs water if given the chance. Humidity promotes unwanted reactions, sometimes invisible until your results fall flat. I’ve had to toss out experimental runs due to mysterious contamination, traces that tracked back to a careless screw-cap on a humid day. Silica gel packs or desiccators bring peace of mind. Storage containers need to close tight.

Material of the Container

Glass works best for long-term storage of most ionic liquids. Plastic gets tempting for convenience, but leaching is no myth—small components find their way into your sample over weeks or months. Most manufacturers ship in amber glass bottles for a reason—not just tradition, but protection against stray light and chemical interactions. Stainless steel piping or other metal surfaces can ruin the liquid over time; always check compatibility before use.

Label Everything, Always

Mislabeling or skipping the details throws off everyone—especially six months down the road when a new batch of researchers start poking through shelves. Include not just the chemical name, but also the date received or opened, your initials, and any hazard information. I’ve dodged plenty of disasters by triple-checking the points that seem “obvious” when you’ve just unboxed a fresh reagent.

Keeping Things Safe and Legal

Regulatory audits drive home the point: chemicals with complex names also carry strict rules. In Europe, REACH registration puts guidance in black and white. The US follows OSHA’s Hazard Communication Standard. Safety Data Sheets (SDS) aren’t just paper to lose in a drawer. Reading the SDS before storage or transport not only protects you—it keeps the lab from running afoul of inspection. In my experience, the most common fines stem from ignoring basics: unlabeled bottles, chemicals sitting near food, or stockpiles in open air.

Emergency Prep: Not Just for Show

Even chemicals with low toxicity and high stability come with risk. Spills can still stain, irritate, or spark confusion. Keeping absorbent material and chemical-resistant gloves ready isn’t overkill. I’ve been grateful for an emergency shower more than once; don’t assume a benign chemical means zero risk. Training is as critical as the storage room temperature.

Looking Forward: Continuous Improvement

Some of the smartest labs I’ve worked in treat chemical storage as living science. Label reviews, inventory checks, and even culture-shifting conversations about “how we do things” end up saving time, money, and stress. Adopting this attitude toward 1-sulfobutyl-3-methylimidazolium methanesulfonate pays off in reliable data and safer spaces. It’s one lesson worth sharing—keep things cool, dry, labeled, and always keep learning.

The Reality Behind Product Hazards

Many people look at a bottle, bag, or container and wonder if the stuff inside is a hazard to their health or the planet. Some chemicals, cleaning agents, or industrial powders definitely cause harm if touched, breathed in, or dumped down a drain. Labels often flag risks right away—words like “corrosive,” “toxic,” or the simple skull-and-crossbones symbol shout their warning. But a lot of everyday products have hidden dangers that you only discover after something goes wrong.

Regulations Set the Bar

Laws carry weight for a reason. Agencies like the Occupational Safety and Health Administration spell out exactly what needs careful handling and storage. Paint thinners, pesticides, battery acid, and powerful detergents belong on this list for good reason. Anything flammable can burn or explode in the wrong setting. Something as common as bleach, if mixed with ammonia, creates gases that can damage lungs within seconds.

Home Hazards Aren’t Just Industrial Problems

Growing up, many of us found ourselves in garages or kitchens packed with bottles and jars that we barely glanced at. I still remember the strong smell of solvent from my uncle’s workshop or the stain remover under the laundry sink. It never hit me that even small doses could cause burns or breathing trouble. Years later, a friend called in a panic after accidentally splashing drain cleaner on his hand. The burn sent him to the emergency room, driving home the point that these products reach far beyond factories and labs.

Why Risk Matters

People always try to cut corners, and busy schedules breed mistakes. Some think gloves and goggles slow them down. Others ignore directions and transfer chemicals into old soda bottles. Every year, doctors treat children who drank poison from an unlabeled jug in a garage. Firefighters deal with household fires that started from rags soaked in paint or fuel. The costs pile up—lost wages, medical bills, property damage, and sometimes permanent health issues.

Questions Worth Asking

Before opening something new, consider these questions: Is it flammable? Poisonous? Will it burn skin or eyes? What about the fumes? Can it leak, spill, or react with other stuff nearby? These questions matter for everyone—parents, contractors, janitors, and anyone tempted to “just get things done.” Even products marked “green” or “eco-friendly” sometimes pose dangers in the right concentration or if mixed in the wrong way.

Carrying Out Safe Practices

Local waste collection sites provide take-back programs for all sorts of products—from old batteries to half-empty paint cans. Using these programs means fewer leaks into streams, less risk in garages, and fewer emergencies at home. At work, storing chemicals on sturdy shelves, away from heat and direct sun, makes a real difference. So does labeling everything clearly and locking up the worst offenders. Training matters too. Even just a diagram or checklist by the supply shelf helps keep everyone alert.

Time for a New Habit

Checking labels and reading safety data sheets never takes long, but it can make all the difference. Relying on real information, not shortcuts or old myths, gives families and workers a better shot at staying safe. The risks rarely look dramatic at first—a small splash or whiff, a careless storage job. But one bad moment can reshape a life. Taking basic steps to check and handle these items with care costs almost nothing and means a safer day for everyone.

The Science Behind the Name

I remember my early days in university, staring at long chemical names and wondering if any of it would ever stick. Over time, these names began to make sense, revealing not just a jumble of syllables but real structure and function. 1-Sulfobutyl-3-methylimidazolium methanesulfonate stands as a good example of a mouthful that packs meaning into every part.

The chemical formula—C9H18N2O6S2—comes together from two main building blocks. There’s the 1-sulfobutyl-3-methylimidazolium cation, with a butyl chain swinging off one nitrogen of an imidazolium ring (not a structure you run into on your grocery run), and then the methanesulfonate anion grounding the other side. This combination invites chemists to go beyond simple reactions by offering them tunable ionic liquids. For folks pushing forward in battery research, separation science, or greener solvents, this kind of compound isn’t just a curiosity. It’s a real tool.

Looking at the numbers, the molecular weight clocks in at 314.38 g/mol. I take this figure seriously for a few reasons. Not every lab project succeeds, but accurate weights make or break yields, calibrations, and safety calculations. It’s tough work keeping reactions balanced, and a slip with the molecular mass can throw the whole system off.

Why Does This Matter?

Back in my grad student days, I worked with various ionic liquids—some would flow like syrup, others more like oil. What I loved most was their flexibility. Many are non-volatile, which makes them safer than traditional solvents like acetone or ether. No knocking you out with fumes, if you get my drift.

Environmental concerns add weight to these choices. Ionic liquids such as this one can often be recycled, and their inherent design cuts down on environmental hazards associated with more volatile organic compounds. Friends of mine working in sustainable chemistry push for exactly these types of compounds—less hazard, more sustainability, tailored application without the mess.

Challenges in Using Advanced Compounds

Not every innovation lands perfectly. Using 1-sulfobutyl-3-methylimidazolium methanesulfonate comes with its own challenges. Cost ramps up compared to standard solvents, and not every lab stocks it. Handling remains a learning curve for those used to simple alcohols or water-based solutions. There’s also the matter of understanding toxicity and biodegradability. Data continues to emerge. I tell students that working with cutting-edge chemicals often means making decisions before all the answers are in.

Making Safer Choices and Next Steps

Every researcher must weigh trade-offs. For my part, I like giving new tech a fair shake, but I ask hard questions about purity, residual contaminants, and what happens to these compounds at end-of-life. Teams involved in curriculum or lab management can improve safety by teaching solid weighing, grounding theoretical knowledge in the practical business of mixing, and always reviewing new environmental data. Industry groups and journals also play a key role—sharing best practices, safety data, and application notes so labs don’t have to reinvent the wheel each time a new compound hits the shelf.

1-sulfobutyl-3-methylimidazolium methanesulfonate holds promise because it bridges needs both in technology and safety. With its specific formula and weight clear, everyone from chemists to engineers gets a shot at real innovation—safer, more effective, and built with a nod to responsibility.